For those who are able to build a house themselves, it is also quite possible to do the water supply for a frame structure on their own. As a rule, frame technologies are chosen by those who need to get a budget home at a minimal cost. This means that you need to supply water as cheaply and simply as possible. Outside the city there is often no central water supply, so you have to choose an autonomous water supply system. How to provide water to your home at minimal cost and in accordance with all the rules?

Necessary communications

The laying and installation of sewerage communications in a frame house is carried out before the construction of the foundation.

Their installation begins along with the construction of the foundation. A ground loop is installed. Install pipes for sewerage and water supply. Some of the work is carried out after the construction of the box.

Communications in a frame house have a peculiarity. Due to the multi-layer walls and floors, it is easier to hide wiring and pipes in them, without harming the design of the room.

Usually this is not necessary. The house retains heat well inside in winter and maintains a comfortable temperature in summer. Complex heating and ventilation systems are unnecessary in many cases.

The technology is suitable for permanent residence and construction of seasonal houses. Take a closer look at this option if you are planning to get your own home.

Advantages of a wooden house

Sewerage in a wooden house is very easy to install yourself

Today, there has been an increase in the popularity of wooden houses, both in Europe and Russia. This pattern is explained by the following advantages of this material:

- Heating a room requires less energy;

- It has climate control, which has a beneficial effect on the health of residents;

- Capable of absorbing toxins;

- Has a beneficial effect on the human psyche;

- High level of structural stability due to the installation of screw piles. It is also worth noting that the house made of wood has a powerful frame belt.

Screw piles look like solid metal pipes that have special blades that screw into the soil like a screw. This frame body allows a wooden house to withstand loads, deformations, ground vibrations and temperature. Let's consider the structure of screw piles, which are made from high-strength alloys and have anti-corrosion resistance. These elements structurally form an area with high strength.

In order to increase the rigidity of the installation, you need to fill the pipe with a concrete solution. In practice, there are situations when piles need to be reinforced. You can install screw piles using a special machine or with your own hands. What makes them so popular in the construction of timber buildings? Piles are known for the following unique properties:

- Speed up the installation process by 30 percent;

- Screw piles can be used on swampy and subsidence soils;

- Do not depend on surface waters;

- There is no vibration during working processes, which allows the piles to be placed close to the house;

- The time of year does not affect DIY installation;

- There is no need for earthworks or soil leveling;

- Piles will save money on installation.

Attention! Screw piles are the most rational option for a wooden house, according to economic and technical criteria

Design Features

In practice, septic tanks, pits or treatment stations are very common

Considering the design features of sewerage in a frame building, we can say that this is a complex of systems that are aimed at collecting, moving and storing wastewater. Let's look at the components of this device:

- Domestic drainage is the sum of all the pipes, toilet components and plumbing fixtures within the home;

- The external part is a combination of pipes that transport wastewater from the toilet and plumbing to places of their storage and disposal outside the building;

- Tanks are screw or on stilts. who are engaged in the storage and processing of sewage waste. In practice, septic tanks, pits or treatment stations are very common.

Internal networks

In order to make a sewerage system in a frame house correctly, you need to familiarize yourself with all the nuances of this work.

In order to make a sewerage system in a frame house correctly and with your own hands, you need to familiarize yourself with all the nuances of this work. Each network has its own characteristics, so when installing the internal complex, you should not forget about the gaps that protect the pipes and the shrinkage of the building on screw piles. All horizontal elements must be of minimal length and attached to the walls without rough connections.

For optimal pipe performance, you should choose PVC or polypropylene material with a diameter of 5 cm, and for connecting a toilet - 11 cm. It is worth noting that the first thing you need to do is install the wiring from the bathroom, which includes a toilet, bathtub, washing machine, etc. d.

At all pipe bends it is necessary to install an inspection that will help with their cleaning. A mandatory item is the need to seal all joints and seams, which will increase strength. After organizing the internal water supply network, you can begin installation of the external equipment.

Attention! It is imperative to make ventilation in a frame house - this will protect against shutter failures and unpleasant odors.

What are septic tanks?

Such an important stage as installing a sewerage system outside a private house or cottage should not be overlooked. Subsequent difficulties may be associated with flooding of adjacent areas and the occurrence of unpleasant odors, as well as possible violations of the rules for installing a septic tank, which, when checked by the sanitary and epidemiological service, will be identified and will result in material losses.

First you need to decide on the choice of septic tank. They come in two types: septic tank type and storage type. Most people with a suitable budget prefer to install structures of the first type. We mentioned them at the beginning of the article. This is the approach when a deep cleaning station is used. But you can do without it. It is enough to install two septic tanks at different height levels. With this arrangement, heavy precipitation remains in the first chamber, and light runoff flows into the second, which, with the help of additional equipment, can be cleaned and used for watering the area. You can buy a septic tank or make it yourself from Eurocubes.

Septic tanks of the second type are storage tanks, easier to install, cheaper and more practical, but require more labor. For them, a container of at least 2 cubic centimeters is selected, or it is constructed from reinforced concrete rings with a diameter of 3 meters. Sediment accumulates in such a structure, and a sewer truck is required to pump it out.

Basic materials

The flow of clean water into the house and its further removal along with waste products must be of high quality, because the comfort and health of people depends on this. This means that materials for this communication system must be selected very carefully. The most important thing in this case is to choose normal pipes.

They can be made of metal, plastic, asbestos and other materials. Metal pipes are considered the most expensive. Firstly, the material is expensive, and secondly, a welding machine is required to install them. But this design is quite strong and reliable.

Asbestos is used exclusively for the sewerage system, since it is not suitable for water supply. These pipes have a very high level of sealing. As for plastic pipes, this is the best and cheapest option.

Prefabricated well

Last in the order of wastewater, but not in terms of its role in the operation of the sewerage system, is the collector or septic tank - a well into which sewage flows from the pipeline. The well is located so that it is at the lowest point of the drainage system.

Distance between the well and other objects located on the site and nearby:

| An object | Distance not less, m |

| non-residential outbuildings | 1 |

| residential buildings | 5-7 |

| water well | 50 |

| fence between plots | 2 |

| open waters | 15 |

Types of wells

For a private home, you can equip a well of one of three types:

- storage well or collector - a sealed container into which wastewater flows; when the collector is filled, the sewage is pumped out;

- a well with post-treatment, a septic tank - a container of several series-connected chambers in which wastewater gradually settles, the sediment is processed by bacteria, and partially purified water enters the last of the chambers and from there goes into the soil;

- deep treatment station - a well with filters and a bioreactor (a set of substances and bacteria), in which wastewater is purified from dangerous microorganisms and safe organic matter is separated, the purified water goes into the soil, and the separated organic matter can be used as fertilizer.

The first two types of wells can be equipped with your own hands. Ready-made plastic containers or reinforced concrete rings are used for these purposes. Septic tanks are also built from brick and concrete.

It is difficult to equip a deep cleaning station with your own hands, as it requires special knowledge. It is easier to buy a well of this type and install it ready-made in a prepared pit.

How to calculate the volume for a septic tank and collector?

The dimensions of the well are calculated based on the number of residents of the house, the presence of various household and plumbing appliances connected to the sewer system, the activity of water consumption and the planned frequency of pumping out wastewater from the septic tank, if it is a storage tank.

The volume of the septic tank is calculated based on the maximum daily water consumption by a person. If plumbing and household equipment are available, one person per day consumes no more than 0.25 cubic meters. m. In the septic tank, wastewater settles for about 3 days. Therefore, to obtain the volume of the collector, you need to multiply the number of family members by 0.25x3, that is, by 0.75 cubic meters. m.

You can use an online calculator to calculate the minimum volume of a septic tank. This calculator takes into account the number of residents, the availability of plumbing and household appliances and the frequency of their use.

The volume of a sealed collector can be calculated by knowing the average monthly water consumption in the house. If cleaning is planned to be carried out 2 times a month, then the well should have a volume of about half the average monthly water consumption.

When calculating the volume of the collector, it is worth taking into account the capabilities of the vacuum cleaners, which will need to be used periodically to clean the tank. Typically, the volume of a sewage disposal truck tank is 3 cubic meters, so it is better to make a well of multiple volumes. This will allow you to spend money more efficiently: you won’t have to overpay for calling an extra truck that will leave incomplete, and you won’t leave unpumped sewage in the sewer because there isn’t enough space in the sewer tank.

Attaching the top harness

Fastening can be done using three methods:

- To the end of the rack, which is located in a vertical position, with nails or screws. The method is suitable when making a structure from a single board.

- To the end of the rack through notches. With this option, a notch is made in the harness, the depth of which should be one third or half the thickness of the wood. The top edge of the rack fits into this recess.

- Fastening with steel corners. A very reliable method that strengthens the fastening using the first method.

Additional fastening with steel corners increases the strength of the structure. Source initechno.ru

The advantage of the first and second methods is that you can position and secure the vertical posts one after another. To fix it using a notch, mandatory calculations and absolutely accurate markings are required. If there are violations, then there will be a defect in the vertical placement of the racks, as a result of which the structure will begin to collapse.

Grooves are made in the strapping beam or board for all the posts, which must coincide with the same grooves that are on the fastenings for the posts of the lower trim. In addition, the structure is secured with nails. Fastenings using corners are secured with self-tapping screws.

Installation of heating system and water supply pipes

The requirements for laying pipes for heating and plumbing systems in a frame house are largely similar, so it makes sense to consider the features of their installation at the same time. Since repairing hidden communications is difficult, you should carefully consider all the nuances. Thus, it is not recommended to use steel or cast iron pipes for laying inside frame walls, since these structures are susceptible to corrosion. In addition, salt deposits quickly accumulate in metal pipes, and replacing them will be quite problematic.

Modern heating systems are made of very durable materials. PEX (cross-linked polyethylene), metal-polymer and metal-plastic pipes can last up to 75 years. The cause of accidents and leaks during their operation is most often the poor quality of connections.

To prevent leaks, it is necessary to pay special attention to connections during installation. It is recommended to carry out pressure testing of the heating system at an increased pressure of about 8-10 atmospheres

The operating pressure should be doubled and pressure testing should be performed for 8-12 hours. At this time, it is necessary to regularly check the pressure in the system. If it remains stable, it means that the work was completed at a sufficiently high level.

The presence of small leaks during control testing is considered quite acceptable. Usually it is 2-3 liters, but can reach 10-50 liters. Identifying weak spots in your heating or plumbing system will prevent much larger leaks that could lead to extensive damage to internal structures.

When installing a plumbing or heating system, you should keep the number of connections to a minimum, using as many long pieces of pipe as possible, although this method can significantly increase costs. The quality of the connecting elements deserves special attention. Do not use cheap fittings made in China. Practice shows that approximately 20% of such parts turn out to be defective. In the best case, they will fail during crimping, but worse if a leak occurs during operation, when the finishing work is completed. And one more thing - although pipes are usually very durable, they can be damaged during careless transportation or during loading and unloading.

Condensed moisture may appear on cold water supply pipes, which should be taken into account during installation. Therefore, such pipes are usually protected with a special corrugated sleeve so that moisture does not get on the insulation and damage it. Holes for cold water supply are made approximately 50-100 mm larger than the diameter of the pipe protected by corrugation.

Internal water supply

The complexity of distributing water around the house is related to the number of consumers (taps and mixers) and their location. Therefore, first of all, it is necessary to develop a scheme. This is the most important stage in the installation process, which should not be neglected. There is nothing difficult in drawing up a diagram. You just need to arm yourself with a tape measure and measure the distances from consumers to the connection points of each device.

Transfer all this to paper, taking into account the size and configuration of the pipes. The diagram will show exactly how many pipes and fittings will need to be used in the installation process, where deviations from straight-line wiring will occur, and where passages through load-bearing and non-load-bearing elements of the building will be installed. And the more rooms are involved in the plumbing system, the more complex the scheme will be.

One of the plumbing diagrams

Features of sewerage installation

There are no special requirements for laying a sewer system in a frame house. It is usually installed in walls and under the floor. The outer part of the sewer system is connected to a septic tank or other treatment facilities provided on the site. The use of free-flow PVC sewer pipes poses some danger to a frame house.

The fact is that wastewater whose temperature exceeds 60 degrees cannot be discharged into such pipes. If an automatic or dishwasher is installed in the house, waste water heated to 90-95 degrees may enter the system. This can lead to rapid breakdown of the sewer system. It is better to use more heat-resistant polypropylene pipes that can withstand temperatures of 100 degrees.

How to create a project yourself?

In order to properly plan the plumbing system, you must first draw up a house plan, placing in it all the plumbing fixtures and equipment that will be connected to the water supply.

All dimensions are indicated on the same scale, according to actual measurements of the premises. The more accurately the plan is drawn up, the more accurately it will be possible to determine the required amount of materials and components.

The water supply diagram should reflect as accurately as possible all water intake points, the length and location of pipes for transporting water, and even sewerage, since these communications are often located nearby. The number of filters, boiler volume, and pumping equipment parameters are also taken into account.

The wiring diagram must be simplified as much as possible, trying to avoid crossing pipes. Water pipes are located closer to sewer pipes in order to hide them with a common duct. When placing pipes under the floor, the outlet of the tees is positioned straight up

The project must take into account the requirements of building regulations, as well as the rules of water supply and sanitation approved and in force in the country.

The main problems of sewerage installation

It is not as difficult to make the inside of the sewer system in a building as to equip this communication outside. But the sewer system must be impeccable both inside and outside the house.

If the house is located in an area where it is possible to connect to a common central sewerage network, the problem of biological waste disposal is easier to solve. But if you have to make an autonomous system, the task becomes much more complicated, because then its life support must be monitored exclusively by the owner of the house.

In most cases, the sewer system of a private house is connected to a septic tank, and it can be of several types. But there are situations when the sewage system in a frame house cannot end in a septic tank, and other structures have to be used.

Hood arrangement

To prevent odors from entering the room, a curved pipe is provided at the bottom of all plumbing fixtures (sinks, toilets, etc.) - a water seal

. However, with intensive use of the sewer system, a vacuum sometimes forms in the riser. In this case, a “water seal failure” occurs - gases begin to penetrate into the house without the resistance of water.

To avoid this, it is necessary to provide for their release into the atmosphere. The drain pipe for ventilation of the sewer system is discharged through the roof. Its diameter is always equal to the diameter of the main pipe. If the vent pipe runs through an unheated attic, it must be insulated.

If the sewerage capacity is small, sewerage equipment without exhaust is allowed

. However, in this case, the riser must necessarily end with a cleaning or inspection hatch.

Inspection hatch and cleaning hole (equipped with a plug)

Electric floor

Unlike a water floor, this type of floor is quicker to install and easier to connect. This is the main advantage of the system. However, this design also has disadvantages. Electricity is quite expensive, so operation will be expensive. The system must be installed under an open floor, not furniture

You can install any floor covering on top of it, make a thin screed, but it is important to carry out the work in such a way as to prevent short circuits and fire

Calculation of electrical power per 1 m2

| Assignment of rooms | Power(Watt/m2) | Main heating |

| First floor (kitchen, room) | 140-160 | 180 Watt/m2 The heated floor heating area must be at least 70% of the total area of the room. |

| Second floor and above (kitchen, room) | 120-130 | |

| Bathroom and toilet unit | 140-150 | |

| Balcony, loggia | 180 |

It is advisable to install an electric heated floor during the construction of a house, but since it is simpler than a water floor, it can be done in a finished building.

Its installation occurs according to the following scheme:

- The cables are mounted on wooden joists. In places where cables are laid, cuts are made.

- First, the surface is lined with a waterproofing film, and then with a layer of foil, which acts as a heat reflector.

- After laying the cables, they are covered with a small layer of screed or slabs of chipboard, plywood, and a finished floor is arranged.

It is allowed to lay tiles and laminate on top of an electric heated floor. It is not the best solution to lay parquet, since due to constant heating it can dry out. When installing the system, you must ensure that there are a sufficient number of thermostats in the room: one device will not be able to correctly display the temperature in the entire house. The smartest options for underfloor heating allow you to program them, intelligently reducing the heating of the room at night or when no one is in the house.

Features of hidden installation of electrical cables

You need to know the rules for hidden installation not in order to do all the work yourself. Understanding its main nuances will help you control the actions of the electrician and avoid the negative consequences of his “skill.” The available information may be needed by emergency services in the event of an emergency.

What you should absolutely not do

Based on the provisions of regulatory technical documents, there are three prohibitions in work.

- Do not lay cables close to wooden surfaces. The ban applies even to those cases when they are isolated in a plastic box, channel or corrugation. Such insulation is a fire hazard and susceptible to damage by rodents.

- Do not lay cables on wooden surfaces in metal sleeves. In the event of a short circuit, their walls burn out.

- Distribution boxes must not be hidden behind wall cladding. They need free access at any time - for troubleshooting and routine inspection.

Detailed information for specialists is contained in a large number of regulatory technical documents. These are GOSTs, SNiPs, Rules for the construction of electrical installations, Rules for the technical operation of consumer electrical installations.

Rules for laying hidden wiring

To safely install hidden electrical wiring in a frame house, a number of rules are followed. They relate to the choice of insulating materials and the installation work itself.

- The cable layout is designed so that the number of bends is minimal. For this, there are 3D programs that take into account the design of the house, the required distances and other parameters.

- Power lines are laid parallel to one of the walls to make it easier to replace wiring in the future.

- To ensure fire safety, wires are placed in metal pipes or boxes - steel, copper. It is permissible to use PVC corrugations and boxes, but only with fireproof material. To do this, plaster, alabaster, and cement are laid between plastic and wood.

- The cable should occupy no more than 40% of the space in the pipe or box.

Note! For hidden installation, triple-insulated cables are used. You cannot replace them with PUNP - a universal flat wire.

Features of frame houses

As with any capital construction, it all starts with the foundation. There are few differences from conventional technologies.

Both a pile grillage and a monolithic slab are used. The choice depends on the soil and the number of floors.

A wooden frame is mounted on the foundation. The best quality lumber is used for it. They are first thoroughly dried and processed.

Then the box is assembled. If you order a project from a company that specializes in turnkey houses, ready-made panels with holes for windows and doors will be delivered to the site. To attach them to the frame, ordinary nails are often used.

Then everything is as usual. The house is insulated and tiled. The roof is being installed, windows and doors are being installed. If the project includes a terrace, balcony or porch, begin their construction.

All that remains is to install communications, supply plumbing and carry out interior decoration. All this takes less than a year, and you move into a ready-made and equipped house.

Types of communications in a frame house

The frame house is provided with a water supply system, sewerage system, ventilation, heating, and electricity supply. The features and layout of their installation are taken into account when designing a house.

Heating and water supply system

At the design stage of the heating system, it is determined whether it will be series or collector. In the first case, one pipeline line runs through all rooms in the house. In the second, it branches into several directions. The collector circuit is more expedient, as it ensures uniform distribution of heat throughout the rooms.

To construct a heating system, polypropylene pipes of different diameters are used. They are laid in interfloor ceilings and walls. At the intersection of communications and racks, holes of a suitable diameter are drilled. The pipeline is fixed to the beams using metal clamps.

To avoid heat loss during the operation of communications, the pipes are insulated. For this purpose, insulation materials with a low thermal conductivity coefficient are used, which do not lose their properties under constant exposure to high temperatures. In the case of a water supply system, the principle of laying communications in a frame house is the same. Only instead of polypropylene they install PVC pipes.

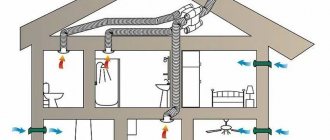

Supply and exhaust ventilation system

Without a good ventilation system, a frame house with plastic windows may well pass for a thermos. To prevent this from happening, a number of requirements must be observed:

- the exhaust vent should be in the kitchen, in the boiler room and bathrooms, in the corridors with bedrooms;

- when constructing the foundation, air vents are left;

- air ducts are laid in interfloor ceilings and in the attic;

- to supply fresh air in the rooms, install wall valves for artificial ventilation, window supply valves or supply systems with air recovery;

- For the natural outflow of polluted air, a pipe is installed on the roof of the house.

Please note: the air duct in the attic must be insulated with insulation

Laying the sewer system

One of the utilities in a frame house is the sewerage system. It is a pipeline for draining wastewater and a settling tank for it. The role of the latter is most often played by a septic tank, in which the water is treated before being discharged into the ground.

Please note: sewer pipes are laid with a slope of 2-3 cm per 1 meter of their length. It is needed for the natural movement of sewage, preventing siltation and freezing of communications

A shower, bath, toilet, all sinks, a washing machine and a dishwasher must be connected to the sewerage system. The location of the kitchen, bathroom and the above-mentioned household appliances next to each other simplifies pipe routing

Particular attention is paid to the location of the central riser

Electrical supply in a frame house

You should not think about laying communications yourself if we are talking about electrical wiring in a frame house, and you do not have special knowledge. Incorrectly installed wiring poses a fire risk. The cost of a mistake can be much higher than the cost of an electrician.

Cables are laid both on the street and in the house, where they are supplied from an electric pole. Internal wiring can be hidden in the walls or open - laid and fixed to the walls and ceiling. The second option is safer, since cable damage can be detected and repaired in a timely manner. For the installation of power supply systems, the location of large-sized household appliances is determined in advance. Some appliances require a dedicated line from the distribution panel.

What else is important when wiring electrical communications:

- cables should not come into contact with wood, for which suitable insulation is selected (metal pipes, PVC corrugations, etc.);

- if the house has a boiler room, a separate panel is installed for it;

- cables are insulated along their entire length.

Detailed regulation of work with the power supply system is contained in technical regulatory documents.

This is interesting: How to connect a washing machine yourself - we’ll tell you in general terms

How is a septic tank different from a cesspool?

Many people are interested in how to make an effective sewer system at their dacha so that waste water not only accumulates in a cesspool, but is also partially purified. The only way to make visits to sewer trucks less frequent is to install a septic tank, either factory-made or home-made, instead of a cesspool.

It is worth distinguishing between two types of septic tanks. Some of them actually purify water up to 68–97%, because the purification process occurs under the influence of anaerobic and aerobic bacteria. The lowest degree of purification is represented by systems in which wastewater is processed through sedimentation and the action of anaerobes.

They are supplemented with filter wells, filtration fields, and infiltrators that perform groundwater post-treatment of wastewater.

If aerobes are involved in the operation of the septic system, then the second compartment is equipped with a compressor for supplying air and a special load necessary for their fruitful life.

The breeding ground for them is a suspension of clarified sewage, which moved to the second compartment along the overflow. Systems with aerobic purification produce the most purified water, which can be discharged onto the terrain or into the ground without additional treatment.

After “cleaning procedures” in the chamber, the liquid enters the filter well, onto the filtration field, or is forcibly pumped into a ditch using a pump.

The second type is a two-chamber storage tank, in which the first chamber also serves to separate fractions, and the second – to filter clarified water. The first tank is cleaned with the same regularity as the removal of waste from the cesspool; dirt is removed from the second tank less frequently. This is usually a gravel filter replacement that replaces the bottom.

It should be remembered that activated sludge accumulates in septic tanks over time, which can later be used as fertilizer. The contents of the cesspool can also be used, but under one condition: if the peat waste processing technology is followed.

A biological treatment station is most effective, but an expensive installation, as noted above, is not practical for temporary housing. Therefore, as a sample, we will consider the instructions for installing a septic tank from ready-made factory-made concrete blanks.

How to install heated floors in a frame house on stilts?

The peculiarity of a frame building on stilts is that its arrangement requires more complex thermal insulation, and more powerful heating systems must be installed. This is the main difference. Therefore, at the stage of building a house, waterproofing is laid on the subfloor, preferably from a perforated membrane. Insulation (mineral wool, polystyrene, expanded clay) is placed on top of it. It is also advisable to make a layer for vapor barrier.

For pile frames, water or electric systems are used

It’s just that at the design stage of a building it is important to insulate all cold zones and carefully seal any joints and cracks. A more economical option in terms of operation is a water floor, although the initial costs of its installation are higher than those of an electric one.

Water floor

In frame houses, a water floor is used quite often, since its operation reduces the load on the electrical system and it is quite economical. Its main disadvantage is expensive components, limited choice of screeds, and the need to make hydraulic calculations. Also, a water floor requires at least a minimum screed of 5-7 cm.

Installation of such a system for frame houses is mainly carried out as a floating screed. It must be included in the house design and done during the construction of the building, after the subfloor has been formed.

The thickness of the screed is no more than 5 cm, which does not create a large load on the foundation:

- First, a layer of waterproofing is installed. It is placed on a rough base. The optimal material is polyethylene film. It is fixed with an overlap.

- Then a layer of thermal insulation is formed. For this, any insulation in rolls can be used, and foil on top of it.

- Next, the reinforcing mesh is laid out and the pipes are laid. They can be placed in a snake or snail shape. In the frame, the pipes are laid at a distance of 10-15 cm. They are fixed to the reinforcing mesh using the power of the casings.

- After this, a communications test is performed to check for leaks. If everything is in order, then perform the screed.

The peculiarity of the floating screed is that it does not come into contact with the wooden panels of the house or the floor, so the warm floor will not cause the wood to crumble and pull apart.

Separation based on water supply principle

Installation of a DHW and cold water system can be carried out in two ways:

- With “deaf” wiring. The water supply pipe to the last water intake point ends in a dead end. This scheme is more beneficial for saving space and from an economic point of view, but can create inconvenience during the operation of the water supply system. Water will flow into the last node with a delay, and only after it reaches the plug will it begin to flow into the tap.

- With closed circulation wiring. With this method, water constantly moves in a circle, has the same temperature at each point of the system and reaches the user immediately after opening the tap. The peculiarity of this wiring method is advisable to use specifically for a hot water supply system - it is important to prevent sudden temperature changes in it.

In order not to unnecessarily complicate the plumbing in the house, it is more rational to use a combined option. The cold water supply system is carried out with the help of blind wiring, the hot one - with the help of circulation.

This is interesting: How to insulate a well with your own hands for the winter with polystyrene foam or fencing: Step by step

Laying methods

Let's consider the main methods of laying an electrical cable in a frame house.

Outdoor

External installation of an electrical cable in a frame house can be done independently. There are several options.

Open cable

When arranging this wiring, a rigid wire with double/triple insulation made of materials that do not support combustion is used. To secure the line to the walls, install special brackets. To reduce the risk of fire, an asbestos or metal backing should be placed between the cable and the wooden wall. Its width directly depends on the thickness of the cable and is made 20 mm larger (the line is laid right in the middle).

External wiring in a frame house

This method is the cheapest and most reliable, but the electrical wiring does not look aesthetically pleasing. The system looks even worse if there are several wires nearby. On the other hand, this option is suitable for houses in retro design or loft style.

Electrical pipes

Electrical wires can be hidden in special corrugated pipes made of non-flammable materials. They can withstand high temperatures and have a diameter that allows multiple cables to be accommodated inside. Using special clips, the pipe is fixed to the wooden walls of the building.

Wiring takes up a minimum of free space, increases electrical and fire safety, and reduces the risk of mechanical damage during operation. However, we can again talk about unaesthetics associated with the untidy appearance of metal pipes. They will attract dust and dirt from the street.

Laying wires in electrical pipes

Cable channels

Such protective devices for electrical wiring have a more laconic and thoughtful design, which is what makes them better than corrugated pipes. The products are available in different colors, so they fit into any interior or exterior. Ideally straight cable channels can reveal a potential drawback of a frame house - the curvature of the walls. But if the house is built to last, then this will not happen.

Cable channel is a plastic box installed on walls or ceilings. Self-tapping screws or glue are used for fixation. The plastic from which the products are made does not support combustion and retains its properties when exposed to high temperatures.

Cable channels are available in different colors and dimensions. The specific width is selected depending on the communications. After fixing the box on the wall, lay the cable inside and then hide it under the cover.

Open wiring in cable channels

The main disadvantage of cable channels is associated with the potential shrinkage of the frame house, due to which the products will begin to crack. As a result, you will have to re-do the electrical wiring and change various components. To the advantages listed above we add the moderate cost of the products and ease of installation.

Wiring hidden in the casing

The PUE lists the basic rules and recommendations that should be followed when laying cables inside walls or ceilings. We wrote above that hidden wiring must be additionally protected by metal pipes. You will have to buy a lot of pipes, so the total cost of electrifying the house increases significantly. In accordance with the joint venture, you can get by with a more budget-friendly option by replacing the pipes with corrugated or metal hose. However, if finances allow, it is better not to save.

When purchasing metal pipes, try to select products with a wall thickness of 2–4 mm. This value will allow the products to withstand high temperatures resulting from short circuits. To avoid rust, paint the pipes inside or outside, or purchase galvanized elements.

Metal pipes for cable laying

Any electrical wiring has numerous bends and other route features, so the pipes will have to be welded together or secured with threads. To simplify the installation process, preference should be given to copper products, but they are more expensive than galvanized steel. To protect the plastic insulation layer, place protective sleeves on the ends of the cut pipes.

Pipes are installed at the initial stages of construction. You are guaranteed to need physical assistance. This type of wiring in a frame house requires a lot of time and serious investment, and therefore is extremely irrational.

How to lay a pipeline correctly

It is necessary to lay a line from the outlet of the internal sewer system to the septic tank.

Moreover, it must be located at a certain slope, due to which the outflow of all waste liquid is ensured. The larger the diameter of the pipe, the smaller the angle needed for the line to work normally. On average, the slope should be about 2 degrees. The main line should be lower than the freezing level of the soil in winter. Usually this is about 1 meter, but depending on the region, this figure may increase or decrease. If you live in a warm region, then there is no need to deepen the pipes. It is enough to lay them at a depth of about 70 cm. Moreover, before installing the pipes, sand must be poured into the bottom of the trench and compacted thoroughly. This will securely fix the pipes and prevent their destruction when the soil moves.

The best option for a dacha would be to lay a line in a straight line from the house to the septic tank. Of course, turns are allowed if necessary. But in the place where the pipe turns, you need to install an inspection well. It is allowed to use both cast iron and plastic pipes intended exclusively for arranging an external sewage system.

The minimum pipe diameter is 110 mm. All joints must be treated with sealants. It is necessary to first fill it with sand, then with soil. If it is not possible to lay the pipeline at great depth, it will need to be insulated. For this, thermal insulation is used.

Safe wiring

A modern dream home can hardly be imagined without modern technology. This means that it will be necessary to supply electricity to it. Electricity must be distributed through the building in accordance with all the rules.

There is no need to hide the fact that providing electricity at home is one of the most dangerous things for human life. A minor flaw can take a person’s life

For this very reason, special attention is given to the installation of the power supply of the structure.

Pipes can be made from copper and stainless or black steel. Distribution boxes must be made of steel. All sockets and switches must be “sheathed” in special metal socket boxes.

Power supply elements can also be mounted in corrugated hoses. In this case, all sections of the wiring must be hermetically insulated. All these requirements are a manifestation of concern for people. If a cable fire occurs in such a structure, it will not be able to spread due to the lack of air.

Installation of the electrical system in steel tubes is carried out using a welding machine. Accordingly, it will be necessary to carry out welding work within the premises. However, they are strictly prohibited in wooden buildings. Accordingly, it is very difficult to install power supply in this way. There is only one option: weld all the pipes before installing the wall structures.

All work on the installation of electrical systems must be carried out by specially trained people in strict accordance with current regulations. Upon completion of the work, the installers must issue a work certificate.

Wiring installed in the building in accordance with all the rules will not cause harm or disturbance. Only it can be considered safe.

Heating

In order for a building to be livable, the first step is to take care of its heating. This means that you need to plan and install the heating. Most often, to carry out work of this kind, the owners of the structure resort to the help of qualified specialists, and they carry out the installation in the shortest possible time. However, even in this case, you will still have to deal with the necessary minimum of concepts and technologies. As a last resort, you can purchase a convector.

At first glance, installing a heating structure is not such a difficult job. You just need to place pipes of a suitable diameter in the correct way in the space between the walls. In order to strengthen the entire structure, the heating elements are attached with special brackets to the frame posts and floor beams. You should also remember the need to isolate it. This will reduce heat loss.

Everything seemed simple and clear. However, this is only at first glance. When designing and performing installation, it is necessary to remember the existing real requirements for fire safety. There are some other difficulties.

Difficulties

If the heating was designed for some reason after the actual construction of the structure, then a conflict between the building and its sections may appear. In this case, you will have to make additional efforts when installing the heating. Additional assemblies to bypass existing obstacles in the building may be needed. There will be a need to convert one or another part of the structure into a technical room.

When designing a building's heating structure, keep in mind that equipment is easily accessible. This is necessary for monitoring and cleaning the system. This will make it easier to carry out scheduled or emergency repairs.

It is also important that individual sections and the entire heat supply structure of the structure must be organized in accordance with safety requirements. The possibility of burns should be prevented. You should also remember about the possible freezing of its components and high heat losses and condensation.

It is very important to properly isolate hot areas as they can ignite gases, aerosols and dust. It is necessary to control the surface temperature of exposed areas.

Methods

The question of whether to equip a building with heating or not is never a question. However, the question of choosing a method of heating rooms is sometimes quite acute. To choose the most suitable option, you should familiarize yourself with all existing methods.

Existing heating systems:

- air;

- electric;

- open;

- traditional with liquid coolant.

The air system is the safest heating structure. However, it requires significant installation and maintenance costs. The main element is air. It is taken from outside and, after warming up, is distributed throughout the rooms of the building.

The electrical system can become a very real competitor to warm air. It is unpretentious to use. The main element is a source of electricity. The negative aspects of this option are significant energy costs and dependence on the power supply.

The most primitive heating option will be an open system. Here fireplaces and stoves are used as heat sources. The main element is fire. The effectiveness of this option is unlikely to be suitable for a modern residential building. It simply won't be enough.

The traditional heating system for buildings is the one with a liquid coolant. It consists of three main elements: a boiler, heat pipes and radiators. The boiler is the main one. It comes in different types. Among the entire set, you can always find something suitable for the desired building.

Deciding on the type of heating is not enough. It is necessary to plan the installation of future structures.

This is interesting: Is it possible to fix a leaking heating pipe under pressure? Review

Wiring

Among the various utility networks that need to be built in a frame house, there are more and less safe ones (from the point of view of doing the installation work yourself). Electrical wiring carries a risk of fire if connected incorrectly. Therefore, laying wires and cables requires the work of a professional electrician. We also need a project signed by Oblenergo authorities.

Electrical wiring in ceilings.

Turnkey frame houses in Moscow with communications are more expensive, since the work in them is carried out by professional craftsmen in accordance with construction standards. What is usually more expensive than self-building without rules and regulations.

What you need to consider when laying electrical wiring in a frame house:

- The correct choice of electrical wire material is necessary. Inside the house, it is necessary to lay wires with the same conductive material (either copper or aluminum) to avoid their oxidation in the galvanic pair and short circuit.

- Copper wires have better performance characteristics. Therefore, when laying electrical wiring in a new frame house, copper cables are used. Aluminum wires are in demand only when repairing old electrical wiring in which aluminum was originally used. And one more thing - for hidden wiring inside the walls of a frame house, it is necessary to choose insulated wires.

- It is necessary to correctly calculate the electrical load and the cross-section of wires and cables. This will ensure the safe operation of electrical equipment in the future home.

- Lightning protection is needed (lightning rod and grounding).

- It is necessary to install a circuit breaker at the entrance to the house, after the electric meter. So that if the load is exceeded, it stops the current supply and prevents fire.

The main requirement for electrical wiring outside and inside a frame structure is safety. Incorrect wiring and faulty electrical appliances are one of the main causes of fires.

Results

For heating via gas, this will be a gas-type boiler, piping and radiators. For electric - a boiler and pipes with radiators or an electric cable, and also a heated floor system. Another option for electric heating would be infrared emitters, or more precisely, heating elements, rugs and heaters.

Heating with solar energy is based on the principle of electrical heating of a house. It will differ in that it has a battery and the supply of electrical energy from collectors on the roof. The solar system also works on the principle of electric heating, in which the electricity comes from a solar converter.

The cost of turnkey frame houses with everything necessary may seem high due to the price of installation work for laying utility networks. The amount of expenses for their arrangement is sometimes 15% of the cost of the overall frame structure. But it will be justified by the high-quality speed of installation and the possibility of future all-season operation of the frame.