Every person dreams of a beautiful modern home. Often, to create a unique home design, you need to pay a certain amount of money. But this option is not always suitable for everyone, because it is better to use these funds to purchase materials.

The solution to this problem is a standard project, which in most cases can be used as the basis for building a house. Such documents can be provided either free of charge or for a certain price.

Modern projects of two-story houses made of timber include all calculations, which allows for immediate installation of the building.

Standard series for reinforced concrete frames

| No. | Number | Name | Notes |

| 1 | Series 1.090.1-1/88 | Prefabricated reinforced concrete structures of interspecific use for large-panel public buildings and auxiliary buildings of industrial enterprises with a floor height of 3.3 m. | Look |

| 2 | Series 1.090.1-7с | Prefabricated reinforced concrete structures of interspecific use for large-panel public, administrative and domestic buildings with a floor height of 3.3 m for construction in areas with seismicity of 7, 8 and 9 points. | Look |

| 3 | Series 1.100.1-3 | Elements and components of 1-2 - storey monolithic residential buildings for rural construction in non-seismic areas and seismicity of 7, 8 and 9 points. | Look |

| 4 | Series 1.100.1-4 | Elements and components of monolithic and prefabricated monolithic residential buildings for construction in climatic regions II and III under normal engineering and geological conditions. | Look |

| 5 | Series 1.266.1-3 | Folded reinforced cement and reinforced concrete roof structures with spans up to 18 m for public buildings. | Look |

| 6 | Series 1.420-8/81 | Designs of two-story industrial buildings without cranes with column grids of the first floor 6x6, 9x6, 12x6 m, the second floor 18x6, 18x12, 24x6, 24x12 m, floor load up to 5 tf/m2 and reinforced concrete two-story columns. | Look |

| 7 | Series 1.420.1-32 | Designs of two-story industrial buildings without cranes with grids of columns of the first floor 6x6, 9x6 m, second floor 18x6, 24x6 m, floor load up to 5.0 tf/m2 and reinforced concrete columns. | Look |

| 8 | Series 2.400-7 | Assembly joints for prefabricated reinforced concrete structures of one-story industrial buildings. | Look |

| 9 | Series 2.400-12.93 | Assembly joints for prefabricated reinforced concrete structures of one-story industrial buildings. | Look |

| 10 | Series PK-01-17 | Prefabricated reinforced concrete pre-stressed rafter structures. | Look |

Linking the engineering section of the house project

• Engineering support for the house (hot and cold water supply, electricity and gas supply, sewerage) in the finished project is calculated for specific connection conditions. If they do not meet the connection conditions for your site, these sections of the project will need to be revised accordingly.

• In addition, if the height of the groundwater on your site is higher than the base of the house foundations, it is necessary to work out moisture protection measures: waterproofing the foundations and lowering the groundwater level by drainage. To protect the foundations of a house from surface moisture, it is necessary to carry out drainage planning of the site on which it is located.

Typical series for reinforced concrete columns

| No. | Number | Name | Notes |

| 1 | Series 1.423.1-3/88 | Reinforced concrete columns of rectangular cross-section for one-story industrial buildings up to 9.6 m high without overhead support cranes. | Look |

| 2 | Series 1.423.1-5/88 | Reinforced concrete columns of rectangular section for one-story industrial buildings with a height of 10.8; 12.0; 13.2 and 14.4 m without overhead support cranes. | Look |

| 3 | Series 1.424.1-5 | Reinforced concrete columns of rectangular cross-section for one-story industrial buildings with a height of 8.4 - 14.4 m, equipped with overhead support cranes with a lifting capacity of up to 32 tons. | Look |

| 4 | Series 1.424.1-6/89 | Reinforced concrete columns of rectangular cross-section with passages at track level for one-story industrial buildings with a height of 10.8 - 14.4 m, equipped with overhead support cranes with a lifting capacity of up to 32 tons. | Look |

| 5 | Series 1.424.1-9 | Reinforced concrete columns with a two-leg section for one-story industrial buildings with a height of 15.6; 16.8 and 18.0 m. | Look |

| 6 | Series 1.424.1-10 | Reinforced concrete columns of a two-leg section with passages at the level of the crane tracks for one-story industrial buildings with a height of 15.6; 16.8 and 18.0 m with overhead support cranes with a lifting capacity of up to 50 tons. | Look |

| 7 | Series 1.424.1-12 | Reinforced concrete columns of rectangular cross-section for one-story industrial buildings up to 10.8 m high with steel roof structures of the “Molodechno” type. | Look |

| 8 | Series 1.424.1-13 | Reinforced concrete columns for one-story industrial buildings equipped with manual overhead support cranes. | Look |

| 9 | Series 1.823.1-2 | Reinforced concrete columns for agricultural industrial buildings. | Look |

| 10 | Series 1.823.1-3С | Reinforced concrete columns for agricultural industrial buildings for construction in areas with seismicity of 7, 8 and 9 points. | Look |

| 11 | Series 1.423-3 | Reinforced concrete columns of rectangular section for one-story industrial buildings without overhead cranes up to 9.6 m high. | Look |

| 12 | Series 1.423-5 | Reinforced concrete columns of rectangular section for one-story industrial buildings without overhead cranes with a height of 10.8; 12.0; 13.2 and 14.4 m. | Look |

| 13 | Series 1.427.1-3 | Reinforced concrete columns of rectangular section for longitudinal and end timber frames of one-story industrial buildings with a height of 3.0 - 14.4 m. | Look |

| 14 | Series 1.427.1-5 | Prestressed reinforced concrete columns of rectangular cross-section for longitudinal and end fencing of one-story buildings of industrial enterprises. | Look |

| 15 | Series 1.427.1-8 | Reinforced concrete columns of rectangular cross-section for longitudinal and end timber frames of one-story industrial buildings with steel covering structures of the “Molodechno” type. | Look |

| 16 | Series KE-01-09 | Prefabricated reinforced concrete columns of one-story industrial buildings. | Look |

| 17 | Series KE-01-49 | Prefabricated reinforced concrete columns of rectangular section for one-story industrial buildings. | Look |

| 18 | Series KE-01-52 | Prefabricated reinforced concrete two-branch columns of one-story industrial buildings. | Look |

| 19 | Series KE-01-55 | Prefabricated reinforced concrete columns of longitudinal and end half-timbers of one-story industrial buildings. | Look |

conclusions

A standard project is better than none, a completely viable option, but you need to understand that there will still be additional expenses, and it is unlikely that you will be able to build a house completely “for yourself.” Individual design is a real opportunity to provide yourself with the desired level of comfort. Risks exist, but they can be minimized, as can costs - on the scale of the general construction budget, the difference between “stamping” and exclusive is practically leveled out. But a comfortable, presentable and marketable house will remain.

Read more about the specifics of construction according to standard projects in the material “...Finishing it to suit you.” It will also be useful to read about the nuances of designing communications in a private home. The video is about BIM design.

Subscribe to our Telegram channelExclusive posts every week

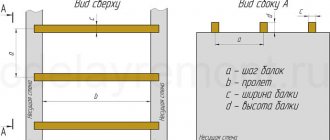

Typical series for reinforced concrete beams

| No. | Number | Name | Notes |

| 1 | Series 1.462.1-10/93 | Reinforced concrete truss beams for roofing buildings with spans of 6 and 9 m. | Look |

| 2 | Series 1.462.1-16/88 | Reinforced concrete I-beams with a span of 18 m for covering one-story buildings of industrial enterprises. | Look |

| 3 | Series 1.462.1-18 | Reinforced concrete rafter beams for one-story industrial buildings with span-long slab coverings. | Look |

| 4 | Series 1.462.1-23 | Reinforced concrete I-beams with a span of 15 m for covering one-story buildings of industrial enterprises. | Look |

| 5 | Series 1.462.1-24 | Reinforced concrete I-beams with a span of 21 m for covering one-story buildings of industrial enterprises | Look |

| 6 | Series PK-01-115 | Reinforced concrete beams with spans of 6 and 9 meters for roofing with roll roofing. | Look |

| 7 | Series PK-01-116 | Prefabricated reinforced concrete prestressed single-pitch beams for roofing buildings with a span of 12 m with a beam spacing of 6 m. | Look |

| 8 | Series 1.438.1-3 | Reinforced concrete strapping beams for industrial buildings. | Look |

| 9 | Series 1.462-1 | Reinforced concrete prestressed beams with parallel chords with a span of 12 m for covering buildings with flat and pitched roofs. | Look |

| 10 | Series 1.462-3 | Reinforced concrete prestressed gable lattice beams for covering industrial buildings. | Look |

| 11 | Series 1.462-12s | Typical reinforced concrete beams in the roofs of one-story buildings with a calculated seismicity of 7, 8 and 9 points. | Look |

| 12 | Series 1.462.1-1/88 | Prestressed reinforced concrete beams with a span of 12 m for covering buildings with flat and pitched roofs. | Look |

| 13 | Series 1.462.1-3/80 | Reinforced concrete truss lattice beams for covering one-story buildings. | Look |

| 14 | Series 1.462.1-3/89 | Reinforced concrete truss lattice beams for covering one-story buildings. | Look |

| 15 | Series KE-01-58 | Prefabricated reinforced concrete beams and lintels for industrial buildings. | Look |

Standard series for reinforced concrete trusses

| No. | Number | Name | Notes |

| 1 | Series 1.063.1-4 | Reinforced concrete trusses with a span of 6; 9; 12; 15 and 18 m for covering buildings with an asbestos-cement roof slope of 1:4. | Look |

| 2 | Series 1.463.1-1/87 | Reinforced concrete trusses without braces with a span of 18 and 24 m for one-story buildings with a low-slope and pitched roof for the V snow region. | Look |

| 3 | Series 1.463.1-3/87 | Non-braced reinforced concrete trusses with a span of 18 and 24 m for one-story buildings with low-slope and pitched roofs. | Look |

| 4 | Series 1.463.1-15 | Reinforced concrete rafter trusses with a span of 12 m with a sagging lower chord for buildings covered with span-long slabs. | Look |

| 5 | Series 1.463.1-16 | Reinforced concrete segmental trusses for covering one-story industrial buildings with spans of 18 and 24 m (in formwork forms of the PK-01-129/78 series). | Look |

| 6 | Series 1.463.1-17 | Polygonal reinforced concrete trusses with a span of 18 and 24 m for roofing buildings with low-slope roofs. | Look |

| 7 | Series 1.463.1-19 | Pre-stressed reinforced concrete rafter trusses with a span of 12 m for roofing buildings with pitched roofs. | Look |

| 8 | Series PK-01-27 | Prefabricated reinforced concrete prestressed segmental trusses for roofing buildings with spans of 18, 24 and 30 m with truss spacing of 6.0 m. | Look |

| 9 | Series 1.463-3 | Reinforced concrete prestressed non-braced trusses with a span of 18 and 24 m for roofing buildings with pitched roofs. | Look |

| 10 | Series 1.466.1-5 | Reinforced concrete multi-wave shells of positive curvature measuring 18x24, 18x30 and 18x36 m from 3x6 m slabs. | Look |

| 11 | Series PK-01-129 | Prefabricated reinforced concrete prestressed segmental trusses for building roofs with spans of 18, 24 and 30 m with truss spacing of 6 and 12 m. | Look |

| 12 | Series PK-01-129/68 | Prefabricated reinforced concrete prestressed segmental trusses for building roofs with spans of 18, 24 and 30 m with truss spacing of 6 and 12 m. | Look |

Typical series for reinforced concrete crane beams

| No. | Number | Name | Notes |

| 1 | Series 1.426.1-4 | Reinforced concrete crane beams with spans of 6 and 12 m for general purpose overhead support cranes with a lifting capacity of up to 32 tons. | Look |

| 2 | Series KE-01-13 | Prefabricated reinforced concrete crane beams. Working drawings. | Look |

| 3 | Series KE-01-50 | Prefabricated reinforced concrete prestressed crane beams. | Look |

Standard series for reinforced concrete floor slabs

When designing floor slabs, the following series may be useful:

| No. | Number | Name | View via link |

| 1 | Series 1.065.1-2.94 | Reinforced concrete ribbed slabs 250 mm high for roofing buildings. | Look |

| 2 | Series 1.137.1-8 | Reinforced concrete hollow-core loggia slabs for residential buildings. | Look |

| 3 | Series 1.137.1-9 | Reinforced concrete balcony slabs for residential buildings. | Look |

| 4 | Series 1.138-3 | Reinforced concrete cornice slabs for residential and public buildings. | Look |

| 5 | Series 1.141.1-30 | Reinforced concrete hollow-core floor slabs. For sanitary facilities. | Look |

| 6 | Series 1.141.1-40s | Reinforced concrete hollow-core floor slabs, reinforced with At-V class steel rods, for the construction of residential and public buildings in areas with seismicity of 7, 8 and 9 points. | Look |

| 7 | Series 1.143.1-7 | Solid reinforced concrete floor slabs for residential buildings with transverse wall spacing of 3.0 and 3.6 m. | Look |

| 8 | Series 1.165.1-12 | Coating slabs and lightweight concrete trays for large-panel residential buildings with a warm attic and roofing made of rolled materials. Working drawings. | Look |

| 9 | Series 1.238.1-2 | Parapet reinforced concrete row and corner slabs for public buildings. Working drawings. | Look |

| 10 | Series 1.243.1-4 | Flat reinforced concrete slabs of length 80, 110, 130 and 160 cm, reinforced with welded mesh made of BP-I class steel. Working drawings. | Look |

| 11 | Series 1.442.1-1.87 | Reinforced concrete ribbed floor slabs 400 mm high, laid on crossbar flanges (modified design). | Look |

| 12 | Series 1.442.1-2 | Reinforced concrete ribbed floor slabs 400 mm high, laid on rectangular cross-section beams. | Look |

| 13 | Series 1.442.1-3 | Reinforced concrete ribbed slabs 500 mm high for floors of industrial buildings. | Look |

| 14 | Series 1.442.1-5.94 | Reinforced concrete ribbed floor slabs 400 mm high, laid on rectangular cross-section beams. | Look |

| 15 | Series 1.465.1-15 | Reinforced concrete ribbed slabs measuring 3x12 m for covering one-story industrial buildings. | Look |

| 16 | Series 1.465.1-16 | Reinforced concrete ribbed slabs measuring 1.5x12 m for covering one-story industrial buildings. | Look |

| 17 | Series 1.465.1-17 | Reinforced concrete ribbed slabs measuring 3x6 m for covering one-story industrial buildings. | Look |

| 18 | Series 1.465.1-18 | Complex coating slabs for industrial buildings. | Look |

| 19 | Series 1.465.1-19 | Small-sized reinforced concrete slabs for covering one-story industrial buildings. | Look |

| 20 | Series 1.465.1-20 | Reinforced concrete ribbed slabs measuring 1.5x6 m for covering one-story industrial buildings. | Look |

| 21 | Series 1.465.1-21.94 | Reinforced concrete ribbed slabs measuring 3x6 m for covering one-story industrial buildings. | Look |

| 22 | Series 1.041.1-5 | Hollow-core floor slabs for interspecific purposes. | Look |

| 23 | Series 1.042.1-2 | Prefabricated reinforced concrete floor slabs of the “TT” and “T” types for multi-storey public and industrial buildings. | Look |

| 24 | Series 1.042.1-5.94 | Prefabricated reinforced concrete ribbed slabs 300 mm high for floors of multi-storey public buildings, production and auxiliary buildings of industrial enterprises. | Look |

| 25 | Series 1.141.1-32с | Reinforced concrete hollow-core floor slabs, reinforced with rods made of steel of class A_IV and At-IVC, for the construction of residential and public buildings in areas with seismicity of 7, 8 and 9 points. | Look |

| 26 | Series 1.141.1-39 | Lightweight hollow-core slabs of reduced height for the floors of manor houses. | Look |

| 27 | Series 1.041.1-3 | Prefabricated reinforced concrete hollow-core floor slabs of multi-storey public buildings, production and auxiliary buildings of industrial enterprises. | Look |

| 28 | Series 1.400-11/91 | Recommendations for the use of prefabricated reinforced concrete standard slabs in coverings of industrial buildings. | Look |

| 29 | Series 2.140-2m | Details of floors of residential and public buildings for climatic region I. | Look |

| 30 | Series 2.140-5c | Floor assemblies for residential and public buildings erected in areas with seismicity of 7, 8 and 9 points. | Look |

Advantages and disadvantages of custom design

An individual project is developed from scratch by a professional to meet the requirements and conditions of a specific customer. A second house for such a project can only appear with the consent of the customer, if he decides to share, and it will not “migrate” to the standard section of the performers. IP has enough advantages.

- Exclusivity - in most cases, the house will be in a single copy.

- Originality is a special geometry, a specific layout, and unique space-planning solutions.

- Convenience - a house that is completely designed for itself, taking into account the needs of all household members, always outperforms a standardized one.

- Ideal “fit” - unlike a standard one, which is adjusted to the site as much as possible, an individual one is immediately developed for all the features, which allows you to level out the shortcomings.

Individual projects have two disadvantages.

Victoria Lokhtina

Individual design allows you to take into account all the interests of the client and build a house according to his ideas and needs. However, there are pitfalls here too.

- First, designers often do not have construction experience, and there is a risk of making mistakes and economically unjustified decisions. As a result, changes to an already “ideal” house design have to be made at the construction site.

- Secondly, the price of this service on the market is high; on average, design will cost from 100 to 300 thousand rubles.

Considerable sums, especially if the construction is in economy mode, but they will justify themselves.

I789 FORUMHOUSE participant

Could not find a standard project. We ordered an individual one. The toad was choking terribly. Upon completion of construction, the cost of the project was less than 2%. We received a house that fit us like a good glove for our hand. The result pleases the eye and soul. Take risks, the game is worth the candle.

Plus, there is an opportunity to reduce costs.

Victoria Lokhtina

Why buy a standard project and spend money on remodeling, if you can immediately make it for yourself - quite quickly and quite inexpensively. For example, we offer an individual design service at an affordable fixed price, so as not to make a mountain out of a molehill (usually, during the design process, the price of the project increases, since the actual area is larger than the planned one). We also understand that a project is a tool that should create a clear and optimal construction budget and save the contractor and client from problems during implementation.