A huge hello to all blog readers!

I'll ask you a question right away. What element does the construction of any object begin with? Of course, you don’t have to think here - this is the foundation. And the most common type of base is “ribbon”. To make it, you need formwork. But from now on, let's look at the question in more detail. So, the topic of the article is permanent formwork for a foundation made of polystyrene foam (Penoplex)…

The world has been changing very quickly lately. Construction technologies do not stand still either. What was “in the order of things” yesterday is no longer relevant today. Builders everywhere use both removable and permanent formwork options for foundations and even walls. Here is a link to the blog topic article. Well, we will break down the main points, as the technology of permanent formwork is increasingly gaining its “fans”.

Advantages of expanded polystyrene formwork

As we just found out, it is better to use foam plastic for formwork. After all, this is an environmentally friendly material, in the production of which no toxic substances are used. Other advantages of this material include:

- ease of installation, allowing you to save a lot of time and money;

- long service life;

- the ability to dig a not too deep trench during installation;

- efficiency;

- For waterproofing protection of the base, drainage is quite sufficient;

- foam boards do not attract rodents as much as other materials, and, moreover, do not rot;

- high thermal insulation properties, allowing significant savings on insulation;

- installation channels in blocks designed for laying various types of communications.

Flaws

Of course, the designs also have weaknesses, even if they are few. These include:

- impossibility of construction in winter;

- mandatory grounding of a house under construction;

- The humidity in such walls will be very high, and therefore it will be necessary to install forced ventilation.

Important points

Recommendations:

- The formwork must be durable. Violation of the requirement will lead to distortion of the wall geometry and the solution will leak out.

- Strictly maintain 0 vertical. If the permissible deviation is exceeded, the wall may collapse.

- The next tier must be poured quickly, otherwise delamination may occur.

- The mandatory use of reinforcement will make the structure more durable.

Technology is making it easier to build walls. Even inexperienced people can build on their own if they follow simple requirements.

A video showing how easy it is to use permanent formwork:

Permanent formwork – PENOPLEX FOUNDATION®

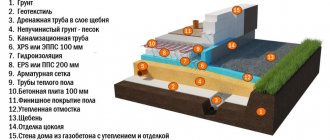

In private housing construction, strip foundations are widespread. In the classic version, such a structure must first be erected and then insulated. However, an innovative solution involves an elegant combination of these two stages. Let's tell you about everything in more detail.

The formwork required for concreting is constructed not from the now expensive wood, but from high-quality PENOPLEX thermal insulation boards. After the concrete has hardened, such formwork is not dismantled, but remains in the foundation structure, providing reliable thermal protection. This technology is called permanent formwork.

Advantages of PENOPLEX® thermal insulation

For the manufacture of permanent formwork, we recommend using especially durable thermal insulation PENOPLEX FOUNDATION. These slabs, along with a low thermal conductivity coefficient (up to 0.034 W/m•K), have a compressive strength at 10% linear deformation of at least 0.3 MPa. Therefore, under the influence of the concrete mixture, the material does not change its configuration, and after the concrete hardens, it becomes a reliable part of the foundation structure.

Construction of permanent formwork from PENOPLEX FOUNDATION slabs at the site

An important quality of PENOPLEX is water resistance, which allows it to maintain its heat-shielding ability, otherwise water, a good conductor of heat, penetrating into the structure of the material, significantly increases its thermal conductivity coefficient. PENOPLEX is characterized by almost zero water absorption, which retains its strong heat-shielding properties throughout its entire service life, and at the concrete hardening stage it prevents the penetration of “concrete milk” into its structure. The absolute biostability of PENOPLEX does not allow the development of fungus and mold.

Fastening permanent formwork from PENOPLEX

For this purpose, a universal screed is used, to which you can attach an extension element that can increase the thickness of the concrete structure being built up to 40 cm.

Universal screed for fastening assembled permanent PENOPLEX formwork

Extension element and two reinforcement clamps for fastening permanent PENOPLEX formwork

The universal tie simplifies and makes installation convenient, allowing you to fasten the reinforcement directly to the tie.

A fragment of assembled permanent formwork made of PENOPLEX boards secured with a universal screed

1 – Outer layer made of PENOPLEX board

2 – Inner layer made of PENOPLEX board

3 – Universal coupler

4 – Reinforcement frame

The manufacturer of thermal insulation boards PENOPLEXOOOO "PENOPLEX SPb" has extensive experience in using permanent formwork technology in private housing construction. The company’s specialists are ready to advise customers and carry out installation supervision. To help those wishing to take advantage of the company’s achievements in the application of this technology, PENOPLEX SPb LLC has developed a “Technological map for the installation of strip monolithic foundations using permanent formwork technology using PENOPLEX slabs and universal polymer screeds.” The document sets out in detail the procedure for organizing and technology of installation work, reflects safety issues, quality control of work, and provides a list of necessary regulatory documentation.

The process of constructing permanent formwork using PENOPLEX boards is presented here in a simplified and visual way.

Economic benefits

In addition to the cost of purchasing wood, permanent formwork will save time and labor costs on the manufacture of a wooden structure and its dismantling. Note that when arranging a strip foundation, the construction of removable formwork is one of the most expensive processes.

If we compare two options for constructing a strip foundation (the first - with removable formwork and subsequent insulation with PENOPLEX® slabs, the second - with permanent formwork made from such slabs), then the first will cost 20% more.

In addition, by combining the operations of constructing formwork and insulating the foundation into one stage, the work is simplified and accelerated, and construction time is reduced.

How is foam formwork made?

We recommend that you read the step-by-step instructions below.

Stage one. Let’s immediately say that there is nothing complicated in making polystyrene foam formwork, but only on condition that you strictly follow our instructions. So, first mark the area and prepare all the materials necessary for the work. Draw up a construction plan for the future building, and then mark the area for the foundation in accordance with it.

It is important that each of the corners is aligned with utmost clarity using a mounting level. Moreover, you need to carefully level the entire area of the construction site, since only under such circumstances will you be able to apply the required markings with a minimum error

Stage two. Next, arrange a trench for the future foundation. The depth of this trench should be 0.5 meters and the width should be only 0.4 meters

When working, pay special attention to the horizontalness of the bottom of the pit. The fact is that the formwork will not be removable, therefore, it will no longer be possible to level the surface for the walls

Stage three. Then proceed to make a drainage pad. Such a pillow should be laid exclusively on a leveled surface (the mounting level will help you!). Use a sand-gravel mixture as a cushion - pour it onto the bottom of the trench in a 15-centimeter layer and level it. This way, the future load from the building will be distributed as evenly as possible.

The pillow will also have another function - a thermal insulator and a drainage system. Insert reinforcing rods into the cushion - in the future they will take part in connecting the formwork blocks.

Stage four. Pour a thin layer of concrete mortar over the pillow - it will serve as a kind of “sole” for the base

Thanks to this “sole” the surface will be as smooth as possible, which is very important when constructing formwork with your own hands

Stage five. After the concrete solution has hardened, place the foam blocks on the reinforcing rods installed in the previous steps. Install jumpers between the blocks, with the help of which they will be connected to each other. It is typical that the blocks must be connected according to the tongue and groove principle, which will minimize the number of additional assembly seams. For corners, use special corner joints - this way you will protect yourself from labor-intensive fastening of elements in the corners.

Note! In some cases, additional reinforcement is installed in special grooves (the said grooves must be in blocks). Although a lot here depends on the specific project for which the facility is being built

Stage six. Having installed a row of blocks No. 3, align them vertically. Make sure that the side surfaces always coincide with one another.

Stage seven. As soon as all the voids inside the polystyrene foam plates are filled, you can begin to actually pour the concrete solution. To compact it, experts recommend using special deep vibrators. Having finished compacting the surface, take a trowel and carefully level the upper “mirror”

It is worth adding that foam formwork involves adding coarse crushed stone to the concrete (it is important that the size of its fractions exceeds 0.8 centimeters)

Note! This kind of formwork has recently become increasingly popular, since it does not need to be dismantled after the solution has hardened, but on the contrary, it will also serve as an additional thermal insulation layer in the future. Stage eight

This completes the construction of the formwork. As a result, you will get walls that will look like a “sandwich” in cross-section: two rows of foam plastic, between which there is a heavy-duty concrete monolith. Characteristic, but the inner layer will be thinner than the outer one, due to which the insulating properties of the material will be excellent

Stage eight. This completes the construction of the formwork. As a result, you will get walls that will look like a “sandwich” in cross-section: two rows of foam plastic, between which there is a heavy-duty concrete monolith. It is typical, but the inner layer will be thinner than the outer one, due to which the insulating properties of the material will be excellent.

Calculation of the optimal thickness and amount of material

If it has been decided to insulate the foundation of a house with polystyrene foam, you first need to find out the optimal thickness of the material and its required quantity.

The first step is to determine the purpose of the work:

- reduction of heat loss in the room;

- basement insulation;

- converting a basement into a living room.

The required thickness also depends on:

- climate;

- operation and purpose of the building;

- measures to protect against moisture condensation;

- energy saving.

The most important characteristic for foundation insulation is its thermal conductivity. The lower this value, the better heat retention

Thermal conductivity can be defined as the amount of thermal energy that passes through a material with an area of 1 m² if the surface temperature difference is 1 °C. This value is measured in W/m²*°C. To calculate the required insulation thickness, you need to know one more value - heat transfer resistance. It is measured in m²*°C/W. To calculate it, you can use the following formula: R=d/k, where d is the thickness of the wall, K is the thermal conductivity coefficient, and R is the required thickness of polystyrene foam.

Table. Calculation of thermal insulation thickness.

Thermal insulation thickness, mm Heat transfer resistance, m2*°C/W Thermal conductivity coefficient, W/m2*°C

| 40 | 1 | 0,83 |

| 50 | 1,25 | 0,68 |

| 60 | 1,50 | 0,58 |

| 70 | 1,75 | 0,51 |

| 80 | 2,00 | 0,45 |

| 100 | 2,50 | 0,37 |

| 120 | 3,00 | 0,31 |

| 130 | 3,25 | 0,39 |

| 140 | 3,50 | 0,27 |

Calculation of insulation thickness

The required amount of polystyrene foam can be calculated by multiplying the height by the perimeter of the house and dividing the resulting value by its area. The final result will help you find out how much polystyrene foam you need in sheets. To work, you will also need glue, the consumption of which depends on the manufacturer and is indicated on the packaging.

How much insulation is needed?

Main types

There are types of permanent formwork:

- from expanded polystyrene;

- wood-concrete panels or blocks (arbolite);

- glass-magnesite;

- facing.

Let's consider the building materials used in order.

Fixed polystyrene foam formwork

She is one of the most controversial reviews. A negative attitude towards the material has formed because it makes a thermos house. Since the entire foam structure remains inside the building. Fixed polystyrene foam formwork for a home has a number of pros and cons.

Fixed polystyrene foam formwork

pros

- the result is a soundproof building and a warm building, which does not always require additional. insulation;

- due to the use of reinforcement, the walls are self-supporting and columns are not required;

- speed of construction.

The list could be expanded with low cost, however, when you take into account the price of subsequent interior and exterior decoration of the house, this advantage ceases to play a role. According to the manufacturers of the material, non-flammable foam plastic is used in production, but the issue of leaving it inside the house is still controversial.

Minuses

- expanded polystyrene has an extremely low vapor permeability rate, which is why homes have high humidity and an unfavorable microclimate;

- there is difficulty driving nails into polystyrene foam walls, which makes it difficult to install building materials and furniture;

- without using plastic ties instead of a foam partition (which are easily pierced), mice can be infested.

But the main drawback is that the inner layer of the walls of permanent formwork made of foam plastic has almost no heat transfer and does not balance temperature fluctuations, which requires thinking through the ventilation system of the house. Application: permanent formwork made of polystyrene foam is used for the foundation and walls of buildings.

Fixed wood concrete formwork

The building material is a mixture of wood sawdust and cement. This wood concrete is laid in rows, and the same polystyrene foam is used for insulation. After laying, corrugated reinforcement and concrete are loaded into the walls, then plastering work is carried out.

Fixed wood concrete formworkPros:

- if polystyrene foam insulation is used, it must be done outside the house, which improves the microclimate;

- the internal walls are rigid, which is good for installation work during finishing.

Minuses:

- poor moisture resistance;

- high price and small quantities of wood concrete are present on the Russian market.

Application: for building wall structures.

Fixed formwork made of glass fiber reinforced concrete

Essentially, this formwork is a frame made of rolled metal, which is sheathed on the outside with glass-magnesium sheets. From the outside, this material looks like drywall. Foam concrete is poured into such partitions.

Pros:

- low cost;

- high sound insulation.

Minuses:

- complex installation;

- not applicable for external walls.

Application: for internal partitions of an object. Cannot be used as load-bearing elements of a building.

Drywall

Permanent plasterboard formwork is more used in private panel housing construction. This often saves time on finishing. This design is not suitable for casting heavy concrete.

Permanent formwork made of concrete blocks

Permanent concrete formwork is produced in the form of hollow blocks for foundations. Monolithic construction technology using these blocks represents innovative engineering solutions.

Monolithic foam concrete in permanent formwork

Due to the absence of costs for the delivery of building materials and its laying, it is often possible to achieve impressive economic benefits, in contrast to working with block walls. As a result, during the construction of structures where such material is used, the thickness of the walls decreases, but the heat storage property remains.

Feasibility when building a house

Permanent formwork used in the construction of a house gives its elements additional reliability and strength. In addition, this element contributes to the following factors:

- the work on laying materials and constructing the necessary structures is accelerated;

- by reducing the thickness of the walls, the total weight of the structure is reduced;

- permanent formwork structures are used in almost every design solution for the construction of facilities;

- modern materials for arranging formwork are used in various climatic conditions without changing their characteristics;

- The formwork system may have a molded or structured surface, which eliminates the need for additional finishing of the facades.

Racks for organizing a permanent form of floors

The traditional option for organizing floors in monolithic or any other buildings involves the use of special telescopic (sliding) racks. These products are used to fix temporary flooring, which is made from moisture-resistant plywood for formwork. This method is not convenient, as it requires a lot of time and quite a lot of physical exertion.

The stand, which plays a supporting role, consists of several structural elements. The lower part of the telescopic product is equipped with a tripod, which ensures the stability of the pipe. In turn, in the upper part there is a special attachment, which is necessary for capturing and holding the construction beam - the crossbar. All racks for floor formwork are divided into two categories depending on the location of the thread. Some of them are equipped with open threads, while others are equipped with closed threads.

The pipe, which has a smaller cross-section, is distinguished by the presence of special holes along its entire length. The pitch of the holes can be different - from 11 to 17.5 cm. The outer pipe is equipped with a support nut. As a result, when it becomes necessary to fix the rack at a certain level, a special earring is threaded through the holes in the pipes. This element has a support (nut), so it is held in the desired position.

The organization of floors in monolithic and other buildings involves the use of special telescopic sliding racks

Telescopic formwork posts can vary in length. This figure ranges from 1.7 to 4.5 m. They can withstand quite heavy loads (up to 4 tons). It is worth noting that such support products are made of metal, so they are coated with special anti-corrosion compounds, since steel can rust.

Permanent formwork for floors: features and characteristics

Unlike the standard method, which requires the presence of support posts, polystyrene foam formwork for floors has a completely different installation technology. As the basis for such a system, special matrices are used, which are made from dense and durable polystyrene foam.

Such matrices should be laid on load-bearing walls. The advantage of this method is that these elements are lightweight, so their installation does not require serious physical effort.

As a basis for formwork, special matrices are often used, which are made from dense and durable polystyrene foam

Docking the matrices together is quite simple. Each product is equipped with a tongue-and-groove connection system. Thus, any person who does not have experience in this field can perform such an installation. Thanks to the tongue-and-groove system, it becomes possible to quickly organize a continuous flooring.

Such formwork for a monolithic floor can withstand a layer of concrete up to 15 cm thick. As a rule, this value is quite enough to organize a reliable structure. Before you start pouring concrete, it is necessary to place reinforcement between the joint areas of the floor elements. The metal frame must be assembled into a continuous beam that occupies the entire width of the gap.

Then you need to place the reinforcing mesh on top of the matrices. It is made of rods whose diameter ranges from 10 to 15 mm. Knitting of reinforcement is done in the traditional way - using a special wire.

The final stage of creating volumetric floor formwork involves pouring concrete, after which you need to wait for it to harden. In this way, floors are organized using polystyrene foam matrices. The result of this process is a durable structure that can withstand significant loads.

Any design errors or displacement of blocks during their installation can lead to the collapse of the structure

After the cement mortar hardens, the formwork made of polystyrene foam is not dismantled. It remains in the ceiling pie and from that moment begins to perform a thermal insulation function. This method of organizing a structure is more technologically advanced when compared with the traditional method, which takes into account the use of removable beams for floor formwork.

It is important to remember that independent use of such technology requires an understanding of its nuances. The main thing is that even before starting work you need to know that laying the floor elements requires care

Any design errors or displacement of blocks during their installation can lead to the collapse of the structure.

Step-by-step construction with your own hands

The step-by-step assembly process looks like this:

The first step is to dig a trench or pit under the perimeter of the foundation (read about how the volume of excavation work is calculated when developing a pit, and from this article you will learn how much it costs to dig a trench under the foundation and how to do it correctly).- Then the bottom is leveled and the pillow is covered. It is better to make it from gravel, carefully leveling it with sand on top.

- Then the required base width is determined. This value is variable and depends on various factors. Traditionally, it is customary to make a foundation 30–60 cm wide.

- A foam sheet with a thickness of 5 cm is laid on top of the sand backfill. This lining guarantees excellent thermal insulation of the concrete mixture.

- After this, the corners of the structure are formed using special screws. EPS sheets are suitable for the internal as well as external walls of foam formwork.

- The layers are joined by performing a slight shift. This prevents concrete from leaking through the cracks.

- The installed walls are connected to each other, for which you will need universal ties. They allow you to accurately set the required width of the foundation, being at the same time guides and mortgages for the formation of the reinforcement frame. Everything in purchased products is clearly thought out, so assembling such a construction set is simply a pleasure.

- Having fastened the lower part with ties, install ventilation vents in several places, and then attach a horizontal reinforcing layer. Typically, sections of plastic pipes with a diameter of 110 mm are used for vents. They are easy to cut using a regular grinder.

- Metal rods are securely fastened with clamps located both on the inner and outer edges of the blocks. Fiberglass can also be used as reinforcement instead of steel. It is even more preferable, although in practice metal is traditionally used.

- When the creation of the lower reinforcing belt is completed, the next universal ties are attached at the top of the formwork, which hold the sheets together. The upper reinforcing belt is mounted on them.

- The final stage of the formwork installation is the fastening of the vertical elements of the metal frame. All intersections of the rods must be tied using soft wire.

After this, the permanent formwork, containing a reinforcement cage inside, is ready for use.

Attention! After pouring the concrete mixture into it, you only need to walk through the liquid mass with a vibrator to remove air pockets. When there is no such device, you will have to use the old-fashioned method - “pierce” the liquid solution with a stick.

From the video you will learn what permanent polystyrene foam foundation formwork is and how it is installed:

More information about polystyrene foam formwork

It’s worth stopping and considering the polystyrene foam version of permanent formwork, since it is the one that is most often used in construction today.

The key reason for its popularity is the simplicity and ease of installation of polystyrene foam boards. The work absolutely does not require the involvement of qualified specialists or any equipment. The block wall elements are firmly fastened together, and then concrete is poured into the formed space.

Various communications are laid in pre-designed technological openings. With this installation method, an insulated reinforced concrete wall with a monolithic structure is obtained.

This design does not require any additional sound or heat insulation work, since polystyrene foam performs such functions perfectly. In addition, the surface of this material does not absorb moisture and does not allow water vapor to pass through it at all. For a monolithic foundation with fixed polystyrene foam formwork, unfavorable weather is not a problem.

The advantages also include the resistance of expanded polystyrene to cracking and thermal structural expansion - that is, this technology can be used to build houses in hot, earthquake-prone regions.

The structure of permanent formwork, assembled from polystyrene foam boards, is simple and consists of the following parts:

— plastic ties;

— steel (galvanized) L-shaped hooks designed for strong fixation of plastic ties;

— external and internal facing decorative plates. They are made from concrete mixture and have a beautiful external structure.

Block design

Each formwork element consists of two panels connected to each other by jumpers. The panels have connecting grooves that ensure a tight connection of the blocks between the rows and prevent them from moving when pouring concrete. Dense polyethylene bridges provide rigidity. The straight block contains eight jumpers fixed at 175 mm intervals.

Permanent formwork block. Photo from the site vosaduly.ru Each lintel has four grooves for horizontal reinforcement (two each in the upper and lower chords) and two central grooves of larger diameter (in the upper and lower chords) for laying plastic pipes intended for heating the concrete in winter. On the outside of the block there are strips along its entire height, which are part of the lintel and are called the mounting part. Auxiliary and finishing materials can be attached to it with self-tapping screws. A set of elements of different sizes allows you to build walls of any configuration. Expanded polystyrene panels are easy to cut with a hacksaw if you need to ensure the required height or length. Polyethylene lintels have grooves for installing horizontal reinforcement with a diameter of up to 8 mm, as well as vertical reinforcement rods. The jumpers ensure tight fixation of the polystyrene foam walls of the block. Despite the fact that the jumpers run along the entire height of the structure, the ratio of their effective cross-sectional area to the total cross-sectional area of the block transmitting heat flow does not exceed 0.4%. Therefore, the influence of jumpers on heat transfer is minimal. Additional articles and discussions about permanent formwork and polystyrene foam:

- Concrete or wood?

- The whole truth about polystyrene foam insulation

- Which brand of polystyrene foam should I choose for walls made of foam blocks?

Advantages and disadvantages

If we talk about the advantages that permanent foam formwork has, the following factors should be mentioned.

The main advantage of all non-removable structures that are made from materials with low mass will be the presence of an auxiliary type function. In addition to creating a space where concrete can be poured, formwork of this type will also perform an insulating function. Foundations and walls that are made monolithically do not need to be further insulated, which will save money. And if instead of the mentioned material you use the most ordinary formwork made of wood, then you simply will not get a similar effect

With a reduced thickness of monolithic type floors, polystyrene foam slabs will make it possible to retain a third more heat than if the walls are made of regular-sized brick or concrete. Permanent formwork made from the mentioned material not only retains heat, but also provides moisture protection, which will be important in winter and when the seasons change. This allows you to increase the durability of a monolithic type foundation, even in difficult conditions, by at least 15-20 percent. Reducing the construction cost of the facility

If we take into account that a fairly significant percentage of the estimate is made up of the costs of creating walls and foundations, then the use of this category of formwork allows us to reduce the thickness of the wall thanks to additional thermal insulation and make the cost of the foundation lower. In total, you can save about 30 percent of money. The use of a material such as polystyrene foam allows concrete to gain strength evenly in all places, even at temperatures up to +5 degrees Celsius. Thermal insulation makes it possible to keep the temperature of the solution inside and at the edges of the fill at the same level. For the mentioned reason, the material hardens more evenly, which increases the strength properties of the concrete solution. In wood formwork, the solution will quickly become thin around the edges, and inside the temperature drops much more slowly. Because of this, the quality of concrete decreases, and the increase in strength is uneven. It is not difficult to assemble this type of formwork. This doesn’t even require any special skills, so anyone can do it.

Disadvantages of this design.

A building created using permanent formwork cannot be reconstructed or rebuilt in any way. When planning a construction project, especially an individual one, you should remember this and immediately make a building plan so that it is final

It will also be extremely important to mark everything as accurately as possible and lay out communications when pouring monolithic type walls. A serious drawback is that it is impossible to fill the solution if the temperature is below +5 degrees. In addition, at high temperatures there are also difficulties, because if it is too hot, you will have to additionally moisten the solution. Protection made from polystyrene foam boards does not allow the walls to “breathe”

To solve this problem, at the design stage it is necessary to provide for the installation of forced ventilation in advance. Only such a solution makes it possible to eliminate the greenhouse effect indoors without reducing its thermal insulation benefits. It will be important to carefully fit the blocks so that there are no breaks. If the formwork is not tight, then moisture will begin to get inside the base, which will cause the formation of fungus. It is especially important to pay attention at this point to builders without experience who assemble formwork from such material on their own.

Grillage. Formwork. Part 4. We set up and tighten the formwork with studs. We concrete the grillage.

Posted By: YanaShi 10/14/2016

Let us remind you that the first part of the article was devoted to the reinforcement of the grillage frame, the second - mostly to the formwork, in the third we talked about tying knots and piles. And finally, we have come to the final part of our article, in which we will tell you whether we ended up with a foundation or not. There is very little left to evaluate all our actions... Complete all manipulations with the formwork and concrete the grillage. So let's get started!

Formwork for grillage.

Let's start with the formwork. It needs to be leveled. In some places the level has dropped due to various construction works that were carried out next to it, on it, etc. Thus, the formwork at this stage is not level, in some places everything is normal (in terms of level), but in others it has dropped or sagged. We checked the level of the formwork using a stretched cord, which was still tensioned when marking the foundation of the house and was temporarily removed during the work, as well as using a bubble level. By the way, at this stage, in places where the formwork sagged, we did not tighten the studs inserted for structural strength. This would make things more difficult.

In order to level the level of the formwork, we needed to pour sand into the sagging areas, and to do this, lift the entire structure from heavy OSB sheets. It's impossible to do this by hand, so we built a homemade jack from a long metal stick mounted on wooden boards. On one side, a homemade jack was hooked onto the protruding parts of the formwork, and on the other, a person eventually sat down and lifted the OSB sheets with his weight. We can say that we have a so-called “construction swing”.

Level the formwork level.

After we put the formwork in order, i.e. Having set it level, we decided to put reinforcement clamps in problematic places of the grillage in order to avoid further reinforcement going beyond the concrete, which could happen due to the general load on the foundation. We used “Zvezdochka” reinforcement clamps, which create a protective layer of concrete of 5 cm. The price of 1 package (50 pcs.) is 98 rubles, we spent about 3 packages of clamps in the amount of about 300 rubles. Then the remaining studs were tightened, and our preparatory work for pouring the grillage with concrete came to an end.

Foam formwork

Foam formwork is assembled from blocks of expanded polystyrene foam, fastened together with locks on them. To connect foam blocks, do not use glue or other fastening agents. The blocks are stacked on top of each other in a checkerboard pattern.

There are variations of foam elements such as cast and prefabricated blocks. The first is also known as a fuser. They are characterized by a fairly high density and have good thermal insulation characteristics. The blocks consist of two plates connected to each other by jumpers.

The average weight of one such block is 1 kg. Standard dimensions are 100x25x25 cm. With such dimensions, the thickness of the foam plates at the edges is 5 cm. The thickness of the concrete layer when using such formwork will be 15 cm.

Manufacturers also offer options for blocks of other sizes.

Even those without construction experience can construct permanent formwork from foam plastic.

Such structures are poured in layers. That is, they fill the inside of the foam part with concrete and then wait for it to harden. When it is necessary to give the structure additional strength, reinforcing elements are added, which are installed inside the formwork.

The first row is laid out on a surface equipped with waterproofing.

DIY installation technology

It is immediately necessary to indicate that permanent formwork is installed on a concrete screed, which is poured along the bottom of the dug trenches. That is:

- dig trenches;

- cover their bottom with a layer of sand and gravel;

- pour a concrete mortar screed 5-10 cm thick;

- when the concrete dries, it is covered with a waterproofing material, for example, coated with bitumen mastic, although this is an optional operation.

Assembling formwork from slabs

The technology for assembling slab elements is quite simple. It’s easier to assemble the formwork somewhere to the side, that is, connect two slabs with ties along the lower level. And then install them at their location, connecting the blocks together with a special adhesive composition, similar to foam, which does not expand in volume after its use. In this design there are no corner elements or jumpers; all assemblies are formed by panels that can be easily cut to the required dimensions. You can cut polystyrene foam boards with a regular wood saw.

- As soon as the formwork is formed from interconnected slabs, a reinforcing frame made of reinforcement is installed into it.

- Then the upper level fastening ties are installed.

- Next, soil is added from the outside of the installed structure.

Assembling formwork for walls

For monolithic construction today, special polystyrene foam blocks are also used, which are assembled like a construction set. Their design includes tongue-and-groove connecting locks, which give the joints of two blocks strength and tightness. That is, the blocks are simply installed on top of each other without additional fasteners. Typically, such blocks are products of rectangular cross-section with cross members that give strength to the product. At the same time, the crossbars act as supports for laying reinforcing frame lattices on them, which simplifies the process of installing the reinforced frame. The main task of the work manufacturer is to make holes in the corner blocks to move the concrete solution through adjacent cavities.

To fill the walls, formwork is first erected from three rows of blocks. Each subsequent row is shifted relative to the bottom one so that the joints between the elements do not fall on one vertical line. The standard installation is in the form of brickwork with an offset of half the length of the block.

The laid rows must be checked with a level for verticality and the required amount of vertical reinforcement is installed inside. By the way, if the verticality of the installed structure is not confirmed, wooden wedges are driven under the bottom row of blocks to raise one of the sides of the assembled formwork.

After which the permanent formwork is poured with moving concrete. Next, three more rows are built, and all processes are repeated. And so on until the walls are completely erected.

Economical option

Permanent formwork can be assembled from ordinary Penoplex slabs - a high-density insulation material known today. It is durable and has the best thermal insulation characteristics, second only to polyurethane foam.

The dimensions of the penoplex panels are 600x1000 mm, which exceeds the standard sizes of finished blocks. This is already savings. The only thing you need to think about is the system for fastening the plates to each other. There are many options here, for example, installing through jumpers from reinforcement with threads on the edges. It is this part that is brought out to the outside of the slabs, where it is tightened with a nut and washer.

You can purchase ready-made lintels that are used in ready-made permanent foam formwork. These are most often plastic products that have holes for installing fittings. The main thing is to install them correctly between the Penoplex panels.

All other steps are exactly the same as when assembling formwork from ready-made polystyrene foam boards (the first option in this article). That is:

- a reinforcing frame is installed inside;

- a number of upper fasteners are installed;

- concrete solution is poured.