Every owner who has installed aluminum radiators in a house or apartment is concerned about extending their “life,” the efficiency and safety of their operation. Often the answers lie in the quality of the coolant.

In apartment buildings connected to a centralized heating system, there is no need to talk about the composition and Ph level of the water, since after it runs under pressure through the numerous pipes of the heating main, suspensions and dirt are constantly present in it, which affect it.

It’s a different matter when it comes to an autonomous heating system, which gives a person the right to choose what to use, water or special antifreeze for aluminum radiators.

Antifreeze properties

Consumers are so accustomed to using water as a coolant that they do not even suspect that there are liquids of better quality. Water's biggest advantage is its cost and non-toxicity, but otherwise it can be an enemy for a heating system. Its ability to cause corrosion in metals has “ruined” more than one generation of radiators.

In addition, in the event of an accident on the heating main in winter, when the heating is forced to not work, it can freeze in the pipes even at zero temperature. Its ability to expand, both when frozen and heated, causes them to rupture.

Antifreeze, enriched with special additives for use in heating systems, has some advantages next to water, but it also has negative qualities:

- This coolant freezes at -70 degrees.

- It does not harm aluminum, which is very important for such a “sensitive” metal.

- It has a good level of thermal conductivity, although it takes a little longer to heat up than water.

These were the positive qualities of antifreeze. Among its disadvantages:

- It has a higher viscosity, so to move it through the heating system you need a fairly powerful boiler.

- The fluidity of antifreeze poses a threat if the integrity of the joints or elements of the heating network is compromised.

- Antifreeze is toxic, so precautions should be taken when using it.

Many consumers wonder, knowing about these shortcomings, whether it is possible to use antifreeze in aluminum radiators. In this case, it is even preferable when it comes to an autonomous heating system. The durability of this coolant is enough to heat a house for 10 winters, which in itself is good news. During this period, aluminum batteries do not change at all under its influence, which also has a positive effect on their service life.

Results

Discussions on the topic of whether it is possible to pour antifreeze into aluminum radiators brought very specific answers. Responsibility for choosing a coolant lies entirely with the owners of the household. When considering various liquid options, one should keep in mind one more feature of systems filled with antifreeze coolant. If the operating temperature regularly exceeds the limit of +70ᶷ degrees, it is better to refrain from using antifreeze solutions, because because they have a very high expansion due to the alcohol content. This is fraught with pipeline ruptures and damage to heating devices.

Types of antifreeze

Depending on what substance is added to distilled water, the technical characteristics of antifreeze change.

- Glycerin works well as an additive; it is non-toxic and highly soluble, which allows it to be used in the system for a long time without fear of precipitation.

- Ethylene glycol-based antifreeze is the cheapest and most toxic. The second indicator concerns its ingestion, when it can lead to death. If you handle it carefully and check the system for integrity, it will not cause harm and will serve for a long time inside aluminum radiators.

- Propylene glycol is the best addition to distilled water in the production of antifreeze. It is non-toxic, does not produce residue, and its only drawback is its rather high price.

Since ethylene glycol-based antifreezes are very popular due to their cost, before purchasing such a product, you need to check its compatibility with the heating system. Such a carrier is used exclusively in autonomous systems with a single-circuit boiler, since if it gets into water, it can cause serious poisoning, even death.

Antifreeze containing ethylene glycol cannot be used in open heating systems. In the case of fumes, the damage can be equally irreparable.

On the other hand, coolants that include propylene glycol or glycerin are completely safe and can be used in all types of individual heating systems.

Historical excursion

To begin with, I’ll briefly talk about the history of engine building. The first motors were designed and implemented about two hundred years ago. Previously, there were no antifreezes, and they had not yet figured out how to use water as a coolant. As a result, the engine was cooled naturally - using air.

Literally a few years later, a water-cooled motor appeared, which subsequently began to be actively introduced. The first antifreezes were developed only in the 19th century, and were produced in the form of layered, alcohol or glycerin (with the addition of sugar and honey) formulations. Only at the beginning of the 20th century did substances protect internal combustion engines from the negative effects of corrosion go on sale.

How to choose the right antifreeze

In order for the coolant to be truly effective, you should know which antifreeze for aluminum radiators is optimal.

- Any type of antifreeze has a heat capacity lower than water, so more radiator sections will be required.

- The battery size should also be different. Since this coolant expands greatly when heated, it needs 50% more capacity than water.

- You should make sure that the boiler in the heating system is suitable for working with antifreeze.

- All joints need to be checked and made sure that the seal is not broken. If flax fiber is used as additional gaskets in the heating network, it will have to be replaced with rubber analogues.

- Antifreeze is not friendly with zinc, so you need to check all fittings and pipes to ensure that there are no products made of this metal among them.

How to pour antifreeze into the heating system

As professionals advise, a heating system using antifreeze should be planned before installing it. It must take into account such nuances as the power of the boiler, the material of the pipes and shut-off devices, the presence of an expansion tank through which the coolant is supplied to the system.

If the product is introduced into a system that previously operated on water, then a lot of work will have to be done to recalculate the power and size of its radiators, thoroughly rinse or replace the pipes.

If you need to add coolant to the heating system, you can only use the same brand as when filling it for the first time. Different types of antifreeze enter into a chemical reaction, causing the formation of sediment, and the additional additives they contain will be neutralized.

To summarize, we can say that non-freezing coolant has a number of advantages that attract many consumers. Thanks to antifreeze, aluminum radiators last much longer. It is important to follow safety rules and not use the product without protective gloves, and in the case of an ethylene glycol-based carrier, also a mask.

Until recently, all houses were heated using conventional cast iron radiators. Today the situation has changed and they have been replaced by aluminum, steel and bimetallic heating radiators, i.e. there was a choice.

Let's look at the advantages and disadvantages of each type, try to determine which one is better suited for an apartment or a country house and calculate the heating radiators.

Cast iron heating radiators

Cast iron batteries were installed in all standard apartments. Now they are also in demand, although to a lesser extent, mainly for apartment buildings.

Cast iron heating radiators are highly inert, i.e. They take a long time to warm up when heat is applied and take just as long to cool down. It is necessary to take into account that one such cast iron section has a volume of 1.45 liters, which is a disadvantage, especially for suburban buildings.

A significant drawback is that water hammer is dangerous for such batteries, because cast iron itself is a rather fragile material. The average pressure that cast iron batteries can withstand is 9 kg/cm2 at a temperature of 130 0 C.

The appearance leaves much to be desired, so they are often covered with special screens for a more aesthetic appearance. They require constant painting, because... The cast iron on the outside is constantly rusting. They are heavy and inconvenient to use.

Positive properties include the price and the ability to expand additional sections.

Cast iron radiators are resistant to corrosion and have high thermal conductivity. One cast iron section produces 160 W of heat.

Comparison of working environment parameters of different types

| Characteristics | Unit change | Water | Antifreeze |

| Heat capacity | kJ/(kg*K) | 4,19 | 3,5-3,7 |

| Thermal conductivity at 20 °C | W/m*K | 0,605 | 0,433 |

| Density | g/cm3 | 0,998 | 1,04-1,075 |

| Prone to corrosion | There is activity | No activity | |

| Hazard Class | 5 safe | 3-4 moderately hazardous substance | |

| Viscosity | mm2/s | 1,002 | 5,8-7,1 |

| Freezing point | °C | 0 | -35…-65 |

| Boiling temperature | °C | 100 | 104-108 |

| pH level | 7 | 7,5-9 |

Aluminum heating radiators

Aluminum batteries have good heat dissipation, about 190 W, and low inertia, i.e. able to heat up quickly when heat is applied. They can withstand operating pressure of about 20 atmospheres, so they can be installed with centralized heating. It is possible to expand individual sections if necessary.

For a private developer, it is important that one aluminum section has a volume of about 0.37 liters, which allows saving on heating water or antifreeze in the heating system.

Aluminum is a soft metal in properties, so it is sensitive to various solid and debris particles. This is mainly true for houses with central heating. For a private developer this is not particularly important. But still, if you have chosen aluminum radiators, it is recommended to install additional filters along with them to collect various dirt in the system.

Aluminum radiators differ in the manufacturing process. There are cast and stamped. Stamped batteries are not recommended for installation in houses with central heating because... they are sensitive to the quality of the coolant.

Aluminum is a reactive metal, which means it has some disadvantages. When in contact with other metals, a so-called galvanic couple can form at the junction. This is where metal corrosion occurs. To do this, the various parts of the heating system are connected to each other using adapters, which prevent the metals from coming into direct contact, and therefore prevent the corrosion process.

If you use antifreeze as a coolant, then there is a high probability of corrosion inside the battery because... it reacts with aluminum, which reduces efficiency. Therefore, it is better to use such radiators in a country cottage, where the coolant is water.

When heated, the inside of aluminum radiators reacts with the coolant and, over time, hydrogen begins to be released and accumulates. To ensure that hydrogen does not linger in the pipes, a special valve is installed that slowly releases it. Aluminum heating radiators have an aesthetic appearance and do not require additional painting.

- high efficiency;

- elegant design;

- withstands high pressure;

- light section weight.

- possible corrosion due to low-quality antifreeze;

- it is necessary to remove air using a valve.

Main characteristics

The main technical characteristics are:

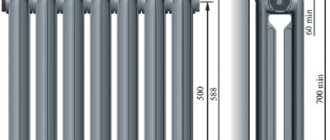

- The depth of the section is usually from 7 to 12 cm, the width is 8-10 cm, and the height ranges from 37 to 57 cm;

- Working pressure reaches no more than 18 atmospheres;

- 200W is the power of each section;

- The radiator weight is quite large. The weight of each section can be from 3 to 7 kg;

- The section volume is 0.7-1.5 l;

- The average service life is 30-50 years.

- Radiators made of cast iron are superior to other batteries in many ways.

Bimetallic heating radiators

Bimetallic heating radiators, as the name implies, consist of two metals and combine their best properties.

As a rule, they have a steel core, which allows them to withstand high pressure, as well as an aluminum shell, which has high heat transfer.

Can be installed in a central heating system.

Such bimetallic batteries have a modern design, quickly heat up and cool down, and have high efficiency.

In appearance they are not much different from aluminum radiators.

Advantages of bimetallic radiators:

- high heat transfer;

- withstands high pressure;

- modern design;

- greater reliability;

Calculation of heating radiators

In order to correctly calculate the number of required sections, you need to know some reference data. These data show how much heat needs to be spent to keep the room warm. All values are given for an area of 10 m2.

- For a panel house you need 1.7 kW;

- For a brick house 1 kW;

- For corner rooms, we multiply this data by a factor of 1.2.

Now you can easily calculate the required number of heating radiator sections.

Example: Room 15 m2, corner, brick house. We divide the area of 15 m2 by the estimated area of 10 m2 and multiply by 1 kW.

15m 2 /10m 2 *1kW=1.5 kW.

Because We have a corner room, then this value must be multiplied by a factor of 1.2. We find that to heat such a room, 1.8 kW of heat is needed. Then you need to select the required heating radiator. This data must be contained in the battery data sheet. Here are just some approximate capacities for various radiators.

- cast iron - 160 W one section;

- aluminum - 190 W one section;

- steel - 450-5700 W for the entire panel;

- bimetallic - 200 W one section.

It turns out that if you decided on bimetallic heating radiators, then you will need 1.8 kW/0.2 kW=9 sections. Take more stock in one section because... It is easier to reduce the temperature in the room than to install an additional section.

What to put in the heating system

This question arises only for private developers, because only they have a choice. What is better to fill with water or antifreeze depends on the boiler and pumping equipment, heat exchangers, heating pipes, etc.

Water is the cheapest and most accessible liquid. It is used for heating in private and multi-storey construction, but it has a number of disadvantages.

It must be operated at positive temperatures. When freezing, a breakdown of pipes, boiler, etc. may occur, which will lead to failure of the entire heating system. Therefore, if you turn off the heating of the house, you will have to drain all the water from the system.

The water used for heating is usually not distilled and has many different impurities. When heated, various chemical reactions occur, which leads to the appearance of salts on the inner surface of pipes and heating radiators. As a result, efficiency is lost and efficiency decreases.

In heating where water is used, any type of radiator can be installed : cast iron, aluminum, steel, bimetallic .

The main property of antifreeze is freezing at lower temperatures compared to water. The service life is about 10 heating seasons, after which it is better to replace it.

With such heating, elements containing zinc cannot be used, because it will disintegrate and settle on the inner walls of pipes, boilers, batteries, etc.

Let us remind you once again that if you use antifreeze, it is better not to install aluminum heating radiators, but instead purchase steel or bimetallic heating radiators; you can, of course, use cast iron ones, but they are increasingly becoming a thing of the past.

Quite often, many owners of autonomous aluminum radiators use ordinary water to fill them. This negatively affects the operation of the heating circuit, reduces its service life, promotes corrosion, and ultimately disables the system. Today, you can use many other liquids designed specifically for use in radiators. The most common of these is antifreeze.

Advantages and disadvantages

When choosing antifreeze to fill into a radiator, you should select a special composition intended for these purposes. Antifreeze refers to a special liquid that does not freeze at low temperatures. Special solutions for heating circuits contain special impurities and additives that do not harm the radiator and maintain its stable operation.

Antifreeze is very durable, so this coolant can be used for quite a long time.

Among the negative aspects of antifreeze, several factors can be noted.

- The thermal capacity of antifreeze is low. Such liquids are 115% inferior to water in this indicator.

- To use this coolant in a radiator, a special pump is required to start the entire system, since fluids for heating circuits have a high viscosity. Therefore, they must be accelerated by a pump for the system to start working.

- Antifreeze has high fluidity. For this reason, special attention should be paid to welds and connections on the radiator.

- Some compounds are extremely toxic and harmful to human health.

Such toxic antifreezes should never be used in conjunction with hot water supply.

But despite the above-mentioned disadvantages of this type of coolant, it is perfect for use in aluminum circuits with an autonomous heating system.

The most popular brands of refrigerants

Today there are several brands that deserve attention from drivers. The following companies produce good auto chemicals for aluminum engines:

- "Tosol-Sintez" A Russian company that produces antifreezes of the popular Felix line. There are four types of compounds that have different properties.

- Liqui Moly. German manufacturer. The compositions from this company are very high quality and today are among the leaders in sales.

- Motul. A French company that pays special attention to the biological safety of materials and the complete safety of users.

- "Obninskorgsintez" A Russian brand engaged in the development and production of Sintec antifreeze.

Various antifreezes are popular in Russia. In addition to these, we can also highlight Long Life and Nord.

Types of antifreeze

Antifreeze has different properties depending on the content of various impurities in it.

Let's look at some of the most commonly used types of coolant.

- Glycerol. This composition is practically non-toxic and harmless. It dissolves well and has a long service life in radiators. This composition does not cause harmful precipitation in the system.

- Ethylene glycol compounds. This radiator filler should be handled with extreme caution, as it is very harmful and toxic. The advantage of this type of coolant is its low cost. Otherwise, this coolant is suitable for use in heating circuits. Such an admixture is usually used as a base for coolant.

- Propylene glycol. Unlike the previous coolant, this type of radiator fluid has a fairly high cost. But otherwise, it has the most positive qualities - harmlessness to health, long service life, prevention of precipitation in the radiator.

In some situations, a simple radiator coolant can be made on your own. To do this, you need to mix distilled water with 40% ethyl alcohol. This composition is less viscous and is quite suitable for use in contours. But it is worth remembering the proportions. When temperatures drop to -10 degrees, you need to use about 20% ethyl alcohol in the total volume of the solution. At lower temperatures, for example, -23 degrees, you need to use a little more than 30% alcohol in the composition.

At such low temperatures, it is common to mix one liter of alcohol with three liters of water.

Ethanol compounds

The significant cost of this antifreeze for aluminum radiators often becomes a serious obstacle to its use in private autonomous systems. The composition can be obtained from distilled water and 40% ethanol (ethyl alcohol). The quality of such a solution is superior to the factory analogue in certain parameters. The matter mainly concerns its low viscosity (although compared to water it remains quite high). There is also a decrease in fluid fluidity, which makes it possible to be less demanding on the connecting areas.

The use of homemade ethanol antifreeze for heating radiators has a beneficial effect on the safety of the rubber sealing gaskets that are present in any circuit. It is recommended to dilute alcohol with hard water: in combination with ethanol, it will become a serious obstacle to the formation of scale on the inner walls. In this case, you cannot do without solid sediment, but you can easily get rid of it by flushing the system. In cases where the percentage of ethyl alcohol in water does not exceed 30%, it will not evaporate.

Due to the fact that the coolant for aluminum radiators is similar in its characteristics to water, its boiling point is approximately the same as that of water. This suggests that when the temperature reaches + 85-90ᶷ, no steam release will be observed. Thanks to ethanol, the thermal expansion of water is reduced by an order of magnitude, which allows the system to more comfortably tolerate lower temperatures in the room.

When should you not use antifreeze?

It is not possible to use a special coolant in all cases.

There are restrictions on the use of such formulations.

- Antifreeze cannot be used in the heating circuit of electrolysis boilers.

- The use of these coolants in open heating systems is strictly prohibited, since many compounds are toxic. This mainly applies to those compositions based on ethylene glycol, but glycerin or propylene glycol can be used in open systems.

How to fill coolant into an aluminum radiator?

Typically, many heating systems are made specifically taking into account the further use of antifreeze in them. The power of the boilers and the materials used in the system itself are planned. But this doesn't always happen. A situation often arises when you need to pour a special coolant into a radiator that previously used water. In this case, some recalculations related to the boiler power should be made.

And it is also strongly recommended that the pipes be thoroughly cleaned or completely replaced.