Design and diagram of a manual hydraulic pump

Diagram of a hydraulic hand pump

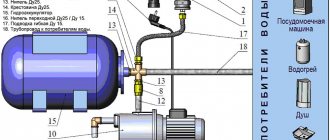

The manual hydraulic pump consists of two main parts, the pumping unit (1) and the hydraulic tank (2). They are connected to each other by a pin (3). You need to fill the liquid through the hole, having first unscrewed the plug that closes it (4). The handle (6) with the lever (7) drives the plunger (8) of the first and second stages, made as one part. The pumping unit has a two-stage structure. Stage number one, with reduced pressure and higher productivity, serves to accelerate the movement of the hydraulic cylinder plunger. Stage number two, at high pressure and lower capacity, serves to obtain the operating force of the actuator. Overload protection is provided by a safety valve (9). Pressure is released and hydraulic fluid is extracted from the cylinder cavity into the tank using a screw (10).

Hatsan devices

These pumps for air rifles are in great demand. However, the devices are not suitable for PP models. The adapter for pumps is used with a jumper. If you believe customer reviews, the hose is installed without problems. The model has three filters in total. The upper valve of the device is made of aluminum alloy. The maximum pressure indicator is 3 bar. In turn, the overbrightness parameter is maximum 6 microns. The plunger mechanism is located at the foot rests. The handle is standardly made with side pads.

The stabilization system is used in the second degree. According to experts, the bar can withstand heavy loads. The spring of the pump is 2.3 cm. The height of the stand is 46 cm. The model's pressure gauge is used with one measurement scale. It has a moisture protection system. The swing valve is of high quality. It keeps the maximum pressure at 2 bar. Pump pushers are used with an expander. You can buy a model on the market for 17 thousand rubles.

Working principle of a manual hydraulic pump

Before starting to work with any pump, be sure to inspect the tool and if cracks and chips are found on the surface, do not use it. It is important to check whether the high pressure hose is tightly connected to the hand pump.

Work algorithm:

- We connect the pump to the hydraulic system with a quick-release coupling;

- Turn the valve all the way clockwise.

- Using progressive movements, pump the pump handle up and down. As a result, oil is pumped into the system from the pump. At the same time, pressure builds up in the system, and the piston of the hydraulic tool moves, into which we pump oil.

- In a situation where the working piston of the system into which oil is poured reaches its final position, increased pressure will be created in the system, as a result it will be impossible to pump oil. Then it is necessary to stop the pump to avoid failure of the device.

- In order to lower the pressure in the system, you need to slowly turn the valve all the way counterclockwise. As a result, oil from the system will flow back into the pump. This occurs due to the return of the piston to its original position.

- After finishing pumping oil, you should inspect the hydraulic system for oil leaks, and you should also inspect the pump. If leaks are found, they should be corrected immediately.

Features of Umarex pumps

The design of the high-pressure pump for Umarex pneumatics is similar to the previous model. A model is produced with two adapters. Its leg stand is made of aluminum type. If you believe the reviews of experts, the top valve used is of high quality. It can withstand maximum pressure of 5 bar. The pump stand is used with a round cross-section. The return spring in the device is provided at 2.5 cm.

The plunger mechanism is installed at the bottom of the structure. The pressure gauge is provided with one measurement scale. It is installed near the jumper. The bottom valve of the model is made of cast iron alloy. The overload parameter for a pump of this type is about 3.3 bar. In total, the device uses three sealing sleeves. The model is perfect for air rifles of the PP series.

The hose included in the standard kit is braided. The adapter for it is matched with a clamping ring. The model is not suitable for rifles of the KR202 series. If we talk about the disadvantages, it is important to note the small handle. The device weighs as much as 4.8 kg. The model's stabilization system is of poor quality. You can buy a pump of the presented series for 13,800 rubles.

Malfunctions and their elimination

- The manual hydraulic pump does not supply pressure. The main reasons for this behavior may be the lack of hydraulic fluid in the tank or the drain valve is not closed. In any case, it is worth checking these versions; if the tap is still closed and there is liquid, then perhaps the reason is that the suction or discharge valve is clogged. Then you will have to disassemble and wash the hydraulic pump valves.

- Oil (hydraulic fluid) is leaking in the gap located between the body and the plunger. In this case, it is highly likely that the O-rings are worn out or damaged. It is recommended to replace them immediately to prevent failure.

- Does not produce the performance specified in the data sheet. Most likely the filter element of the manual hydraulic pump is clogged. It is recommended to thoroughly rinse the filter element.

- Does not develop the pressure specified in the technical data sheet. The safety valve is not adjusted correctly. You need to set the safety valve to the pressure indicated in the data sheet.

Model Gehmann

This high-pressure pump for pneumatics is used quite often by professionals. First of all, it is chosen for its compact size. In this case, the pressure gauge is used with two measuring scales. Its protective glass can withstand heavy loads. If you believe the reviews of experts, the bar rarely deforms. The hose included in the standard kit is braided.

In total, the pump has two in-line filters. The plunger mechanism is located at the bottom of the structure. The advance clutch is installed under the upper valve. Its threshold pressure parameter is 4 bar. The sealing sleeve of the model is made of rubber. The stand is used with a round cross-section. The pressure gauge has a moisture protection system. The device is perfect for air rifles of the KR220 series. You can buy the presented pump in a specialized store for 19 thousand rubles.

How to choose the right hydraulic manual pump?

Choice

Three main selection factors:

1. The hydraulic pump tank must be larger than the hydraulic cylinder capacity.

2. Manual hydraulic pumps come in two types: single-acting and double-acting, pay attention to this parameter.

3. The pressure level should match what you need for work. Select a hydraulic pump with a pressure equal to or greater than the maximum pressure of the hydraulic cylinder.

What is a plunger pump. Operating principle

The main element of the pump is the plunger - a long cylinder-shaped displacer with a small diameter. Unlike the piston type, the seal is located inside the outer cylinder, in which the plunger moves, coming into contact with its walls. During the reverse stroke of the plunger, liquid is sucked into the working chamber through the inlet valve; during forward movement, the inlet valve closes and the liquid is pushed out through the outlet.

Rice. 1. Design and principle of operation of a plunger pump

Is it worth making a manual hydraulic pump yourself?

At the moment, hand-made pumps are almost never found. Despite this, you can make a hydraulic pump with your own hands. We will need a steel tank. The body will be made from it. To control the pressure in the tank you need a valve. It needs to be secured at the top with a washer. A lever is installed to control the closing valve. A cast iron pipe may be suitable. Use a pressure gauge to monitor pressure. In the end, you will end up with a device that will not withstand pressure of more than 4 atmospheres. With all this, a homemade hydraulic pump will take up a lot of space and be inconvenient to carry. The disadvantage of homemade hand pumps is their low efficiency; quite a lot of force will be required to activate the pump. Also, homemade devices are very unreliable. And if you take into account all the disadvantages, then spending resources on creating a homemade manual hydraulic pump is very ineffective. That is why they are not common.

Homemade high-pressure pump from plumbing fixtures

Today we will tell you how to make a high-pressure pump from propylene pipes and other materials that can be easily purchased at any hardware store. Using such a pump, you can easily pump air into an air rifle or a fire extinguisher cylinder.

So, first we need:

- The piston and valve of the pump will be made from a nipple from tubeless tires or, as they say in common parlance, a nipple, which can be bought at an auto parts store

- The rod for the piston will be an aluminum tube 12 mm in diameter

- The cylinder will be a reinforced sanitary PP pipe with a diameter of 20 mm

- Next we need a water socket with ½ internal thread with a crimp on the other end

- Adapter made of polypropylene to ½ male thread

- Brake hose, for example, from a Gazelle

- 10 mm fitting with ½ internal thread

- And the remaining small things - a board, EDP-1 epoxy resin, a rivet, a nipple cap.

Let's start making our pump.

The tubeless nipple needs to be shaped into a cone. To do this, we fix it in a drill and use coarse sandpaper, and then sharpen it with fine sandpaper to the desired shape.

The diameter of the cone head should be 21 mm, given that the diameter of our pipe is 20 mm.

We roughen the edge of the 12 mm aluminum pipe with sandpaper, which will give better adhesion when gluing.

Since the piston is inserted into the tube, mark a point 1 cm above its future location

We drill a small hole at this point so that the tip of the syringe can fit

We treat the nipple with epoxy and insert it into the tube

Next, insert a syringe through the hole and fill the tube with epoxy (preferably heated) so that it fills the air niches.

Next we move on to the cylinder.

We need to weld the fitting to the pipe. But since we do not have a special soldering iron for propylene pipes, we use friction welding technology.

You need to screw a fitting onto the adapter with ½ polypropylene, and the fitting itself needs to be fixed in the drill.

Turn on the drill and insert the fitting into the adapter - thanks to friction, it will warm up and make it easier to climb through..

We take the other nipple and saw off the “hat” from it to the line

Insert the nipple without a cap into the adapter

Fill the free space with epoxy up to the level of the nipple and leave to dry.

Let's move on to making the hose.

Cut off one end

At the second end we grind the thread using sandpaper

We cut off a part of the water socket, as shown in the figure below

Carefully cut the hole with a 9 - 9.5 mm drill

To get rid of useless volume in a water socket, we use cold welding

After the welding has dried, drill holes at both ends of the water socket so that the holes meet

We insert the hose by inserting the o-ring and coating the end of the hose with epoxy

We fix the water socket nut.

In the meantime, this element of our pump is drying, let’s return to “our sheep,” i.e. to the cylinder.

We shorten the polypropylene pipe (20 mm) by 5-7 cm compared to the aluminum pipe.

In the middle of the plug for a 20 mm propylene pipe, drill a hole and screw a bolt and nut into it

Next, using the cold welding principle, we place the plug on the pipe.

We drill a hole in the plug for our aluminum pipe

To allow air to be sucked into the piston, we drill two holes in the PP tube at a distance of approximately 10 cm from the edge

Then we insert the rod into the cylinder, treat the piston with silicone lubricant and push it into the cylinder.

We screw the 20mm pipe into the adapter and fill the gap with epoxy.

Next, we make a connector from a car nipple so that we can pump anything with our pump

To do this we need a metal nipple cap and a rivet

We fix the rivet in a screwdriver or drill and, using sandpaper, grind the head down to 7 mm, and the leg itself to 3.5 mm

We cut several notches like on a fitting

The hose needs to be drilled with a 4 mm drill

Now we insert the fitting into the rivet. We lubricate the inside of the hose and the tip of the rivet with glue and insert it into the hose, further strengthening the adhesion due to the nylon thread.

We proceed to the final assembly of the entire pump

Seal the thread

Place a rubber ring

We screw the cylinder to the water socket, and, in turn, fix it on the board using self-tapping screws.

All that remains is to attach the handle and you can check our pump in action!!

The resulting pump produces 30 atmospheres.

You can increase the efficiency of the pump by increasing the efficiency to 60 atmospheres.

About this, as well as a more detailed video description, see below:

Manual hydraulic pumps NRG

NRG hydraulic pumps are very reliable devices and are very common here in Russia as they are produced here. The NRG line of pumps contains devices with distributors. The letter “P” is usually placed at the end of the designation of such instruments. This letter means that the tool can work with double-acting hydraulic devices. Let's consider several models of NRG manual hydraulic pumps:

NRG pumps

- Model nrg-7020R. Creates a maximum pressure of 700 bar. And it has a nominal tank volume of 2 liters. The kit includes a hydraulic distributor that allows you to work with both single- and double-acting devices.

- Model nrg-7007. Also creates a pressure of 700 bar. The nominal tank volume is 0.7 liters. The advantages of this model are the presence of a safety valve, minimal force on the handle, and two stages of oil supply. This tool is designed for single-acting hydraulic tools with a spring return rod.

- Model nrg-67016R. The nominal tank volume is 14 liters. Handle force 55 kg. Pressure maximum 4 MPa. Capacity is 115 cubic cm. Such a device weighs as much as 30 kg and is quite large. Suitable for a small car service.

Model "Axor"

This high-pressure pump for pneumatics differs from other models by its wide foot rest. This device weighs only 4.6 kg. If you believe customer reviews, problems with the bar rarely occur. The model is suitable for cylinders from almost all well-known manufacturers. The hose is applied at 0.6 meters. The lubricant on the plunger mechanism holds up remarkably well. According to buyers, the stand is made with an excellent protective coating. The device is not afraid of sub-zero temperatures.

However, this pump still has disadvantages. First of all, it is important to note that the buyer may have problems with the pressure gauge. In this case it is used with one scale. It does not have a moisture protection system. If you believe the reviews of experts, the fitting is designed with a small width. This puts a lot of pressure on the spring. The bottom valve of the modification is designed for 4 bar. The pump does not have a drying filter. The protective sleeve is located behind the adapter. The bottom valve is made entirely of aluminum alloy. The price for a pump of this series fluctuates around 15,200 rubles.

Summary, pros and cons of hydraulic hand pumps.

Pros:

- Easy to use;

- Do not require any additional energy source;

- High maintainability;

- Have high mobility;

Minuses:

- Low performance;

- Muscular strength of the operator is needed, therefore, additional load on the operator;

Bottom line, it is reasonable to use a manual hydraulic pump in small workshops and mobile services, where there is no need to pump in large volumes of oil and build up significant pressure. In general, hand pumps are very convenient, and most importantly, they are mobile since they do not depend on any energy sources.

Modifications "Diana"

These high-pressure hand pumps for pneumatics are manufactured with two adapters. A distinctive feature of the model can also be called a wide footrest. The handles in this case are made with side pads, and they are rarely washed. The rod in the device is made of aluminum alloy. According to experts, the pressure gauge used is of high quality. In total, it has two measurement scales. The model has a moisture protection system.

The stand is used with a round cross-section. The upper valve of the device is made of cast iron. The maximum overload parameter is 6 microns. The stabilization system is used in the third degree. In total, the model has two sealing sleeves. The device is perfect for PP series cylinders. You can buy a pump of the presented series for 14,400 rubles.

Conclusions and useful video on the topic

You can make your own pump, piston well pump, pumping mechanism and other pumping equipment. To do this, you will need materials and units that can be found in almost any garage. Suitable waste is from repairs, installation of plumbing systems, decommissioned equipment, etc.

The type of construction is determined by the conditions dictated by the situation. In some cases the driving force is the flow of the river, in others it is the vibrations of the waves. If these factors are not present, you will have to install a device that runs on electricity. And if this is not available, you can use a swing-type pumping mechanism. As a result, in any situation you can get out of the situation.

If the theoretical part is not enough, then videos can be used as visual aids. They tell in detail and show what and how to do to make the pump work efficiently. This will be in addition to the recommendations and instructions given earlier.

The described homemade water pumps can be used for various purposes:

- The equipment will help organize watering in your garden plot. Liquid from the reservoir is pumped into the tank.

- Distribution of water throughout the area. From the tank (even if it is dug into the ground), the liquid also needs to be pumped to the consumer, namely to the beds. You can use a pump for this.

- Fill the tank for industrial purposes. Water used for cooling or other purposes may not be taken from a centralized water supply system, but from a stream, lake, or reservoir.

These designs are of particular importance in cases where the problem needs to be solved urgently. So, for example, if the main pump fails, and it is not possible to repair it (or replace it) immediately. Moreover, most models do not require connection to an electrical outlet.

HelpfulUseless

Application area

Plunger models are special-purpose devices that create very high pressure, so they are practically not used in everyday life. The main areas of their use are the industrial sector, they are used in the following industries:

- In the chemical industry for pumping substances with high viscosity and their precise dosage in the manufacture of chemical compounds that do not react with metal.

- For supplying measured quantities of water and other high-pressure liquids.

- In the oil and gas industry when drilling wells.

- In the energy industry in steam generators.

- In mechanical engineering in the manufacture of hydraulically driven equipment with operating pressures up to 3000 bar, in the automotive industry in injection systems of diesel engines.

- Plunger water pumps are widely used in car wash service centers.

One non-traditional application for plunger pumps is water jetting and cutting materials. At a pressure of about 2000 bar. A jet of water can remove paintwork or rust without leaving any residue. The technology is widely used in cleaning reinforced concrete structures, the sides of ships and runways. A water jet with a pressure of 3500 bar allows you to obtain the highest degree of cleanliness of WJ-1 surfaces according to the international standard.

Diagram of the device from the electric petrol drive

In this case, a jack or a puller can act as an actuator. In this case, the station is attached directly to the pump. For this purpose, only rubber clamps are used, which provide high grip. The pressure gauge is installed as standard near the actuator.

The tap should be mentioned. For a hand pump to work properly, it must be a two-way pump. In this case, the air tank will withstand any load. The safety valve in this system is mounted immediately above the high pressure hose.