Supply ventilation, in which the air is always heated, is one of the ways to maintain a comfortable indoor microclimate. The amount of heated air and other settings are adjusted by the user depending on current needs. Ventilation with heating It features easy installation and a wide selection.

ventilation with air heating

The main difference between supply ventilation systems is that air enters them from outside. Most air conditioning systems operate on a slightly different principle. The air not only increases or decreases the temperature, its composition becomes enriched with oxygen. If there is a constant need for warm and enriched air indoors, the solution will be relevant.

The system is perfect for different types of objects:

- Industrial premises.

- Apartments.

- Private houses.

The spent composition and the one coming out of the equipment do not mix with each other thanks to the modern design. The system simultaneously works for heating and cleaning. They are usually installed in apartments and private houses with plastic windows. Indeed, in such conditions, natural ventilation is associated with some difficulties.

forced ventilation with heating

Regardless of the type of structure, the following main elements are included:

- Electric heating elements or water heaters.

- Electric heating elements or heaters. They heat the incoming air masses.

- Filter to clean the incoming air. But they need to be changed at least every six months.

- valve . It blocks the passage of hot or cold air depending on what time of year it is. The electric drive makes the operation of this component automatic.

- Air-shaped grille. It is needed for aesthetic design and serves as a kind of barrier.

There are details that are not mandatory:

- Recuperators.

- Noise muffler.

- Diffusers.

- Fans.

What is forced air ventilation with air heating?

Ventilation with an influx of air masses differs from standard air conditioning systems. The principle of its operation is to draw air from the outside. Thus, in addition to cooling and heating, such ventilation enriches the room with oxygen, while conventional air conditioning systems simply circulate the air in the room.

The supply air is heated in the ventilation unit. The heated supply ventilation unit has high heat transfer. Therefore, even during severe frosts, ventilation continuously supplies masses of fresh hot air.

Ventilation with heating is carried out through air exchange. Circulation and heating of the influx of air masses is carried out in supply and exhaust units with a recuperator. Air drawn from outside is heated in the recuperator due to the temperature of the exhaust air masses. The recuperator prevents the mixing of “exhaust” and supply fresh air.

Another way to heat the supply ventilation is through recirculation. With this heating method, fresh air masses are mixed with “spent” ones. The influx of air from the street is heated to the desired temperature and supplied to the room.

Using a recuperator

Currently, a very popular ventilation system is a supply system equipped with a recuperator. Indeed, the temperature in the apartment all year round ranges from +18C to +27C. Why not use this in a supply and exhaust ventilation system. How it works?

Air coming from outside passes through a recuperator, in which warm air from the room heats incoming cold air without mixing with each other. In the summer, everything happens the other way around: warm air leaves the apartment and is cooled by air entering from the street. Everything is extremely simple. There are three types of recuperators:

- Lamellar.

- Rotary.

- With intermediate coolants.

The cheapest and therefore most popular is a plate recuperator, but, in fact, the most effective is a rotary unit. Unlike its cheap brother, the rotary recuperator can operate at temperatures below – 15C. The use of such a device allows you to save up to half the heat or cold in the apartment, thanks to which you can significantly save on gas, electricity, and on the installation of air conditioners and split systems or heaters.

Use of compact supply systems

Today there is a compact supply ventilation system that has proven itself very well.

The installation is really small, and also energy-saving, providing an influx of already purified and heated (or cooled, depending on the time of year) air into the room. Inside this box there is a fan that supplies air from the street, a filter that purifies this air, a recuperator, the principle of operation of which we discussed above, and automation that regulates the operation of the devices. The exhaust air is sucked in by a second fan, passes through the recuperator, where it gives off its heat (or cold) to the incoming air and is discharged outside the room. Convenient and efficient. Installing it in an apartment is extremely simple:

- First of all, choose where to install it.

Important! Experts recommend installing such systems in rooms with the greatest concentration or frequent use by people.

As you can see, independent installation of supply and exhaust ventilation of this type is not particularly difficult, but breaking through a load-bearing wall is not so easy. Use a hammer drill and protective equipment for this: glasses, gloves, etc. If the work is carried out in a high-rise building, then it is best to hire professionals to do it.

The need for supply ventilation with heating

Supply ventilation is a proven way to ensure normal air exchange in an apartment. It is necessary to replace heavy stale air not only in the kitchen or in the bathroom: in all rooms where residents spend the bulk of their time, care must be taken in advance to supply fresh air from the street.

According to the old standards adopted back in Soviet times, for each person constantly staying in a living room, a minimum of 60 cubic meters is required. m of fresh air per hour. A similar indicator is relevant for a bedroom or children's room.

For an area with periodic occupancy, for example, a living room, the minimum threshold for the amount of supply air is 30 cubic meters. m/h. Modern European standards for supply ventilation system performance are lower and offer 30 and 20 cubic meters. m/h per person for rooms with permanent and periodic stays, respectively.

However, even a reduced flow of fresh air from the street can significantly affect the temperature in the entire apartment. Cold air masses increase the load on the heating system, reducing its efficiency. As a result, energy is wasted, which is spent on warming up the cooled air.

Additionally, staying in a room with low air temperature can cause hypothermia and provoke the occurrence of certain diseases.

A cold room and high humidity due to poor ventilation are an ideal environment for the development of mold, which not only spoils repairs, but also causes significant damage to health

These problems can be solved with the help of an air heater, which is installed on the supply ventilation of the apartment. For the domestic climate, such a unit in the ventilation system is an urgent need. When the temperature outside the window noticeably drops, an air heating element will be the only effective way to prevent drafts and keep the house warm.

A ventilation system with an air heater allows you to simultaneously compensate for heat loss and saturate the internal climate with the necessary volume of fresh air masses.

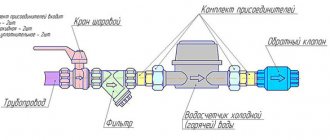

Connection diagram

There are many schemes and methods for placing equipment and organizing air exchange. The choice of a specific scheme depends on the type of room (apartment, private house, office), the dimensions of the system, and its equipment (read about the arrangement of ventilation in an apartment here).

For example, when organizing ventilation in a private house, the simplest scheme with an air supply device in the corridor or hallway is often used. In houses and apartments, the hallway communicates with almost all rooms, so heated, purified air can be supplied into it, which will be distributed throughout all rooms.

Before you begin to develop or apply a circuit, you need to carefully calculate the air flow.

Attention

If the calculation is made for private housing construction, then the air flow for the operation of the boiler room is added to the result obtained using the standard formula. If the house has local exhaust devices (pipes, hoods), then their performance values will have to be included in the calculation.

Design features of the device

Main elements of supply ventilation

- Air intake grille. Acts as an aesthetic design and a barrier that protects debris particles in the supply air masses.

- Supply ventilation valve. Its purpose is to block the passage of cold air from outside in winter and hot air in summer. You can make it work automatically using an electric drive.

- Filters. Their purpose is to clean incoming air. I require replacement every 6 months.

- Water heater, electric heating elements - designed to heat incoming air masses.

- For rooms with a small area it is recommended to use ventilation systems with electric heating elements, for large spaces - a water heater.

Supply and exhaust ventilation elements

Additional items

- Fans.

- Diffusers (contribute to the distribution of air flow masses).

- Noise muffler.

- Recuperator.

The design of ventilation directly depends on the type and method of installation of the system. They come in passive and active action.

How to use a fan heater

The main purpose of a fan heater is to heat air masses. For more intense circulation of flows, the fan forces air into the air. This makes this device universal.

Options for operating the fan heater:

- This device can be used as the main source of heat supply to a room that does not have central heating.

- The fan heater can complement the main heating system.

- For heating construction sites and workers on them.

- For quickly heating air in a small room.

- The fan heater can be used as a regular fan: in winter for heating, in summer for cooling the air.

- For ventilation and heating of enclosed spaces.

Types of heated air ventilation

Ventilation systems with heated supply air are divided into two main types.

Central ventilation

As a rule, supply fans with air heating are responsible for the supply temperature. Heating is carried out using a heater, which can be electric or water. The first operates from the mains, the second is built into the central heating system. Some air heaters are equipped with a recuperator, thanks to which heat exchange is possible between the heated air exhausted outside and the cold air supplied from the street.

Central ventilation is, without a doubt, a very functional system. However, it has its own requirements: it needs a lot of space for placement, it will have to involve specialists for design, and installation will require a complete renovation. And most importantly, significant financial investments will be required.

Compact supply ventilation with air heating - breather

This is a small household device that hangs on the wall and supplies fresh air to the room. A ceramic heating element heats the incoming air, and the climate control function allows you to set it to the desired temperature. In addition, the device purifies the air using a three-stage filtration system. It traps dust, dirt, soot, pollen, allergens, pathogens and odor

Installation of the breather takes only one hour and does not spoil the repair. Therefore, if you need effective and convenient ventilation in your apartment with heated air, a breather may be the best option.

Principle of operation

Heated supply ventilation is very simple in operating principle. At the first stage, air is drawn in through the air intake and filtered from large debris and insects. After this, air is transferred directly to the device body.

At the next stage, the incoming air is specifically purified from all small particles. To do this, there are several thin filters in the inlet for varying degrees of purification.

After thorough cleaning, the air flows directly to the heating elements. If the device has the ability to control heating, then it occurs only within the specified parameters. After heating, another cleaning process starts, during which the air is freed not only from dust, but also from pollen, other allergens and odors.

As a result, purified and sufficiently warm air enters the room, the temperature of which can be controlled from the control panel.

Operating principle of compact heated ventilation

- First of all, the air from the street passes through the air intake, closed with a plastic grille. It does not interfere with the flow of air, but it prevents large contaminants, fluff and insects from getting inside.

- Next, the air goes through a through channel in the wall - an air duct. The walls of the air duct are insulated using heat and sound insulating plastic pipes. All joints are treated with sealant. This protects the wall from freezing.

- At the junction of the air duct with the device body there is an automatic damper. If the device is turned off, it will automatically close so that cold air from the street does not enter the room. It also closes when the incoming air becomes colder than set by the owner. The breather operates down to a temperature of –40°C.

- Passing through the heater, the air is heated to a set temperature using the climate control function. The user specifies the desired supply air heating temperature (up to +25°C), and it is maintained automatically.

Thanks to this device, the breather eliminates the occurrence of drafts even in the most extreme cold. The air temperature is maintained at a comfortable level without effort on the part of the user.

Blowing the car

To speed up the drying of passenger cars, blowing with cold or heated air is used.

After washing, cold air is blown using a powerful blower installation of Sirocco type fans, which force air into air distribution pipes with slotted nozzles at an angle of 60° to the surface being blown.

The installation for blowing air after washing cars consists of three fans 1 brand EVR-6, driven by electric motors with a power of 20 kW. To direct the air stream, each fan is equipped with a rectangular shaped nozzle 2. The installation is mounted on frame 3 and enclosed in a casing.

The disadvantage of drying with cold air is the significant energy consumption (the power of the fan motors reaches 60 kW). However, the use of warm air due to its low thermal conductivity (250 times less than the thermal conductivity of iron) is also not effective enough due to the too low heat utilization coefficient.

A promising method of drying a car can be considered the use of lamps with infrared rays, as well as thermoradiation drying with dark infrared panels with high efficiency. and slight heat loss.

Types of systems

The supply ventilation unit with air heating is available in several types. This can be central ventilation, which will heat a large industrial premises, or an office center, or it can be individual, for example, in an apartment or in a private house.

In addition, all heated ventilation systems are divided into the following types:

- With recovery. Essentially, this is a heat exchange system when incoming masses come into contact with outgoing masses and exchange heat. This option is suitable only for regions with not very cold winters. These systems belong to passive ventilation schemes. It is best to place them near radiators.

- Mermen. This heated air supply operates either from a boiler or from a central heating battery. Its main advantage is energy savings. Supply ventilation with water-heated air is especially popular among consumers.

- Electrical. They require quite significant electricity consumption. According to the principle of operation, it is a simple electric heating element that heats the air with its constant movement.

Before choosing one specific model, it is recommended to sit down and calculate how much electricity you will have to spend to heat your apartment or private house.

Supply ventilation may also differ in the method of pumping air into the room. There are natural options, and there are forced ones, when air is taken in using fans. The types of ventilation also differ according to the type of control. These can be manual models or automatic ones, which are controlled using a remote control or from a special application on the phone.

Parts that make up the ventilation system

Supply ventilation with air heating for an apartment includes several main parts on which the quality of operation of the entire system depends. Such details include:

- Air filter.

- Shut-off valve.

- Heater.

- A fan that blows air.

- Noise muffler. It makes the entire device operate as quietly as possible.

The most important parts in the supply ventilation are the air (shut-off) valve, the filtration element and the heater. With the help of an air valve, air will enter the ventilation only when necessary. Filtration cleans all incoming air as much as possible and prevents dust particles from entering the house.

Thanks to the fan, air enters the room from inside. If the device is turned off, air intake will not take place.

Based on the principle of operation and its characteristics, a heated air supply for an apartment is not suitable for those rooms where there is too much moisture and gas is constantly formed. Therefore, it is better not to hang the vent in the kitchen and bath.

We recommend that you read: Recirculating kitchen hood without duct

Types of filters for ventilation

What filters are needed to capture all of the above? There are three types of household air filters:

1. Class G filters

: G1, G2, G3 and G4. They are designed for large contaminants. Most of the medium and fine dust will pass by them. Therefore, a supply fan with a filter (single) of this class is suitable only for environmentally friendly areas.

The higher the class number, the higher the retention efficiency. For example, the G1 filter filters on average 60% of large particles, and the G4 filter – up to 95%. This is true for filters of any class.

2. Class F filters

: F5, F6, F7, F8 and F9. Such filters “catch” smaller particles: dust (except fine dust), pollen, microfibers, soot, etc.

3. Class H (E) filters

, also known as HEPA (EPA) filters: H10 (E10), H11 (E11), H12 (E12), H13 and H14. The specialty of such filters is the smallest particles. HEPA filters even cope with PM2.5, against which filters of lower classes are powerless.

There are also more effective filters: Class U filters, which are used to purify the air in areas where a sterile environment is required, for example, in pharmaceutical production. However, for household supply or exhaust ventilation with filtration, such cleaning is redundant.

Separately, it is worth highlighting carbon filters and adsorption-catalytic filters (AC), containing a special mixture of sorbents and catalysts. The active substances in such filters “cling” to gas molecules and hold them in their pores. Such filters are good protection against odors and harmful emissions.

| FILTERS SPECIALIZATION: | |

| Major pollution | Filters G |

| Medium and fine dust | Filters F |

| Micropollutants, PM2.5 | HEPA filters |

| Pollen and mold spores | Filters F |

| Odors and harmful gases | AK filters |

Connection diagram

There are many schemes and methods for placing equipment and organizing air exchange.

The choice of a specific scheme depends on the type of room (apartment, private house, office), the dimensions of the system, and its equipment (read about the arrangement of ventilation in an apartment here). For example, when organizing ventilation in a private house, the simplest scheme with an air supply device in the corridor or hallway is often used. In houses and apartments, the hallway communicates with almost all rooms, so heated, purified air can be supplied into it, which will be distributed throughout all rooms.

Before you begin to develop or apply a circuit, you need to carefully calculate the air flow.

Attention If the calculation is made for private housing construction, then the air flow rate for the operation of the boiler room is added to the result obtained using the standard formula. If the house has local exhaust devices (pipes, hoods), then their performance values will have to be included in the calculation.

Supply system device with heating function

Technically, the design of the supply air unit is not a high-tech device. True, the latest developments in this area, aimed at providing specialized areas of the national economy with air supply machines, have stepped far forward.

Industrial structures are equipped in accordance with the latest technology:

- control controllers;

- electric motor speed regulators;

- control and analysis sensor systems;

- effective filters and recuperators;

- air heating (cooling) modules;

- channel cut-off mechanisms.

As a result, the treatment of outside air is achieved at a truly high level, which contributes to the creation of a favorable atmosphere inside the work premises.

Is it possible to do something similar for use in a private home?

Industrial high-tech system for the supply and processing of external air, equipped with full automation, capable of stable operation with the support of periodic maintenance

Perhaps, for a single-family private house, such air treatment is quite acceptable.

But for implementation in a city apartment, this is already a difficult task. The complexity of the task for a city dweller is determined by various nuances - both technical and economic.

Design features of the heated “inlet”

To better understand the complexity of the task, let’s consider the classic design of an air supply unit with functions for additional processing of street air.

First of all, the purely installation factor should be taken into account. After all, an air treatment system is a rather large installation that requires the allocation of part of the room area.

Relatively small-sized branded supply and exhaust systems are produced, designed for sub-ceiling installation. For cases with private houses, this approach can be considered

The default “inlet” design contains:

- electric motor;

- impeller;

- air capture diffuser;

- air injection diffuser;

- duct shut-off valves;

- filters;

- air channel system.

In order to ensure stable heating of the air flow forced by the fan impeller, a heating system is installed after the discharge diffuser.

Types of heating systems for ventilation

Technologically, in conjunction with forced ventilation, use a water or electric heating system. Or it is possible to use two heating options simultaneously, which, although rare, occurs when operating industrial supply air processing machines.

Implementing a water option in a domestic environment (in an apartment) for arranging ventilation with heated air with your own hands is an extremely difficult task, especially if you plan to operate the supply system in winter conditions.

Execution of the air handling unit, where a water heater is used as an air flow heater. This option, however, is extremely problematic to implement for urban conditions, but is possible for a private single-family home

Water heating requires reliable control and mandatory protection against “defrosting” of the water circuit. To achieve high heating efficiency, the water circuit must be made with a multi-pass, multi-row design. Such a heating device must be removable. We recommend that you familiarize yourself with the types of water heaters for supply air and their operating principles.

The introduction of an electric heater into the design of a home air supply system promises to result in somewhat less difficulties. However, in this case, electricity consumption will inevitably increase, and, accordingly, monthly costs.

To ensure heating of the supply air electrically, it will be necessary to install powerful electric heaters (TEH).

An example of an apartment project with heating

The modern market for technological equipment, in particular, fans and electric heating elements of various designs, theoretically makes it possible to implement a home “warm air supply” project. For example, it is quite possible to consider a design based on a duct fan.

This is what the design of a duct axial fan looks like - a device theoretically suitable for the manufacture of a heated home air-handling unit

The design of an axial fan, for example, is well suited for an apartment project. This device is small-sized, lightweight, low-noise. The equipment is distinguished by relatively low energy consumption with fairly high productivity. Supports step-by-step speed control, which is also relevant for home “air-fitting” when making it yourself.

However, in addition to the axial duct fan, you will need to select an electric heater (TEH), a design that would ensure full heating of the air mass passed by the fan.

That is, it is necessary to calculate the power of the heating element sufficient for maximum performance of the Dospel device.

For calculations you can use the following formula:

Qt = L * 0.36 * (Tv – Tn),

where: Qt – heating element power; L – duct fan performance; Tv and Tn – air temperature inside and outside.

Additional components in the “inflow” scheme

Having decided on the selection of the main components of the apartment supply system - a fan and a heater, you should consider options for providing other accessories. In particular, equipping the air handling unit with a coarse air filter. That is, we are talking about creating equipment in a complex.

The rules for the installation of fresh air ventilation necessarily require the introduction of an air filter of cleaning class “EU3”, no less, which must be placed in front of the electric (water) heater. One of the main functions of the filter is to separate small dust particles from the incoming air.

If there is no filter, the electric heating element or water heater quickly becomes dirty, which is fraught with a serious loss of heating power, and for the electrical structure there is also a risk of fire.

The filter installed in the system must be periodically replaced with a new one as it becomes dirty. Accordingly, a do-it-yourself home structure should provide for the ability to quickly and easily change the filter element.

It is worth noting that industrial air supply structures are usually equipped with differential air pressure sensors. In turn, the sensors are connected to automatic control, which signals the user that the filter is dirty.

In fact, it is also advisable to supplement a serious home air supply system, made by yourself, with a filter condition monitoring function.

How to make forced air ventilation with heating yourself

For those who want to make fresh air ventilation in a private house with their own hands, we can say that it is not difficult. The main thing is to approach the process very carefully and take your time. If you create the drawing and make the calculations incorrectly, the device will not work correctly, which will affect the indoor air and temperature.

Schemes and drawings

Before you begin installing the device, you need to fully implement your plan on paper. The drawing should include all dimensions and directions, so it will be more convenient to install the finished system and make calculations. Be sure to mark the presence of grilles and dampers on the valves. The scheme must take into account the following nuances:

- Air movement should go from clean rooms to contaminated ones, that is, from the bedroom to the kitchen and bathroom.

- A heated supply ventilation valve must be located in all rooms and areas where there is no exhaust hood.

- The exhaust ducts must be the same size everywhere, without expansions or contractions.

Calculations

In order for the device to fully perform its functions, it is necessary to calculate its power as accurately as possible. To do this, you will need all the parameters of the room. Including the number of floors, the area of rooms, the layout of the room, the number of people who can be there at the same time, as well as the presence of equipment in the form of computers or machines.

Installation

In order to install supply ventilation, you must have the following tools:

- Hammer.

- Spanners.

- Sledgehammer.

- Screwdriver.

- Hammer.

- Ratchet wrench.

- Clamp.

First of all, you need to prepare the place and choose the size of the hole. Using a diamond drill or hammer drill, you need to drill a hole with a slope towards the street. A pipe is then inserted into this hole. The diameter should be larger than the diameter of the fan.

After this, a fan is installed, and all the cracks between the pipe and the wall are foamed. Then the channels for wiring are laid. In some rooms, it is convenient to connect the wiring to a switch; this will make it possible to automatically turn on the ventilation system after the lights are turned on in the room.

Finally, all remaining parts are installed, including sound absorbers, temperature sensors and all filters

It is important to constantly check the diagram to avoid errors during installation. Grids are attached to the ends of the system

As a result, the entire system needs to be checked. This is easy to do: you need to bring a sheet of paper to the grates. If it moves even slightly, it means the ventilation is working.

It is important to note that recently people are increasingly shielded from extraneous noise. As a result, along with the sounds, we stop the access of fresh air to the room

This provokes allergic reactions and upper respiratory tract diseases.

Therefore, any room, be it an office or an apartment, must have ventilation. And in order not to freeze, ventilation should be installed with heating. Then it will be both good for your health and warm.

Auto

MagicAir is a smart control system that is responsible for the specified mode. This is a small device that issues commands to other equipment and, if necessary, changes the indoor microclimate indicators.

The base station controls other elements depending on what level of carbon dioxide should be maintained. 800-1000 ppm is considered a comfortable level. If this level is exceeded, unpleasant sensations may appear in all people who are inside. But the device is able to ensure that the level of carbon dioxide never goes beyond certain limits.

How to heat air using recirculation?

The principle of operation of the device due to recycling:

- The air flow comes from outside into the duct. Part of it, using a special system, is removed back outside the room, and the remainder ends up in the mixing compartment (read separately about the specifics of installing ventilation outlets that lead the air flow outside).

- In the compartment, fresh air enriched with oxygen is mixed with exhaust air, that is, that which was already in the room. Mixing, the air masses are warmed up and sent to the heater or air conditioner, and then into the room.

Circulation

Regardless of the type of system, for proper circulation you will need door overflows or a gap under the door at least 20 cm wide. You can start the cycle from any room, but it is better to remove it from the most polluted room - the kitchen or toilet, otherwise all the “aromas” will smoothly spread throughout the house and cause wild delight of the residents.

Remember: a room air conditioner does NOT provide fresh air to your apartment. It drives air from the room through itself, cools/heats it - but no more. There are special air conditioners with air intake from outside, but given their cost and energy consumption, it is easier (and cheaper) to arrange closed circulation in each room separately.

Automated air heating in supply ventilation

Options for constructing round and rectangular ventilation shafts - the system is automated

- The operation of the equipment is controlled using a control panel (CP). The user presets the mode for regulating the supply air flow and temperature.

- Using a timer, the heated ventilation system automatically turns on and off.

- Equipment that provides heating can be connected to an exhaust fan.

- Heaters are equipped with a thermostat that prevents fire.

- A pressure gauge is installed in the ventilation system to monitor pressure differences.

- A shut-off valve is installed on the supply ventilation pipe; it is designed to block the entry of incoming wind masses.

Attention! Automatically controlled supply ventilation in a heated private house is expensive to maintain. Installation and maintenance are carried out only by specialized companies. Although it is very convenient to use.

Electric heater

A so-called duct heater is built into the installation, which operates from the network. Simple and quick installation are the main reasons for the popularity of such equipment. The system begins to function immediately after connecting the device to an energy source.

Such installations can be easily installed with any systems, and their position can be horizontal or vertical. Compact dimensions ensure that there is a lot of free space left. The installation ensures reliable and stable operation over a long period of time.

How to install a supply valve - instructions

Before installation, you need to decide 2 questions: where to put the ventilation valve and how to drill a neat hole in the wall. We will give the following recommendations regarding placement:

- Ventilators with a pipe diameter of 50–60 mm are best placed between the heating radiator and the window sill. Provided that the gap height is sufficient. Then the cold street air will immediately mix with the rising convective flow from the battery.

- We place a device with an air duct more than Ø100 mm on the side of the window opening, making an indentation of 30 cm (to prevent freezing). The second option is between the window and the ceiling, the minimum distance from the ceiling is 15 cm. In both cases, the ventilator is located in the zone of convection flow from the radiator.

- The height of the passive valve above the floor is 180...200 cm.

- When installing the recuperator valve, maintain a distance of 0.5 m from all structures - ceiling, window, nearest corner, as shown in the drawing.

- Place the transfer device in a convenient place without restrictions.

Comment. If the room is heated with heated floors, then the passive type ventilator can be placed at any distance from the window; the minimum distance remains the same - 30 cm.

It is better to entrust drilling of a reinforced concrete wall to professionals armed with a machine with a diamond bit of the required diameter. You can make a hole in a brick yourself, although you will have to tinker. Using a long thin drill, make many holes around the circumference, then carefully knock out the middle.

Two important points. Before starting work, make sure that in the selected area of the structure there is no electrical wiring or heating pipes laid in a hidden way. Second: the hole is drilled with an inclination of 2–3° towards the street to allow condensate to escape.

How to properly install a supply valve into a wall:

- We cut the air pipe flush with the structure or with a small outlet - as specified in the manufacturer’s installation instructions. The Vents telescopic air duct cannot be trimmed.

- We insert the pipe into the hole and fill the gaps with construction foam. Cement-sand mortar cannot be used.

- We attach a grille with a mosquito net to the outside. We observe the correct position of the element - the visor is at the top, the blinds are directed downwards.

- We insert a heat-insulating element inside the air duct and, if necessary, cut it to length.

- We disassemble the valve head, attach the body to the pipe and the inner surface of the wall with dowels. We install the filter, dampers and lid with the inlet slots facing up.

Assembly diagram of the interior of the room ventilator

The installation technology of the recuperator valve is identical. First, an air duct is embedded in the wall, an external grille is attached, then the elements of the unit are installed from the inside - a ceramic heat exchanger, a fan and other elements. Differences: thermal insulation is mounted outside the pipe, a power cable is supplied to the fan.

Reference. There are ventilator models with a fan powered by its own solar battery. An example is the Vents valve PSS-102, shown in the photo.

Valve model with solar powered fan

What will you need to create?

A new supply valve costs at least 1200-1500 rubles. Higher quality models will cost about 3-4 thousand. Let's calculate how much it will cost to make a homemade ventilator.

We will need:

- Plastic pipe.

- Lattice.

- Insulation.

- Filter.

- Housing with valve.

Below we will look in more detail at how to choose the right parts to create a supply valve with your own hands.

The pipe will play the role of an air duct. The length of the plastic pipe is selected according to the thickness of the wall. If the thickness is unknown, you can take a meter piece with a reserve, and already in the process of work, cut off the required piece.

The diameter of the air duct is up to 100-120 mm. More is not recommended: too much air will not have time to heat up. In addition, a hole in the wall of a large diameter can lead to serious disruption of the indoor microclimate.

To create a wall inlet with your own hands, a regular non-pressure PVC pipe will do. Price – 150-250 rubles (per meter).

Installation of a wall supply valve

The grille will be placed on the outside of the pipe and protect it from various debris and precipitation. The product should be plastic, ideally have an internal protective mesh. The shape doesn't matter.

The size of the grille should cover the diameter of the pipe (that is, if the air duct is 100 mm in diameter, the grille should be at least 120 x 120 mm). Cost – about 150-250 rubles.

Insulation - inserted inside the pipe. Thanks to thermal insulation, the wall around the valve will not freeze in winter. The insulation can be made from polystyrene foam, extruded polystyrene foam, polyurethane foam or mineral wool.

Any pipe insulation that is suitable in diameter will do (that is, for an inlet with a diameter of 100 mm, you need to take a “shell” of the same diameter). The length does not have to be taken according to the length of the pipe - it will be enough to insulate the third of the air duct located closer to the room. The thickness of the insulation will be 20 mm. You can get by with 200 rubles.

Filter – inserted inside the valve body. Serves to retain dust and pollen. You can make a filter from a porous material called polyf or from ordinary foam rubber. A small piece is needed, approximately 110 x 110 mm in size (to cover the pipe). It will cost up to 50 rubles.

Valve body – installed inside the room. It’s not easy to make it yourself, so the most convenient option is to purchase a ready-made ventilator head. These, for example, are produced by Vents and are sold in ventilation equipment stores. Cost - about 300-450 rubles.

As an option, the inner casing can be replaced with a ventilation grille that has adjustable blinds. This way it will be possible to change the amount of incoming air, or completely block the flow.

- Air duct – up to 200.

- Lattice – up to 200.

- Insulation – up to 200.

- Filter – 50.

- Head – up to 450.

In total - 1100 rubles. This is an average figure: in fact, it is possible to make a wall inlet valve cheaper.

How to improve the device: fan or heating

You can supplement a homemade supply valve by installing a fan in it. A regular duct will do, the main thing is that it matches the diameter of the air duct pipe. It is connected to the network and controlled through a switch placed on the wall.

There are two ways to install the fan: towards the room or towards the street. Air can be either forced into the room or, vice versa, removed. In the second case, the valve will work as a passive supply, and when the fan is turned on, as an exhaust.

Cost: an axial duct fan with a diameter of 104 mm, which has a humidity sensor and a shutdown timer, will cost approximately 1200-1400 rubles. The air capacity of such a model (for example, Vents 100 VKO) is about 100 m³/h.

Integration of the heater into the ventilation system

It is possible to properly install the necessary heating in the inlet at the stage of installation of the entire ventilation system, since disassembling a ready-made complex to integrate a separate unit is a rather labor-intensive process. But to install a water heater, this procedure is practically impossible, since this unit must be connected to the heating system of the apartment.

To install an electric heater into a ready-made and functioning ventilation system, it is necessary to disassemble the latter up to and including the unit with the fan.

The figure shows a schematic design of a supply ventilation system suitable for an apartment with heating of street air using an electric heater

The heater is installed in front of the fan immediately after the filters.

This location is due to the fact that in winter the lubricant of bearings in radial fans tends to thicken, which can cause jamming of parts and overheating of the winding. The heating element neutralizes the effects of cold and prevents damage to such an important unit.

In what cases is it used?

A heated ventilation device uses oxygen-enriched air from outside, unlike air conditioning systems that circulate exhaust air through themselves. Such systems are used in private homes and offices, where it is necessary to regularly maintain the microclimate, where fresh air at a comfortable temperature is constantly needed.

The carefully thought-out design of the device does not allow fresh air, enriched with oxygen and heated to the required temperature, to mix with exhaust air. This ensures a regular flow of oxygen into the enclosed space.

Attention

Such a ventilation system is in demand in rooms where plastic windows are installed, which are hermetically sealed and prevent the flow of fresh air, and in those where it is impossible to regularly ventilate the space: in basements, boiler rooms without windows.