On the eve of winter cold, the question of how to prepare water for heating systems becomes especially important. Proper water preparation is doubly important for owners of private suburban areas that are not connected to a heating plant and receive water from wells or wells. If the water is hard and contains foreign impurities, for example, iron or manganese, this can lead to failure of not only plumbing fixtures and household electrical appliances, but also damage to heat exchangers, corrosion of pipelines and radiators.

Heating system of a country house.

Water treatment for heating system

Ecology of consumption.

Homestead: Water heats the batteries, it makes the turbines work and generate electricity. And if the water quality is low, then constant breakdowns in heating systems are inevitable. The coolant for the heating system is selected at the design stage of the heating system. This is not accidental, since the characteristics of the coolant affect the performance of the entire heating system, which is what you read about in this article and, if necessary, in the next two.

So, what functions does the coolant perform for the heating system, what is it in general, and what are the requirements for it?

The coolant is a liquid poured into the heating system and transfers heat from the boiler to the heating devices. Water and (or) antifreeze are used as coolant.

Water as a coolant for the heating system

Plain water is most often used as a coolant. Why?

Well, first of all, it's accessible.

Water has the highest heat capacity of all substances. That is, when heated, it can accumulate a large amount of energy. And when it cools down, it gives off a large amount of energy, in our case, to the heated room.

Water has a very low viscosity (in other words, good fluidity), making it easy to “move” within the heating system.

Water is an environmentally friendly substance and is not dangerous to our health in case of system leaks.

Disadvantages of water as a coolant

All operating instructions, manufacturers' recommendations and reference books for heating system installers unanimously state: the standard coolant for use in heating systems is distilled purified water.

The latter is not relevant if a house with a water heating system is a permanent place of residence. But what to do if this is a heating system for a summer house, garage, guest house... the risk of water freezing in such heating systems is significant. In this case, there is only one way out: use antifreeze for heating boilers... but that's a completely different story.

Water treatment

If the heating medium is water, then there are also certain requirements for water hardness. Water hardness causes many problems: scale forms in the heating system equipment, which leads to poor performance or failure of this equipment.

Often there is only one way to eliminate the consequences of using hard water: replacing equipment and pipes, which requires significant financial costs.

Typically, ion exchange units are used to soften water, in which calcium and magnesium ions are replaced by sodium ions located in the ion exchange resin.

Ion exchange unit for softening hard water.

As an alternative, magnetic water treatment can be used.

Device for magnetic water treatment.

Magnetic field treatment is economical, affordable, simple and safe. And the taste and salt composition of the water is preserved, and no substances harmful to humans are formed in the water.

The effect of magnetic treatment lasts for twenty-eight days! Magnetic activators can be used in all hot and cold water systems. Magnetic treatment not only prevents the formation of sediment and scale, but also removes scale already deposited on the walls, while the surface is protected by a barely noticeable oxide film. The sediment is gradually removed from the system by the flow of water and settles in filters, from where it is then removed during cleaning.

There are two versions of the magnetic activator produced for domestic needs: with threaded connections from 8 to 32 mm and from 400 to 300 mm with a flange.

There are also ultrasonic anti-scale devices.

Ultrasonic anti-scale device.

They are also designed to prevent deposits on any plumbing and heating devices and assemblies.

The advantages of these devices are the ability to clean large surfaces and the absence of noise during operation.

Ultrasonic anti-scale devices are effective in pipes with a diameter of up to 45 mm or parallel pipes with a diameter of up to 27 mm. Such anti-scale devices are installed quickly and simply, even without cutting into pipes: by winding the wire around the pipe, which, you see, is very convenient.

In addition to softening, these installations also reduce the iron content (about 4 times), due to which the effect of corrosion on equipment is reduced, and this, in turn, leads to savings in energy resources and finances that could be spent on repairing pipes and units heating system.

If you have any questions on this topic, ask them to the experts and readers of our project here.

PS And remember, just by changing your consumption, we are changing the world together! econet

The best filters for the boiler

Before making a choice, you need to refer to the factory instructions and familiarize yourself with what the manufacturer offers as water treatment for the boiler. Then, in any SES laboratory or even from a water supply company, you need to take complete results of an analysis of the water that will be used to feed the boiler and heating networks. Before you begin selecting possible modifications, choose from a line of boiler or water heater filters.

In addition, when choosing, experts also advise paying attention to the following parameters:

- Productivity - determines the hourly volume of purified water, m3/hour.

- Dimensions and installation area so that the purifier can be integrated into the existing free space in the boiler room.

- Thread diameter - it must correspond to the diameter of the heating systems.

- Brand - it is safer to purchase a filter from a popular manufacturer and in branded stores. Unfortunately, there are many counterfeits in the retail chain, and in addition, in branded stores you can issue a reliable guarantee and consult on the procedure for using the filter.

Magnetic filter Aquamax XCAL MEGAMAX

Aquamax XCAL MEGAMAX 1/2″ is an Italian highly efficient magnetic anti-scale filter for boilers and boilers. It cleans the heating surfaces of boilers from limestone formations. Designed for heat supply systems with high circulation rates.

The MEGAMAX magnetic softener is made of first-class non-corrosive steel and is considered not dangerous to people. The device does not require changing filter materials. Suitable for boilers with 1/2" piping and can purify water 0.8 m3/hour. Price: 1860 rub.

Phosphate filter Ecosoft SCALEX 200

The filter for the heating boiler Ecosoft SCALEX 200 prevents the formation of scale in heating systems and contains an ecological filter media that does not have polyphosphate, which allows its use not only in heating boilers, but also in hot water supply systems.

The SCALEX 200 filter has the function of chemical water purification and performs mechanical purification of suspended solids and rust products up to 100 microns in size.

Ecosoft SCALEX 200 does not remove hardness salts from make-up water, but has a comprehensive effect on them thanks to the simultaneous use of 3 protection mechanisms:

- Stopping the growth of hardness salt crystals.

- Destruction of the beginnings of foci of scale crystallization.

- Prevents the connection of scale-forming crystals with each other.

The filter can operate without replacing the filter material for 6 months. Cost 1260 rub.

Anion filter SVOD-AS sbb10

A powerful softener can be used not only in domestic heat and power engineering, but also in industrial boiler houses. The device purifies water from hardness salts, heavy metals and any suspended pollutants and impurities.

Water is processed in a special anion exchange cartridge, the reagent of which is processed using a special technology with chemically active components. As a result, Ca and Mg ions in the water are replaced by Na ions, thereby creating easily soluble sodium salts that do not deposit on hot boiler surfaces.

The filter housing is made of plastic that can withstand medium pressure up to 6 atm. One cartridge can process 262 m3 of water and has a shelf life of three years. Price 6700 rub.

Magnetic filter Caleffi XS

The Italian filter is designed for boiler water treatment and combines two types of cleaning: mechanical and magnetic, using a neodymium magnet and a transparent sludge collection chamber to visually control the process. The device can operate in an environment at a pressure of 3 atm. and hot water temperature 90 C. Hourly productivity for make-up water is 3.5 m3/hour. Warranty - three years. Price: 5600 rub.

Methods for preparing water for heating systems

Some of the shortcomings in preparing water for the heating system are eliminated by preliminary heat treatment and filtration.

In other cases, the coolant is diluted with special additives and reagents, giving it the necessary properties.

What methods can be used to prepare water before filling the heating system?

- Changing the composition of water by adding reagents, that is, chemically active substances.

- Catalytic oxidation to remove excess iron into sediment.

- Application of mechanical filters of various sizes and designs.

- Water softening through electromagnetic wave treatment.

- Heat treatment: boiling, freezing or distillation.

- Sediment of water for a certain period of time.

- Deaeration of water to remove oxygen and carbon dioxide, etc.

Preliminary filtration of water will help remove unnecessary mechanical impurities and suspended particles (stones, sand, fine clay and dirt, etc.).

To purify water with minor contaminants, filters with washable or replaceable cartridge types are used. Heavily contaminated water is passed through filters with a double layer of quartz sand, activated carbon, expanded clay or anthracite.

Why is it necessary to soften water?

Filling the heating system with water that has not undergone the cleaning process significantly increases the risk of premature wear and failure of some elements of the heating system.

Water softening involves reducing the content of magnesium and calcium ions. You can achieve the desired result in several ways.

The use of special filters based on a number of components: slaked lime, sodium hydroxide and soda ash. These substances closely bind magnesium and calcium ions dissolved in water, preventing their further entry into the purified coolant.

No less effective devices are filters based on fine-grained ion exchange resin. The action of this system is to replace magnesium and calcium ions with sodium ions.

Under the influence of magnetic water softeners, magnesium and potassium ions lose their ability to precipitate as solid sediment and are converted into loose sludge, which must be removed from the water.

The choice of one or another method of preparing water for a heating system depends entirely on its type. Each heating system has its own characteristics and recommendations depending on the type and quality of the source material.

Article rating:

(total 1 votes, rating: 4.00 out of 5)

Types of water softening filters

The domestic market is overflowing with offers for water purification filters, both domestic and Western-made. The user needs to understand which softener is best suited for the boiler and autonomous heating system. Next, you will need to select the most appropriate purification method for the initial composition of the water.

Polyphosphate filter

The most affordable and cheapest water softening filter for a boiler, and at the same time a very effective cleaning option. The ion exchange polyphosphate filter module consists of the following basic elements:

- Plastic container in the form of a flask, transparent;

- protective cover for cartridge replacement;

- drainage;

- softening chemical reagent—polyphosphate salt.

Raw or tap water enters the filter container, circulates through a chemical reagent in the form of polyphosphate salt crystals and is impregnated with sodium polyphosphates, forming a phosphate film. It envelops hardness salts, thereby neutralizing their scale-forming properties and protecting boiler heating surfaces from salt deposition.

Polyphosphate is a toxic substance, so after contact with it, water becomes undrinkable. These softeners must be used carefully in hot water supply systems, since due to possible leaks in the structure, water may enter the hot water supply or hot water supply line.

The service life of polyphosphate filters, or rather dissolving polyphosphate salt, is short. The standard consumption of the reagent is 5 grams per 1 ton of water. The reagent is replaced when its volume in the flask is halved. This happens after about six months of filter operation. The cost of polyphosphate ion exchange filters ranges from 500-1400 rubles, and replacing polyphosphates will cost the owner up to 350 rubles.

Magnetic filter

This is the most expensive and effective cleaning method. If you install a compact permanent magnetic filter in front of the boiler, you will not need to constantly regenerate it or change the filter material. It cannot soften water, that is, remove hardness salts from it.

The principle of its operation is different and is based on the transformative effect of a magnetic field on water, as a result of which its structure changes briefly.

Passing through the magnetic filter element, boiler water changes its own physical qualities, while the crystallization process when heating the liquid occurs more intensely, but not on the surface of the heated boiler walls, but in the water column. In connection with this, sludge is formed, which is easily removed by blowing or in a mud pan in front of the boiler.

A characteristic feature of this method of softening boiler water is the temporary nature of magnetization of water, therefore such a filter is installed as close as possible to the boiler unit.

The advantage of this treatment is that when water passes through a magnetic filter, it does not become technical and harmful to humans, therefore it is applicable in double-circuit boilers with hot water heating.

The service life of such softeners is practically unlimited, since the device has no moving or rubbing parts. The cost of installation ranges from 1,500 to 25,000 rubles, depending on the brand, design and hourly productivity of purified water.

Electromagnetic

At a high temperature of hot water in the boiler circuit and a high circulation speed, complete separation of hardness salts from water only with the help of magnetic treatment often does not occur, especially for natural waters with high hardness. To enhance the magnetic effect, electrical treatment of the water is added by placing a specialized electrical treatment on the magnet.

Such a device also functions by treating the source with a magnetic force field, the strength of which is regulated by an effective electrical processor. This pair makes it possible to get a longer lasting effect.

The operation of such a device does not depend on pressure changes and temperature conditions. Transforming hardness salts not only do not harm the boiler, but also act as softening agents for previously deposited scale. Installation cost: from 5,000 to 30,000 rubles.

Preparing water for heating is much more important than it might seem

It just seems that heating networks will not require special water treatment, and technical water, cleared only of stones, sand and algae, will do just fine.

In reality, it turns out that everything is different. Ignoring proper water treatment leads to very unpleasant and costly consequences. First of all, we are talking about hard salts - calcium and magnesium compounds. They can settle on the walls of pipelines through which water flows (the solubility of chemical compounds sharply decreases). Moreover, when heated, this process increases significantly. As a result, we have scale both on pipes and in the middle of heating devices. And thanks to this:

- Reducing the flow diameter of individual elements of the heating system - right up to complete overlap.

- Deterioration in heat transfer - up to twenty percent.

- Increased electrical energy consumption for devices with a heating function (also boilers).

- Detrimental effects on measuring and control equipment. And the problems with the heat generating plant – in this case – are everyone’s problems.

It is also necessary to emphasize the destruction of the walls of the heating system pipes by chemically energetic substances contained in water.

Fighting hardness

So, preparing water for heating includes water softening. This is the most important component that is almost always important. Natural liquid is not ideal. There are enough impurities in it, and calcium and magnesium are in excess due to completely natural reasons - from passing through the strata of limestone rocks and being washed out.

A layer of scale is familiar to all owners of pots and kettles. The same thing happens on the internal surfaces of boilers. It is believed that any millimeter of scale layer reduces the efficiency of the boiler by 1%.

By the way, scale can also be secondary - if, for example, it appeared in the water mass, and then was deposited on the wall (such solid particles are clearly visible). You can combat this using dimeralization.

Ways to fight

Preparing water for heating is an economically viable process. Who wants to change heating devices every 5 years, and change pipes a little less often?

For water purification for the home and heating systems, various devices are used, which we are accustomed to calling filters (not always correctly, but it is clear to everyone).

The most effective and used methods of preparation are:

- Electrolysis exchange - using a special resin that is capable of changing the ions of a number of dangerous substances, while simultaneously restoring the properties of water. The method is perfectly used in household systems - it is compact, easy to use and quite effective.

- Reagent treatment – in other words, the action of chemically energetic substances. Soda liming, liming and treatment with caustic soda are effective against the deposition of hard salts (but due to their complexity, they are used at industrial facilities - the same, as a rule, applies to the following points).

- Catalytic oxidation. Catalyst granules (reaction accelerator) actively oxidize iron and remove it into sediment.

- Magnetic processing. Under the influence of a magnetic field, scale formers (the same CaCO3) crystallize on ferromagnetic particles present in the water mass.

- Diaeration is the removal of dissolved gases.

When selecting a specific method for preparing water for heating, it is necessary to proceed from the required values (each system has its own advice - in some places almost distilled liquid is needed, and in others coarsely filtered liquid will do). In this case, the quality of the initial material and financial opportunities are of fundamental importance. Whatever satisfies all these requirements is acceptable as water treatment!

The need to prepare water for heating will affect everyone. But most of the described methods of water purification are complex and expensive. Enterprises, which in most cases have a professional staff and greater financial opportunities, can afford this. But for small organizations and owners of country houses it is more difficult here. The technical operational level of boiler systems there is usually not high. Very often, small treatment systems are used for water preparation, which are simplified analogues of those described above.

What else to look for when choosing

All softening filters for water of a certain type have the same principle of operation and differ only in the quality of work, less often - in practically insignificant design features. Therefore, there are no specific selection criteria. However, we recommend paying attention to:

- productivity - also throughput, measured in m 3 / hour or l / hour;

- size - magnetic softeners are slightly larger than the diameter of the pipe, while polyphosphate filters require a lot of space around the pipe;

- thread diameter - must match the diameter of the pipes used in the planned installation location;

- manufacturer - it is better to choose a filter from a well-known manufacturer, preferably in specialized retail outlets that can provide repairs or replacements during the warranty period.

Why not water

Indeed, this is the most popular coolant. Water is cheap, accessible, non-toxic, and has fairly good heat capacity combined with heat transfer.

However, there are a number of serious negative features that make water not an ideal option:

- During frosts, the heating system cannot be turned off without draining the water - it will freeze;

- There is some probability that water in the far parts of the circuit will form ice plugs even without shutting down the system if the frosts hit with all the Siberian force;

- Frozen water means not only traffic jams, but also the risk of pipe rupture due to expansion of the coolant;

- Plaque is deposited on pipes in the form of the well-known scale;

- We must also not forget about corrosion, which does not extend the service life of the pipeline at all.

Ethylene glycol

For the above reasons, we need a non-freezing liquid for heating our home. One of the options is ethylene glycol, or more precisely, antifreeze based on it. The main advantages of such compositions:

- low cost;

- freezing point below -60 degrees;

- no corrosion;

- higher thermal conductivity than water.

However, everything can't be that good. Ethylene glycol is poisonous, so leaks in the heating system can cause serious problems. This is the main reason why ethylene glycol based antifreezes are not used in the home. They are used mainly in industrial facilities.

Non-freezing liquid for heating a home should be safer from an environmental point of view.

Propylene glycol

More expensive antifreezes based on propylene glycol have all the advantages of the previous option, but do not have its main disadvantage - toxicity. From the point of view of its own weaknesses, we can note the high price of compositions with propylene glycol and slightly lower thermal conductivity.

However, environmental safety and low freezing point make antifreezes based on this component quite suitable for home use.

Complex formulations

This group of antifreezes uses various components, which makes it possible to achieve maximum thermal conductivity and a minimum freezing point with complete environmental safety.

As a rule, the price of such compositions is also reasonable.

On the other hand, this group is represented by such a wide selection of antifreezes, the composition of which can vary greatly, that an intelligent choice will require studying the specific name and its composition.

Conclusion

For heating systems of country and country houses (especially those that are not heated in winter on an ongoing basis), it is advisable to choose complex antifreeze compositions, the base component of which is propylene glycol.

Operating principle of ITP Softening water for heating

The first and most important stage of work

The main thing that should be done before planning water treatment measures for a heating system is to conduct a chemical analysis of the composition of the water.

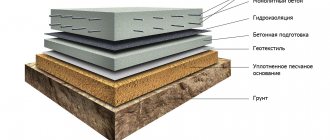

Known (a) and proposed (b) schemes for preparing water for heating: 1 - water heater; 2 — steam-water heater; 3 - refrigerator; 4 - nutrient tank; 5 - high pressure manifold; 6 - low pressure manifold; steam; condensate.

You can carry out tests at home using test kits for aquariums (they are sold at any pet store). However, in order to obtain more accurate values and most effectively prepare water for heating, you should use the services of a certified laboratory.

Water for analysis is collected in a 1.5 liter plastic bottle from non-carbonated drinking water. It is unacceptable to use bottles of sweet carbonated water and other drinks. The cork and bottle are washed well with the same water that is taken for analysis; no detergents should be used. The water is first drained for 10-15 minutes to prevent stagnant water from entering the sample, as this may affect the test results.

To prevent water from being saturated with oxygen dissolved in the air, it is drawn in a thin stream so that it flows down the wall of the bottle. Water is poured under the neck. The bottle is tightly wrapped with a cork to prevent air from entering under it. Oxygen causes chemical processes to occur, and this can also affect test results. If it is not possible to immediately take the samples to the laboratory, then the water can be stored in the refrigerator (not in the freezer!), but no more than two days.

Heating system.

A comprehensive water analysis includes checks for the following indicators:

- rigidity;

- iron;

- manganese;

- pH (degree of acidity);

- permanganate oxidability (indicates the presence of organic substances in water);

- mineralization;

- ammonium;

- oxygen saturation;

- turbidity, color, smell.

If necessary, samples are taken for the presence of microorganisms. Some of them, such as legionella and amoeba, not only can cause serious harm to health, but can also settle inside pipes, forming a slimy microbial film. This promotes corrosion and degrades heating quality.

Related article: Errors and malfunctions of Samsung washing machines

Disadvantages of water as a coolant

All operating instructions, manufacturers' recommendations and reference books for heating system installers unanimously state: the standard coolant for use in heating systems is distilled purified water.

The latter is not relevant if a house with a water heating system is a permanent place of residence. But what to do if this is a heating system for a summer house, garage, guest house... the risk of water freezing in such heating systems is significant. In this case, there is only one way out: use antifreeze for heating boilers... but that's a completely different story.

Conclusion

The conclusion is very simple. In order to avoid problems, you need to choose the right heating scheme (closed two-pipe), design convenient places in the system for filling and draining the coolant, and when creating it, monitor the slopes of the pipes. And you won't have any problems! You will live and rejoice!

And if you do not live in the house permanently, but only come a couple of times during the winter, then instead of using antifreeze, I would really think about electric heating. It will be many times cheaper, by the way.

I hope the process of filling your heating system will not bring you negative emotions. Dmitry Belkin

Article created 09.09.2015

Modification of surfaces of elements in SCT

There are other known methods for preventing corrosion and scale formation associated with modifying the surfaces of elements in the SCT that are in contact with water. It is possible to use alloy steels for the manufacture of elements of heat exchangers and boilers. This allows you to get rid of corrosion, but the price of SCT elements increases significantly.

Despite the increase in equipment costs, there are such examples. These are pre-insulated pipes for heating networks, or condensing water heating boilers and Viessmann. Or water heating sectional boilers made of aluminum alloys and Bosch-Buderus. IN

It is also possible to use plastics for the manufacture of pipes for heating networks, but only for coolant temperatures not exceeding 95°C. There are known designs of air heaters for boilers made from glass pipes or plastic. All these technologies are still quite expensive and are not widely implemented.

Phosphonates

At the end of the 20th and at the beginning of the 21st century, a large number of compounds were synthesized that found application for the protection of thermal power equipment of small-scale energy facilities, including complexones, in particular phosphonates, which showed a number of advantages over other complexones for the above goals.

Unlike Trilon B, they have a different mechanism of action in preventing scale formation, namely, they inhibit the process of scale formation at the stage of crystal nucleation, therefore they work in substoichiometric ratios, that is, their working concentrations are 1-5 mg/dm3, which makes their use economical profitable.

Such compounds work even on “raw” water, which makes the water softening stage unnecessary, resulting in a sharp reduction in the use of table salt, thereby reducing the amount of waste water, which in turn has a beneficial effect on the environment.

Technologies using complexonates based on organic phosphonates have now become sufficiently developed in the water treatment of small and medium-sized boiler houses, and the production of the corresponding reagents is quite widespread.

But the use of these reagents even for heat supply systems is limited;

- firstly, the alkalinity of the environment: at a pH of more than 8.5, alkaline earth metal complexonates, which are more often than other compounds used to protect heat supply systems from corrosion, for example, zinc complexonates decompose to zinc hydroxide and cease to perform their functions of protecting against corrosion;

- and secondly, the use of complexones based on phosphonates is limited by the concentration of scale-forming ions, mainly Ca2+10 mEq/dm3; thirdly, the lack of regulatory documentation regulating the use of methods for stabilizing water treatment in heat supply systems.

As a result, engineering and technical personnel are not prepared to implement reagent water treatment technologies.

Summary

Thus, complex water treatment requires a number of organizational and technical measures for the implementation of the heat and power complex, in particular in heat supply systems, although the payback of such technologies is quite high; there is evidence that capital costs are paid off during the heating season, or in several months.

Prevention or regular cleaning: choosing the optimal operating mode

You should study the scale protection in more detail. Sand scratching the walls of the pipes is noticeable. It is not difficult to separate it with a simple filter for cleaning the heating system. Salts are initially present in a dissolved state. They do not interfere with transparency and, at low concentrations, are indistinguishable in taste.

Even at low concentrations (less than the permissible norm of 7 mEq/liter), such impurities are actively converted into solid particles. The process accelerates in the hottest areas of the system. Scale blocks the movement of liquid, which is accompanied by thermal destruction of the functional unit. The occurrence of such malfunctions during the heating season is accompanied by large financial costs to restore operability. The worst thing is when the accident occurred in the absence of the owners. In this case, ice plugs can rupture the pipes.

It is clear that any attentive person will pay due attention to this problem. However, it is not always possible to make the right decision. Difficulties arise when choosing suitable equipment for cleaning a heating system from a large number of different thematic offers.

To make things easier, some users use cleaning. Such services are offered by specialized service companies. They recommend flushing the gas boiler heat exchanger every 2-3 years, and in individual cases more often. To perform the procedure, they use aggressive acid-based chemicals that can destroy durable calcium formations.

You can perform these same operations yourself. However, we must remember that you will need high-quality specialized equipment, an accurate choice of reagents, and strict adherence to the rules of technology. As a result, the total costs may be higher than if you turn to professionals.

During the reproduction of the technique, experienced specialists monitor the process of removing impurities by changing the color of the liquid. A special reagent is added to the radiator, which acts as an indicator. However, there is no way to check the condition of the pipe walls. Acid destroys metal and solder joints. This negative impact cannot be quickly verified. As with scale, the likelihood of accidents increases.

Does it make sense to create new problems during cleanup? It is much wiser to prevent scale formation. This approach will help maintain the durability and impeccable functional condition of heating equipment - radiators, pipes, boilers.

The recommendations given do not exclude the need for routine preventive measures before the next heating season. Regular maintenance contains the following stages:

- flushing the system;

- cleaning and replacing filters;

- removal of contaminants from the firebox, chimney, pipeline;

- checking and adjusting the burner, external sensors and other functional components.

How to fill a heating system with water

To understand how to fill a heating system operating on the bottom-fill principle with water, you should remember the following algorithm of actions:

- even before filling the heating system in a private house, the valve on the supply pipeline must be pushed in, and the discharge must be opened on the supply section;

- Then on the return pipe you need to slowly open the valve. If the outlet speed of the water in the heating system is high, there is a risk of water hammer, which can lead to the most unpleasant consequences, including the separation of heating batteries;

- Next you need to wait until the water, devoid of air, flows;

- then the discharge is closed, and the supply valve, on the contrary, opens;

- after this, you need to completely de-air all heating areas in the entrance to which you have access, including service premises.

Preparing coolant at home

First, let's figure out how to soften water for heating with our own hands. The simplest and most affordable way to soften a coolant liquid is to boil it. During heat treatment, carbon monoxide is removed from the liquid, which helps reduce calcium hardness. However, a small amount of calcium still remains in the liquid, so boiling does not completely cope with the task of softening the coolant.

You can soften water at home using filters with inhibitors. Essentially, these are scale neutralizers. Inhibitors are soda ash, caustic soda and lime. Hard water is passed through special filters consisting of ion exchange resin. As a result, magnesium and potassium ions are replaced by sodium ions.

A reagent-free way to soften resin is the use of magnetic softeners. As a result of exposure to a magnetic field, the properties of the liquid change so that impurities of magnesium and potassium salts cannot precipitate in the form of a solid sediment, but form loose sludge. However, the sludge still needs additional removal using filters.

Another way to soften the coolant fluid is to use the reverse osmosis method. Its essence is as follows: the liquid is forced through a special membrane, which retains various substances, including magnesium and potassium salts, which contribute to the formation of scale. The disadvantage of this method is the high cost of treatment equipment, as well as excessive water consumption during the purification process (to obtain 1 liter of purified water, 2-10 liters are discharged into the sewer).

If it is decided to use melt or rain water for the heating system, then it should be allowed to settle for several days, and then its acidity should be measured. If it is within 6.5-8, then the liquid can be poured into the heating circuit.

Methods for deferrization of coolant

The concentration of iron in the coolant liquid should not exceed 1 mg/l. The optimal value is 0.3 mg/l. Due to an excess of iron, the internal surfaces of pipelines become silted, and bacteria multiply in the ferrous sediment. Moreover, the process of their active growth is observed already at a temperature of 30-40°C. As a result, heating and hot water systems wear out quickly.

There are the following methods for deferrizing water:

- The simplest technique is settling. As a result of interaction with oxygen, iron oxidizes on its own and forms a rusty precipitate. To carry out the procedure yourself, you will need a tank with a capacity of 200-300 liters, as well as devices for injecting oxygen into the liquid, for example, a compressor.

- Reverse osmosis technology is also suitable. In this case, filters based on ion exchange resins are used. To protect against the proliferation of iron bacteria, chlorination is used. Chlorine is added at the rate that 50 mg is required per liter. However, before doing this, you need to make sure that all elements of the heating system are resistant to chlorine.

- If water from wells is used, the iron concentration may exceed 5 mg/l. In this case, only filters using glauconitic sand, which is enriched with manganese oxide, will help. When passing through the filter, the coolant is cleared of hydrogen sulfide, manganese and iron. All of the above substances precipitate. To clean a clogged filter, use a solution of potassium permanganate, which restores the oxidative capacity of the filter device.

- Mechanical filters for removing peat, sand, dirt, clay, organic matter and zooplankton come with removable or washable cartridges. Pressure filters with granular media are used for heavy contamination.

Dissolved oxygen is responsible for the corrosiveness of the coolant. The standards for this parameter are the same for closed and open heating systems and amount to 0.05 mg/m³. Columns and deaeration units are used to remove dissolved oxygen.

To eliminate the possibility of oxygen entering the system in other ways, it is necessary to monitor the tightness and integrity of all elements of the heating circuit. Filling with water should be done slowly to avoid the formation of air pockets. Pipelines made of gas-permeable materials (polypropylene, polyethylene) are protected with an anti-diffusion aluminum layer.

Water treatment for a country house as a necessity

The water treatment system is the most important part of the water supply of a private home. This or that filtration and preparation device is determined by the composition of the water and the existing inclusions.

In accordance with GOST 2761–84, various hygiene standards are distinguished when extracting water from wells and wells. Let's take a closer look at them in the following table:

| Index | Water quality indicator of underground water supply source | ||

| 1st class | 2nd class | 3rd grade | |

| Turbidity, mg/l, no more | 1,5 | 1,5 | 10 |

| Color, degrees, no more | 20 | 20 | 50 |

| pH value | 6-9 | 6-9 | 6-9 |

| Iron (Fe), mg/l, no more | 0,3 | 10 | 20 |

| Manganese (Mn), mg/l, no more | 0,1 | 1 | 2 |

| Hydrogen sulfide (H2S), mg/l, no more | Absence | 3 | 10 |

| Fluorine (F), mg/l, no more | 1,5-07 | 1,5-0,7 | 5 |

| Permanganate oxidation, no more | 2 | 5 | 15 |

| Number of coliform bacteria (coliforms) in l, no more | 3 | 100 | 1000 |

| Water treatment methods | Not processed | Aeration, filtration, disinfection | Aeration, filtration with preliminary settling, reagent disinfection |

In order to ensure safe water consumption, it is necessary to monitor its quality throughout the year. Water analysis determines its qualitative composition, which can significantly deteriorate due to:

- calcium and magnesium salts, which increase the level of hardness;

- carbon and sulfur dioxide, responsible for acidity;

- dissolved nitrates, which adversely affect health.

An increased level of hardness in water leads to damage to water heating devices and the heating system. Excess chlorine manifests itself in an unpleasant odor and taste and has a negative effect on the human body. It is worth noting that not all microorganisms can be removed in this way, so disinfection is a necessary process. Heavy metals accumulate in the human body, causing various diseases.

Articles recommended for reading:

- Types of water filters and their characteristics

- How to install a water filter - useful tips

- How to drink water correctly: practical recommendations

The economic component plays an important role in the issue of water treatment for the home. Buying a replacement water filter is cheaper than a new kettle or stainless steel boiler.

Take the test

Initially, installation and debugging costs will be significant. But then they will pay for themselves through properly functioning equipment and good health.

Water treatment in a house is more expensive than in an apartment. Tap water is iron-free and free of heavy metals. Provided high-quality water treatment, calcium, magnesium and chlorine remain in the liquid. In rural areas, the situation is different, which is due to the supply of water from a well or borehole.

Read material on the topic: How to check water quality: 9 interesting ways and more

Features of using water as a coolant

From the point of view of heat transfer efficiency, water is an ideal coolant. It has a very high heat capacity and fluidity, which allows it to deliver heat to the radiators in the required volume. What kind of water should I fill? If so, you can fill the water directly from the tap.

Yes, tap water is not ideal in composition; it contains salts and a certain amount of mechanical impurities. And yes, they will settle on the elements of the heating system. But this will happen once: in a closed system, the coolant circulates for years, and replenishment with a small amount is very rarely required. Therefore, some amount of sediment will not cause any tangible harm.

If the heating is of an open type, the requirements for the quality of water as a coolant are much higher. Here, gradual evaporation of water occurs, which is periodically replenished by adding water. Thus, it turns out that the concentration of salts in the liquid increases all the time. This means that sediment also accumulates on the elements. That is why purified or distilled water is poured into open-type heating systems (with an open expansion tank in the attic).

In this case, it is better to use distillate, but getting it in the required volume can be problematic and expensive. Then you can fill in purified water that has been passed through filters. The most critical is the presence of large amounts of iron and hardness salts. Mechanical impurities are also useless, but they are the easiest thing to deal with - several mesh filters with cells of different sizes will help catch most of them.

In order not to buy purified water or distillate, you can prepare it yourself. First, pour and let sit until most of the iron settles. Carefully pour the settled water into a large container and boil (do not cover with a lid). This removes hardness salts (potassium and magnesium). In principle, such water is already well prepared and can be poured into the system. And then top up with either distilled water or purified drinking water. This is no longer as expensive as the initial fill.

Recommendations for selection

Before buying a filter for a gas boiler, you should consult with a specialist who will recommend a suitable device and give recommendations.

General recommendations for selection:

- If you plan to use a gas boiler frequently, it is better to give preference to an electromagnetic device: it will not allow scale to accumulate on parts, and will also work for a long time without additional maintenance.

But it should be remembered that you will have to constantly change the filler and the service life of these filters is shorter compared to electromagnetic ones.

- When choosing a device, you need to immediately decide where to install it. Sometimes installation requires a large space, which is not always possible.

- Be sure to make sure you have a warranty card. Good manufacturers of such devices never sell their product without providing a guarantee for it.

- It is preferable to purchase devices from well-known brands, since such products are more difficult to counterfeit. Often, unscrupulous sellers sell counterfeits under the guise of a well-known brand at a very low cost, so you should also pay attention to differences in prices for filters from the same manufacturer.

- If the tap water is hard, then in order to better protect the gas boiler, it is recommended to buy two filters at once , focused on different degrees of water purification.

- To simultaneously soften the liquid and protect the internal parts of the boiler from possible damage, it is better to use devices that soften water and have the ability to create a protective film on the heating elements.

If you follow all the recommendations described above, you can choose a device that is suitable for the price and technical characteristics.

Creation of a surfactant film

One of the methods for creating a protective barrier against the effects of corrosion and scale formation on the surfaces of SCT elements is the creation of a film of surfactants (surfactants). Surfactants are part of a complex of chemicals used to modify feedwater.

Their addition serves several purposes. The addition of surfactants to solutions of phosphates and phosphonates should stabilize the products of their interaction with hardness salts—suspensions—in water. They should also prevent the accelerated appearance of repeated deposits after washing. But the use of surfactants to achieve these goals is of an auxiliary nature.

The well-known properties of surfactants force us to search among their large range for those that will allow us to simultaneously wash out old deposits and form a protective film that prevents corrosion and scale formation. Surfactants have a prolonged effect and washing of residual deposits continues even after the end of the main process during boiler operation.

Conclusions from experiments

Further experiments led to the conclusion that it is possible to clean the boiler without stopping it if you simply add a certain amount of surfactant to the water.

Depending on the thickness of the deposits, they are completely washed off within one or two months. Observation of the hydraulic resistance of the washed boilers during the next heating season showed that it remained quite stable.

The increase in hydraulic resistance began only in the middle of the second (after flushing) heating season. Visual inspections of the internal heating surfaces after the completion of the heating seasons showed that they were free of deposits after the season when a one-time introduction of a surfactant was made (up to 2% of the volume of water in the system).

New deposits appeared during the next heating season. The system was not subject to thermal deaeration or chemical degassing during all three heating seasons during which the experiment was conducted. Research has also shown that a thin (up to 50 microns) durable gray film appears on the surface, which has dielectric properties.

Considering the electrochemical nature of the corrosion reaction, we can assume that this is what determines its anti-corrosion properties and at the same time prevents the appearance of scale formation centers.