Old-fashioned methods of connecting electrical wires are becoming obsolete. Twists, electrical tape, pliers - all this is no longer used in modern construction. They were replaced by terminal blocks for connecting wires. What is it, what are the varieties of this element, how are they used in electrical networks - we will understand.

Terminal blocks for connecting electrical wires Source i8.photo.2gis.com

How and what to connect the wires with

In addition to terminal blocks, electricians use different methods for connecting electrical cable cores. Here they are:

- soldering - used when there is confidence that the connection area will not heat up;

- welding is an excellent option, but requires the use of special equipment;

- crimping , where special sleeves are used;

- bolted connection - usually used if it is necessary to connect wires made of different metals.

That is, it turns out that when choosing a docking method, it is necessary to take into account several factors. Namely:

- cable core thickness;

- the metal from which they are made;

- operating conditions of the joint;

- number of connected cores;

- type of insulating material used in cable products.

Of course, not all electricians have given up twisting. Especially when connecting wires of small cross-section. It’s easier and faster to twist them with your fingers and wrap them with electrical tape. Although all regulatory documents have already excluded insulating tape from the list of materials that can create safe operating conditions for electrical networks. It is recommended to use heat shrink tubing instead.

Heat shrink tube for insulating wire connections Source setgroup.ru

It is simply pressed onto the joint and heated, for example, with a lighter. The tube heats up, partially melts and compresses the joint, insulating it. It's not as fast as using electrical tape, but it's several times more reliable.

All of the above methods for connecting wires are complex and require either specialized equipment or some kind of tool. In this regard, the terminal blocks are simpler, more reliable, and cheaper. Therefore, we will further disassemble only the terminal clamps.

Recommendations for selection

In order to choose the right pad, you should adhere to the following rules:

- Determine the functional purpose of the component.

- Take into account the cross-section of the conductor and its quantity.

- Select the method of installation work.

- After the above provisions , it is necessary to decide on the most optimal model.

Particular attention should be paid to the characteristics of the plate, which conducts electric current. The base shows the maximum value, which is measured in volts. It is these restrictions that determine the type of conductor.

Classification of terminal blocks

It should be noted right away that this connecting element is used today in all types of electrical installation work. Therefore, manufacturers offer a fairly wide range of them. For example, you can buy small connectors on the market that are designed to connect one pair or a system of pairs at the same time.

According to the installation method, terminal blocks are divided into:

- connectors for individual wires;

- for boards used in electronics;

- so-called DIN rails;

- installed near cross-modules.

Let us add that these elements are also divided by the number of rows in one connecting block and by how the wire is clamped. Here it is either a straight clamp or an angular one.

Terminal block mounted on a DIN rail Source www.elektrikaup.ee

Now the classification according to the structural device:

- Screw. Everything is simple here - the screw is the main clamping element that compresses the wire between two metal washers.

- Detachable . The design of these elements contains a spring. She clamps the inserted wire when the lever presses her. When lowered, the latter compresses the cable core and releases it when raised. A convenient option because the installation process itself is very simple.

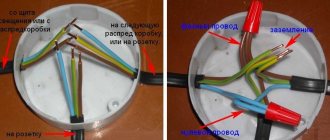

- Terminal blocks for expansion boxes. They are directly mounted into the junction box. The method of fastening the wires is either screw or spring.

- With safety lock. Here, a fuse is inserted into the design of the device, which protects the network from overvoltage. It should be noted that these devices have large overall dimensions compared to other types.

- Terminal blocks for connecting wires. A convenient option because they can be used to connect several wires from different materials with different cross-sections. In this case, the cores of different wires do not contact each other. The only thing you need to pay attention to is the rated current that these terminal blocks can pass through.

- Knife ones, they are also crimping ones. They are usually installed in power networks where wires with a cross-section of up to 2.5 mm are used. And the voltage should not exceed 5 kV.

Terminal block inside the junction box Source i.pinimg.com

Types of cables for connection

The most common cable for home electrical wiring is a PVA connecting cable, consisting of two insulating layers.

Copper strands, stranded, twisted along the central axis. The wire is flexible, making it great for a variety of connections. The voltage of connected devices must be up to 380 Volts. The cross section is selected depending on the load:

- for a current of 6 A, PVA with a cross section of 0.75 mm is used;

- for 10 Amperes - the cross-section is 1 mm;

- for currents of 16 A – 1.5 mm.

In addition to the PVS wire, for connection there are multi-core cables ShVVP, PUGNP, PRS, KG. They are used less frequently for home wiring than PVS.

Technical specifications

What you need to pay attention to when choosing a terminal block for wires. You must understand that this connector will pass electric current through itself. Therefore, it must have high safety characteristics.

First of all, you need to pay attention to the material from which the connecting element is made. Today manufacturers offer two versions:

- high-temperature plastic, also known as liquid crystal polymer, LCP marking;

- fireproof plastic, also known as polyamide, here the markings are wider: PA6 or PA66, there is a new modification - UL94V-0;

- polyethylene is the most common material in the sense that devices made from it are most often used in electrical wiring, because they are cheaper than others, while not inferior in technical characteristics.

Attention! Terminal blocks made from the first material are used mainly in places where high temperatures are present. For example, in ovens.

The second parameter that you need to pay attention to is the material of the clamp. Here preference should be given to those that do not corrode and can easily withstand high temperatures. Therefore, we recommend purchasing devices with clamps made of stainless steel or nickel-plated or phosphor bronze.

Terminal block with stainless steel clamp Source dc-electro.ru

See also: Catalog of companies that specialize in installation of electricity and lighting

Electrical parameters

As mentioned above, connectors for electrical wires are divided according to the ability to connect different numbers of wires. More often there are terminal blocks in which the number of contacts is limited to the range of 2-24. But this does not mean that it is impossible to increase this parameter. There are no restrictions in this regard. It all depends on the order and the manufacturer. On the market, for example, today you can buy connectors with 72 contacts.

It is clear that the dimensions of the terminal will depend on the size of the wire cross-section. This plan has its limitations. The range is small: from 0.08 to 6 mm.

There is one more characteristic that is formed by the standard for the safe arrangement of terminals. This is the distance between the clamps. It varies in the range of 2.5-10.66 mm.

As for the voltage that the terminal block can withstand. Here everything will depend on its purpose. That is, whether he is strong or not. Usually this parameter is indicated in the product passport, and the manufacturer puts it on the device body.

And the last characteristic is withstand temperature. Here, too, everything depends on the purpose of the connecting element. And also from the material from which it is made.

The distance between the clamps is an important technical characteristic Source granat-es-market.ru

Polyethylene terminal blocks

Since this type of terminal is the most popular, I would like to talk about it in more detail. Firstly, it is a simple design consisting of a body in which several brass tubes, also known as sleeves, are arranged in one row. This terminal is in the photo below.

Polyethylene terminal block for connecting electrical wires Source ae01.alicdn.com

The two wires being connected are inserted from different sides into one common sleeve and clamped with separate screws. If necessary, the terminal strip can be trimmed to accommodate the required number of connections.

But not everything is so rosy. It should be noted that aluminum softens even at room temperature. Therefore, its clamp weakens over time. Experts recommend tightening the screws on aluminum cores at least once a year. In this regard, copper wires are better. But if they are multi-core, then you will first need to either tin the end of the wire or put on a tip so that the wires are collected into one twist. The thing is that the stranded end will separate when clamped with a screw. Some veins will be cut, which will cause a decrease in the cross-section of the wire, and, accordingly, heating of the joint.

Therefore, the advice is that it is better to use polyethylene connecting terminals for wires for joining single-core copper wires. If you need to connect multi-core cables, then you will have to put lugs on the ends.

Polyethylene connector with copper wires Source altaircom.ru

Rating of quality terminals from the best manufacturers

The domestic electrical goods market is saturated with products from Russian, European and Chinese manufacturers. Many people do not pay much attention to the homeland of origin of the terminal blocks. However, if these small devices fail, they can significantly affect the safety of property. Therefore, we must take into account that inexpensive Chinese consumer goods at a budget price rarely meet the requirements of the standards.

Products from Russian enterprises are reliable, but, according to buyers, they are technologically and aesthetically inferior to goods from Europe, which are more expensive but of the highest quality.

STEKKER

The models of the German company are used for reliable installation of electrical circuits with a large number of wires of different conductors in a small limited volume, like in a junction box. Manufactured in a transparent case, allowing you to monitor the state of the contact. The installation speed is ensured by the rounded ends of the working levers.

STEKKER terminal

Characteristics:

| LD222-412 | LD222-413 | LD222-415 | LD222-418 | LD226-10A | |

| Current, A | 32 | 32 | 32 | 32 | 10 |

| Voltage, V | 250 | 250 | 250 | 250 | 250 |

| Section, sq.mm | 0,08-4,0 | 0,08-4,0 | 0,08-4,0 | 0,08-4,0 | 4 |

| Number of contacts | 2 | 3 | 5 | 8 | 12 |

| Amount in a package | 1 | 50 | 40 | 5 | 10 |

| price, rub. | 87 | 900 | 1080 | 247 | 700 |

Advantages:

- no special tools or skills are needed for quick installation;

- convenient marking;

- long service life up to 10 years;

- high quality materials;

- good fire resistance;

- modern design.

Flaws:

- no obvious ones were identified.

Legrand

French manufacturer of electrical products known throughout the world. The most popular product in this segment are screw terminal blocks.

Nickel-plated brass products are highly resistant to sudden temperature changes. The popularity of the models is due to their durability and large range of sizes.

Legrand terminal

Characteristics:

| Block 2.5-4 sq.mm | Block up to 10 sq.mm | Block up to 16 sq.mm | Terminal block 4x1.5-16 sq. mm | Terminal block 1x6-25 sq. mm | |

| Current, A | 24 | 57 | 76 | 80 | 100 |

| Voltage, V | 250 | 250 | 250 | 400 | 400 |

| Number of clamps | 12 | 12 | 12 | 4 | 1 |

| Section, sq.mm | 2,5 — 4,0 | 10 | 16 | 16 | 25 |

| Average price, rub. | 167 | 310 | 579 | 262 | 649 |

Advantages:

- reliability;

- heat resistance;

- long service life;

- high build quality.

Flaws:

- no obvious ones were identified.

Legrand Viking 3 terminal blocks - in video review:

One of the leaders in the production of terminals from Germany. Products are manufactured at nine factories. Single-use or reusable products are characterized by high connection reliability and ease of operation.

Models in a durable ceramic case have good anti-vibration resistance and are used for automotive wiring. The conductive element is tinned copper, which provides low resistance to strong contact. Some popular models are filled with anti-corrosion gel.

WAGO terminal

Characteristics:

| 221-412 | 221-413 | 222-412 | 222-413 | 222-415 | 2273-203 | |

| Current, A | 32 | 32 | 32 | 32 | 32 | 24 |

| Voltage, V | 450 | 450 | 400 | 400 | 400 | 450 |

| Section, sq.mm | 0,14-4 | 0,14-4 | 0,08-4 | 0,08-4 | 0,08-4 | 0,5-2,5 |

| Number of contacts | 2 | 3 | 2 | 3 | 5 | 3 |

| Amount in a package | 20 | 20 | 5 | 20 | 5 | 20 |

| price, rub. | 508 | 570 | 88 | 443 | 164 | 186 |

Advantages:

- tight connection;

- high build quality;

- quick installation;

- stylish design.

Flaws:

- not suitable for use in power electrical circuits with a load power greater than 7 kW;

- requires regular maintenance, so it must be in the public domain without being covered with plaster;

- There are many Chinese fakes and similar analogues, but with different characteristics.

Video about WAGO terminals:

Video description

The video shows how terminals are used to connect wires:

Self-clamping wire connectors

Self-clamping terminal blocks are elements that can be called express terminals. It is very convenient to work with them. You just need to insert the end of the wire into the hole in the device, where it will automatically lock. Fixation is carried out by a clamping bar, the force of which is maintained throughout the entire service life.

It should be noted that this variety is disposable. Of course, you can slowly pull out the wire, but the clamping force will not be the same. Therefore, when replacing wires, terminal blocks of this type are also changed. Fortunately, they are inexpensive, for example, twenty times cheaper than pads.

The most important thing is that such elements inside have a pressure plate made of tinned copper. That is, you can insert both copper and aluminum wires inside. In this case, the clamping surfaces are coated with Vaseline, which prevents the formation of an oxide film on the metal. And it is known to reduce electrical conductivity.

Self-clamping connectors on the market are available in transparent and opaque versions. Plastic does not support combustion in any case.

Self-clamping terminal block made of transparent plastic Source st45.stpulscen.ru

Spring connectors

The lever models mentioned above, also known as spring models, are a housing in which a leaf spring is installed. It is clamped and unclenched with a lever. And we must immediately make a reservation that the market today is simply crowded with products from different manufacturers. Not everyone provides guarantees for the stated parameters. This is especially true for current strength. For example, branded terminals can easily withstand 25 A. Products from unfamiliar companies may not support this characteristic. This means that the terminal block will simply overheat during operation.

The main steps in the process of connecting wires using terminals

You can find out in detail how the wires are connected using terminals from our table. Let's look at connection options using examples of different Wago models:

| Photo | Process description |

| To connect the wires using the 22÷73 series terminal block. It is necessary to strip the conductors to a length of 10 mm. | |

| We insert the bare parts into the terminal block until it stops. | |

| If necessary, remove the terminal block by turning it in the opposite direction. Both parts must be inside the fixture. This option is used to connect light. | |

| Terminal blocks 222 series Wago are recommended to be used for repair work and temporary connections. | |

| The connection is made using special levers. The wire is also stripped to 10 mm and inserted into the terminal block, then the levers are latched. | |

| The 224 series is used to connect all kinds of chandeliers, lamps and sconces. | |

| Using this terminal, you can connect solid and stranded wires. | |

| The single core is inserted into the hole with lubricant. | |

| The stranded wire is inserted into another hole. | |

| A special cap is used for PPE conductors. | |

| The cap is screwed onto the conductors. | |

| To improve the quality of such a connection, the wires need to be stripped to about 6 cm. | |

| Then the PPE cap is screwed on. This results in a very reliable connection. | |

| The connection is insulated using electrical tape. | |

| You can use a household terminal block. The monocore must be cleaned and placed inside the terminal block. Then it is tightened using a special screwdriver. |

Video description

The video shows the design of the WAGO 222 series self-clamping connector:

It should be noted that the lever model is reusable. In principle, it has no other differences from disposable terminal blocks. The manufacturer today offers models that can operate at currents up to 32 A.

Let's add to the advantages of self-clamping and spring designs the fact that during operation the terminals heat up, and accordingly their pressure plate expands. And this increases the downforce of the element.

Spring type connector Source a.allegroimg.com

Where can I buy

Before going to a specialized department of an electrical store to purchase the necessary accessories, it is advisable to read the best reviews and recommendations from customers, as well as find out the advice of a professional electrician.

Electrical goods stores offer a wide range of terminal blocks, so you need to choose budget products that are suitable for a specific installation. You can find out which company is better to buy in advance or directly from a consultant who has undergone special electrical training.

In addition, you can order terminals online from an online store of construction or electrical marketplaces. The Yandex.Market aggregator also offers to find out how much the required terminal block costs, read the description, compare functionality, select a store and order online.

Twist

This method is used in the absence of special tools and additional devices. The wires are twisted and wrapped with electrical tape. This option is reliable, but you need to follow some rules. Copper twists only with copper, and aluminum with aluminum. It is forbidden to twist copper and aluminum products, as this causes an electrolysis process and destroys the components. The twisting option depends on the material, diameter and purpose of the connection.

The modern version of twisting is performed without pliers, but with the help of special polymer caps, inside of which there is a metal spiral. To make the connection, the ends of the wires must first be stripped to a distance of 15 mm, and then inserted into the cap. Then the body is turned all the way.

Pros of twisting:

- simple technology;

- available materials.

Minuses:

- Do not connect aluminum and copper wires;

- not very high quality connection.

This option is suitable for temporary wiring.

Twisting wires

Important! Twisting is not used in rooms with high humidity or in buildings made of wood.

Stranded and single-core

When connecting multi-core wires, the following rules should be followed:

- strip the insulation by 4 cm;

- unwind the conductors by 2 cm;

- connect to the junction of untwisted conductors;

- twist the wires only with your fingers;

- You can tighten the twist using pliers;

- bare wires are insulated with special tape or heat shrink tubing.

Peculiarities

When carrying out a major renovation, a person changes everything in his house, including the wiring. A new junction box is installed where wiring needs to be done. To do this better, it is best to use terminal blocks. This is an excellent device that will provide tight fixation for the entire period of operation.

Today, new types of this product are being produced, which are many times superior to screw ones. To carry out installation and wiring, a person will need a minimum of time. This was largely made possible thanks to self-clamping terminals.

General installation requirements

The quality of connections and branches during installation is of paramount importance. When troubleshooting an electrical circuit, most often the problem occurs due to a lack of contact. Poor contact can lead not only to a circuit break, but also to overheating of the wires. This is often the cause of fire.

Therefore, strict requirements are imposed on them.

Regardless of which terminals are used for installation, the following rules must be followed:

- During installation, it is necessary to leave a reserve of wires before all connections (for reconnection).

- All connections must be located in accessible places.

- The location of the connecting elements must be protected from vibration and any other mechanical influences.

- The insulation of the connecting elements must match the insulation of the conductors.

- All connections must be made in junction boxes, cabinets and control panels, and special niches in building structures.

There are many types of terminal blocks available for different purposes:

- plug-in;

- hybrid;

- mini and micro terminals;

- fuse terminals;

- disconnect terminals;

- multi-pin;

- multi-tiered;

- checkpoints and others;

For all varieties, the installation rules are the same.