One has only to look at the image of smoked delicacies, and the desire to eat it all immediately appears, which is quite natural for a person. Has your appetite also increased? What to do now? The first reaction is to go to the supermarket and buy everything your heart desires (and your wallet allows). But, alas, store-bought products are only called smoked because they are processed with liquid smoke. Opinions differ about the benefits of such nutrition, but if you have a small plot of land, you can set up your own production. In this article we will tell you how a cold smoked smokehouse can be made with your own hands from various materials.

Types of wooden smokehouses and their features

There are two main types of wood smokehouses.

One is suitable for hot smoking, and the other is for cold smoking. Sometimes combined structures are used on the farm. They all differ from each other in manufacturing technology and temperature conditions that must be maintained in the smoking chambers. Depending on the chosen processing option, the taste result of the finished products will also be completely different.

Typically, a wooden smokehouse is designed in the form of a hut or a compact house with a pointed gable roof. The unit is available with flat and pitched roofs. In any case, each type of smokehouse consists of three basic elements:

- smoking chamber;

- combustion device (smoke generator);

- chimney.

A wooden smokehouse is made from hardwood, among which the greatest preference is given to:

- alder,

- linden,

- oak,

- birch,

- cedar.

To create the structure, you will need bars for the frame, plywood or edged boards for lining the chamber.

Expert opinion

Valery Garmash

Chef of the Grill House restaurant, griller

Wood blanks are pre-treated with a special antiseptic. However, it should be borne in mind that the manufacture and installation of a certain type of smokehouse will require an individual approach. This is due to various operating principles and design features.

What kind of firewood can you use?

Firewood from different types of trees

Not all firewood can be used. Firewood from the following trees is best suited:

- plum;

- cherry (without bark);

- pear;

- Apple tree;

- dogwood;

- apricot.

If you need to give smoked meats a tart taste, then the following are suitable:

- elm;

- oak;

- nut;

- beech.

For smoking fish caught in heavily polluted waters, it is recommended to use the following wood:

- willow;

- broom;

- willow.

If there is no firewood from fruit trees or if the smokehouse is made in camping conditions, the following trees can be used:

- Linden;

- poplar;

- alder;

- aspen.

Coniferous trees and those affected by fungus are unsuitable for smoking. In addition, since the pores of the fungus are easily carried by the wind, all trees located within a radius of 50 m around the infected tree automatically become unusable.

Pros and cons of wood

Among the main advantages of wooden smokehouses are the ease of assembly with your own hands and the ability to give the structure any shape. The camera body can be decorated with carved decor or tinted with special impregnations.

Wooden buildings are lightweight and mobile. If necessary, they can be moved; even one person can cope with such a task.

pros:

- environmental friendliness of the wooden blanks used;

- quick replacement of damaged structural fragments;

- the ability to assemble a structure without the use of welding tools;

- low cost and availability of building materials and components.

Minuses

- Wood is susceptible to fire, but this can be avoided with proper operation of the smokehouse. To reduce the negative impact of atmospheric manifestations and sudden temperature changes, the external structure should be treated with special varnishes and impregnations.

For the hot method

Principle of operation

A hot smoked smokehouse involves cooking food using an open fire. The firebox in this design is located directly under the body of the smoking chamber. The resulting smoke from the heat source immediately hits the food hanging inside the cabinet.

Thanks to the high temperature, the cooking process takes from 40 minutes to 4 hours . After hot processing, smoked meats turn out juicy and aromatic with a crispy crust.

Design

A hot smoked smokehouse is a single enclosed space. The dimensions of the structure are selected taking into account the amount of food needed for cooking and the free space in the suburban area.

First of all, a frame is assembled from vertical and horizontal bars. On the sides of the body, crossbars should be provided on which grates for storing products will be placed in the future. At the bottom of the chamber, these crossbars will be needed to install a tray to collect grease.

A non-flammable gasket must be installed between the pan and the base of the smokehouse body, which does not transfer heat to the surrounding walls. For these purposes, you can use basalt foil cardboard or a metal sheet with an asbestos backing.

The bottom and inside of the frame are covered with boards on three sides. They should fit tightly against each other. You can plug the cracks with tow and caulk the joints with hemp rope. The front side of the chamber is partially covered with boards to leave an opening for the doors.

The outer lining of the housing with clapboard or plywood will help improve the thermal insulation properties of the smoking chamber. Foil insulation is placed between the walls to create the effect of a thermos. The door frame is also upholstered on both sides with clapboard or plywood sheets.

The gable roof option is assembled using a rafter system. The frame is then sheathed with boards and completely sealed. A hole is made in one of the ceilings for the smoke exhaust pipe.

A wooden roof can be covered with slate or other roofing material to protect the structure from precipitation. The exhaust pipe is usually made of wooden blocks or metal sheet.

In addition to wooden blanks, to create a smokehouse you will need:

- latches, hinges, door handles;

- nails or screws;

- gratings and hooks;

- indicator for measuring temperature.

A thermometer or thermostat is needed to maintain the set temperature. If desired, a fan can be installed. It is useful for wilting and drying food.

At the last stage, the finished wooden structure is covered with mastic and varnish.

Tips for use

To ensure high quality smoking, it is recommended to follow several tips for operating the smokehouse.

Cold smoked pork is a delicacy that is not embarrassing to serve to guests.

- The fire in the firebox should burn evenly.

- To obtain a rich and pleasant aroma of finished products, wood chips and shavings of plants such as juniper, birch, alder, and branches of berry bushes are used.

- To prevent the fuel from igniting, it is slightly moistened before placing it in the oven.

- If the above-ground chimney becomes very hot under the sun's rays, damp burlap or other dense fabric is placed over the pipes.

There is nothing complicated in building a cold smoked smokehouse. A wide selection of materials allows you to make a temporary assistant within an hour, and a solid one in a few days.

For cold smoking

Operating principle

Cold smoked cooking technology is a longer and more labor-intensive process. It usually lasts from 24 hours to 5 days . In this case, the products are smoked at a temperature of 18 to 30 degrees. The combustion device (stove) is placed at a distance of several meters from the wooden structure so that the smoke cools to the desired temperature. You can also use a cylindrical smoke generator purchased from a store.

Ready-made food after cold smoking does not lose its beneficial composition of microelements and is stored much longer. Smoked meats acquire a smoky aroma, but not as rich as with the hot smoking method.

Device Description

The main components of the design are exactly the same as those of hot-type models. They are also made in the form of a small house, but are arranged differently.

The key feature is that the cooled smoke enters the smoking chamber through a long chimney. Thus, there is no direct thermal effect on the products. In this case, the firebox and smokehouse are located at a certain distance from each other and are connected using a pipe.

the firebox in the ground. It must fit completely into the soil. Loading firewood can be done through the top of the firebox or door. If the soil at the installation site is loose or often subject to flooding, then it is necessary to lay a foundation.

To do this, a hole is dug, corresponding in width and length to the dimensions of the firebox, with a depth of 30 or 40 cm. The bottom is filled with crushed stone, concrete blocks are laid around the perimeter of the hole, which are tied with reinforcement for reliability. At the last stage, cement mortar is poured.

You can arrange a place for the firebox using bricks or metal plates. It should also be ensured that the combustion device has a convenient ash pan and a door to trap smoke in the container.

A ditch for the chimney is laid from the place where the firebox is installed to the smoking chamber . Slate or metal plates are laid in this tunnel. The opposite end of the chimney is connected to the inlet of the smoking cabinet. The junction of the pipe and the chamber should be located at the bottom of the wall of the structure or at its bottom.

Manufacturing process

A pipe is laid and buried in the ditch.

Following step-by-step instructions, any master is able to build a high-quality, beautiful and durable smokehouse.

The collapsible structure is erected in the following sequence:

- The terrain is being marked.

- A ditch is made for the chimney. The pipe is laid and buried in it.

- A pit is dug for the base slab. The bottom of the ditch is compacted, and a cushion of sand and crushed stone is poured onto it.

- Slabs, bricks are installed or concrete is poured.

- The firebox is installed and the chimney pipe is led into it.

All that remains is to make a camera, place it on a pedestal and connect the pipes.

Smokehouse with a smoke generator in the ground

A smoke generator is a metal vessel with holes for air. The product is filled with small chips, branches and sawdust. This solution allows you to achieve fuel savings with acceptable device performance.

The structure is being erected in the following order:

- Digging a trench at least 300 cm long. Laying bricks at the bottom to form a channel.

- Filling the ditch with steel or concrete slabs. Backfilling on top of the ground.

- An excerpt from the far edge of the pit, installing a smoke generator in it.

- Construction of a house starting from laying the foundation and ending with laying the roof.

In all cases, the final stage is decorating the structures.

Do-it-yourself universal smokehouse: step-by-step instructions

The future construction will be universal: it can be smoked cold or hot. The smoke generator will produce warm smoke, and the built-in heating element will heat it to the required temperature.

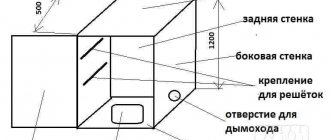

First, a frame is assembled for the future smokehouse. Recommended material is pine timber.

Size - 40x40. The height of the finished frame is 1 m. The width of each side is calculated in the following way: the horizontal beam is cut at 53 cm plus the beam itself is cut at 4 cm. Total: 61 cm.

It turns out that the parameters of the finished frame are 1 m by 61 cm.

Next, a frame for the door is made. The width is 35 cm. At the top it drops to the height of the bar, and at the bottom it rises by 20 cm, because the smokehouse will be hot smoked. In addition, you need to install a heating element - space allows.

The smokehouse is usually stored in the garage, so you will need to constantly move it from place to place. In order not to carry it on yourself (after all, the weight is quite decent), the support for the smokehouse is made of metal and placed on wheels.

Metal pieces of different sizes and calibers are suitable. 2 wheels can be bought in the store.

The metal must first be cleaned if it has already been used, and then welded. This design will be convenient and mobile.

The finished support looks like this:

Paint the product and let it dry.

While it dries, continue assembling the smoking cabinet itself. When it is ready, install it on a dried support (place it on the bolts).

At the bottom, make the mounting holes wider so that when the lining is laid on top, the bolts do not interfere.

The very bottom is made of pine clapboard. Foil is placed on the edges.

Now you need to put the insulation on top of it - lining (linden). The finished back wall and floor look like this:

At this point, the floor should be sealed and insulated from below. On the back surface of the wall there is a niche into which penoplex is inserted. Not necessarily a new, store-bought one, but also an old, unnecessary one will do. Place it in, wrap it in foil, and cover it with pine clapboard on top.

All that remains is to make two side walls and a ceiling. After that, you can hook and hit from the outside.

The box, beaten on all sides and insulated, is almost ready. The main thing is to lay the foil correctly so that you don’t have to disassemble and redo it later.

All that remains is to make a door, a roof, and remove the chimney.

Drill a hole in the middle of the roof. Take a pipe (a regular sewer pipe will do) and cut it to the required height.

The hole is made smaller than the pipe itself so that there is a small margin. On the back of the hole, liquid nails are applied on all sides with your finger.

Again, everything should dry out a little, then apply foil, insulate it, and cover it with clapboard.

Start making the roof. Assemble the front and rear gables. The roof is covered last.

Install a chimney: drill an additional hole to lead it outside.

The roofing is installed as the last thing after all the main stages and modifications.

While the first layer of oil dries, install birch hangers inside - three in two rows, top and bottom. More can be done. It would be better if they were adjustable. So that when necessary, they can be removed and rearranged.

All that remains is to finish painting, hang the door, knock off the edges, corners (if necessary), just trims somewhere, install locks, equip.

A smoke generator is placed on the side.

The hood is installed at the rear.

The smokehouse is sometimes equipped with temperature sensors and the display is placed in a convenient place, for example, in the front, above the door.

The structure of the smokehouse is ready.

You should run it to check if it works. Pour just a little into the smoke generator, just for the sake of testing. Once it is filled, look from below to see if there is any draft: just bring a lit match, by the flame of which you can determine the presence of air movement.

A properly made smokehouse will draw the fire inside, and not weakly.

Next, you need to monitor whether the smoke comes out of the chimney correctly and well and through the gaps at the doors.

Smoking should take place at a temperature of 20 to 25 degrees, so in winter it may be difficult to maintain this regime. It’s a good idea to add additional heating: install a heating element. It turns out that the smokehouse will be both hot and cold smoked.

Useful improvements

In order to make a wooden smokehouse more convenient to use, you can additionally make several more elements.

Drovnitsa

In order to store firewood next to the structure, it is enough to make a firewood shed. To do this, one of the sides of the roof is stretched and placed on special supports. Additionally, the place for firewood can be fenced off.

Temperature sensor with thermometer

With their help, you can easily control the smoke temperature and cook smoked meats, exactly following the chosen recipe.

Smoke generator

Not only a separate firebox, but also a compact smoke generator is used as the main source of smoke. This device can be made on your own or purchased in specialized stores.

The smoke generator consists of simple functional modules, with the help of which the smoking process and the intensity of the smoke entering the smoking chamber are regulated. Installed on the outside of the smokehouse: behind or on the side.

Expert opinion

Valery Garmash

Chef of the Grill House restaurant, griller

There are various options for homemade smoke generators. They have a similar principle of operation, but differ in the elements from which the devices are assembled.

From a used fire extinguisher

It is considered the simplest, but at the same time reliable option. To assemble the structure you will need the following parts:

- empty fire extinguisher;

- chimney;

- air compressor;

- nipple;

- long exhaust for smoke removal;

- transition tee;

- union;

- copper tube with a diameter of 14 mm.

The top of the fire extinguisher is cut off; later it will be used instead of a lid. The lever does not need to be removed; it will act as a handle. Two holes are drilled in the lower part of the body for connecting tubes. One will serve as a chimney, the other will supply air.

From a thermos

For a homemade smoke generator you will need an internal flask, which is removed from the thermos. The housing itself is not required during manufacturing. A hole with a diameter of 30-50 mm is made in the upper part of the container. A pipe of the appropriate size is then welded into it.

On the connected chimney, in its upper zone, 4 cm from the flask, a hole is drilled for a pipe with a diameter of no more than 6 mm. This opening is necessary for connecting a flexible hose from the compressor.

Holes are made in the lower part of the flask for ignition and pouring out wood ash. Condensation will escape through this gap. The operation of a smoke generator from a thermos is as follows: a fuel filler is poured into the bottom of the vessel and ignited, an air mass is pumped into the nozzle from the compressor, which displaces the accumulated smoke into the smoking cabinet.

Every owner of a summer house or country house can build and install a smokehouse on their site. In order for your creation to serve properly for a long time, you must strictly follow the manufacturing technology and fire safety rules.

What can you cook

With the help of a smoking cabinet, regardless of what material it is made of, you can smoke a wide variety of products.

As a rule, meat and fish, a variety of sausages, and chicken are selected for processing. You can even cook vegetables and your favorite fruits using the device. It is very important that all products are properly prepared. Otherwise, the smoked meats will not turn out tasty. Meat and fish must be marinated for some time. Don't forget to have enough salt.

If the smoking cabinet is made correctly and equipped with additional elements, then smoking a variety of products will be very easy and simple. In this case, you can follow the chosen recipe without any problems, and then the smoked meats will turn out even tastier than those that can be purchased in the store.

It is not necessary to buy a factory-made smoking cabinet.

You can make it yourself at home. For this purpose, available materials and a minimal set of tools are suitable. As a supplement, you can use diagrams and drawings presented on the Internet.

Drawings and models

Below we provide drawings and models for making smokers (smokers) with your own hands. You can also contact companies that will manufacture the product to order. You just need to provide the drawing (model) file.

Drawing of a large grill-smoker-smoker in PDF and SLDPRT format

Drawing of a smokehouse with a lid-house and a water seal in DXF and CDR format

Drawing of an octagonal smoker-smoker in STP, IPT formats

Drawing of a simple smokehouse with a water seal in PDF format

Drawing of smokehouse No. 1 with a water seal in DXF, PDF, KOMPAS formats

All drawings of smokehouses

Varieties

The most common are 2 options for smokehouses with their own design features:

- Vertical (shaft). The easiest to manufacture, taking up little space. The smokehouse looks like a kind of cone; products are located on its top. The disadvantages include inconvenient adjustment of the smoke volume.

- Horizontal (tunnel) . More difficult to produce, requiring a suitable site, preferably on a slope.