In this article we will look at how to replace a two-wire wiring with a three-wire one with a protective grounding system.

When organizing household power supply systems, the grounding procedure is a mandatory step. This is the easiest way to avoid electric shock when wire insulation is damaged and/or short circuits occur in the network. Grounding can also provide protection against failure of various household electrical equipment. Unfortunately, in many old (and not only) houses and apartments there is no grounding of electrical wiring; instead, grounding is used, or there is no protection at all. Grounding, as practice has shown, is not the most reliable method of protection, since this system, in fact, only protects equipment when short circuits occur. If the insulation is damaged and current leaks onto the housing of an electrical device, the grounding system will not be able to protect a person from electric shock (if he accidentally touches the exposed part of the housing).

Tile cutting device

It's been a while since I added anything here.

Preface: why exactly this way, and not using a machine.

Firstly, I’m not entirely sure that the so-called wet tile cutter will cope with this task, and I’m sure that a cheap one definitely won’t cope, and an expensive one, let’s say from 50 thousand rubles. Maybe he can handle it, maybe he won’t.

Therefore, with such a daisy, I refused to buy an expensive machine because the work will not pay for such costs, and cheap rubbish is not needed.

This means we work the old way, proven and cheap.

In general, I have a tile cutter, it’s not the worst, it successfully coped with various tasks, but there was a problem with this porcelain tile. It (porcelain stoneware) breaks off along the cut line completely uncontrollably, it can clearly break, or the arrow can go to the side. The second problem is that the surface is very fragile, just like a glass surface; even behind the roller, chips can occur. A diamond cup can also chip even with a light touch. There is no need to talk about a diamond disc at all, the surface after it is jagged and chipped, which means that not every water-powered tile cutter can cope with such a task.

Coloring phase

In cases where the electrical installation is installed using rigid metal busbars, the tires are painted with indelible paint in the following colors:

- yellow - phase A (L1);

- green - phase B (L2);

- red - phase C (L3);

- blue - zero bus;

- longitudinal or inclined stripes of yellow and green color - grounding bus.

The color of the phases must be maintained throughout the entire device, but not necessarily over the entire surface of the bus. It is allowed to mark the phase designation only at the connection points. On a painted surface, you can duplicate the color with the “ ZhZK ” symbols for paint of the corresponding colors.

If tires are not accessible for inspection or work when there is voltage on them, then they may not be painted.

The color of phase wires connected to rigid busbars may not coincide with them in color, since there is a difference in the accepted designation systems for flexible conductors and rigid stationary distribution busbars.

Is it possible to connect wires by twisting

Very often, especially in old houses, we start removing old wallpaper, unscrewing old sockets, disassembling dilapidated junction boxes and what do we see: a lot of wires twisted together and wrapped in insulation:

I know that many electricians still twist wires this way and consider it the most reliable. However, from a fire safety point of view, no firefighter will approve of electrical connections in an apartment made only by twisting.

The fact is that sometimes you have to connect wires of different sections and different materials, for example, copper and aluminum wires. And it is precisely for such cases that twisting is unacceptable. For example, with the same load on the network, it will act differently on thick and thin wires twisted together, one of which will feel good, and the other will heat up.

Safety precautions

During installation work, you should remember that you cannot connect zero to the switch, and during repair work you must check that zero or phase is supplied to the contacts.

The check must be performed for your own safety. To avoid accidental exposure to voltage when replacing a light bulb or repair work.

If you do not have the skills to work with electrical appliances, you should contact a specialist who will competently install a single-key switch for hidden wiring. The electrician will agree with the customer on how to properly install the light switch and advise at what height they should be installed.

Is it possible to connect wires of different sections of the same material?

If, for example, you need to connect wires of different cross-sections (they are also suitable for the same cross-section) and the same material (copper or aluminum), then in this case the special connecting blocks presented below are well suited.

They have different numbers of inputs: in the figure, respectively: 2, 4, 6.

That is, this is a “sort of” twist for 2, 3, 4, 5 or 6 wires.

Moreover, if you need to connect 3 wires to each other, then for this you can use a block that has 4 or 6 inputs:

By reading my blog, you are probably making repairs.

this page to your bookmarks .

This is where all the useful home improvement stores are located. The block is simply pressed tightly onto the wires:

You need to understand that after connecting the wires in this way, they can no longer be removed from the block. Therefore, if you have never tried to work with such devices, buy a few of them in a store with a supply and practice at home. They cost pennies.

Briefly about household grounding systems

Since 2003, a decree has come into force, which contains updated requirements for the construction and refurbishment of apartment buildings (and other buildings), including the installation of grounding systems. According to the rules, buildings must be equipped with a riser consisting of 5 wires, where the 5th serves as a grounding conductor.

Regarding private houses. Grounding systems (if not available) must be installed by residents themselves. Typically, such a system is a grounding loop dug into the ground. The circuit, as an option, is made of 3-4 steel stakes driven into the ground and combined into a single chain.

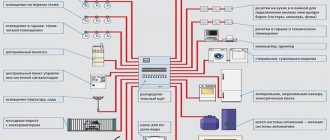

To organize a grounding system in a house/apartment, a three-core cable is used, the connection of which is carried out according to a simple diagram. Let's consider this issue in more detail.

How to connect copper and aluminum wires

When you need to connect wires made of different materials (copper and aluminum), and even different sections, in this case you will be helped by pads whose inputs are filled with a special paste that prevents oxidation:

The same pads, of course, are suitable for wires of the same cross-section and the same material. As in the previous case, if you have already put wires on them, then they will no longer be removed from the blocks. Therefore, think through all your connections in advance.

Differences

Five of them can be distinguished:

- number of conductors

- number of insulation layers

- quality of insulation and conditions of its use

- digital and letter markings

- lifetime

Let's take a closer look at how they differ and how they are similar?

One of the options for connecting wires in a chandelier

If you need to connect a chandelier, then one of the options for connecting the wires coming out of the ceiling with the wires coming from the chandelier would be to use blocks in which the wire connection is secured using screws:

For a chandelier, the option of using wago type terminals, especially if the wires coming from the ceiling are short, will not be very good, since, as already mentioned, in this case the wires cannot be removed (for example, you will need to change the chandelier or wash it) and you will have to cut them off. In the case of terminals with a screw connection, it will be enough to simply unscrew the fastening screws and release the wires.

PVS or VVG

And if there is another external insulation, then can we immediately consider it a cable? No not always. This is where the mistake of many lies. A single conductor or “noodle” can be distinguished by everyone, but if there is a second shell, doubts begin.

For example, PVS, ShVVP or PUGNP are not cables at all, as some people believe, although they have external protection.

Here are the transcripts of their names:

- PVA – Wire with vinyl insulation Connecting

- SHVVP – Shnur with insulation from INinyl with a shell of INinila Psmooth

- PUGNP – Wire Universal Purpose Flexible Flat _ _ _ _

More details on the characteristics, markings and technical specifications for cables, cords and wires can be found in GOST 53768-2010.

Here is a summary comparison table of VVG cable and PVS wire. Their disadvantages and advantages.

Important Notes on Wiring Connections

Let us note important points regarding electrical wires.

- All wires twisted together should not dangle somewhere in the air! They must be placed in a junction box.

- Do not try to remove the wire from terminals that are not intended for this purpose. For example, there are craftsmen who manage to remove wires from wago terminals. But I do not recommend doing this, since such removal is always associated with deformation of the wire. And this is unacceptable, because the load on the network should be experienced by whole wires, and not half-broken ones, which can lead to short circuits.

For all wire connections, ensure that the bare ends of the wires are completely hidden in the connection block. That is, try to make the connection so that after this connection it would be impossible to reach the bare end of the wire with your hand.

This is where the article ends. We have studied in detail the issue of how to connect wires in an apartment. Now, when moving the socket from one place to another, you can easily extend the wires by laying them in the wall and making the correct connection.

Did you like the article? Share with your friends!

There are now so many convenient and varied terminals for connecting wires, not like before - electrical tape - and nothing else.

For an ignorant person, connecting 4 ends of the wires was not yet possible, but 6 ends is already a serious problem!

Thanks for the clarification, we usually soldered the wiring, but with special pads it is much easier.

The topic is very important. Indeed, many people connect wires at random, and this poses some dangers, including fire. If a person does something on his own, then first he needs to consult with the experts in this matter.

What detailed instructions, thank you! I would like to see everything explained to our children in the same detail during labor!

Thanks for the useful information, twists are a thing of the past.

Interesting article . I learned something new for myself. Thank you .

A good article, detailed with pictures. Everything is very clear, thank you.

They installed these pads for me at home... It would be better if they did everything with twists. The socket doesn't work and that's it. I called an electrician, he immediately said that the problem was in the pads and that they (the problems) would appear periodically. I reached into the box and sure enough: I turned the wire in the block, the socket started working. But problems cannot help but appear: in the block the wires are pressed with thin petals, very similar to steel ones. So I'll look for something else instead of pads...

I’ll honestly tell you that I made all the connections at home through the blocks. The kitchen has a lot of electricity supply: 3 sockets, heated floor. dishwasher, hood, microwave and everything is on blocks that are hidden in junction boxes or sockets.

I don’t argue that there are cases, but these are the exception rather than the rule. There might have been a defective batch. And the examples are very different. Some people's walls fall apart after plastering, while others have had no problems for 25 years. But this does not mean that now there is no need to plaster the walls. Somewhere the technology was broken. Therefore, here we need to study the problem, look deeper into why this is happening. And if twists were the most reliable, then firefighters would not prohibit them.

Thank you very much for the instructions! It became more or less clear what was what.

Write if you have any questions!

Hello. I am installing electrical wiring for a mini-bakery. Everything is great except for one thing. The fact is that I am opening a company in a remote corner from civilization in a small village. The city is 2000 km away and only by plane. Therefore, I stocked up on everything in advance. Except of course the wires. And then I somehow found the usual white two-wire and three-core aluminum noodles with a cross-section of 1.5 sq. mm. and copper three-core 2.5 sq. mm. Three-phase electrics. I installed 2-wire noodles for lighting, and three-wire for sockets with chargers. I have only three equipment supplying 380 W. Dough mixer 2.4 kW, Flour sifter 1.2 kW, Oven 19.2 kW. Since there is no choice, all three of them carried out wiring with a cross-section of 2.5 sq. mm. In addition to the stove, the dough mixer and flour sifter work perfectly. But when I turn on the stove after 5 minutes, the RCD 63A 30Ma turns off the electrical supply. I think this is due to the cross-section of the wire because... I found on the instructions that you need to use a wire with a cross-section of 6 sq. mm. How can you get out of the situation? Of course it would be great to find a 6 sq. mm wire. But I only have 2.5 sq mm. Please tell me whether it is possible to use a three-core wire as one wire, i.e. connect all three to one?

Yes. It would be optimal to make all three wires of one wire 1 phase (7.5 sq. mm), another 3-core wire for the second phase, and also for the third phase, also for zero (also 7.5 sq. mm, respectively), and grounding. With such loads (about 60 A), no terminals will withstand (except screw ones, but for myself I would not risk it), it is necessary to twist, which should be tinned and soldered (use acid-free flux solder and a simple gas torch + futorka (copper tube with a diameter of 25mm, one end is rolled onto a holder so that the solder does not leak out, approximately 3cm deep), or a welding machine and a copper electrode (boil the ends of the twists until all the cores are welded together into a ball at the end).

This is the best and least expensive option.

Thank you very much for such an article, very useful information for those who do not understand electricity, but it is very necessary for repairs. Once again a huge THANK YOU.

What can you say about clamp-couplers that pierce insulation, how safe are they?

Good afternoon. I write about what I have personally tried or know what other masters do. Where there is no information, I don’t write about it.

Good afternoon Is it possible to connect the copper wire coming from the switch and the aluminum wire going to the chandelier through the block? This is absolutely not possible or can be left. Thanks for the answer

Yuri! Just through the block it’s possible. This is one of the few ways. Direct contact of copper and aluminum will lead to oxidation of the aluminum wire as a result of electrochemical corrosion and loss of contact with subsequent heating. In the best case, the light will go out, in the worst case, the insulation (or the switch itself) at the heated contact will light up. In addition, the article is rather weak for understanding how to connect wires. There are no other methods: soldering, welding and crimping. And the pros and cons of each connection are not disclosed. I believe that connecting via terminal blocks is also not the best way. First: screw terminal blocks require periodic tightening; self-clamping and spring-loaded screw terminal blocks may not cope with tightening the power wire, which is loaded to its nominal value and begins to heat up. Second: even the Vago terminal blocks are very weak for normal power lines. My opinion: to connect wires for lighting yourself, you can use terminal blocks, and for power (sockets) use the crimping method, as a relatively simple method for doing electrical work on your own (you will have to spend money on crimping the sleeves, if you don’t mind buying a hair dryer for heat shrinking, you can take a turbo lighter and practice with it on a couple of joints and everything will work out (it’s not God who crimps pots). By crimping using copper-aluminum adapter sleeves you can also solve your problem (this is the best way for strength, since aluminum has high fluidity and in a screw terminal, the contact will weaken).

If I were to write an article, I would cover all connection methods and give the pros and cons of each. In conclusion, I would recommend those methods that are convenient for beginners. Well, in parallel, it would be necessary to write an article about choosing the type of cable that is allowed for use in electrical wiring, as well as choosing the cross-section of conductors and circuit breakers in the panel. General rules for constructing electrical panels, indicating which lines should be separate and which are recommended to be separated separately. Just connecting the wires is not enough to understand the issue.

Popular electrical cables for the home

When a specialist decides which cable to use for wiring in a house, he, first of all, focuses on existing types of wires. An important selection criterion is the number of cores required. Many manufacturers produce cables with 1-5 conductive elements. Such products have different purposes. Therefore, it is necessary to consider the main common types of wires for electrical wiring in private residential buildings.

Type 1 – VVG cable

When laying in-house electrical wiring, including installation of an electrical network using distribution boxes, VVG cable is often used. It is through it that current is transmitted. It can withstand a maximum voltage of 1000 V. Manufacturers produce this current conductor with cores, the number of which does not exceed 5 pieces.

Four-core electrical cable VVG Source files.glotr.uz

For VVG products the cross-section can be:

- flat;

- round;

- square;

- triangular.

The advantages of VVG electrical cables include the wide temperature range at which these products are used. For such current conductors it ranges from -50 to +50 ℃. Electrical wires of this type can withstand high breaking loads. They are also renowned for their ability to be used in environments that are 98% critical.

Electric cable VVG can be designated as follows:

- NG – insulating shell that does not support the combustion process;

- Z – the presence of rubber material or polyvinyl chloride bundles between the external protection and the insulated conductors;

- P – flat wire.

On a note! VVG cable for electrical wiring, with the exception of the wire with the letter “Z”, is manufactured without filling the space that is located between the insulated conductors and the external protection.

Three-core electrical cable VVG with empty space between the outer sheath and the insulating material of each current-carrying core Source kemerovo.tdsevcable.ru

When creating home electrical lines, a wire marked VVGng-LS is often used. Such products meet all safety criteria and are sold at an affordable price. Its insulation contains a minimum of halogens. Therefore, the wire burns and smolders more slowly. This makes it possible to inhale less dangerous doses of toxic substances during a fire. In addition, people will be able to evacuate longer.

How to choose the right cross-section of the grounding conductor

To connect the protection system, not only natural grounding conductors can be used, but also artificial ones. The selection rules in each case differ from each other and have their own technical features.

Networks with a power of more than 1 kW are equipped with artificial ones; in other cases, the operation of natural ones is permissible.

The artificial segment is made of galvanized alloys, steel and copper. The cross-section is selected in accordance with the Electrical Equipment Installation Rules in special tables.

In the distribution panel it is connected to the busbar, housing and panel door made of metal. In the box, the connection tends to the ground wires. The grounding conductor must not be connected to the residual current device.

Symbols on electrical diagrams: for direct current, standard grounding, to the electrical equipment housing, clean and protective.

Types of heating devices

Heating cables are available in two types. Resistive conductors can be single-core or double-core. The former are completely unsuitable for heating a pipeline. Therefore, a two-core design is used.

Twin-core heating cable Source tvergrandelektro.ru

The heating cable is connected to a 220 V network through an automatic control unit. And since the resistive conductor emits only a constant temperature, a chromium-nickel alloy is used, which gives a stable high resistance.

The above conductors have been replaced by a self-regulating heating cable, the operating principle of which is based on the presence of an elastic matrix inside the device. It reacts to changes in ambient temperature and independently regulates the resistance of the conductor. Thereby reducing electricity consumption during thaws.

Neutral color

What color the neutral wire is is specified by GOST , therefore, when looking at the installation of a power plant, the question should not arise whether the blue wire is a phase or a zero, since the blue color and its shades (blue) are accepted to indicate neutral (working grounding).

Other colors of neutral cores are not permitted.

The only acceptable use of blue and cyan insulation is to indicate the negative pole or midpoint in DC circuits. This color cannot be used anywhere else.