Ventilation of a septic tank made of concrete rings is carried out to eliminate unpleasant odors and ensure safe living for people in the country or in a private household. Typically, energy-dependent septic tank systems are created in areas adjacent to private buildings, designed to effectively process sewage waste and wastewater due to the bacteria living in them.

A septic tank is a structure in which bacteria live. They develop and multiply quickly during the active processing of organic waste discharged through the sewer system. Processing is accompanied by the release of gas, as a result, silt deposits remain in the septic tank, and clean water goes into the ground. The main problem and danger for people living in households is the possibility of gas poisoning. Therefore, the ventilation system needs to be equipped and done correctly.

Why is ventilation needed in sewer systems?

In household wastewater that flows through sewer pipes into a collection tank, complex physical and chemical changes in composition occur. In a septic tank, the liquid is divided into fractions. Substances heavier than water sink to the bottom, and those that are lighter concentrate on the surface. In all layers, a serious change in the structure of household waste occurs. The decomposition of organic substances under the influence of bacteria leads to the destruction of large inclusions. The system will work much more efficiently when providing air access for the following reasons:

- Oxygen is needed for the life of aerobic bacteria that decompose organic matter in wastewater;

- Ventilation is needed to remove released gases, the excessive concentration of which is undesirable in a septic tank;

- Heat removal. During the decomposition process, the temperature of the wastewater increases. Intensification of decay occurs, which promotes the proliferation of pathogenic bacteria. Gases that are harmful to health and other carcinogens are released.

Good ventilation optimizes the processes occurring in the container. Lower risks to the health of housing residents due to the accumulation of harmful substances are one of the main tasks when performing this work. Therefore, the question of whether ventilation is needed in a septic tank made of concrete rings has a clear answer. It is necessary.

The most popular ventilation option for a septic tank

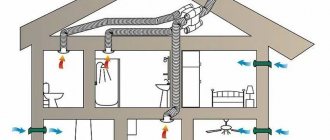

Installation of pipes along the external wall of the building and on the roof

It is desirable that this be a gable wall. Before entering a bathroom or room, especially if the plumbing fixture itself is still a few meters away from the outer wall, you need to stretch an additional air duct along the outer wall, which also runs above the roof. This measure will ensure better circulation within the system.

When the sewage system inside the house is assembled at the highest point, after the plumbing fixture, a tee is installed in the pipeline with the socket facing up. Then a pipe of the same diameter is inserted into it and brought out through the ceiling to the roof. If there are various obstacles along the route (rafters, chimneys, etc.), they will have to be bypassed without changing the angle of inclination using bends.

Products from the store often do not fit in size. You'll have to cut it with a grinder and then chamfer the end to make it easier to join the bell of the next piece.

On the roof itself, the shaft exit should protrude at least 50 centimeters above the roof. Then a headband is put on its end, which will prevent moisture and snow from getting inside.

Moreover, it is unacceptable to install a weather vane or deflector; this can lead to the formation of ice and subsequent blockage of the pipeline. It is enough to put a small umbrella or visor

Throughout the entire external ventilation, inspection fittings must be installed, which look like a standard tee with a socket and an inspection window with a lid. This part is necessary to solve problems of diagnosing the internal state of the highway and performing preventive maintenance. If a blockage occurs or a foreign body enters, through such a unit it is possible to accurately determine the clogged area and eliminate it.

Important! The rubber bands must be left in the sockets and lubricated with oil or sanitary sealant. Also, if the length of the pipe was changed by cutting, a chamfer must be made at the end of the part, otherwise the cut end will rest against the sealing ring and lift it inside the socket.

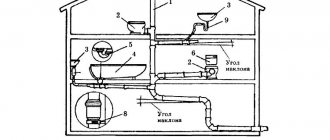

What does a septic tank ventilation system consist of?

In a sewer well made of concrete (or plastic) rings, the following elements must be installed:

- Fresh air supply pipe. It is carried out from the street directly into the wastewater capture chamber. It must be installed to feed aerobic bacteria with oxygen, since without it they will simply die (unlike anaerobes, for which oxygen is harmful).

- A pipe for removing accumulations of gases formed during the processing of household waste by bacteria. This is essentially an exhaust hood that ensures the removal of methane, hydrogen sulfide, and various phosphorus compounds that are harmful to the structure itself and to people or animals on the site.

Septic tank ventilation system diagram

These are mandatory structural elements of the system. Additionally, the exhaust air duct can be equipped with a fan to create a more stable and strong draft. In fact, such a solution is not necessary: air exchange will be sufficient if the natural system is installed correctly.

How to ventilate a septic tank with your own hands

In order for a self-made concrete septic tank to work smoothly, several principles must be followed:

- To prevent blockages in the pipeline, the diameter of the pipes must be at least 30 percent larger than the expected volume of waste.

- The drain should be as straight as possible. Otherwise the air will encounter resistance.

- Protective visors will not only prevent moisture from entering the pipes. Together with the mesh, they will prevent foreign objects, small birds and insects from entering there.

- All joints must be sealed.

- The pipeline must be carefully insulated from the ingress of ground moisture. Otherwise, water from the sewer drain pipe coming from the soil can clog the passage and interfere with the exchange of oxygen.

What is a fan boner?

It is needed to ensure communication between the sewerage system and the external environment, that is, to ensure that the sewerage system is not closed.

Most often this is a plastic or polyethylene pipe of the same diameter as the sewer. However, sometimes cast iron and metal are still used.

The sewer pipe is actually a continuation of the sewer pipe, except that water should not flow through it; this is the so-called dry pipe.

Ventilation of a septic tank without a drain pipe

In a sewer system that does not provide for a drain pipe, organizing the flow of atmospheric air is also a prerequisite. To do this, ventilation branches are cut into the main pipe, which emerge from the ground to a height of at least 30 cm, and it is better to raise them along the facade of the building at the base of the roof. Through these pipe sections, air will flow into the main pipeline and then through the channel into the sump itself. The upper inlet socket must be covered with a mesh and a protective umbrella. Recently, special plugs with built-in valves have become very popular, which allow oxygen to pass in one direction and prevent odors from the tank from entering the atmosphere.

With such a system, the inflow pipe riser performs two functions at once, ensures proper flow circulation and, if necessary, can serve as an inspection hole for cleaning the sewer.

Types of ventilation

Depending on the location of the vent riser, there are different types of sewer ventilation:

- Internal ventilation. The vent pipe is located inside the house and is a ventilation riser to which plumbing fixtures are connected. Water is discharged in one direction, and a mixture of gases moves in the opposite direction and is discharged outside the house. The diameter must be at least 100 mm so that the waste material occupies approximately 1/3 of the total volume, the rest of the space is intended for air.

It cannot be combined with a general house ventilation system so that the exhaust air does not mix with other flows and does not enter the premises of the house.

- External ventilation. The sewer pipe is located outside the house, often mounted to the wall of the house away from the windows, or to another building on the territory of the house, depending on how the sewer system is located. The pipe is not connected to the plumbing riser, but is included in the drain pipe in the section from the house to the septic tank.

Limitations and recommendations

If, after familiarizing yourself with the regulatory requirements, you are still full of doubts as to whether you need ventilation of the sewer system or not, we offer simplified explanations:

- If you are designing a house, then know that the district architect will not approve your project without drain outlets if the future building has more than 2 floors;

- If the number of floors is 1-2 floors, then the number of toilets and bathrooms matters. A fan output is not needed if there is only 1 of them.

But that’s not all - even if your project includes only 2 floors with one bathroom and one bathroom, their location will play a role:

- A drain pipe is needed if the bathtub and toilet are located at different levels;

- A connection to the roof is needed if a pipe with a diameter of less than 100 mm will be used to lay the sewer;

- A connection between the sewer system and the atmosphere is required if there is a swimming pool in the house;

Vacuum valve

(hereinafter referred to as VK)

In a one-story house, as well as in a building where plumbing fixtures are installed only on the first floors, it is allowed to use VK instead of FS.

In order to provide ventilation, a special mechanism can be installed in a small system, which is mounted using a tee connection.

It works on the reverse principle. The device has a sealed curtain with spring resistance. When a vacuum occurs in the sewer, the vacuum draws in the valve and with it the air from the room, and when the balance is restored, the spring closes the valve again, preventing the smell from leaving the pipe.

How to install

The installation of an air duct can be combined with the laying of an air duct, but you need to remember several nuances with this combination:

- The valve should not be higher than the fan riser.

- In some cases, it is possible to install the mechanism not only on a vertical, but also on a horizontal pipe.

- If the length of the horizontal section of the shaft with plumbing fixtures is more than 8 meters, install two valves at an equal distance from each other.

How to make it yourself

To do this, a plastic plug is inserted into the tee, in which several holes are drilled in a circle. So that they can be closed, a flat disk with a diameter slightly larger than the halo of holes is cut out of foam rubber.

Then you will need a simple wood screw and a loose return spring. In order for the foam rubber to press down and close the holes after the valve operates and the pressure in the system normalizes, a plastic or iron plate is inserted between the spring and the disk.

Now the screw is screwed into the cover from the reverse side. It is worth considering that the performance of a valve made independently will be several times lower than a factory one. In the factory, all calculations and drawings are carried out, which are based on all the indicators of the future sewer system, and the volume of air required to be supplied inside is calculated. It is unlikely that such actions will be possible to perform under domestic conditions.

Note : You can combine the use of a vacuum device and the FS system. In this case, the valve is installed at the end sections of the sewer pipeline.

Country well water supply diagram

To present the scope of work, we will analyze the scheme of autonomous water supply along the entire length - from the source to the points of water use.

The main mechanism for pumping out water is a submersible or surface pump. The submersible option is located at a sufficient depth, but not at the very bottom (no closer than 50 cm).

It is suspended on a strong cable, to which an electrical cable is also attached. In addition to the electrical wire, a pipe is connected to the pump through which water enters the house.

Wiring is installed inside a residential building so that water flows to various points. The “heart” of the system is the boiler room, where a hydraulic accumulator and a heating boiler are usually installed.

The hydraulic accumulator controls the water pressure, uses a relay to balance the pressure and protects the structure from water hammer. You can monitor the indicators using a pressure gauge. For preservation, a drain valve is provided, mounted at the lowest point.

Communications go from the broiler room to water intake points - to the kitchen, shower room, etc. In buildings with permanent residence, a heating boiler is installed that heats water for use and the heating system.

There are many options for constructing circuits, their assembly depends on the needs of homeowners. Having drawn up a diagram, it is easy to calculate the cost of technical equipment and building materials.

What types of cesspools are there?

Cesspools are designed to collect a wide variety of liquid waste. Making such a structure is not at all difficult. You can use rings cast from concrete, old tires and any other material. There are several types of cesspools:

- absorbing type;

- sealed type;

- septic tank

It doesn’t matter which cesspool you use, but you should know that its depth should not be more than three meters. Otherwise, there is a risk of contamination of groundwater, and this has a bad effect on the environment.

The cesspool should not be located close to the house.

When constructing it, it is necessary to select the correct tank volume. Then you can avoid overfilling and unpleasant odors.

It is necessary to periodically clean the cesspool using special antiseptics. There are even products that destroy detergents, paper and other nitrates. After treatment with this preparation, the bad smell will disappear and the liquid in the pit will decrease. If you constantly perform such actions, then you will not have to pump out the liquid soon.

How to conduct water from a well - trench, equipment, installation

Let's consider the cheapest and most technologically advanced option for carrying water from a well to a house using a submersible pump. But making water supply to your home using a pipe and a pump is not as simple as it might seem at first glance... How to conduct water from a well or borehole and not encounter problems later, as well as the most significant nuances of this event.

Trench for water supply pipe

As a rule, it is more expedient to lay the pipe below the freezing depth than to use heating and insulation, but not in all regions... For the middle zone, a depth of 2 meters or more may be needed - depending on the topography, the creation of a constant slope of 1-2% for gravity flow into the well is also taken into account and adding 0.2 meters of sand under the pipe.

How to dig a trench for a water supply

- To set a uniform slope of 1-2% of the trench, a horizontal cable is pulled over it along a level, from which a measuring gauge is taken.

- It is advisable to put extruded polystyrene foam 3-5 cm thick on the pipe, especially if you skimped on depth.

- The trench is made straight with a smooth turn allowed if necessary.

Selecting a water supply pipe and its installation

A HDPE pipe with a diameter of 32 mm is used, preferably in one piece, from the house to the exit to the well. A HDPE pipe suitable for water supply is marked along its length with a blue or green stripe with a wall thickness of 3 mm.

It is recommended to lay the pipe and pump power cable at the bottom of the trench in a protective casing called a sleeve. You should not save a penny on protective measures. It is optimal to use a 110mm sewer pipe. The sleeve will protect against mechanical damage, water, mice under the house, and will make it possible to pull out the contents...

The sleeve is sprinkled with sand, on which a layer of insulation is placed. The wider it is (and thicker too), the more heat you can count on from the ground.

Inserting the pipeline into the house and into the well

The task when inserting a sleeve into a well is to seal the hole made for this purpose to prevent surface water from entering. It is made using well construction technologies. In this case, the use of any “chemistry” is unacceptable.

When entering a house, it is advisable to go under the house as far as possible from the outer wall and lift the sleeve at 90 degrees (30+30+30) at the inner wall of the room, which will prevent freezing at the foundation.

It is advisable to protect the well from surface waters with a blind area - a hydraulic lock.

Suspension, electrical supply and pump equipment

The pump is suspended on a cable of appropriate strength in the center of the well, fixed to a crossbar. Only a water-submersible cable may be laid in a sleeve underground. If the pump is equipped with a very short cable, then the additional equipment must be appropriate to create a waterproof connection.

It is advisable that the check valve be installed directly on the pump body. Some models are initially equipped with a protective shutdown against drying. If this is not the case, then the pump must be equipped with a “frog” that opens the power circuit when the water level drops.

How to use a submersible pump when the water level is low

If the pump suction is closer than 0.5 meters from the bottom, turbidity will be raised by the turbulence of the water - water supply will become impossible. What to do if the pump lifts sludge from the bottom?

Shallow wells are not uncommon; they contain only 1–1.5 meters of water. But you can use a submersible pump. There are pump models that capture water not at the bottom, but through holes in the middle of the body - these are preferable.

To reduce water turbulence, a polyethylene bucket with crushed stone is lowered to the bottom, and the pump suction is placed in it. Now the flow will be directed from top to bottom, and its speed will decrease significantly due to the larger diameter. Or the pump is inserted into the cross of 110mm pipes with tees pointing upwards, the same thing happens - the water intake is done at the top.

Equipment for water supply in the house

The water supply equipment installed in the house is typical. A hydraulic accumulator is used for drinking water of 50 - 100 liters and a pressure switch to control the pump. The recommended water supply and pump control scheme is as follows.

The pressure in the home water supply system is set by the pump relay. Let us recall that the pressure switch turns off the pump when the maximum pressure in the system is reached, and turns it on when the minimum value is reached. Usually this range is set to 1.2 - 2.5 atm, and some set it even less, as long as the household appliances work. The lower the pressure in the system, the more pump resource and energy are saved, and the less air escapes from the hydraulic accumulator, which is regularly pumped with air to a minimum value.

How to drain water from a pipe without climbing into the well...

A tee is installed in the pipeline in the well, to which a branch of a flexible high-pressure hose “for a washing machine” with a tap at the end is connected. In the normal position, this tube is raised up, but if you need to drain the water, the tap opens and it lowers to the water itself on a string...

Aerator for sewerage

Types and design of aerators

You can buy a ready-made aerator or you can equip it yourself. It must be resistant to corrosion as it operates in a hostile environment. It must also be reliable because it is mainly installed at the bottom of the septic tank and replacing it is not the easiest solution. Its operation should not be accompanied by constant noise, which will naturally irritate those living in the house.

Aerators can be tubular or disc shaped. The tubular model is the simplest option.

The tubular device has positive qualities:

- are flexible;

- long service life;

- minimal likelihood that the holes may become clogged;

- it has a function for maintaining the supplied pressure;

- distributes oxygen evenly throughout the medium; The material is resistant to mold formations.

The disk model is no less convenient to use.

Disk device properties:

- very durable and reliable;

- has no connection, i.e. has structural integrity;

- easy installation;

- resistant to corrosion formations;

- has maintainability;

- there is no risk that water or dirt may get into the device;

- slight decrease in pressure;

- it can be used in high-performance systems.

Making your own aerator

You can modify a conventional septic tank, manufacture and install an aerator installation yourself. This is not difficult and even an inexperienced master can do it. Moreover, there are a lot of training videos on the Internet.

Manufacturing principle of a tubular aerator

Manufacturing principle of a tubular aerator:

- The base is taken. A one or two meter pipe, fifty centimeters in diameter, is suitable for this, depending on the volume of the container;

A plug is placed at one pipe end;- The other side is equipped with a pipe for connecting the pipe and the compressor hose;

- From 200 to four hundred holes are drilled into the pipe, always of the same size and equally spaced around the entire perimeter. This is necessary to ensure complete air exchange.

- The aerator is installed in chamber 2 of the settling tank, where wastewater, already purified from large masses of wastewater that settles at the bottom of the primary compartment, enters.

Is it worth carrying out this modification at all? What does this aeration give? Installing an aerator, firstly, significantly reduces wastewater processing time and improves the quality of treatment.

It is possible to reduce the volume of the septic tank by reducing the time while maintaining the same productivity.

The presence of this device eliminates bad odors that appear in anaerobic settling tanks.

This will significantly reduce costs for sewage disposal services, and it also eliminates contamination of water and soil with sewage. To summarize, we find that thanks to the aerator system in the settling tank, the environment is saturated with oxygen, which promotes the favorable existence of aerobic bacteria. Upgrading the septic tank with this installation and compressor significantly increases the efficient operation of the treatment device and eliminates unpleasant odors.

Water supply maintenance rules

A correctly installed system rarely fails, but preventative maintenance and inspections can prevent some breakdowns.

To do this, we recommend paying attention to the following system elements:

- pump - monitor the operation of the pump, clean it on time and replace consumables, for example, rubber gaskets;

- sealing - if the composition of the water changes, check the sealing of the well (surface water may enter);

- pressure - monitor the pressure in the system (the norm is from 2.5 to 4 atmospheres);

- filters - use filters that purify water from large particles and impurities, thereby preventing mechanical breakdowns of equipment.

Automating the process will allow you to control the system even in your absence. In the event of a sudden change in pressure or emergency drying out of the source, the triggered relay will stop the operation of the station.

We waterproof the structure

Example of waterproofing joints to prevent ingress of surface water

Connecting water supply from a well or borehole to a dacha or country house requires mandatory waterproofing of the water intake structure. This needs to be done for several reasons:

- First of all, over time, due to a violation of the sealing of the seams, contaminated groundwater (overwater), wastewater, melt and sediment water, organic decomposition products, ground salts and alkalis, chemicals, and bacteria can begin to enter any well. Such leaks can make the well water unusable for drinking. The same goes for wells.

- Additional waterproofing of the walls of a concrete well will help protect structures from destruction under the influence of soil acids and salts.

External waterproofing of the concrete rings of a new well can be done at the stage of its construction using a coating method and several layers of roofing material or using penetrating compounds. The old well is dug out to a depth of 3-4 m and insulated from the outside with roofing felt on tar mastics.

For internal insulation of the walls of a well or well, two-component cement-polymer coating insulation is used. This environmentally friendly composition will in no way affect the quality of drinking water. In addition, bedding and a concrete seal are made around the water intake structure. The well must be excavated on the surface of the ground.

Advantages of autonomous water supply

Residents of megacities who are not puzzled by the problem of private water supply may be surprised to learn that the well water supply system has many advantages.

The largest is contained as a liquid. It has almost spring purity - its composition is completely free of harmful impurities such as chlorine or rust.

The second advantage concerns saving the family budget - you freely use natural resources without paying monthly bills.

And another nice bonus is control over the operation of the system. For example, you can independently regulate the pressure or lay pipelines to a garden plot or flower bed.

Many doubt the feasibility of installing a water supply system from a well to a house, arguing that a water supply system with a well would be much more efficient.

Perhaps, but if you have a strong, deep well with a sufficient water level in your dacha area, there is no need to drill a well for the following reasons:

- registration of permits for an artesian well, drawing up a project and drilling work take a lot of time;

- the cost is high and not everyone is happy with it (about 130 thousand rubles for a well up to 30 m);

- setting up a well system is a little easier (especially the summer version);

- the presence of a well does not require permission from government agencies.

If minor repairs or cleaning of silting are required, it will take much less effort and money than cleaning a well.

In case of temporary power outages, there is always a backup option - a bucket on a rope or a special lifting mechanism (the narrow borehole does not allow the use of improvised devices).

There are a number of difficulties, but they can be solved. For example, an old wooden structure becomes unusable over time - it is better to replace it with concrete rings.

If the structure has lost its tightness and allows water and domestic waste to pass inside, it is necessary to thoroughly seal the seams on both sides, internal and external.

Exploitation

After successfully resolving the issue of how to connect a private house to the central network, many take a breath and for some reason believe that now everything will work like clockwork. However, such sewerage still needs to be monitored. To ensure that its service life does not decrease, you need to follow simple rules, the main ones of which are:

- Try to prevent large-sized and durable debris from entering the drain, for example, solid kitchen waste, personal hygiene items, hair, paper, etc.

- Clean kitchen siphons regularly.

- Use a plunger to clean the toilet.

Video on the topic:

Operating principle of a sewage disposal machine

The main elements of any sewage disposal machine are: a reservoir (tank) for transporting liquid, a vacuum pump, a pipe for pumping water from septic tanks, sewer wells, drainage systems of car washes, natural reservoirs, etc. The operating principle of such equipment is as follows:

- One end of the pipe is connected to the machine, and the other is lowered directly into a container of liquid.

- Using a vacuum pump, water mixed with sludge is pumped into the tank. The process continues until the septic tank is completely empty or until the tank is full.

- Disposal of reinforced waste products is carried out in strictly designated areas, taking into account environmental standards.

Theoretically, the transport tank and pumping equipment can be installed on any vehicle chassis that meets the technical requirements. In Russia, as a rule, GAZ, KamAZ or ZIL are used for such purposes.

Machine for collecting and recycling wastewater based on GAZ 3309

The maximum distance within which water can be drawn depends on the length of the pipe (hose). The standard length, regulated by the manufacturer, usually varies between 6-15 m. By individual order, this parameter can be increased to 25 m. Some sewer trucks use additional hoses, which allow increasing the length by another 5-10 m. However, even this is sometimes not possible enough to clean a septic tank located at a great distance from the roadway. In this case, additional measures will be required from the owners of the site.

Making an aeration chamber yourself

If your overflow well does not have such a wonderful system, then you can equip a second tank with it. Installing an aerator in the first chamber will lead to rapid siltation of the system.

Sometimes owners of private houses decide to purchase an aeration station. A special factory container is designed to quickly turn feces into sludge. However, there is a need for regular cleaning. Residual detritus may be an excellent fertilizer, but it will have to be removed quite often.

So, to equip the aerator you will need a compressor. An air blower is needed for any type of system. We purchase a device based on the main performance characteristics:

- Type of motor (diaphragm and rotary). The latter need daily disconnection from the network. Modern models have a special relay that allows the engine to rest without outside intervention;

- Chamber volume.

An effective cleaning process is possible when gas bubbles penetrate into the filtered solution. To do this, a special plastic pipe with a diameter of 50 mm is attached to the bottom of the chamber (at a distance of about 30 cm). One end is sealed. Using a drill, you need to make many holes (200-300) 2 mm each. Air will escape through them. A supercharger (or aerator) is connected directly to the pipe. A vertical pipe is used for this. The device itself is placed above the container. It is better to protect it from atmospheric moisture.

Air bubbles penetrate the liquid. Oxygen is absorbed by microorganisms and activates the cleaning process. Next, the water is poured into a separate container with biofilters or goes to the filtration fields.

So, making an aeration chamber in a septic tank with your own hands is not at all difficult. However, its elements will require regular maintenance. For example, a membrane-type compressor needs to replace the main working element. The membrane will have to be changed 1-2 times a year. Rotary types also require servicing. A regular compressor will last 4-5 years. Next, it will have to be sent for repairs or replaced with a modern model. And the well container must be cleaned of silt deposits annually. This sediment is excellent for fertilizing plants.

Making an aeration chamber yourself

If your overflow well does not have such a wonderful system, then you can equip a second tank with it. Installing an aerator in the first chamber will lead to rapid siltation of the system.

Sometimes owners of private houses decide to purchase an aeration station. A special factory container is designed to quickly turn feces into sludge. However, there is a need for regular cleaning. Residual detritus may be an excellent fertilizer, but it will have to be removed quite often.

So, to equip the aerator you will need a compressor. An air blower is needed for any type of system. We purchase a device based on the main performance characteristics:

- Type of motor (diaphragm and rotary). The latter need daily disconnection from the network. Modern models have a special relay that allows the engine to rest without outside intervention;

- Chamber volume.

An effective cleaning process is possible when gas bubbles penetrate into the filtered solution. To do this, a special plastic pipe with a diameter of 50 mm is attached to the bottom of the chamber (at a distance of about 30 cm). One end is sealed. Using a drill, you need to make many holes (200-300) 2 mm each. Air will escape through them. A supercharger (or aerator) is connected directly to the pipe. A vertical pipe is used for this. The device itself is placed above the container. It is better to protect it from atmospheric moisture.

Air bubbles penetrate the liquid. Oxygen is absorbed by microorganisms and activates the cleaning process. Next, the water is poured into a separate container with biofilters or goes to the filtration fields.

So, making an aeration chamber in a septic tank with your own hands is not at all difficult. However, its elements will require regular maintenance. For example, a membrane-type compressor needs to replace the main working element. The membrane will have to be changed 1-2 times a year. Rotary types also require servicing. A regular compressor will last 4-5 years. Next, it will have to be sent for repairs or replaced with a modern model. And the well container must be cleaned of silt deposits annually. This sediment is excellent for fertilizing plants.

Construction device

A septic tank made of reinforced concrete rings is characterized by a set of parameters such as volume, number of cleaning chambers, drainage pipe and other additional equipment. To make the right choice in a particular case, we will consider all the options for the main modifications of an autonomous sewer system and the basic diagrams of their operation.

Table of possible options:

| Design option | Description |

| Single chamber without bottom

| This design is based on two rings, the top of which has a hatch, and the bottom has no bottom and is in direct contact with the ground. Sewage flows into the sewer system, as a result of which the solid fraction of the waste settles to the bottom and subsequently decomposes there, while the liquid gradually goes into the ground. Advantages:

Flaws:

|

| Double chamber

| Here the septic tank design is more complex - the scheme assumes the presence of two “wells”. Sewage flows directly into the first chamber. In it, the solid fractions settle to the bottom (a closed “well” is used), and the upper light/liquid fractions flow through a pipe into the second chamber. The second, also called the overflow, “well” has no bottom. However, it can be filled with a filtering agent (crushed stone, expanded clay) to purify suspended matter. Or it can be empty - to receive wastewater coming from the first chamber and purify it with the help of bioactive components. A home-made device for sewage - two-chamber has the following advantages:

Flaws:

|

| Three-chamber

| In this case, the septic tank made of rings already includes three chambers. The first one performs the same function as for the two-chamber version, the chamber plays the role of a filter with a bottom. Technically purified water enters the third compartment. Pros:

Minuses: High price for equipment, materials and installation. |

Advantages of the device

No matter how ideal the design of concrete rings may seem, before you start building it, you need to take into account its main pros and cons.

Advantages:

- Unlike a cesspool, even the most basic septic tank is single-chamber, but at the same time correctly calculated in volume; even if it requires pumping out sewage, it will be an order of magnitude less frequent.

- Problems with sewer odor both indoors and outside – near the cameras – are completely eliminated.

- Sewage water, if it gets into the ground, does so in small quantities that do not disturb the ecological situation of nearby soil layers and water bodies.

- In relative proximity next to the structure there is a well for collecting drinking water, which is extremely unacceptable in the presence of a cesspool.

Flaws

A septic tank in a country house, of course, is not without its drawbacks. However, all of them are completely solvable with correct calculations and compliance with the installation requirements of its structure.

First of all, this concerns the characteristics of the soil in the area where it will be installed

If there is a rock under the septic tank, you can do without special precautions. On the other hand, it cannot be poured onto moving soil. Chambers with a bottom must be installed on pre-prepared concrete pads. Bottomless “wells” are best used in monolithic form - or use reinforced concrete rings with a locking connection system for their construction. For reliability and to create a single strong frame, they are also fastened together with special fastening plates

Also, so-called crushed stone pillows are prepared for them.

In addition, one of the significant disadvantages of installation concerns the technical side of the process. It is impossible to install a septic tank using rings with your own hands without the use of lifting equipment. The weight of even the smallest reinforced concrete ring reaches several hundred kilograms.

Choosing a method of supplying water to the house

The choice of equipment for delivering water from the source to the consumer depends on many factors, for example, the number of residents, water collection points or the needs of the owners.

Let's say a permanently living family with a small child uses much more water than a retired couple. After analyzing the situation, they choose either a conventional pump or a pumping station.

Which pump do you prefer?

There are two types of pumps: submersible and surface pumps . The factor that plays a major role in the choice is the depth of water in the well. For a shallow reservoir, a surface mechanism is appropriate.

Its coverage area is up to 6-8 m (less often – up to 10 m). The equipment is placed on the surface. Sometimes, in order to increase the suction depth, they are equipped with an ejector.

An example of a surface centrifugal pump is a budget domestic model of the Vikhr . It is not suitable for servicing a residential building, but it is quite suitable for supplying water to summer residents who come on weekends or on vacation.

Models of this type are most often used for watering a vegetable garden or garden. This pump is ideal for shallow wells with slow recovery. More powerful units are capable of delivering 3 thousand l/h.

If you are planning to equip a more serious system, pay attention to submersible pumps. They have high performance, produce less noise and save energy.

The power of a submersible device directly depends on the depth of immersion. Well models have a low cost, on average 2-3 thousand rubles, but you can find them even cheaper - for 1500 rubles, for example, Olsa Rucheek .

Affordable brands that are quite powerful and easy to repair and replace are popular, for example:

Inexpensive submersible models have an average capacity of up to 1500 l/h. For a small country house, the ZUBR NPV-240 or any of its analogues is suitable.

Maximum productivity is 24 l/min, which is enough to uninterruptedly provide several water points.

The maximum height is 60 m, that is, the pressure will be enough to deliver liquid from great depths to the second floor or attic. The BISON is equipped with an upper fitting, which means it is protected from accidental intake of bottom sediment.

Submersible models easily “digest” mechanical particles up to 2 mm in diameter and, if necessary, can serve as drainage equipment.

To protect the water supply system, control devices - pressure gauges and pressure switches - are installed along with the pumps.

Another device - a dry running sensor - protects the mechanism by stopping its operation when the water level drops or the pipes are not sealed.

When choosing a pump, do not forget to read the characteristics and installation instructions - technical information will help you decide whether the model meets your requirements.

Advantages of pumping stations

If you do not want to constantly turn the equipment on and off and depend on power surges, instead of a pump, purchase a pumping station - a unit for those who love comfort and stability.

A hydraulic accumulator (also a damper or water tank) ensures the constant availability of water in the network, and additional devices control the pressure and perform standby or emergency shutdown.

It is better to install the pumping station in the basement, basement, or utility room - this makes it easier to connect to a source of electricity and frees you from laying an electric main.

If it is necessary to stretch cables over a long distance, three-core copper wires with a cross-section of one and a half millimeters are used.

Cables enclosed in polymer corrugation are buried at a depth below the seasonal freezing level. To protect them from accidental damage, they are covered with sand and gravel.

If there are residential premises in the immediate vicinity, when purchasing, choose a model with minimal noise levels. The supply of water through the pipes to the tank is controlled by a pressure switch.

The device works in such a way that even in the event of an unexpected power outage, a reserve of about 1/3 of the tank is created.

When choosing a particular brand, pay attention to the following characteristics:

- power – 250-1400 W;

- productivity – 1500-4000 l/h;

- depth – from 8 m to 50 m;

- volume of the damper tank (60-80 l).