In winter, at least 25% of the heat is lost through the roof of an uninsulated building; the losses are compensated by increased heating. Of course, the load falls on the heating system and entails increased energy consumption. A budget-friendly way to solve the problem is to insulate the ceiling in a private house; the attic remains cold. The overlap is smaller than the roof slopes in area, hence the savings. Our task is to tell you how to properly insulate a ceiling by first selecting the appropriate materials.

Why is ceiling vapor barrier necessary?

Rockwool ceiling vapor barrier is an excellent way to protect and extend the life of a wooden floor, which:

- significantly extends its service life, eliminating rotting from the inside and deformation of building materials;

- increases the percentage of heat retained by the ceiling in the room;

- makes the attic an inaccessible place for mold and mildew to form.

In addition, it is worth paying attention to the absolute absence of the need for further additional maintenance of vapor barrier materials, given their composition and the design of the entire floor. Therefore, by installing a vapor barrier on the steam room ceiling during the initial construction or during repairs, you don’t have to worry about possible problems in the future

Video description

Which insulation divides heat better, watch the video:

Advice! When working with penoizol, it is recommended to wait until it hardens completely; it has a slight shrinkage that will have to be compensated to prevent the formation of voids.

The process of thermal insulation of the ceiling with foam insulation Source lestorg32.ru

Vapor barrier for attic pie

- Attic floor (ladders) - necessary for maintenance, repair of the roof and attic space. In order to get to the attic, provide an attic ladder with an insulated hatch (Thermo). To exit from the attic to the roof, we recommend installing blind or glazed exit hatches (Velux, Vilpe, etc.) on the roof.

- Para- or super-diffusion moisture-proof membrane - for effective removal of steam from insulation.

- Insulation - mineral wool slabs. Recommended thickness for the Moscow and Leningrad region is 300mm. 200 mm are laid in the space between the beams, the remaining 100 mm are laid perpendicular to the laid layers - counter-insulation. For comparison, building codes in Finland determine the thickness of insulation from 400 to 500 mm. It is recommended to delay the installation of insulation as much as possible - no earlier than 6 months after the completion of the construction of the house frame. Because For the construction of floors, timber with natural moisture is mainly used. The timber must dry thoroughly, otherwise there is a high probability of wood being damaged by fungi and mold, which entails additional costs for dismantling/installation work and treating the wood with bleaches and antiseptics.

- Counter grille and ventilated gap. For effective ventilation and removal of steam from the surface of the moisture-proof membrane.

- Floor beams. As a rule, in private housing construction a 50x200mm board or 100x200mm natural moisture timber is used.

- Lathing is the basis for laying insulation. It is recommended to use a 100x20 (25) mm board as lathing and lay it in increments of 70-80 mm. The resulting cracks will form an additional air thermal layer under the insulation. That. The insulation slabs (mats) will not lie on a vapor barrier film, but on a rigid base, already under which there will be a vapor barrier. This solution eliminates the possibility of accidental damage to the vapor barrier or its pushing through when laying insulation, during maintenance and repair work of the roof and attic. In this case, you can begin interior decoration of the premises, and postpone the installation of insulation as much as possible (see above).

- Vapor barrier of the attic floor on wooden beams

- is attached using a construction stapler from below to the rough ceiling (lathing), which allows you to cut off vapors from the entire floor structure. It is necessary to overlap the vapor barrier rolls by at least 15-20 cm and carefully glue them with aluminum adhesive tape. It is necessary to form overlaps on the walls of 15-20 cm and carefully glue them (place them under plaster and other wall finishing). Carefully seal the places where chimneys, ventilation pipes and other utilities pass through the attic floor using special hoses. The best material for vapor barrier is high-density polyethylene film of 200 g/m² and above. - We close the attic - the finished ceiling is attached to the vapor barrier

. The finished ceiling (OSB, gypsum board, etc.) is installed along the sheathing and guides. For the best fire protection, it is recommended to “sew up” the ceiling with 2 layers of plasterboard sheets.

Which material to choose?

And since all this work is carried out using the same type of materials, the choice will be based only on the ratio of price and quality. Most often, for the vapor barrier of Ondutis ceilings, they use: ordinary polyethylene film or polypropylene, foil, special waterproofing and vapor barrier membranes.

The main advantages of using polyethylene film:

- affordable price;

- you can lay the film yourself without additional knowledge or outside help;

- additional strength is achieved when used in conjunction with reinforced mesh.

But the film creates a not very comfortable indoor climate and may not last as long as other vapor barrier materials.

- more durable material than standard polyethylene;

- has an additional moisture-absorbing cellulose layer;

- Condensation removal is achieved by ventilating the space between the waterproofing and insulation.

The use of foil polyethylene film allows you to simultaneously create an excellent vapor and heat insulation layer, thanks to the foil and metal mesh. This film has quite good characteristics for long-term use in any residential area and works much better, in contrast to standard one-sided polyethylene.

Membrane hydro- and vapor barrier film is today considered the most advanced material that fulfills its duties 100%. Thanks to the special design, it allows the entire room to “breathe”, which creates very comfortable conditions for people. The cost of membranes is, of course, higher than that of polyethylene, but this difference in price is completely justified.

Additionally, such membranes can be divided into three more types:

- Membranes with limited hydropermeability allow you to remove all excess moisture from the room. The percentage of moisture extracted is controlled due to the specific design of the material.

- Membranes with variable permeability are a more advanced design that begins to allow a greater amount of moisture to pass through, depending on its current concentration in the room.

- Foil membranes are very widely used in the construction of bathrooms, swimming pools, saunas and baths. Thanks to their design based on a metal mesh, they allow not only to control the level of humidity, but also to return a certain percentage of heat back into the room.

The complex Izospan system is used in the construction of not only floors and roofs, but also walls. Regardless of the manufacturer, it is an almost universal set of materials that can replace both individual elements of thermal, hydro and vapor barrier, and all together. Each roll of such material of any brand of the Izospan system has a convenient installation diagram and instructions for use. Buying such material is also not difficult - today it is a fairly common type of building materials. For information on how to properly insulate a ceiling, see here.

Advantages of a cold attic

The advantages of choosing a cold attic are that:

- Waterproofing is much more reliable. The fact is that when creating a warm attic structure, the integrity of the rolled waterproofing is in any case interrupted by superstructures, which significantly reduces its reliability. In the design of a cold attic, add-ons should be done to a minimum.

- Maintenance becomes as simple as possible. An attic is an attic and often something needs to be corrected or replaced, which is as easy as shelling pears with this design. There is a lot of space, repairing a cold attic is convenient and practical.

- The heat-transfer surface area is minimal. With this design, there is only minimal heat loss from those rooms that are located directly under the attic.

- Possibility of operation. As mentioned above, such an attic can be easily adapted both for storage and for other needs of the owners. Depending on the method of entry into the attic, whether it is a ceiling hatch from the living room, or a door from the street, even feed supplies can be stored in it, if we are talking about a rural house.

What is it for?

Vapor barrier is a special material that is not capable of allowing moisture to pass through. These products are designed to protect insulation, as well as internal surfaces in the house from possible moisture penetration.

If this material is not used, a significant amount of water may condense on both sides of the ceiling. The liquid will penetrate into the pores of building materials and lead to the formation of fungus, destruction of the structure of the support beams on the roof of a cold attic, etc.

Indoors, high humidity negatively affects the finishing of walls, ceilings and floors.

What kind of film to put under the insulation in the attic All about insulation and energy efficiency

When ensuring insulation of a private house and insulation of the roof along the rafters, one must not forget that special attention should be paid to such a place as the attic. Development of attic floor insulation with mineral wool

Development of attic floor insulation with mineral wool

Warm air tends to rise to the top, and therefore, in a temporarily unheated room, heat can escape through the cold attic space. Therefore, the issue of insulating the attic must be resolved without delay.

1 Why do you need attic floor insulation?

Insulating a cold attic floor with stone or mineral wool is generally necessary in lightly used rooms that are properly equipped with special roof ventilation.

The attic, or rather its ceilings, serves as a kind of boundary between heat and cold. In such places, the attic floors are exposed to intense moisture due to the formation of condensation.

However, you can properly insulate the floors in the attic of a house with mineral wool with your own hands. The very process of insulating the floor in the attic with mineral wool is the creation of a durable thermal insulation coating, which will have a low degree of thermal conductivity.

The technology itself for insulating mineral wool floors in the attic, as well as Energoflex thermal insulation for pipes, implies strict adherence to its stages and requirements.

The technology itself is quite simple and understandable. Good attic floor insulation using mineral wool helps close unwanted gaps.

To do this, the insulation must be laid tightly. In most cases, mineral wool is used to insulate the attic of a house.

The presented insulation is the most suitable for this type of work; it can also be used to insulate the floor surface in the living areas of the house.

Schematic insulation of the attic floor with mineral wool

By organizing good insulation with mineral wool, the most optimal temperature will be maintained in residential premises.

If the procedure is performed incorrectly, moisture rising from the floor of the house will lead to the formation of condensation.

It will accumulate on the ceiling and then seep through the ceilings. The resulting temperature difference in those areas where the attic floors adjoin the walls of the house initiates the formation of mold and microscopic fungi, which can be causative agents of allergic diseases.

1.1 Requirements for attic insulation

The process of insulating the attic floor and insulating the roof of a house with your own hands, or rather the level of its quality, has a direct impact not only on the size of heat loss, but also on the service life of the entire truss structure and roof covering.

The fact is that water vapor located inside the heated room diffuses to the attic of the house. In order for the insulation used to provide a high degree of calculated efficiency of the thermal insulation layer, it must always be dry.

Based on this, the insulation must be protected from excessive humidification by vapors of rising heated air using a special vapor-proof material.

Application of new technologies

Among modern materials used for thermal insulation of ceilings, the following are most in demand:

- Polyurethane foam

. Refers to new and quite expensive thermal insulation materials. Its characteristics have much in common with extruded polystyrene foam. This insulation is not afraid of moisture, it has a long service life - manufacturers provide a 50-year warranty on it. But polyurethane foam, similar to extruded polystyrene foam, is a waterproofing material, and since it is applied in a continuous layer, it is not suitable for wooden floors. - Penoizol

. It is a widely advertised material. But in reality it is ordinary foam plastic, but in a liquid state. In addition to all the previously described advantages of this insulation, penoizol is applied without gaps, which means that the material is recommended to be used only for thermal insulation of concrete floors. - Ecowool

. It is considered the most suitable choice of insulation for the ceiling. For its production, natural cellulose is used, adding a binder, antiseptics and fire retardants. Ecowool absorbs water, but its level of water absorption is lower than, for example, mineral wool. At the same time, their vapor permeability and thermal conductivity are almost the same.

An important feature of using foam insulation is that their application requires the use of expensive compressor equipment, and with the participation of professionals. An exception is the installation of glass wool, which in a dry state can be poured independently onto the floor of an unheated attic. If it is necessary to carry out insulation from the inside, a compressor will also be required for ecowool.

Steam and thermal insulation of a cold attic

For a roof with a cold attic, it is most important to minimize heat loss through the attic floor. Vapor barrier is mandatory for both wooden and reinforced concrete floors

It is laid on the ceiling itself and protects the insulation from vapors that can condense in the heat insulator after passing through the ceiling of the living room. Slab and bulk materials can be used as insulation. The ceiling pie consists of a vapor barrier, floor beams and insulation.

The following types of heat insulators are often used in ceiling coverings:

:

- expanded polystyrene and foam boards;

- mineral wool slabs or mats;

- expanded clay granules;

- fuel or granulated slag;

- sawdust with lime or clay;

- pumice.

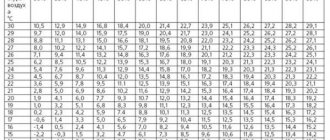

The thickness of the required insulation layer is selected depending on the estimated winter temperature using the table below.

Winter temperatures are calculated according to SNiP 2.01.01-82 (building climatology and geophysics) or selected by regions of the Russian Federation from the corresponding climate maps.

The insulation is laid between the joists or ceiling beams, and a boardwalk is made on top for the attic passages. Joists are usually 50 mm thick, and decking boards are 25-35 mm thick.

Attic waterproofing device

Waterproofing roofs with a cold attic, according to many experts, is a controversial issue. Some say that waterproofing must be present under the roofing material, while others categorically recommend that it be abandoned. Here, a lot depends on the type of roofing material and the angle of inclination of the roof slopes.

Metal roofs are most susceptible to corrosion, which occurs due to possible small leaks or condensation

Therefore, we once again draw your attention to the fact that ventilation plays one of the main roles in the fight against condensation.

For flat metal roofs, experts recommend installing superdiffusion membranes. It will prevent moisture from entering the outside of the roof when snow or rain blows in. No matter how well the roof is laid, there is always the possibility of minimal leaks. That is why, by paying a little extra, you will receive additional protection from moisture getting on the insulation in the ceiling of a cold attic.

If, for example, slate is used as a roofing material, then waterproofing can be abandoned. There is also corrugated sheeting with an anti-condensation coating on the market, which can hold up to 1 liter of water per 1 m2. For our part, we recommend always using waterproofing membranes, because this is the cheapest and easiest additional way to protect your roof from possible leaks

.

When installing waterproofing membranes, a counter-lattice is used. It serves as a fixing strip and, due to its height, provides the necessary clearance for ventilation of the under-roof space. The installation of lathing in a cold attic is no different from insulated roofs. The dimensions of the sheathing and its pitch determine the type of roofing being installed.

Cold attic temperature

To prevent ice and icicles from forming on the roof, it is necessary to maintain the correct temperature and humidity conditions in the attic. If the thickness of the thermal insulation material is insufficient, significant heat losses occur through the ceiling. Warm air, heating the roof covering, causes snow to melt and ice dams to form. By choosing the right insulation layer, this can be avoided.

The effectiveness of a heat insulator can be assessed by measuring the temperature of the top layer of insulation. The electronic thermometer is immersed in insulation by 10-20 mm. The temperature readings taken should correspond to the values in the table below.

As you can see, the design of a cold attic pie is not particularly complex in design. The main task is to ensure the necessary intensity of ventilation and the thickness of the thermal insulation layer in the ceiling.

We will install copper roofing quickly and efficiently

Option No. 1 – foam insulation

The work of laying this heat insulator is not difficult:

- Concrete slabs generally have a flat surface, so surface leveling problems rarely occur. All you have to do is putty the joints between the plates, or better yet fill the cracks with polyurethane foam.

- The next step is to apply a deep penetration primer to the ceiling twice. Since smooth concrete has low adhesion, without this treatment the required effect will not be achieved.

- Next, they take pre-prepared sheets of insulation, spread them with adhesive and apply them to the ceiling surface. Many craftsmen place them without gaps, as densely as possible. But there will still be gaps between the sheets, so they are initially glued with a gap of 5 - 7 millimeters. Then the gaps are filled with foam, the coating is continuous.

- But polystyrene foam should not be left in this state, since it is a flammable material and the ceiling looks ugly. Its surface needs to be plastered. To do this, apply a layer of Ceresit CT83 3–4 millimeters thick with a spatula and immediately embed a reinforcing fiberglass mesh in it.

- Next, to be on the safe side, the foam plastic is additionally secured with umbrella dowels, which requires a hammer drill. A hole is drilled in the concrete through the thickness of the ceiling insulation, a plastic dowel is placed in it and the central rod is driven in. For one square meter of such fasteners you will need 5 pieces.

When everything is dry, begin applying the decorative finish. If you don’t want to use Ceresit CT8, you can use any starting plaster, but before doing this, the foam should be primed.

If the ceiling is to be insulated with this material in a wooden building, then the insulation is laid between the load-bearing beams to their entire depth and the gaps are foamed. The ceiling is hemmed from below, and it is better to fill the subfloor on top, since you will have to move around the attic. In this case, installation of a vapor barrier is not required, since moisture is not dangerous to the foam.

Despite the fact that there is a large selection of adhesive compositions on the construction market, experts most often use the following three options:

- "Liquid Nails"

. High-quality glue, but the process of applying it is not easy and therefore when using it you need to follow the instructions. - Polyurethane foam

. A pattern of it is applied to a sheet of foam plastic. Then they apply insulation to the ceiling. Next, the sheet is pressed against the surface several times over the course of an hour, since the foam expands and until this process is completed, the material will move away a little. - Dry mix Ceresit CT83

. It is simply diluted according to the instructions, applied to the sheet using a notched spatula and glued. If such a tool is not at hand, it is necessary to lay “buns” at several points and attach the insulation.

Peculiarities

Most of the warm air masses escape through the roof. Therefore, when building a house with an uninsulated attic, you need to carefully approach the topic of insulating the attic floor with wooden beams. After all, it creates a certain barrier between warm rooms and a cold attic.

Let's consider the special criteria for attic insulation that affect the maintenance of temperature in the house:

- Purpose of the room.

The attic is a kind of buffer between the environment and the living rooms. Its task is to regulate the temperature difference between the external environment and the house. - Temperature regime.

In any season and on any day, the temperature of the air masses in the attic will always be higher than outside the window. This is why the attic is very cold in winter, and unbearably hot and stuffy in summer. - Heat loss in winter.

The more a substance heats up, the less dense it becomes. This is a physical phenomenon. This is why in residential premises with a heating system, warm air from household appliances is concentrated in the ceiling area. That is, if you do not insulate the ceiling, then in winter all the warm air will warm the attic.

- Excessive heat in summer.

In summer, the reverse process can be observed. The roof, heated by the rays of the sun, will warm up the attic air, which, in turn, will penetrate into the room through the attic floors. - Reverse circulation of air masses.

In contact with the ceiling without thermal insulation, warm air becomes cold, more dense and, as a result, sinks to the floor. This is reflected in the living space in the form of circulating drafts that cause harm to human health.

- The appearance of excess moisture.

When it comes into contact with an uninsulated attic, hot, humid air turns into condensation. The overall level of humidity in the house increases, which leads to mold growth in the corners. - Saving

. The heat lost through the roof without insulation is about 30%. This means that with proper insulation of the attic floor, you can save 30% of the fuel used. Using air conditioning in the summer will also cost less.

The entry of warm air masses into a technical attic (non-residential) leads to negative consequences:

- Due to the mixing of warm and cold masses, condensation may appear in the attic. Water falling on the surface can lead to rotting of wood on load-bearing beams.

- If the attic is warm, the snow collected on the roof will begin to melt. The water dripping at the same time will begin to turn into icicles. Ice forms on the drainage system.

Video description

Insulating the ceiling from the inside, watch the video:

The process of insulating the ceiling from the inside with polystyrene foam Source nl.decorexpro.com

Thermal insulation of the ceiling from the inside with polystyrene foam boards Source barmanlive.ru

Vapor barrier membranes

Diffuse (breathable) membranes are classified as the most effective and expensive vapor barriers. This group of products contains both single-sided and double-sided materials

The former allow steam to pass through only in one direction, so during installation it is extremely important not to confuse which side to lay the fabric towards the insulation and which to the load-bearing surface. Double-sided ones work in both directions, so there are no problems with them

Vapor barrier membranes can be single-layer or multi-layer. The first ones have an affordable price. Multilayer ones have the function of accumulating moisture inside the canvas and gradually releasing it.

A special group of products in this category are “smart” membranes. They are able not only to absorb vapors, but also to regulate the level of humidity of surrounding materials, while simultaneously acting as a water barrier. These membranes are the best choice. But their cost is beyond the means of most private home owners.

Vapor barrier membranes "TechnoNIKOL"

The undoubted leader in this category of materials is TechnoNikol membranes. For vapor barrier of wooden ceilings, the “Optima” brand is recommended for use. This hydrophobic polypropylene membrane consists of three layers:

- upper and lower polypropylene;

- medium – high-tech functional vapor-permeable film.

- weight 80 g/m2;

- thickness 0.3 mm;

- vapor permeability 5 g/m2x24 hours.

The TechnoNIKOL Optima membrane is produced in rolls. The width of the canvas (roll height) is 1.5 m. The length is 50 m. This material is optimal for vapor barrier of any type of ceiling, intended for installation indoors and on external surfaces of buildings.

Superdiffuse reinforced membrane

Diffusion membrane films "TechnoNikol"

Rules for installing a vapor barrier for a wooden ceiling

Step 1. The membrane is laid directly on the insulation so that the smooth side is directed inside the room.

Step 2. It is possible to lay the strips in different directions: parallel or perpendicular to each other.

Step 3. During installation, an overlap of at least 10 cm must be observed.

Step 4. To attach the membrane to a wooden floor without insulation, use galvanized screws with wide heads or staples with an anti-corrosion coating.

Step 5. The joints of the canvases are sealed using self-adhesive mounting tape.

Use foil tape, width 50 mm, length 30 lm.

Step 6. When laying on a floor with insulation, it is necessary to bring the edges of the panels onto the wall by 15-20 cm and secure them with suitable materials (slats or metal profiles).

Step 7. Mounting tape is glued along the perimeter of the vapor barrier layer.

Step 8. Between the membrane and the material with which the wooden floor will be lined, leave a ventilation gap 3-4 cm wide.

Step 9. Particular attention is required to the places where the vapor barrier comes into contact with the structural elements of the floor and the building: beams, chimneys, ventilation ducts.

Ceiling vapor barrier in wooden floors

During installation of the vapor barrier, it is necessary to ensure that the film is laid evenly, without folds or sagging. A guideline for correct installation can be a colored stripe, which is the center line along the entire length of the canvas.

Video - Ceiling vapor barrier

An equally good choice are multilayer vapor barrier membranes of other brands: Dorken Delta REFLEX/REFLEX PLUS and Dorken Delta LUXX. The first is a four-layer material, is particularly durable and can provide 100% waterproofing of a wooden floor. The second has limited vapor permeability, ensuring gradual and uniform removal of moisture from the living space.

Expanded clay, vermiculite, perlite

These bulk insulation materials are made from mineral raw materials - clay, shale, volcanic rocks. High-temperature swelling results in the formation of porous granules with low thermal conductivity.

Mineral materials do not burn, tolerate waterlogging well, and shrink little. But there is a significant drawback - it is quite heavy in comparison with fibrous or polymer heat insulators.

A higher load may not be critical for load-bearing structures if they are calculated with a margin. But bringing, pouring out and leveling several dozen cubes of expanded clay in the attic is not such an easy task. For comparison, the weight of 1 cubic meter of mineral wool weighs 50 kg, foam plastic - 35 kg, and expanded clay of fractions 5-40 mm - 300-400 kg. In terms of an attic area of 100 sq.m and a layer height of 25 cm, the result is 7.5-10 tons.

The second drawback is that a fairly thick layer is required. Its thickness should be determined by calculation. On average, it is 25-30 cm. In the southern regions, it is allowed to reduce the thickness of the insulation to 15-20 cm. In the northern regions, it should be increased to 35 and even 40 cm.

Bulk materials must be protected from moisture from steam. To do this, a vapor barrier made of dense film is spread on the base under the insulation layer. There is no need to cover the top with anything; moisture evaporation should occur naturally.

Floor design

Construction and floor of the second floor in a wooden house

Before proceeding to a detailed description of creating the correct “pie” for the first floor, it is worth noting the constituent elements and technical rules.

- Priming. The ceiling of the first floor separates the room from the underground space, the surface of which is soil. The soil becomes a source of moisture entering wood structures, which can negatively affect their technical properties. Therefore, this surface must be waterproofed. There is no need to waterproof the second floor.

- Ventilation must be provided in the underground space so that moisture penetrating from the ground is evaporated and does not enter the floor ceiling.

- Brick pillars on which wooden floor beams lie.

- Wooden beams. The beams serve as a supporting element for the floor joists. Depending on the step at which the beams are laid, the choice of the thickness of the boards for the supports depends. The structure should easily tolerate possible loads without deforming the floor.

- Logs are transverse boards lying on the end sides. They serve as the basis for laying the finished floor in the form of floor boards or using plywood or other tile backing.

- Insulation material is filled between the bars. In this case, it is necessary to take into account that there is a gap between the insulation and the finished floor for ventilation.

- Vapor barrier and waterproofing, allowing you to protect the insulating material from moisture entering it.

- Finish floor with or without sheet and tile backing. When using boards, they are laid on bars, and finishing coatings such as laminate, parquet, tiles are placed on a leveling layer of tile material.

When using an insulated coating, it is necessary to take care of damping gaps for ventilation under the floor.

Option No. 2 - installation of mineral wool from the inside

It can be done in two ways. The first of these is similar to gluing and plastering foam. The second option, no less common, is internal installation, carried out under a suspended sheathing, which is installed on concrete or wooden ceilings.

The frame for the sheathing can be made from wooden blocks or from two types - UD and CD profiles. Experts recommend using metal products, since they will not move in the event of a temperature change.

The sequence of actions is as follows:

- First of all, a horizontal line is struck along the perimeter of the room at the level of the future ceiling plane. The easiest way to do this is with a laser level, but if you don’t have one, you can use a hydraulic level, which is a long soft tube with graduated tips that operates using the communicating vessels method.

- Then, according to the applied markings, two UD profiles are fixed on two opposite, longer walls.

- Perpendicular to them, the location of CD profiles is marked on the ceiling, usually observing an installation step of about 50 centimeters.

- In accordance with the markings, the perforated suspensions are secured with dowels at intervals of one meter, their wings are bent downwards.

- Next, they begin to glue the mineral wool slabs to the ceiling. The insulation under the wings of the suspension is cut with a knife.

- To complete the work, CD profiles are inserted into the UD profiles and fastened to each other and to the hangers using self-tapping screws. Now you can begin covering the frame with plasterboard or other finishing material.

Choice of insulation

The methods of insulating the ceiling of the upper floor of the ceiling along beams in a private house are very diverse. When doing the work yourself, the insulation is placed between the joists and provides reliable thermal insulation and noise protection. There are many options for insulating a structure, the most common of which are:

- insulation with mineral wool;

- laying expanded polystyrene (foam plastic or penoplex) on wooden beams;

- filling with expanded clay;

- insulation with sawdust;

- filling the ceiling space with foam.

Each of these options has its own characteristics and advantages.

Mineral wool insulation

The material is available in two versions: plates and rolls. Insulating the attic floor with mineral wool has the following advantages:

Styrofoam

Foam plastic has become one of the most common materials for thermal insulation. It has earned its place in the top three thanks to its very attractive price. Using this insulation in an individual home provides the following advantages:

- high degree of protection;

- resistance to rotting and mold and mildew;

- low degree of water absorption;

- ease of installation and no need for complex tools and protective equipment;

- the light weight of the material prevents excessive load on the structure and allows for insulation from below.

Extruded polystyrene foam

More often this material is called a shorter word - penoplex.

Being the closest relative of foam plastic, penoplex is devoid of most of its disadvantages. In the process of improving performance characteristics, the cost has increased. The material is produced fireproof, it has sufficient strength for use as a base for flooring and is light in weight for use in ceiling construction. Do-it-yourself installation is quite simple. This issue is discussed in detail in the article. The text discusses options for using both penoplex and polystyrene foam for different types of floor construction.

For people who decide to build their own wooden house, the naturalness of the materials is usually important. Here penoplex, like foam plastic, loses to other types of insulation due to its artificial origin.

Expanded clay or sawdust

If you decide to use completely natural materials in your home, these two types of insulation will become indispensable helpers. They do not have high heat-protective characteristics, like previous types, but provide reliable protection from the cold with a sufficient layer thickness. Sawdust can be obtained almost free of charge; expanded clay is also an inexpensive material.

Insulation of the attic floor can be carried out by non-professionals and does not require special skills. The application is limited by the physical characteristics of these materials: they cannot be used for thermal protection from below.

Heat protection foam

Polyurethane foam insulation is a fairly new material in construction. When constructing a building yourself, this method can provide high speed work and reliable protection from the cold. You can read about insulating a building, including attic floors, with foam in the article.

This provides a large selection of materials for insulation and significant savings on construction.

A large percentage of heat losses occur precisely through the ceiling of the upper floor, which is why it is so important to choose the right insulation and follow the installation technology. Are you insulating your house for winter and don’t know how to insulate the attic floor using wooden load-bearing beams? Having gained experience in this matter, I will accurately convey the technical aspects of thermal insulation, and also describe step by step the procedure for carrying out the work

Are you insulating your house for winter and don’t know how to insulate the attic floor using wooden load-bearing beams? Having gained experience in this matter, I will accurately convey the technical aspects of thermal insulation, and also describe step by step the procedure for carrying out the work.

Spray polyurethane foam

To do it yourself, you need to rent a special installation for mixing a two-component composition, which is supplied through a sprayer with nozzles in the form of “snow flakes”.

They stick well to any surface, even those not treated with expensive primers. The advantage is that the tube can be supplied to all hard-to-reach places in attics.

Liquid coatings

A fairly new solution, created thanks to the achievements of chemists. Looks like regular varnish or mastic. It is applied to the surface in the same way as conventional paints. After drying, a special coating is formed that can allow air to pass through, but prevent the passage of water vapor. Such materials are often used to vaporize the ceiling on the cold attic side.

In addition, this will be a very effective solution if flat roofs are treated in buildings that do not have an attic. In this case, a suitable insulation is laid on top of the applied insulation and the entire structure is waterproofed. In some cases, such materials may be harmful to health and can only be used in non-residential premises. Be sure to familiarize yourself with the characteristics of the selected paintwork material.

Required Tools

To carry out thermal insulation work, you will need tools such as: fasteners (screws, screws, dowels, anchors, liquid nails), construction staples, tape measure, hammer drill for working with concrete, screwdriver, hammer, construction knife for cutting sheet products.

The material used is insulation, vapor barrier film or membrane, metal profiles to create a frame, wooden blocks 3x3 cm or 5x5 cm.

Adviсe

Compliance with simple installation rules and operating standards will help to significantly extend the service life of the vapor barrier.

- The film material should be secured using staples or small nails, placing a thin wooden strip under the fasteners. This will allow the material to be better pressed to the base and will reduce the likelihood of accidental damage to the film.

- The size of the overlap when installing any materials should not be less than 15 cm. The joints should be glued using a wide tape, and when installing materials made of foil, you should use foil tape.

- Laying vapor barrier materials should only be done with thermal insulation.

- During installation, it is recommended to carefully monitor the tension of the material: the film should be in a free position. This will prevent the material from rupturing when it is stretched and compressed under the influence of thermal changes.

- To form insulation for the ceiling of a residential building, it will be sufficient to use a membrane or reinforced polypropylene film, and during the construction of bathhouses only foil vapor barriers should be used.

Vapor barrier is one of the prerequisites for the construction of houses and baths with a cold attic.

Properly selected material and proper installation will extend the service life of the ceiling, significantly reduce heat loss and make staying in the room pleasant and comfortable.

For more information about ceiling vapor barrier, see below.

conclusions

We talked about the basic principles of installing vapor barrier films and membranes in insulated wooden floors. The main approach is to protect the insulation from steam and, if water vapor gets into the ceiling, to escape. Those. do not lock the thermal insulation into two layers of vapor barrier , and this mistake is often made. And do not wrap wooden beams with vapor barrier, unless it is a film specifically designed for this purpose. Another nuance - ensure the tightness of the vapor barrier . Overlaps, joints, and junctions with walls, skylights, stove and ventilation pipes must be sealed with materials recommended by film and membrane manufacturers.

We recommend the topic Waterproofing in a cold attic, which tells you whether it is necessary to install waterproofing under the roofing.

- What does improper vapor barrier lead to: real experience and repair methods

- The correct “pies” of a frame wall, which are recommended by FORUMHOUSE users.

- The most complete instructions on the RuNet for installing a roof window with the stages of installing a vapor barrier, a moisture-proof film and a gutter for condensate drainage.