Home » Building a house

Alexander Korovaev 03.23.2020

38700 Views 1 comment

The basement under the house is not the best place for long-term storage of workpieces. The temperature there is elevated, and closer to spring the vegetables in it will become flabby. Therefore, sooner or later, novice homeowners have a reasonable question: “How to make a free-standing cellar with your own hands?”

Types of cellars

The oldest way to preserve food is to keep it in a cool, dark place. For this purpose, holes were used, dug in the ground and covered with a lid. The walls were made of logs impregnated with hot resin. Such storage facilities served for many years.

Nowadays, a cellar can be not only earthen, but also above ground. And in order to maintain the necessary conditions - a favorable temperature of about 2-5° and a humidity of 85-90% - modern building materials are used.

Zemlyanoy

This is a traditional type of cellar, where earth is used as a temperature-holding layer. The storage pit is dug to a depth below the soil freezing level - approximately 1.8-2.5 m.

The walls are laid out from bricks or blocks, poured from monolithic concrete or sheathed with boards on a frame made of logs. The roof and door (hatch) must be reliably insulated. Foam plastic, expanded clay, moss, earth or other materials with low thermal conductivity that are resistant to high humidity and frost are used as thermal insulation.

The main condition for constructing an underground cellar is dry soil and a low groundwater level. During the snow melting season, the groundwater level should not rise above 3 m to the ground surface. In all other cases, it is advisable to make the basement semi-buried or above ground. If the layout of the site allows, the cellar can be attached to the wall of a barn, garage or house.

Semi-recessed

The basement of this structure is half or one third of the height submerged in the ground. Moreover, the floors must be at least 50 cm above the ground water level.

A separate semi-buried cellar is completely filled with soil, and a hill is formed on the surface of the earth. If it is cultivated, it can be used as a decoration for the site, for example, an alpine slide.

A convenient option is a cellar in the basement of a residential building. It is necessary to isolate the rooms from each other as much as possible in order to protect the underground part from excess heat, and the house from cold and humidity.

Ground

How to make a cellar with your own hands if the water supply is very close to the surface of the earth? The only way out is construction without deepening. Its advantages:

- the room will always be dry, water will not penetrate there when snow melts or groundwater fills;

- there is no need to carry out a large amount of excavation work.

The disadvantages of this method of construction are the high need for building materials, because in essence this is a permanent structure with walls and a roof, and good insulation. The decoration of the above-ground cellar can be in the style of neighboring buildings, then it will not stand out from the general ensemble.

The second option is embankment with earth or peat in the form of a bulk hill. To do this, you will need to import a large volume of soil.

For thermal insulation of above-ground and semi-buried structures, clay, foam plastic, expanded clay, and dry earth are used. The total thickness of insulation should be at least 0.7-1.2 m.

Wall-mounted

In this design, the cellar is more economical in terms of material consumption and labor costs - one wall is already there. The pit can be dug no deeper than 0.5 m, since loosening the soil close to the main building is not recommended. This can cause uneven soil deformations and the formation of cracks in building structures.

The outside walls and roof of the basement are well insulated; you can use synthetic materials and embankment with earth. Decorative finishing upon request - plaster, siding, tiles.

Caisson

If the groundwater level in the area is very high, and a deep cellar is needed, special sealed containers are used - caissons. They are made of thick metal or durable plastic and can withstand high lateral soil pressure.

To prevent the caisson from being squeezed out when the water rises, it is strengthened in the ground with the help of anchors. The liquid accumulated under the bottom is periodically pumped out with a pump.

Compared to other types of cellars, the caisson is more reliable in terms of the absence of leaks, but is more expensive. However, in areas near water bodies, marshy soils, and low-lying areas, this is the optimal way to store supplies.

Choosing the type of structure and location for it

The cellar is usually located in a separate place on the street or under a residential building. Its main purpose is to store food supplies. By installing racks, shelves and other devices, it is possible to increase the functionality of the room.

Interesting design solution in the design of the upper part

Classification of cellars by depth level:

- underground structures are installed in dry places;

- semi-underground structures are erected in damp places with average groundwater levels;

- above-ground buildings are made when groundwater is too close.

Example of an underground storage facility located in a dry location

Note! In an area with too high humidity, a special cushion of sand and gravel mixture should be installed. It will separate the structure from groundwater.

The construction of a cellar does not require obtaining permission from any regulatory authorities, however, the developer must in any case decide on its location, taking into account some nuances. You should choose a site that is as dry as possible, away from trees.

The structure is conveniently located under an alpine hill

How to choose a place

The site for constructing a cellar at your dacha with your own hands must be dry and protected from seasonal flooding. The higher the platform, the better.

Objects located nearby that pollute the soil are potentially dangerous - compost pits, toilets, sheds with livestock, bathhouses, summer showers. SNiP 30-02-97 recommends safe distances:

- 12 m from cesspools;

- 12 m from the barns;

- 8 m from compost heaps;

- 8 m from the bathhouse, shower, sauna, swimming pool.

You need to take into account not only the sources of pollution on your site, but also on your neighbor’s. If the storage facility is located underground, it is recommended to move at least 7 m away from the residential building to prevent heat transfer through the ground. You can draw a diagram of all buildings in advance and determine the location of the cellar that corresponds to specific conditions.

Recommendations

In an above-ground cellar, vegetables will remain fresh for a long time.

Any person can master the theory of cellar construction. However, in order to avoid unforeseen difficulties, you should use the advice of the experts:

- when choosing a location, consider the risk of flooding;

- before construction, start drawing up drawings;

- do not deepen the building below half a meter;

- use moisture-resistant building materials;

- do drainage;

- treat wooden elements with antiseptics;

- Perform electrical wiring in accordance with fire safety requirements.

To build an above-ground storage facility for grown crops, follow the technology and the drawn up project. Supplies will remain fresh for a long time if the building is equipped with ventilation and the walls are insulated.

How to find the groundwater level in your area

Water is the main enemy of all building structures, especially those located underground. To find out the groundwater level on the site, it is recommended to conduct small geological studies:

- Drill a hole 3 m deep. It is better to work in late autumn or spring. If the groundwater level is close, a wooden pole lowered into the well will be wet.

- Contact your local hydrogeological organization. There are all the answers regarding questions about UGV.

- Talk to your neighbors. Usually, nearby areas have similar conditions.

- Explore the area for the growth of moisture-loving plants - horse sorrel, sedge, nettle, alder, willow and others. If they are abundant on the site, groundwater is very close.

Nearby ditches, wells, and boreholes are also a source of information. Another telltale sign of a nearby aquifer is heavy dew falling at night. If, in addition to a high groundwater level, the soil has a clayey composition, building an underground cellar is very risky. It is better to focus on more “elevated” options.

Pit preparation

If it is necessary to determine the groundwater level in the wettest season of the year, it is recommended that the construction of the cellar be carried out in the middle or end of summer. During this period, the groundwater level reaches its lowest point.

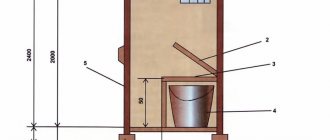

The dimensions of the pit are determined based on the expected volume of supplies for storage. Usually it is 2.5x2.5-3x3 m, but there are no restrictions on area. The optimal depth of the cellar is 1.8-2.5 m. With this height of the room, a person can stand up to his full height.

The width and length of the pit also depend on the properties of the soil. If it is loose and prone to crumbling, a larger pit is dug, and retaining walls made of shields and struts are installed inside. If the soil is dense and holds its shape well, no additional reinforcement is needed.

You can dig manually, selecting the soil with a shovel. It is lifted to the surface in a bucket and poured at a distance so as not to collapse the wall.

If the cellar is large, it is better to save energy and hire an excavator, and then level the bottom manually.

Earthen cellar. Do-it-yourself above-ground basement at the dacha, step by step

In order to prevent soil shedding, a hole for a semi-buried pit is dug with a slope. Its dimensions are selected from the expected volumes of food storage, the level of groundwater and the desires of the owner.

A broken brick or stone is placed in the clay diluted with water poured onto the drainage, and a layer of more densely mixed clay is poured again. All this is sprinkled on top with medium-sized brick or stone chips, ensuring that the flooring above the drainage layer is at least 150 mm.

The walls of the cellar are coated with a thick layer of clay, at least 5 centimeters thick, and also sprinkled with appropriate small pebbles. To ensure rainwater drainage, a shallow ditch is dug along the entire perimeter of the above-ground cellar, in accordance with the terrain.

Waterproofing

Any type of above-ground cellars must be systematically equipped with waterproofing, even if the groundwater is located at a depth of more than three meters and the flood control scheme is practically not used.

Read more: waterproofing the basement from groundwater.

Cellar cover

To protect from moisture, the ceiling is covered with poles and boards (can be used), covered with roofing felt, and a mixture of clay and soil removed when digging a pit is poured on top of it, in a layer of at least 600 mm, which will contribute to the preservation of vegetables and fruits all year round. You can also lay turf on top of the roofing material or plant grass, throw branches or grass, straw and other seemingly unnecessary materials.

A cellar will help you save space in your home

Entrance device and ventilation

The most difficult thing in this option is arranging ventilation in the cellar and the entrance. The upper exhaust ventilation is equipped with a tin (plastic, asbestos concrete, iron, etc.) pipe with its outlet through the top of the wall or ceiling (roof) of the cellar. The pipe must be covered with a cap and a mesh installed to prevent rodents and insects. The lower, inflow, closing one (also with an inserted mesh) is under the door (it can also be placed in the wall).

It is better to make a ground pit with a convenient approach to the door and further into the basement itself, avoiding structures using temporary lowered ladders and hatches on the roof to get inside. Before constructing an above-ground cellar and, accordingly, entering it, it is necessary to find out the most frequent wind direction for this area and especially in winter. Since if the door is located on the leeward side of the building, the thermal insulation of the above-ground cellar will increase significantly, but the fact that before going to the cellar in winter you will have to clear the snow a little is a small price to pay for the safety of its contents.

The place for the entrance and hanging the doors is outlined immediately, since simultaneously with digging the cellar hole, it is necessary to make a trench with steps and create an opening for installing the doors. The doors (it is advisable to make two of them, internal and external, moreover, even separated by a small vestibule) must be carefully insulated (felt, polystyrene foam, unnecessary “rags”, and so on).

Read more: arrangement of the entrance to the basement from the street.

Important! When constructing any above-ground pits, one should not forget about the need to install ventilation, waterproofing, drainage and their insulation.

Foundation structure

Without a solid foundation, you can only build a cellar made of wood. And if the walls are made of brick or concrete, a good foundation is required.

The foundation can be arranged in two ways:

- Lay reinforced concrete strip. To do this, a groove measuring 20x30 cm is dug around the perimeter. The bottom is covered with sand to a thickness of 10 cm and compacted. Then you need to lay reinforcement cages from Æ10 mm rods and fill the trench with concrete. After 2-3 days you can start laying.

- Fill the monolithic slab. The structure has a multi-layer structure - a cushion of crushed stone and sand 10 cm thick with compaction, a layer of lean concrete 50-100 mm, hot bitumen plus 2 layers of roll waterproofing, a reinforcement frame and concrete of a grade not lower than M250. Such a foundation is practically waterproof and serves as a finished basement floor.

Construction of a cellar on a slope or slope

For the basement, natural unevenness is used, where the soil has a slope. This allows you to significantly save on the purchase of material, as well as on excavation work, but the cellar will have a smaller area. The stages of work during such construction are no different from the two previous cases, since any option can be used, but there are a number of features:

- Along the top of the slope it is necessary to dig a drainage ditch at a distance of 3 or 5 meters.

- The floor of such a basement must be made of clay and sand so that it is completely impermeable to moisture.

- The ceiling of the cellar can be made from any available material, including thin logs.

- To keep the structure cool inside, a 30-centimeter thick mound of soil is made.

- The door structure should be light, but at the same time sufficiently insulated, and also have a vestibule.

It is worth noting that this is the least expensive option for making a cellar for a summer house, however, to use it, you will need to select the appropriate slope or bevel (natural unevenness of the ground).

Drainage

At the excavation stage, it is recommended to install a ring drainage:

- Dig a groove 30-50 cm deep around the perimeter of the foundation (outside)

- Lay perforated pipes with a slight slope at one point.

- Connect them to a vertical collector.

- Fill the drainage with crushed stone.

Based on the presence of water in the well, it will be possible to judge the rise of groundwater and take timely measures. Pumping is done with a submersible drainage pump. The liquid is discharged into a drainage ditch or onto the ground in a lower part of the site.

Kinds

Let's figure out how to erect this structure on your summer cottage. This will require serious excavation and construction work.

We are building a blocked cellar

If the site has a hill or ravine with a height of up to 3 meters, then the storage can be arranged directly in it.

To do this you need to do the following:

- If the elevation has a round shape, then one of the sides is trimmed. This can be done using a bulldozer.

- The leveled side is dug inward - this will be the internal area of the future storage.

- The walls of the recess are reinforced with metal structures; concrete slabs or reinforced frames can be used for the walls.

- The outer side is covered with a wall. It can be made from a wooden timber frame, which is sheathed with oriented cement-bonded or thin concrete panels.

- An entrance door is made into the frame of the wall, which is lined with felt and allows for hermetically sealed closure of the cellar.

- Air vents are installed on top of the earthen elevation. They are made using an extendable excavation drill.

Made of brick

A cellar on a slope can be made entirely of aerated concrete blocks or bricks.

All excavation work is carried out in the same way as during the construction of the previous type of cellar, but the interior decoration, strengthening of the walls and the outer wall are made of brickwork.

Important!

In the middle of the masonry, special grooves can be made across the entire surface of the brick row to lay the reinforcing rod. This will greatly strengthen the masonry.

Walling

For the construction of the cellar, red brick, concrete blocks, rubble stone, and monolithic concrete are used. You can dig in large diameter sewer rings. It is not recommended to lay sand-lime bricks or large-porous cellular blocks in the ground. They have high water absorption, so they freeze and quickly collapse. If the cellar is above ground, the same materials are used as for the construction of buildings, but with enhanced insulation.

Masonry of walls made of bricks or blocks is carried out in bandaging seams with reinforcement every 3-4 rows. This will allow you to withstand the lateral pressure of the soil without the formation of cracks and eliminate the risk of collapse.

For the installation of monolithic walls, formwork made of plank panels is installed. Reinforcing cages are placed inside, concrete M250-M300 is poured. The solution must be compacted along its entire height with a metal pin to release air bubbles. It is advisable to carry out the pouring as quickly as possible, before the formation of seams between the set and fresh concrete.

You need to worry about a hole for ventilation in advance, so that later you don’t have to work with a hammer drill and break through the hardened wall. At a height of 50 cm from the floor, a sleeve is installed in the brickwork or in the formwork for concreting - a piece of pipe with a larger diameter than the future channel. The hole can be temporarily plugged with paper or a rag.

What kind of brick to lay the cellar with?

It took 4 pallets of bricks, each containing around 400 pieces. Total 1600 bricks. The brick is, of course, red, the same as the one used for the base of the house. The floor of the cellar is filled with concrete - 15 cm. No insulation or waterproofing was thrown under the floor. In this case it is not needed. Firstly, we’re not on the street, and secondly, there’s really no point in it there. The main thing is that when pouring the floor, a masonry mesh was laid. The cells are 10 by 10 cm. It is used precisely for these purposes, in case anyone didn’t know. You guessed it, you need the floor to turn out to be a solid slab, and suddenly not burst anywhere. Although, again in this case, it’s a safety net.

The solution was mixed manually using a concrete mixer. Because if you serve it from a mixer at once, it might not turn out neatly. And the volume of concrete on the floor was not so large. Around 1.5 cubic meters.

So it turned out that the solution was carefully poured down the gutter in buckets (seen in the photo below), and then gradually a perfectly flat floor was obtained. It’s good that there are friends who are specialists in this matter who understand the intricacies:

Floor installation

The roof of the cellar can be prefabricated - made of slabs, beams, boards - or monolithic reinforced concrete. The wood is pre-treated to prevent rotting. When laying slabs, the joints are carefully filled with mortar or foam.

If the cellar is underground and free-standing, waterproofing from roll or coating materials is installed over the ceiling. Then thermal insulation with a thickness of at least 300 mm is installed - expanded clay, clay with sawdust, polystyrene foam, slag wool. The last layer is laid earth. A slight slope is provided for water drainage.

In above-ground or semi-buried structures, waterproofing and roofing materials are installed on the insulation layer. In the basement, located under the house, in a garage or shed, the roof is the floor of the superstructure.

Ventilation system

Without good ventilation, it is unlikely that it will be possible to preserve supplies for at least some time. Properly organized air exchange will not only reduce air humidity, but also get rid of harmful radon, methane and carbon dioxide, which are dangerous at high concentrations.

A simple but effective ventilation system for a small cellar consists of 2 pipes located in opposite parts of the room at different heights:

- The supply channel is led outside and supplies clean air. The bottom of the pipe should be at a height of 30-70 cm from the floor.

- Exhaust air is removed through an exhaust pipe fixed to the ceiling and vented to the atmosphere. To create good traction, the top of the pipe must be located at least 0.5 m above the roof level.

Pipe sections on the street are insulated. External openings are covered with protective caps, internal ones - with rodent nets. If there is insufficient ventilation, a duct fan is built into the system.

Pros and cons of semi-buried cellars

Like any design, storage has advantages and disadvantages. Advantages of semi-buried cellars:

- 2/3 of the structure is located in the above-ground part;

- even with high groundwater, flooding during spring floods and during heavy rainfall is excluded;

- less physical costs for underground construction;

- cheaper in cost, because less hydro- and thermal insulation materials are required;

- more convenient to use, because the room is built in accordance with the height of the person, the staircase is conveniently located;

- The vestibule cuts off cold winter and hot summer air, leaving the room at an ideal temperature level all year round.

The disadvantages include the construction of a reliable thermal insulation layer. As well as the need to arrange a supply and exhaust ventilation system.

Waterproofing

Measures to protect structures from moisture are carried out comprehensively. The waterproofing shell must be airtight and continuous, including floors, walls, and ceilings.

The most effective is double-sided waterproofing, which protects structures both outside and inside. This option is more preferable because the materials remain dry, freeze less and last longer.

As long as there is access to the outer surface of the walls, they are coated with mastic, covered with roofing felt or covered with fused materials.

A good effect can be obtained by using clay soaked in water. The solution in a plastic state is poured into the sinuses between the walls of the cellar and the pit. After hardening, a waterproof lock is formed.

If it is not possible to install waterproofing from the outside, all that remains is to install it from the inside. This will not save the walls from moisture, but will significantly reduce the risk of leaks.

Deep penetration agents are used as waterproofing for concrete, forming insoluble crystals in the body of the material. For bricks or blocks, it is optimal to use waterproof plaster or ordinary plaster followed by treatment with a penetrating compound or liquid glass. Rolled materials are ineffective in this case, since when water leaks in and the walls get wet, they peel off.

On the floors, the waterproofing is spread on top of the insulation layer. This will protect it from getting wet during precipitation and melting snow.

Insulation

During severe frosts, the cold penetrates into the room through the weakest points - hatches, doors, insufficiently insulated walls and ceilings. If frost is periodically detected somewhere inside the cellar, then the thermal insulation is not coping with its function.

In underground basements, the entrance area and ceiling most often freeze. For insulation, you can use polystyrene foam, polystyrene foam, polyurethane foam, securing them to the surface using dowel bends or glue and filling the joints with polyurethane foam.

Polymer materials have very low thermal conductivity and are not afraid of moisture. Their only enemy is rodents. To protect the insulation from mice and rats, it is recommended to cover the materials with a fine-mesh metal mesh.

Door to storage

Any cellar built with your own hands must be equipped with an entrance. It should be located at ground level.

Internal and external doors.

It is worth noting that the door must be installed in the wall, and in no case in the ceiling (which an earthen cellar usually has).

When constructing an entrance, it is also necessary to provide for the presence of a vestibule to ensure normal thermal insulation of the room. In other words, you will have to make two doors. The inner door must be insulated with some kind of insulating material (felt or foam plastic will do). Doors can be made of either wood or metal.

Doors, stairs, hatch

The doorway is the main route for heat loss. If it is poorly insulated, icing and freezing of the door is observed in winter. To prevent this from happening, the canvas is insulated with polystyrene foam or polystyrene foam and additionally sheathed with boards. Along the perimeter you need to lay a sealing tape in 2 circuits - along the box and the canvas itself. If winters are very frosty, double doors are installed.

The staircase to the basement can be either stationary or mobile - portable, folding, retractable. Structures are made of metal, wood, concrete, brick. The main emphasis should be on descent safety and fall protection.

The hatch, unlike the entrance door, is installed horizontally. You can make it yourself from wood or metal or buy it ready-made. The optimal dimensions of the hatch are 80x60 cm. Factory hatches are equipped with holding devices, hinges and locks. You can similarly equip a homemade structure.

If the cellar is located in the house, the finishing is done with flooring material so that the crawl space is visually invisible. A box is constructed above the street hatch to protect against precipitation and freezing.

Advantages of a cellar located in the house

The basement of a private house is convenient due to its compact placement and optimal air temperature inside for storing food. In addition, you do not need to leave the cottage to use the cellar.

A basement located separately from the housing will require special efforts in constructing its roof, insulating the walls, and other difficulties will arise. Therefore, professional builders recommend building a cellar in a private house, and not outside it.

Another option for using a basement is to install a boiler room in it. In this case, the heating system will not take up much space in the house; only pipes, radiators and a chimney will remain there.

Wiring

Due to constant humidity, the cellar is classified as a high-risk area, so the electrical wiring is installed according to strict rules:

- sockets are located outside the basement in a dry room;

- cables are laid only openly in corrugated channels or boxes; metal pipes cannot be used;

- luminaires must be sealed to avoid condensation.

It is recommended that you consult a professional electrician before installing wiring.

Interior decoration, racks and shelves

The most common method of finishing cellar walls is whitewashing with slaked lime. It dries the surface well, destroys fungal spores and insect larvae.

You can line the walls with waterproof plaster, ceramic tiles, and plastic panels. It is necessary to carefully ensure that the surface is as smooth as possible, without pores, since it is very difficult to fight mold on loose coatings.

Racks and shelves in the cellar are used in conditions of high humidity. Materials for manufacturing must be resistant to rot, moisture and fungi. This:

- impregnated timber and boards;

- metal with anti-corrosion coating;

- durable plastic;

- brick, stone, concrete.

Before storing supplies, the racks are dried, disinfected and, if necessary, the protective coating is repaired.

Useful tips

At first glance, building a cellar with your own hands is a simple matter. But every builder needs to remember:

- choose a location at a higher elevation, away from sources of pollution;

- The groundwater level must be at least 0.5 m below the floor;

- use materials that are resistant to moisture and decay, carry out protective treatment;

- foundation drainage, although not necessary, is very desirable, especially for regions with high precipitation rates or areas near water bodies;

- do not forget to reinforce the masonry;

- Observe electrical safety precautions when laying wiring.

Good insulation, reliable waterproofing and effective ventilation will help you preserve the harvest in the cellar without loss.

Ventilation

Without proper ventilation, no waterproofing, regardless of its quality, will be effective. It is also quite possible to make a ventilation system with your own hands. There is nothing tricky about this work, but in the future, its correct implementation will ensure normal operation of the storage facility at any time of the year. What needs to be done to create a reliable ventilation system in a semi-buried cellar?

Ventilation using pipes.

- We make a small hole in the cellar wall, about 20–30 cm from the ceiling.

- We install a plastic air duct pipe (it can, in principle, be made of any material).

- We cover the pipe at the top with a cap, which will protect the cellar from precipitation.

- A mesh filter must be installed in the pipe to prevent insects and rodents from entering the cellar.

This design will work on the principle of extraction. The air, which is usually very humid in the cellar due to the food, will be gradually drawn out of the cellar, so moisture will never accumulate.

To ensure maximum efficient ventilation, another pipe can be installed, which will be a supply pipe. It is designed to ensure a flow of clean air into the cellar. With this approach, the optimal temperature will almost always be maintained in the storage.

Even with the highest quality ventilation system, you need to periodically monitor the condition of the walls and ceiling of the cellar. After all, pipes may well become clogged for some reason, which will lead to condensation, which should not be allowed.