If the floors in the house need not only leveling, but also insulation, the ideal way to do this would be to screed the floor with expanded clay - the technology for doing this work has long been proven and even has several options. Each of them has its own nuances that must be taken into account in order to obtain a high-quality surface. And the choice of method depends on the condition of the base and some other factors, which will be discussed below.

Expanded clay backfill can raise the floor to the desired level Source instrumentotido.ru

Methods of insulation with expanded clay

In construction, 3 methods of laying expanded clay are used - dry, wet and combined. To choose the right option, you should first familiarize yourself with each in detail.

Dry insulation

Dry insulation

With the dry method of thermal insulation, the material is simply poured between the joists or beacons, and a subfloor is mounted on top - boards, chipboard, plywood. To protect from moisture, the base under the insulation must be covered with waterproofing material. To increase the density of the thermal insulation layer, it is recommended to take expanded clay of different fractions and mix it before backfilling. This insulation is done very quickly and does not require much effort.

Wet styling

Expanded clay concrete screed

When insulating using this method, expanded clay is mixed with liquid concrete and the space between the beacons is filled. This option is excellent for floors with large differences in height, where a thick leveling screed is required. Due to the lightness of expanded clay, the load on the base is significantly reduced; The screed itself dries faster and does not crack as much. When choosing a wet method, you should take into account that the thermal conductivity of the material increases sharply, which means that its efficiency will be much less than with dry installation.

Combined method

Combined method

With combined insulation, dry expanded clay is poured between the beacons, leveled, then the top layer is spilled with a liquid cement solution and, after drying, a standard screed is made. Cement mortar makes it possible to strengthen the expanded clay layer and avoid its deformation when pouring the screed. Additionally, reinforcing mesh is used if a large load on the floor is expected during operation.

In what cases is monolithic expanded clay concrete effective and in demand?

The technology for forming strong and lightweight foundations based on monolithic expanded clay concrete is indispensable when performing construction work. It is in demand in a number of situations:

- if it is necessary to fill significant volumes of mortar in rooms with height differences of more than 150 mm;

- when forming foundations in old buildings equipped with wooden floors.

The use of concrete mortar in these cases can cause damage to floors that are not designed for increased loads.

Expanded clay: pros and cons

Insulating expanded clay - granules made by foaming and subsequent firing of clay.

Scheme for the production of expanded clay granules

It has a number of advantages when used as thermal insulation.

- Low thermal conductivity. The clay itself from which it is made is considered a good heat insulator. And the pores created inside, filled with air, further reduce thermal conductivity. As a heat insulator, it is several times more effective than clay bricks and twice as effective as wood.

- Light weight. Increasing the thickness of the expanded clay layer does not lead to a significant load on the floors.

- Cheapness. Despite the fact that it is inferior in thermal conductivity to many modern materials, its use allows you to save money, losing slightly in the quality of insulation.

- Fire safety. This material not only does not burn, but also does not emit any toxic substances when heated strongly.

- Resistance to temperature changes. Thermal insulating properties do not change in heat or cold.

- Resistant to household chemicals and humidity. Even when wet, mold does not form on it.

- Completely environmentally friendly. Made from natural material, it is not completely harmless.

- In addition to thermal insulation properties, it is also a good sound insulator.

- Convenient to use. To work with it, you do not need to have special skills, and no special tools and devices are required. The fact that expanded clay is a bulk material eliminates any requirements for maintaining exact dimensions when laying.

- Long term of use. It is believed that it retains its properties for decades.

Flaws

Expanded clay also has disadvantages. But their list is incomparable with their advantages:

- Large volume of heat-insulating layer. To create high-quality thermal insulation, the thickness of the expanded clay cushion must be at least 10 cm. But in practice, the expanded clay layer is usually 20–30 cm, rarely 40 cm. In some wooden floor designs, such insulation leads to a decrease in the space between the floor and the ceiling.

- Low moisture resistance. When a large amount of water hits it, it absorbs it. This leads to an increase in the weight of the thermal insulation. Over time, moisture will evaporate from expanded clay granules, but this is a long process.

- Laying expanded clay, despite its simplicity, is a tedious task. Spreading a thick layer, leveling with obligatory care so as not to destroy the shell of the granules - all this takes a lot of time.

Varieties of expanded clay

The quality of expanded clay as insulation also depends on the options for its production. Depending on the size, there are three main groups of expanded clay granules. And although for each group there are recommendations for its use, they usually use a mixture of granules of different sizes in one layer.

Expanded clay fractions

- Crushed stone – granules with a diameter of 20 to 40 mm. Recommended for backfilling the main layer of thermal insulation.

- Gravel - from 10 to 20 mm. Used to create thin layers.

- Sand is the smallest granules with a diameter of 5 – 10 mm. Suitable for insulating small voids in floor structures. When mixed with large fractions, it allows you to fill the gaps between granules. Used to create a “wet” concrete heat-insulating screed.

In addition to size, expanded clay insulation varies in density. Industrially produced expanded clay is divided into several categories with a density from 200 to 800 kg/cub.m.

Types of filler filling

Expanded clay screed is carried out using granules of all fractions. Pebbles have different sizes, volumes and weights.

| View | Fraction, mm | Weight, m3/kg |

| Expanded clay sand | up to 5 | 500-600 |

| Expanded clay fine gravel | 5-20 | 300-450 |

| Expanded clay crushed stone | 20-40 | 200-350 |

It is recommended to use several types of filler for the screed. This will ensure high performance properties of the coating. In stores, the material is packaged in bags weighing no more than 20 kg, which greatly simplifies transportation. The higher the density, the more the filler weighs. The prices for lifting the pillow depend on this.

How to insulate a floor in a wooden house with expanded clay

Wooden construction is mainly country houses. Moreover, both new construction and those that were erected long ago as summer cottages. Today, these buildings are increasingly used for year-round living. Therefore, the issue of insulating all parts of the house becomes urgent.

The floor in wooden buildings is one of the coldest parts of the entire structure. According to various estimates, up to 20% of the internal heat in the premises is lost through the floors in wooden houses. It makes sense not only to design good insulation when building a new house, but also to take care of remodeling the floor in an already built one, but without floor insulation. Moreover, usually a residential wooden house is installed on a relatively high foundation. And this allows you to carry out insulation from below, without changing the level of the finished floor and without reducing the height of the room.

When constructing ancillary wooden buildings, the floors can be located close to the ground or even laid directly on the ground. In this case, an insulating layer is still necessary, but it will have to be laid deep into the ground.

Any insulation of wooden floors must be carried out in compliance with the following rules:

- Mandatory installation of waterproofing in two layers. The bottom layer protects the insulation from moisture from the ground. The top layer protects against water penetration through the finished floor boards.

- Rough and finishing wooden floor elements are treated with special anti-rotting agents.

- For insulation, a material is selected that does not change its properties when in contact with wood.

Despite the recent emergence of modern insulating materials, expanded clay insulation of wooden floors still finds its application. And there are reasons for this.

Filling methods

There are three methods of screeding using expanded clay. It is necessary to analyze the method of use and the advantages of each of them in more detail.

Semi-dry screed with expanded clay

This method is used in cases where it is necessary to both raise and insulate the floors in the room. To achieve thermal insulation, the expanded clay layer must be at least 10 cm

Here it is important to take a large fraction of the backfill - at least 20 mm. If it is important for you only to raise the floor to the required level, you can use smaller particles

In this case, waterproofing is necessary in order to protect the expanded clay layer from moisture. Beacons are set to the required height, and expanded clay is backfilled. Walk over it with a rule to compact and level the layer.

After this, you should proceed to pouring the concrete screed. Cement-sand mortar or a special mixture can be used. For ease of work, it is better to first spill the expanded clay layer with a concrete mixture highly diluted with water - cement laitance. This will prevent the expanded clay grains from floating and make it easier to fill with the main solution. Laying a layer of granules with film may also be suitable for these purposes. Only in this case, installation must be done very carefully so that the film does not tear.

Expanded clay concrete

This is the so-called wet screed. In this case, it is necessary to carefully measure all the unevenness of the base and decide how thick the screed layer will be. This method is advantageous to use if you have to raise the floor level to a significant height, as well as to save concrete mixture. Expanded clay is combined with sand concrete, the resulting composition is carefully stirred and distributed over the floor. It is better to first soak the expanded clay granules with water so that later the consistency of the mixture does not turn out to be too dry. It is better to mix using a construction mixer, because no amount of spatulas or sticks can achieve a uniform consistency without clots and lumps.

To strengthen the expanded clay concrete screed, you can use a reinforcing mesh, and any slats that are easiest to obtain can be used as beacons. The mesh should be a couple of centimeters short of the required height level. Next, distribute the solution evenly over the grid, leveling it with the rule. After finishing laying the mixture, do not wait for it to dry. Prepare a solution for the top leveling layer. This can be a cement-sand screed or self-leveling floor. It is applied to the zero mark, leveled with the rule and left to dry.

Dry floor screed with expanded clay

If the semi-dry method is a combined screed, then filling with expanded clay granules does not require subsequent filling with any solutions. The base is prepared as usual, but it is necessary to exclude any possibility of moisture getting on the waterproofing layer. Beacons are set to the required level. The minimum thickness of the expanded clay layer with this technique is 5 cm. Granules need to be selected in small or medium sizes; it is advisable to combine different sizes to distribute the layer more evenly with fewer voids. There is no point in using small waste, because a huge amount of it will be required, but it will not create the desired thermal insulation effect.

It is better to divide the surface into strips using wooden slats - this will make it easier to level the granular layer and lay the following materials. Do not compact the expanded clay, but carefully roll it out. Next, a layer of moisture-resistant drywall should be laid. If the sheets are thin, it is better to lay them in two layers, gluing them together, and the seams must be coated with putty. You can also use waterproofing mixtures. After completing the installation of drywall, it is necessary to cut off any protruding pieces of tape or film.

This type of screed has many advantages:

- The smooth surface is suitable for applying any type of finishing coating.

- The layer can withstand high loads.

- The floor covering is quite light, so it can be used on old, dilapidated floors without any risk.

- Thermal insulation is excellent. There is no need to install heated floors on an expanded clay cushion.

- The work can be completed very quickly, and immediately upon completion, proceed to the next stages of repair.

- Dry screed provides excellent sound insulation.

- The coating is not deformed.

Sometimes builders suggest using expanded clay for adding to the rough screed directly on the ground instead of sand or crushed stone. This can only be done if the groundwater level is low, otherwise increased humidity will lead to negative consequences for the entire climate in the house, and good heat conservation will no longer play a role here.

What will you need when working?

- Container for stirring the solution.

- Level (any).

Level

- Rule.

- Stirring device (mixer or stirrer).

- Net.

- Lighthouses.

- Polyethylene.

- Master OK.

- Scotch.

- Large needle roller.

- Expanded clay.

- Cement, sand or ready-made mixture.

- Mastic.

- Water.

- Plaster or alabaster.

Installation

Covering the floor with expanded clay does not require much effort and time, but first you need to correctly make all the necessary calculations and prepare the foundation to arrange the future “pie”.

First of all, it is important to calculate the pressure on the surface, since the floor bears the main load

Before starting work, you should repair all existing cracks and chips in the old floor, and then apply a layer of waterproofing material, as a rule, roofing felt or polyethylene film is used for this.

It is very important that the coating is cross-coated, that is, its sections are laid overlapping, and also extend onto the walls at least 10 cm above the level of the future filling. Upon completion of the installation work, all excess can be removed fairly quickly

These works take very little time, and after they are completed, you can proceed directly to filling the expanded clay.

The technology of work depends on the type of floor structure. Let's look at each of the options in more detail.

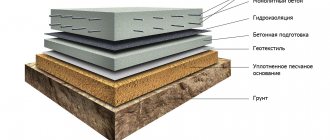

On the ground

Floors on the ground are made in garages and sheds. If all the work is done correctly, then in winter it will not be too frosty there.

In order to pour expanded clay onto the ground, you first need to remove the top fertile layer of soil, level the area and compact it thoroughly. Then pour a mixture of sand and crushed stone onto the compacted soil, thus pre-leveling the surface.

To protect expanded clay from groundwater, a layer of waterproofing is laid, and only then the expanded clay is filled in

It is very important that the entire surface is the same in height. At the final stage, the top layer is impregnated with cement mortar, which gives the insulation the required fixation.

The top of the screed is covered with a vapor barrier material, and the work is completed by applying a reinforced cement screed.

By lags

When using expanded clay as insulation, logs perform several functions at once. Firstly, they help level the backfill, and secondly, they are used as a base for the subfloor.

This method is used to insulate concrete surfaces. First, you need to completely clear the application area and eliminate all deformations and cracks in the coating; the logs themselves must be treated with fungicides. Then, using corners, they are attached to the base so that the upper edges of the guides extend into a single horizontal plane.

Typically, roll coatings or film are used as a waterproofing material, but bitumen mastics, polymer mixtures or rubber water barriers can be laid, and, as a rule, the base itself, the joists, and part of the wall around the perimeter are subject to treatment.

If mastics are used, then first the base is primed; if a film is used, then it is attached to the bars with a construction stapler.

Expanded clay is poured into the sinuses so that there are no empty spaces left, otherwise the thermal insulation properties of such a coating will be significantly reduced.

At the final stage, everything is covered with a vapor barrier material, and a subfloor is formed.

On the balcony and loggia

At its core, a balcony is a protruding slab of reinforced concrete, so standing on it even in the summer heat is quite uncomfortable, which is why many apartment owners decide on the need to insulate their balconies and loggias.

It is not necessary to level such a base; the only thing worth paying attention to is that the surface should not have a slope; for this, beacon slats are attached over the entire area, which are fixed with gypsum mortar. The smaller the step between the beacons, the easier further work will be, since it is by them that the height of the expanded clay layer is equalized

Basic properties and functions of floor screed with expanded clay backfill

In addition to the main problem that a screed with expanded clay solves - high-quality leveling of any, even problematic base, adding filler performs the following tasks:

- leveling;

- sound insulation increases;

- Such screeds provide excellent thermal insulation, which, in turn, reduces space heating costs. Therefore, insulating the floor with expanded clay under a screed is not only the simplest, but also the most profitable choice;

- Thanks to its porous structure, expanded clay prevents the room from overheating during the hot season.

Amorphous aggregate has a relatively low weight and density. But at the same time, the concrete layer provides good strength. The tandem of such building materials results in an excellent floor base, which not only puts minimal load on the floor, but also does not lose its characteristics during operation.

If we take a closer look at expanded clay and its properties, we can conclude that the porous structure gives the granules not only heat-saving characteristics, but also water-repellent properties. In addition, it is inert and has rare qualities - compatibility with any building material and ensuring a high level of adhesion.

Do-it-yourself floor screed with expanded clay is relevant in the following cases:

- when the base is made of reinforced concrete slabs;

- leveling the floors to the same level, provided their difference is more than 10 mm;

- if communications are hidden below;

- minimizing the concrete mixture;

- if heating is carried out electrically or infrared;

- low noise permeability.

Expanded clay

The screed is indispensable for obvious defects in the base, which can not only appear on the finishing coating, but also ruin it.

Proportions of expanded clay concrete for screed

Regardless of the method of performing the work, the composition of expanded clay concrete includes the following ingredients:

- Portland cement grade M400;

- sand cleared of impurities;

- granulated expanded clay;

- water.

Expanded clay concrete for screed can act as gravel, crushed stone or sand

To ensure the quality of the screed, it is necessary to observe the proportions of expanded clay concrete. For example, to fill the foundation in residential premises, it is necessary to mix sand, cement and expanded clay in a ratio of 3:1:4. When forming the classic version of the base, 40 mm thick, you need 52 kg of cement-sand mixture and 45 kg of granulated expanded clay.

The process of preparing the solution is carried out according to the following algorithm:

- Fill a larger container with expanded clay and add water.

- Mix the granules thoroughly and wait until the water is absorbed.

- Drain off the remaining water that the expanded clay could not absorb.

- Load the moistened granules into a concrete mixer or trough.

- Add the remaining ingredients in the required proportions.

- Pour water into the resulting mixture, stir until smooth.

Kneading must be stopped when the expanded clay granules do not stand out in color from the total mass of the solution. When preparing expanded clay concrete, determine the proportions per 1 m3 by calculation, depending on the thickness of the layer being formed.