The need to install fresh air ventilation

Some ordinary people think: if there are vents and the ability to open windows, why install ventilation equipment? You can clean the air in your apartment this way. But in reality, it turns out that natural ventilation does not cope well with this task, and the circulation of air masses does not occur. Unpleasant odors emanating from the kitchen and bathroom stagnate in the house, humidity or dryness is created, and a person begins to experience discomfort.

Following the fashion and advertising of plastic window manufacturers, many of us install them in our apartments. Thanks to this, the space is sealed and an obstacle to free natural air exchange is created. A heavy atmosphere forms inside the room.

The issue of air purification becomes especially relevant in winter. Ventilation through windows causes heat loss and drafts. If you do not open the windows and avoid ventilation, the air in the rooms becomes dry and the amount of oxygen in it decreases. It makes people feel bad.

Do-it-yourself forced ventilation allows you to avoid all these problems. It can be done in several ways:

- install fans in a window or in a specially made hole in the wall;

- arrange a supply and exhaust air duct;

- install a system of inlet openings (valves).

Now the most popular is supply and exhaust ventilation, driven by mechanical devices.

Conclusions and useful video on the topic

The process of installing a fan and check valve through the wall is described in detail in this video:

Here we demonstrate the operation of a high-power exhaust fan with a check valve. The device is characterized by increased durability and low noise level during operation:

Exhaust ventilation is a necessary element for normal air exchange in the house. If it is installed correctly, then normal humidity and a microclimate favorable for human health will be maintained in residential premises.

Do you have experience in installing wall ventilation ducts? Or still have questions on the topic? Please share your opinion and leave comments. The feedback form is located below.

What functions does the ventilation system perform?

Fresh air must penetrate into the premises: without it, a person feels tired and unwell. In unventilated rooms, harmful microorganisms multiply, an unpleasant odor appears and mold spreads.

Mold is the first sign of high humidity in a room

Lack of fresh air leads to fungal growth

In the warm season, you can use open windows for ventilation: air flows circulate freely throughout the rooms, removing dust, wool and other contaminants. During the cold season, a forced ventilation system is used for ventilation. Its functions:

- removal of carbon dioxide;

- normalization of humidity levels;

- air purification in rooms.

People exhale carbon dioxide, so it accumulates indoors. If you don’t remove it, the rooms will be stuffy and uncomfortable. It is difficult to work in such conditions: concentration decreases, and a feeling of constant fatigue appears. In a stuffy room, a person does not get enough sleep and feels exhausted.

Open windows often to let fresh air into your home

High indoor humidity leads to the formation of fungus and mold. Glass surfaces fog up: condensation accumulates in double-glazed windows and forms on mirrors. An unpleasant musty smell appears in the bathroom and kitchen.

Foggy windows indicate faulty ventilation

Animal hair, mold spores, dust, and allergens accumulate in the premises. The surface of the furniture emits formaldehyde vapors - it is part of MDF, chipboard and fiberboard. With insufficient ventilation, harmful substances enter the lungs along with the inhaled air.

How to determine that an apartment has a faulty ventilation system

Apartment buildings are equipped with a natural ventilation system. Special compartments are installed in the kitchen and bathrooms through which the exhaust air goes outside through channels. After several years of operation, the mines become polluted and air masses are removed less well.

The following signs indicate that the ventilation system in the apartment is not working properly:

- increased humidity in the bathroom;

- formation of condensation on mirrors and windows;

- unpleasant odors in the bathroom;

- spread of smoke and steam from the kitchen to all rooms;

- stale indoor air.

Supply ventilation in the apartment solves these problems; it provides a constant flow of fresh air. The microclimate becomes comfortable for work and rest.

Options for ventilation systems for apartments

One solution in this situation is to install forced ventilation. What options do you have to choose from in this case?

Duct systems: for those who are not limited in funds and free space

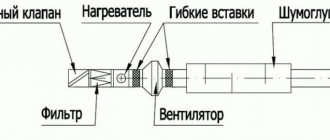

A ducted supply ventilation system for an apartment is an engineering complex that is capable of providing forced (using a fan) inflow, filtration, heating and removal of air masses. Duct ventilation usually includes fans complete with a muffler, corrugated pipes, filtration units, and a recuperator/heater. Air ducts, as a rule, are mounted above the ceiling, and the equipment itself is mounted on a balcony or loggia. This option is one of the best, almost silent and comprehensive.

At the same time, this is an expensive pleasure - along with installation, such a “flush” will cost an average of 300,000-500,000 rubles for an apartment with an area of 90 sq.m. or more. Not suitable for standard housing in high-rise buildings with ceiling heights of 265 - 275 cm and a total area of less than 100 square meters. It also requires annual full maintenance and cleaning of the air ducts.

Option two: installation of ventilation valves

In this case, the flow of air from the street is ensured through special valves that cut into the profile of the glass unit of the plastic window. This option requires replacing the glass unit with glass with a prepared hole. There is an alternative - you can look for special windows on sale with already built-in ventilation valves. The asking price is about 40,000 rubles for one standard window.

Option three: ductless “inlets”

Ductless ventilation systems are a type of ventilation equipment that does not have air ducts. It provides air flow through a through hole in the wall adjacent to the street. Such “inflows” are divided according to the method of supply:

- passive (the air flow enters the apartment by gravity, due to the pressure difference);

- forced (equipped with a built-in electric fan and heating).

An example of passive ductless ventilation is a supply valve - a plastic tube with thermal insulation and sound insulation. It is inserted into a hole that is drilled in the wall.

An active “intake” is a device equipped with a fan and a filter (or a set of filters). Mounted on an external wall.

Minibox Home 350

I chose the Minibox Home 350 air vent for installation on the balcony. It produces up to 350 m3/h and contains three filters.

Filters in it

The first filter is a carbon dust filter FVKas-III-Carb-290-230-30-Bkl/OS0:

I replaced the photocatalytic filter with a carbon adsorption filter FVP-Carb-290-230-25-Bkl-S, which is the second filter:

The last filter is the HEPA filter FVA-II-230-290-30-E11/K1/OS0/U:

The following is a story about how I installed the Minibox Home 350 air vent, what was wrong with it and how I got around it.

System installation

How I bought

I spoke directly with the Minibox manufacturer, not with dealers. Minibox's demo stand is not open on weekends, but their sales manager agreed to show me how the ventilation works on the weekend. Excellent customer focus!

Then I made a 100% prepayment: 109k for the system itself, about 16k for the silencer, wind tunnel and other necessary things, 7k for filters and 17k for installation, a total of 147k rubles.

Overall, the consultation and purchase went perfectly.

The installers arrived and in 1 day they drilled two holes, assembled and installed a completely finished ventilation system. The work was done to an excellent standard: the craftsmen tried not to stain or spill anything in the apartment.

The device consumes up to 3.5 kW, so it needs a separate circuit breaker in the panel. I separately called an electrician and ran a line from the panel to the balcony to the device.

Photos of what my ventilation unit looks like in the end

Silencer and air duct entering the room from the balcony:

The equipment itself on the balcony and the air duct from it to the street:

Anemostat - a round distributor of inlet air, and a control panel in the room:

Air duct grille on the outside of the balcony:

First result

My wife and I began to sleep much better: it became fresh, the air temperature was set to a comfortable temperature for us. CO2 level - 600-800 ppm.

The ventilation is quite quiet: we used it at the second speed, it was 34 dB with a background level of 31 dB.

Complete noise measurements

Measurements of noise from my inlet at a distance of 2m from it using the Sound Meter application:

| Speed | Air exchange, m3/h | Noise, dB |

| off, windows closed | — | 31 |

| 1 | 53 | 32 |

| 2 | 104 | 34 |

| 3 | 153 | 37 |

| 4 | 203 | 41 |

| 5 | 253 | 45 |

| 6 | 303 | 46 |

| 7 | 352 | 48 |

But I was alarmed that the PM2.5 level did not drop to 0 after installing the air supply. The measuring device is located 2 m from the ventilation anemostat, so the first hypothesis is a bad hood in the bathroom. I decided to rule out problems with poor hood and measured the PM2.5 level right next to the anemostat. That is, he measured the air that had just come out of the ventilation. The device showed 21 μg/m3.

Photo

At the same time, on the street at the same time, the device showed 27 μg/m3. It turns out that ventilation filtered out only 22% of PM2.5 particles. The HEPA E11 filter installed inside should capture 95% of such particles.

Photo

My hypothesis was that there might be an air leak in the housing past the filter. But I decided to trust Minibox. They should know better what's going on there.

I'm trying to get it fixed

Next, I tried to get the Minibox manufacturer to fix the system. This process lasted about 3 months.

At first they tried to convince me that pm2.5 particles should not be filtered at 0

At first the sales manager suggested that their H11/E11 filter should not filter pm2.5 at all, but that they only filter H13. Of course this is not true.

Then they sent me the filter specification: it indicated that all measurements of filter efficiency were made at an air flow rate of 2m3/h. I use ventilation at 100 m3/h, so the HEPA filter does not work. This immediately seemed strange to me: what about other devices, what about Tion, why haven’t I seen reviews about this for any device, why air purifiers with filters of the same class demonstrate a 99% degree of purification. Let me get ahead of myself a little: the same filter was eventually able to achieve 80% cleaning efficiency at the same 100 m3/h. But I’m not an expert and I haven’t found any research on the topic of speed, I’ll be glad to hear the experts’ comments.

On the one hand, this can be forgiven for a company if they have never had to deal with this before. On the other hand, how can you sell devices with HEPA filters without knowing basic things about these filters?

Then they sent me a HEPA H13 filter

I was suggested to try installing an H13 (99.95% efficiency) filter instead of an E11 (95% efficiency). The idea seemed strange to me, but I decided to try it.

They hinted to me (so it seemed to me) that I needed to pay for the H13 filter. Since I didn’t believe in their idea, I offered payment after the fact: I’ll pay for the filter only if it removes pm2.5 to 0. But they asked me to at least pay for delivery - 350 rubles. Let me remind you that I ordered equipment and services from them for 147k rubles, of which all three filters cost 7k rubles.

Since I didn’t believe in their idea, I offered payment after the fact: I’ll pay for the filter only if it removes pm2.5 to 0. But they asked me to at least pay for delivery - 350 rubles. Let me remind you that I ordered equipment and services from them for 147k rubles, of which all three filters cost 7k rubles.

Ok, I received the H13 filter and paid for delivery. I take measurements: 18 µg/m3 outside, 16 µg/m3 at the outlet of the anemostat, cleaning efficiency pm2.5 11%. The new filter didn’t help, but I didn’t have to pay for it. I continued to ask the manufacturer to resolve the issue.

I take measurements: 18 µg/m3 outside, 16 µg/m3 at the outlet of the anemostat, cleaning efficiency pm2.5 11%. The new filter didn’t help, but I didn’t have to pay for it. I continued to ask the manufacturer to resolve the issue.

1.5 months of communication and waiting

First they told me that they checked the housing and there could be no air leaks anywhere.

They further informed me that they do not state anywhere that they should protect against these particles at all. And that they did not have the task of removing pm2.5. Formally, yes, but:

- I didn't find any promises about air filtration on their website. It seems that if no filter works at all, they will be able to say that this was not promised.

- If the device has a HEPA filter, and it says so on the website, then I expect it to work.

I was then informed that they had ordered filters from a different manufacturer for the test. Ok, I'm waiting. A month later they told me that they tested it, but it did not achieve 99.9% effectiveness. They reported that they were changing the filter manufacturer and there would be improved filters.

I asked them for an improved filter, even if it was not 99.9% efficient. They refused me, reminding me that they had already given me an H13 filter, and in general they had never stated anywhere about cleaning from pm2.5 particles.

I was also informed that the housing still needs to be taped - it seems that this indicates air leakage past the filter.

I make the following hypothesis:

- It seems that minibox has not figured out why the HEPA filter does not clean the air as expected

- minibox seems to have confirmed that there is an air leak

- This means the problem may not be with the HEPA filter. Air can flow past all filters.

- This means that all air purification may not work at all!

I tried to convey the hypothesis to Minibox, but without success.

I'm trying to cover the case as recommended in Minibox

First, I need to show the structure of my ventilation filter unit:

I was offered to cover the side and rear walls with sealant. But this seemed like a dubious idea to me, because there is a huge hole in the middle of the filter block. Even if the filter unit fits tightly on the sides and back, air will still escape through the central part. But I again decided to trust the manufacturer, after all, they should understand this better. I did as they suggested and additionally inserted a thick seal into the central cavity on one side. I covered everything with tape, otherwise it would fall off when inserting the block inside.

I measured pm2.5 again - no change. Pasting with a sealant didn't help at all.

Based on the results of 3 months of attempts to fix the purification of pm2.5 particles, there was practically no result. It was a shame that I spent about 150k rubles on a system that practically does not clean the air. True, everything is cool with CO2, and my sleep has improved. The manufacturer ultimately refers to the fact that he did not promise to clean pm2.5 and refuses to help or return the money.

I fix it myself

I didn’t want to give up and decided to figure out for myself why pm2.5 particles were not filtered. I remembered how I catch bugs in programs and applied a similar approach.

Step #1: eliminate the problem in the filter

The manufacturer referred several times to the fact that the problem might be in the filter, ordered new filters, and reported that they were going to change the filter supplier. First you need to understand whether the problem is in the filter.

We take a hairdryer and a device for measuring pm2.5. We blow into the device with a hairdryer - we get 16 μg/m3 pm2.5. We take a HEPA H13 filter. On one side, use a hairdryer to create a flow of air into the filter, pressing it tightly. On the other side of the filter, we measure the pm2.5 level with the device. We immediately get 0, cleaning efficiency is 100%! True, this was at average speed, at maximum it was worse.

We repeat with the HEPA E11 filter - the result is similar. It turns out that both of my HEPA filters are working, and Minibox was in vain trying to replace them.

Step No. 2: eliminate the problem in the filter block

Ok, the HEPA filter is working. But what if the filters in front of it create pollution? It sounds unlikely, but it's better to rule it out.

We repeat the experiment with a hairdryer, but now with the entire filter block. To do this, I seal all potential air leaks, including the cavity in the center. The result is similar - about 0 μg/m3 at the output.

This means that the problem is not related to the filters at all.

Step No. 3: rule out or confirm an air leak inside the filter unit

The HEPA filter comes last because there is a cheaper coarse filter in front of it. Let's swap them for a while: let's put HEPA as the first filter. If you leave it like this forever, you will have to frequently change the expensive HEPA filter. But it will do for an experiment.

We start ventilation without filters at all - the pm2.5 level is 10 μg/m3. If the HEPA filter is the last one - 8 µg/m3. We put the HEPA filter first - 5 μg/m3. Whoa! It turns out that air actually leaks out and this happens after the first filter. It also turns out that there is a leak even before entering the first filter, since the result is not 0 µg/m3.

Step No. 4: rule out or confirm air leakage in the cavity in the middle

The cavity in the middle of the filter block is needed for a reason: it contains an ultraviolet lamp. The lamp is necessary for the operation of the photocatalytic filter.

This is what the inside of the case looks like, where the filter unit is inserted:

A UV lamp is located on iron mounts. Let me remind you of the structure of the filter unit:

Take the seal:

And we attach it to the cavity in the middle of the filter block so that there remains a small gap into which the UV lamp will pass. We wrap everything with tape to keep it tight:

We try to insert such a block back into the body - without success. The seal does not hold.

Then I remembered that the UV lamp and its holders are needed only for the photocatalytic filter. And I specifically refused this filter because of its potential harm. Bingo! Let's just remove this lamp design. It is attached with rivets, but they are easily pulled out by hand:

Now that the UV lamp and its mount are gone, the central cavity in the filter block is no longer needed. We seal it tightly with a sealant and tape over it.

We insert the filter block back, the result is 6 μg/m3 (outdoors - 10 μg/m3, by default the installation produces 8 μg/m3). The result is good, but a little worse than where the HEPA filter was placed first. This means that there are leaks not only in the central cavity of the filter block.

We seal several potential gaps in the filter block with tape. Let's launch - hurray, 5 µg/m3! So, we have localized and fixed the leak in the filter unit.

Step #5: fix leaks before entering the first filter

When installing the HEPA filter first, we found out that there was a leak even before entering the first filter. This means you need to look at the bottom of the filter block and housing.

The pipe with air from the street is much narrower than the filter unit itself. Air can bounce off the filters and flow back down the bottom of the chassis. Therefore, we tape everything from below with tape that is not above the pipe with air.

We also glue the seal around the perimeter of the lower part of the filter block.

We launch it and get 3 µg/m3. Great! Now we will seal the entire bottom of the ventilation housing with a sealant and tape it. We launch - hurray, 2 µg/m3.

Step No. 6: fix the air leak in the lid

Air seeks the path of least resistance. After fixing the previous leak, the air found its way through the cap covering the filter unit. I realized this by the whistle that came from there. I had to seal the lid with tape:

Bottom line - I fixed several air leaks. On the day of the experiments, without filters, ventilation produced 10 μg/m3, with filters without my changes - 8 μg/m3, after all corrections of air leaks - 2 μg/m3 . I note that the numbers are approximate, since minutes and hours passed between measurements, and the quality of air outside is constantly changing. A level of 2 μg/m3 was enough for me: that’s where I stopped.

Photos of final measurements pm2.5

It turns out that the HEPA filter worked at 80% efficiency instead of 20%. And since the main problem was air leakage, it seems that the other two filters also began to clean the air more effectively.

Previously, we kept the ventilation on speed two: this was enough to maintain 700 ppm CO2. After fixing the air leaks, I had to turn the ventilation on to third speed to maintain the same CO2 level. Because of this, the noise level rose from 34 to 37 dB. It is much noisier, but you can still sleep.

Forced supply ventilation

It should be noted that there is also forced exhaust ventilation, which differs from forced supply ventilation only in that the fan is installed on the hood. There is another option, which is called a forced supply and exhaust circuit. This is when fans are installed for both air supply and exhaust. This system is most often used in private housing construction. In apartments - either exhaust or supply. Although it should be noted that today manufacturers of ventilation equipment offer various new products in the form of air handling units for apartments. They are compact, effective, but not cheap.

Since the topic of the article is supply ventilation of the apartment, we will consider this option. As mentioned above, the supply circuit means the presence of a fan. Therefore, there are air valves on the market, inside of which low-power fans are installed. The photo below shows two types of such devices: with a cylindrical channel shape and a rectangular one.

Two types of air valves with fans inside

In principle, the process of installing such a valve is no different from the previous one:

- You also need to use a puncher and a crown to make a through hole;

- install a cylindrical valve into it;

- fill the space between the device and the walls of the hole with foam;

- connect the fan to the mains supply;

- install a cover on the street side that will protect the hole from the entry of birds and small animals, debris and dirt;

- A decorative grille is installed on the inside of the valve, with which you can regulate the power and direction of the incoming air flow.

Forced ventilation in an apartment is not only about installing valves with fans inside. There are several options for organizing a ventilation system of this type.

Air conditioner with forced ventilation for an apartment

Conventional air conditioners work like this: the air from the room is forced through a filter, then through a heat exchanger, where it is cooled, and then it is reintroduced into the room. That is, the air masses are purified, cooled, but do not become fresh and saturated with oxygen.

Today, air conditioner manufacturers offer models in which small fans are installed as a separate element; with their help, fresh air is driven into the rooms of the apartment. The design features of fan installation vary greatly from manufacturer to manufacturer, but the meaning is the same for all. The fan is connected to the street by an air duct, which passes through the same channel as all communications of the split system.

It is necessary to indicate that the fan itself can be installed outdoors or inside the house on the housing of the indoor air conditioner unit. The photo below shows the first option with installing a fan outside, which is connected to the room in the apartment with a hose.

Air conditioning with fresh air from outside

Comment

All described problems with Minibox Home-350 ventilation:

- are subjective, and their presence is only my opinion: if only because I cannot guarantee the performance of my device for measuring pm2.5. In addition, the measurements were made with a difference of minutes or hours between each other, which already makes all experiments inaccurate.

- Applies to my installation only; other customers may not have them.

Everything described in the article is my personal opinion. All statements about products and companies are my value judgments and not facts.

Budget options for restoring air exchange

Wall and window valves do not have a fan. The air flow occurs due to the difference between street and “home” pressure. A prerequisite for the operation of overhead inlets is proper exhaust ventilation.

Features of different types of window valves

The design of all window climate control devices is very simple. A typical valve consists of an air intake, a telescopic duct and an indoor unit.

The air intake is installed outside the frame. The external unit is equipped with a visor and a grille that prevents insects from getting inside. The telescopic channel cuts into the frame, forming a through gap for the unhindered flow of air.

The indoor unit is mounted on the side of the room. Some models of inlet units are equipped with a filter and a valve that regulates the throughput of the device

Based on the design features and installation method, the following climate control devices are distinguished:

- slotted;

- folded;

- invoices.

Slot models. The throughput capacity of the unit reaches 20 cubic meters per hour - the influx of air masses is carried out through a micro-hole up to 1.6 cm high and up to 4 cm wide. The device consists of two blocks, which complicates its installation - milling of the window frame is required .

Rebated valves. This is the most affordable and easiest way to ventilate a room. The air flow is carried out through slits in the vestibule. The main advantage of the models is the ability to install them on a window in use without milling a groove.

Additional advantages of rebated models include: low cost, preservation of the sound-absorbing and heat-retaining properties of PVC double-glazed windows and the possibility of automation.

The valve capacity does not exceed 5 cubic meters/hour. To ensure a larger volume of air supply, it is permissible to install several valves on one window

Overhead climate products. This option is rarely implemented in domestic conditions due to the complexity of installation - the valve is inserted at the stage of assembling the double-glazed window. In addition, the product worsens the heat and sound insulation of the window.

Overhead modifications have found their application in production and warehouse premises. The productivity of climate control devices is about 100 cubic meters per hour.

In the simplest models of window inlets, the size of the gap, and, consequently, the intensity of the air flow, is selected manually - the position of the valve is adjusted. High-tech devices are equipped with humidity and atmospheric fluctuations sensors.

Wall model: device and installation

Externally, the wall valve resembles a cylindrical flask or a wide pipe, with a diameter of about 10-16 cm.

The plastic air duct is equipped with the following elements:

- thermal insulation layer - a “sleeve” passes through the entire flask, preventing freezing of the wall and reducing the noise effect from the street;

- filter – located at the outlet of the air duct, provides rough air cleaning.

In some models, an O-ring (silicone) with flaps is placed in front of the filter. The purpose of the part is to equalize the air flow in windy weather.

On the street side, the wall air duct is closed with a metal grille and an anti-mosquito insert, and on the inside - with a decorative cover with an adjustable handle

When choosing an air supply device, the power and “operating” temperature of the unit are first assessed. On average, the productivity of a wall climate product is 40 cubic meters/hour. This value is enough to ventilate a room of 13 sq.m.

The operating temperature range is indicated by the manufacturer on the packaging or in the instructions for the device. For harsh climatic conditions, special models have been developed to prevent the formation of condensation and the appearance of an ice plug in the channel.

The following photo selection will clearly introduce the technology of installing a wall valve:

Image galleryPhoto from At a height of approximately 2 - 2.2 m from the floor plane, we drill a hole in the wall. We select the drill bit in accordance with the size of the future ventilation duct. We rework the hole with a drill of a smaller diameter, trying to give it a slight slope towards the street. In the hole drilled and cleared of dust, we first install insulation, made in the form of a pipe, then a plastic air duct. We cut the insulation flush with the surface, the air duct should protrude by 1 cm. We apply the lower part of the housing to the installation site and mark the fixation points of the device through the holes in it. We fix the lower part of the housing to the wall by drilling holes at the marked points. We place the included filter in the housing. We snap onto the upper part of the housing, equipped with a device for adjusting the air flow. We check the functionality of the system and the ability to regulate the volume of air flow entering the room. On the outside of the wall, we install a grille with inclined lamellas, it will protect against insects and birds. Step 1: Drilling holes for installing the valveStep 2: Refinishing the hole with a drillStep 3: Arranging the drilled holeStep 4: Marking for attaching the valve bodyStep 5: Installing the filter into the fixed bodyStep 7: Installing the supply valve coverStep 7: Checking the functionality of the systemStep 8: Installing the grille from the facade

Stage 1. Determining the location. When choosing a wall, you should consider some nuances:

- It is better to install it on a supporting structure;

- optimally – the valve “exit” to the insulated loggia;

- It is better to avoid installation from the side of the roadway.

Valve manufacturers have designated recommended and undesirable areas for installing the device. When installing, it is important to consider the air flow vector.

In the first option, fresh air entering the apartment warms up at the top and falls down. The second option is that the air masses are heated by the heating radiator

Stage 2. Preparation and drilling of the wall. On the inner wall, mark the place for the through hole and draw the diameter of the valve.

Channel drilling procedure:

- Perform initial drilling with a diamond core bit to a depth of 10 cm.

- Remove debris and use a chisel to knock out a small notch for stable placement of the drill.

- When drilling, keep the slope outward - this position of the air duct will prevent rainwater from getting inside the device.

It is better to carry out the work with an assistant who will periodically wet the drilling area. Humidification will reduce dust levels and protect the instrument from overheating.

Stage 3. Installation of valve components. Clean the groove from dust and place a heat-insulating “sleeve” in the channel. Using screwing movements, install the cylindrical body of the device, and secure the fine-mesh grid on it.

A panel, a ring with dampers and a filter are fixed from inside the wall. The final stage of assembly is installation of the lid with the adjusting handle

Ways to increase the efficiency of inflow

Various techniques aimed at improving the performance of supply ventilation are divided into two main categories:

- measures that increase air flow without blowers;

- use of forced air units.

The first group includes: manual or automatic ventilation, installation of a window or wall valve.

Manual ventilation. Opening the window for 15 minutes every 3 hours. It is almost impossible to implement the method in practice - there is no time or no one to constantly open and close the window. An alternative option is to open the window sash in micro-ventilation mode.

The disadvantage of this method is that dust from the street and noise enter the apartment through the gap. In winter, micro-ventilation gradually cools the room

Automatic ventilation. A servo drive is installed on the flap of the window. The device is programmed to open the transom at specified intervals or is equipped with a weather sensor.

The “intelligent” mechanism reacts to changes in humidity and changes in the atmosphere - during rain, strong wind or snow, the sensor will work and the window will close on its own.

It is possible to connect the automatic electric drive to the general fire safety system. If there is smoke in the room, the drive will operate and the window sash will open.

The automatic ventilation method has the same disadvantages as the manual method.

Window and wall valve. Overhead and built-in air inlets perform the same function - they provide access to fresh air flows into the room. Varieties of valves differ in characteristics and installation technology.

Wall valve models are more productive; they are advisable to use in spacious rooms. Window vents are suitable for compact rooms

Installing a wall device is more complicated than installing an inlet on a window sash, as it requires drilling a through hole through the load-bearing structural element of the building. Products for windows are cheaper than their wall counterparts.

Ductless devices for forced air flow:

- Ventilators. Essentially, this is the same wall valve only with a built-in fan. The supply of fresh air does not depend on the external parameters of the atmosphere (temperature, pressure), but is determined solely by the performance of the fan.

- Breezers. Unlike ventilators, the installation provides high-quality multi-stage filtration. An additional plus is the presence of climate control. The user sets a comfortable temperature, and the smart device automatically heats the air.

- Air conditioners with air supply option. Multifunctional two-block split complexes with air mixed from outside are equipped with an air duct connecting both buildings, as well as an air mass filtration system.

The listed devices are installed without laying an air duct and work to supply air to one room. To comprehensively restore the supply ventilation function in several rooms at once, duct systems are used.

The installation of air ducts must be taken care of even at the repair stage. Otherwise, you will have to dismantle the finishing or create a false box for laying ventilation ducts

Features of duct supply systems:

- high performance;

- possibility of air heating;

- control automation;

- sufficient sound insulation;

- high cost of components;

- complexity of installation.

Duct ventilation is rarely installed in apartments. Priority areas of application: offices, cottages and public premises.

You can learn how to check the efficiency of wall and window ventilation valves by reading the following article.

Main stages of supply ventilation device

To make fresh air ventilation in a house or apartment with your own hands, it is important to carry out competent preliminary work. It consists of several points.

Carrying out calculations. For a private cottage under construction, the ventilation system can be designed together with the general plan. For a finished building and an apartment in a high-rise building, an autonomous air duct is created, taking into account the area of all rooms and each room separately. All calculations are carried out according to a formula that uses the values necessary for optimal circulation of air masses. These include:

- total power and performance of the supply system;

- fan input power;

- air flow rate;

- maximum noise level from device operation;

- diameter of inlet openings, dimensions and length of pipes;

- power and energy consumption of additional devices (heater, recuperator, etc.).

When carrying out calculations, the coefficients established by SANPiN are taken into account.

Based on the calculations performed, a detailed layout of all components of the device is drawn up.

Next, parts are selected from the remaining building materials and the missing elements are purchased.

Now it has become possible to purchase ready-made ventilation devices of the supply and supply and exhaust type. Different manufacturers have different prices. But why spend extra money if every man can install such a system at home on his own. Do-it-yourself supply and exhaust ventilation takes longer and is a little more complicated. It is much easier to equip a regular flow-through air duct.

Drilling a through hole: choosing a location

When installing supply ventilation, it is possible to choose the location for installing the wall unit of the system. Experts usually recommend hanging equipment in the middle of the wall, at a height of 1.5 meters from the floor. This location ensures optimal distribution of incoming air flows and efficient air exchange.

Meanwhile, the final choice remains with the owner of the living space. If the diameter of the hole does not exceed the value established by law, then the owner can choose any place. The restrictions here are purely technical:

- First , to install drilling equipment you need 30-50 cm of free space, so you won’t be able to make a hole close to a corner, right next to the floor or under the ceiling.

- Secondly , the drilling location is selected taking into account the location of electrical wiring or other communications running inside the wall. To determine the course of cables and pipes in the thickness of the wall, ventilation installation specialists use special sensors.

Exhaust ventilation

The task of exhaust ventilation is to remove exhaust air, airborne particles and unpleasant odors from the apartment. Exhaust ventilation systems are divided into local and general. They can work either autonomously or in combination with natural or forced ventilation.

A feature of all exhaust ventilation systems is the presence of exhaust channels through which exhaust air is discharged outside the room. In this case, air intake grilles are always installed in the kitchen and bathroom. Thanks to this arrangement of the exhaust ducts, unpleasant odors and moisture do not spread throughout the apartment and are “locked” in a limited area.

A typical example of local exhaust ventilation combined with a natural ventilation system is a kitchen hood

.

Quite often, small fans are installed in the ventilation shafts of bathtubs and toilets to remove excess moisture and unpleasant odors from the premises.

Installation of duct air exchange systems

When installing duct ventilation systems or kitchen hoods, special boxes or flexible corrugated pipes are used.

They are also needed to move air from technical rooms to a remote entrance to the ventilation shaft. You can carry out the installation work of such an air duct on your own.

Basic rules for duct design

For apartments there is no need to use metal ventilation ducts designed to pass air flow at high speeds and to operate at sub-zero temperatures. Plastic boxes are easy to install and easily fit into the design of any room.

You can find many offers of plastic air ducts for ventilation, differing in color, cross-sectional area, shape, method of connecting sections and method of fastening to walls and ceilings.

The presence of a large number of shaped elements allows you to create a ventilation duct of any geometry. The choice between a round and rectangular cross-sectional shape is not fundamental from a technical point of view.

The cross-sectional area should be selected so that the flow velocity does not exceed 2 m/s. Otherwise, noise will occur in the channel, and an increase in resistance will lead to rapid wear of the equipment.

The size of the plastic ventilation duct for an apartment must be selected so that the air flow speed at maximum load is from 1 to 2 m/s

When designing duct geometry, it is desirable to minimize the number of turns, narrowings and transitions that increase aerodynamic resistance to flow, generate noise and accumulate grease and dust deposits.

Features of installation of plastic boxes

The plastic parts of the ventilation duct are lightweight, so they do not require any special actions during fastening.

Depending on their location, installation proceeds as follows:

- Inside the cabinets, the elements are secured to the cabinet walls using clamps. Foam or foam inserts are introduced into places where they pass through walls and partitions to prevent rattling during system operation.

- Above the cabinets, the elements are secured using any holders and screws.

- The structure is fixed to the wall and ceiling using special clamps, which can be purchased for any channel size. The distance between fasteners should be no more than 1 meter.

Immediately after installing the ventilation duct, which will subsequently be hidden behind a suspended or suspended ceiling, it is necessary to check its operation at the maximum possible air flow power. Detected problems are easier to fix immediately while access to the system is not difficult.

It is quite simple to securely secure the elements of the plastic ventilation duct using special clamps. They are not expensive, so it is better not to use independent solutions

By coating the joints of the elements with silicone sealant, you can obtain an additional guarantee of the tightness of the structural joints.

For these purposes, there is no need to use glue or “liquid nails”-type compounds, since in the future it will be almost impossible to disassemble the system for maintenance or change its configuration.

If depressurization does occur, and to eliminate it there is no way to disassemble the air duct, then in this case it is necessary to wrap the problematic joint with self-adhesive tape to match the color of the shaped elements.

Recuperation units for apartments

The disadvantage of many supply ventilation systems is the high energy consumption for heating or cooling the air entering the apartment. Recuperation units will help reduce energy consumption - they use the thermal energy of exhaust air masses to heat fresh air from the street.

If there is a high temperature difference between the street and the apartment, the recovery unit will not be able to achieve the required parameters, and the air will have to be heated, but the energy consumption in this case will be much lower than for conventional heating of supply air.

The higher the efficiency of the model, the less the need for additional air heating. On average, the efficiency of modern air handling units is 85-90%, which often makes it possible to completely abandon the use of a heater.

Monoblock air handling units with a recuperator take up relatively little space - they can easily be installed on a balcony or loggia. Among the products of leading manufacturers of climate control equipment, models with a capacity from 150 to 2000 m3/h are widespread. For comparison, a one-room luxury apartment with an area of 60 m2 with two residents requires an average air exchange of 300 to 500 m3/h.

Breezers and recuperators

The problem with supplying cold air, typical for wall dampers, has been solved in breathers - local air supply units equipped with a fan and an electric heating element. Advantages of the unit:

- three stages of influent purification - in a coarse, fine and sorption (carbon) filter;

- heating the air to the set temperature;

- automatic and manual control of fan performance;

- air quality monitoring – measuring humidity, temperature and carbon dioxide concentration;

- partial recirculation - return of room air after filtration - allows you to save energy;

- remote control from a remote control or smartphone.

Let us note 3 disadvantages of the unit: operating costs for electricity, high cost of the breather and its repair in case of failure. There is no point in describing the installation technology - the household appliance is built into the wall in the same way as a valve.

Breather device - local air supply unit

Reference. With the help of breathers it is convenient and comfortable to ventilate any living space. But it is difficult to call the units generally available - the price of products from the famous Tion brand starts from 300 USD. e.

A wall recuperator, a supply and exhaust unit capable of removing heat from the exhaust air, will cost even more. There are 3 types of installations, differing in cost and principle of operation:

- Reversible (sellers call them regenerative). The operating algorithm is simple: first, the exhaust air heats the ceramic heat accumulator, then the only fan changes the flow direction and the element releases the accumulated heat to the influent. The cycle is repeated at intervals of about 1 minute.

- Rotary. There are 2 fans constantly running here - supply and exhaust. Both streams pass through a rotating rotary heat exchanger, exchanging heat.

- Cross flow. The exhaust air transfers heat to the supply air through the thin walls of an aluminum or copper heat exchanger. The fans direct the flow towards each other, as shown in the diagram.

The most effective recovery option is in a cross heat exchanger, which allows you to return about 70% of the thermal energy back into the room. The efficiency of the rotary unit is slightly lower - about 5%. The actual heat transfer rates in reversible units are unknown, and sellers, as usual, overestimate the efficiency of these recuperators.

Combining ventilation and air conditioning in an apartment

A city apartment can rarely boast of having extra space, so combining ventilation and air conditioning systems into a single complex

not only reduces installation costs, but also saves valuable space.

The simplest version of a ventilation and air conditioning system is a conventional air conditioner with a fresh air supply function

. It will not be able to provide full air exchange, but at least in one room there will be an influx of fresh air. It can be used in conjunction with Ventmashine ventilation units.

Another option for comfort lovers would be a duct system.

ventilation and air conditioning. It is based on a central air conditioner with the option of adding fresh air or a supply and exhaust unit with a cooler. If desired, the installation can be additionally equipped with a recuperator.

Do-it-yourself supply ventilation installation

Supply ventilation in an apartment in a multi-storey building can be connected to a common house natural air duct system. To do this, you first need to check its condition in a simple way. A notebook sheet is applied to the ventilation hole. If the paper adheres to it and is held, then there is traction and the air duct can be used.

If the channels are clogged and clogged, you can try cleaning them. But in a large house this can be problematic. Then supply ventilation is installed using valves. They are bought in the store. How many of these parts are needed depends on the size and total area of the space. Valves come in different capacities.

The simplest models of these devices include an indoor unit, a protective grille and a connecting pipe. They are usually installed above the radiator to minimize heat loss.

- In the selected location, primary marking is carried out: the outline of the valve device is outlined.

- If it was purchased assembled, then you need to disassemble and free the body.

- Using a hammer drill, a through hole is made in the outer wall, trying to maintain a slope angle of no more than 7 degrees.

- A tube covered with insulating material is inserted into it. It should be invisible from the outside, and protrude 1 cm from the inside.

- At the points where the tube is attached, holes are drilled in the wall for dowel-nails.

- They fix the body of the supply valve, which is additionally clamped by the insulating layer of the tube.

- When the base of the device is securely fastened, the parts that were removed during disassembly are inserted into it.

- A grille is installed outside.

- After this, the operation of the supply valve is checked by opening and closing the valve.

During operation, it is necessary to disassemble and clean the valve twice a year from dirt and dust that clogs it through the cracks in the grille.

Installing fresh air ventilation in an apartment is a simple and reliable way to improve air quality and maintain a favorable microclimate.

Vents in the foundation

Vents, or vents, in the foundation are ventilation holes located above ground level and located in the very foundation, plinth or floor of the basement. Properly designed vents help keep the air in the basement dry and thereby prevent the accumulation of condensation, the formation of fungi, mold and pathogenic microorganisms.

Size selection

The choice of the number of vents depends on the volume of the basement. For every 400 cubic meters of volume it is necessary to arrange 1 vent. In regions with high air humidity, 1 blow is necessary for every 100–150 cubic meters.

The shape of ventilation windows can be any, but for technological reasons they often choose rectangular or round. According to SNiP, the total area of ventilation openings in the foundation must be at least 1/400 of the total area of the basement.

For technical reasons, vents must be round in shape.

In private construction, they prefer to make many vents with minimal sizes for each: this adds aesthetics to the exterior of the house. The most common sizes of rectangular vents are 25x20 or 50x10 cm, the diameter of round ones is 25 cm.

Ventilation location

Ventilation slots are placed evenly along the walls of the basement in increments of 2–3 m. To prevent moisture from accumulating and air from stagnating, vents are created in the corners of the basement at a distance of at least 0.9 m from the inner corner of the room.

The minimum recommended distance from the ground to the vents is 25–30 cm. Through lower holes, wastewater can flow into the basement. It is recommended to install the same number of symmetrically located vents on opposite walls of the basement.

Creation of perfumes

It is easier to make round vents in a concrete foundation. To do this, before the stage of pouring the base, plastic or asbestos pipes of the required diameter are prepared, filled with sand and closed at both ends with plugs. After this, the pipes are installed in the formwork for pouring concrete into pre-calculated places and in the required quantity.

In brick and block structures it is easier to create rectangular vents. To do this, a reinforcement frame is prepared, the rods of which will serve as support for the upper rows of masonry. In brick walls, vents are often made using half or part of the brick.

In brick houses you can make rectangular vents.

Should the vents be closed for the winter?

Vents should be covered with air-permeable grilles to prevent cats, birds and rodents from entering the basement. It is impossible to completely close the vents, incl. in the cold season. And in order to prevent the floor from freezing in winter, it should be properly insulated even at the construction stage.

Option without vents or vents

To equip a basement without vents or vents, it is necessary to create a drainage system that drains water from the foundation. When pouring the latter, it is recommended to use deep penetration concrete with polymers.

After pouring the base, it must be isolated from water. For this, extruded polystyrene foam is used, which is fused onto the concrete base of the foundation. They also insulate blind areas.

The floor inside the basement is waterproofed with polyethylene film or membrane material extending onto the walls to a height of 20–30 cm and secured with pressure strips.

At the last stage, the supply and exhaust air ducts are installed. The latter is brought to the roof through a pipe, while the former is made in the form of a hole in the floor (preferably from non-residential premises) and covered with a mesh.

Installation stages

The use of this type of ventilation is relevant in any room - from the bedroom to the kitchen. The number of valves can be selected in this way:

- 1 valve under each window.

- 1 valve for every 15-20 “squares” of area.

To install the ventilation valve you will need the following set of tools:

- Pencil (marker, pen).

- Hammer.

- Crown for concrete (diameter – 60 mm).

- Drill for concrete (diameter – 40 mm).

- Drill for concrete (diameter – 6 mm).

- Industrial vacuum cleaner (if not, use a broom and dustpan).

- Polyethylene (or rags) - to cover the work area.

- Thick and durable plastic garbage bag.

The product is installed above the battery so that the outlet “looks” at its center. In this case, the distance from the case (or rather, from the outlet) to the radiator must be at least 15 cm.

Drilling a hole for the air duct of the Domvent valve

Now let's look at the process step by step:

- Marking is carried out: the housing is applied to the wall in the selected location.

- Mark the center of the hole for the pipe and the holes for the fasteners.

- Using a crown with a diameter of 60 mm, the wall is drilled to a depth of 7-10 cm. In order not to litter the floor in the room, you should place a bag under the hole (or lay down film/rags).

- Using a drill with a diameter of 40 mm, the wall is drilled through.

- A plastic tube is inserted into the hole made. From the outside it should be flush with the surface of the wall, from the inside it should protrude by 7-10 mm. If necessary, the pipe should be cut to the required size.

- A heat insulator is placed on the end of the tube closest to the room. It should protrude from the hole by about 10 mm, no more. If necessary, excess is cut off.

- From the outside (from the street) a grate is glued to the tube (this will have to be done while leaning out of the window).

- Using a drill with a diameter of 6 mm, holes for fasteners are drilled.

- Fastener plugs are inserted into the holes.

- The valve body is pressed against the wall and fixed with self-tapping screws.

- An anti-mosquito net and seals are installed in the housing.

- The housing closes.

The procedure itself, with the participation of two people and the presence of the above-mentioned tool, will take about an hour on average. The cost of installing a Domvent ventilation valve by hired specialists will cost approximately 2,000 rubles.

Installation stages (video)

Care and cleaning

Over time, the use of the product leads to the fact that the seal located inside the housing gradually becomes dirty. It is recommended to clean it approximately once a year. The warm season is best suited for this, since the use of a ventilation valve is primarily relevant in cold weather.

To clean the sound absorber of the Domvent ventilation valve, you need to remove the housing cover, take out the seal and simply shake it several times to get rid of dust. Alternatively, you can do this with a vacuum cleaner (which is much more effective).

If there is too much dirt, you can wash it with a polyf under low-flowing water. In this case, the seal must be dried before installation. After cleaning, the sound absorber is installed back and covered with the housing cover.

Disassembled Domvent valve body

In addition to getting rid of dust, in winter you should pay attention to the condition of the outer grille - in severe frosts it can freeze. To solve the problem, the valve damper must be completely closed until the ice has completely melted.

Reviews about the model

It’s easy to find reviews about this model - many people have already installed it in private houses, apartments, and non-residential premises (offices, workshops, and so on).

Alexey V., 30 years old, Omsk:

About 3 years ago, supply valves were installed in our office so that noise (we are located in an area with constant construction) would not distract people from work. In winter, of course, you have to close it - despite the fact that the valve is located near the battery - the air still comes in cold.

But in the summer it is an irreplaceable thing. There is no need to open the windows, and the air conditioner is also turned on less often.

Dmitry A., 41 years old, Krasnodar:

In our country now, probably, all new buildings are immediately equipped with inlets. Last year we were choosing an apartment, probably looking at 15 options - and almost every new building had valves. The one we chose in the end turned out to be a Domvent: one in each room.

The model is not bad for its price - it has inflow adjustment and insulation (although it is more likely for show - such insulation is of little use, especially in colder latitudes). Well, it doesn’t let in much air - one valve is definitely not enough for the room.

TOP best air handling units

The best inexpensive air handling units

These models have a low cost (we have placed devices with a price of up to 25,000 rubles in the budget mechanisms segment). Thanks to this, such ventilation units are suitable for buyers with a limited budget. Most often, such models are used for domestic use.

Domovent Solo RA1-35-9R

This model is a supply valve. The device has a low price. The manufacturer of this mechanism saved money on the control panel - it is not included in the package. The unit can be turned on using the switch located on the power cable. You can still regulate the ventilation performance using a pull cord switch. The package weight is 2.5 kilograms.

Cost: 7,500–8,500 rubles.

Domovent Solo RA1-35-9R Pros

- low price (the model is available for budget buyers);

- small dimensions;

- high degree of protection.

Minuses

- There is no control panel.

Blauberg Fresher 50 1000045121

The model of this air handling unit has a high-quality filter, which in turn is capable of fine or coarse cleaning (depending on the desire of the buyer). Products can be connected to each other in series and form a chain. The design also includes a humidity sensor and a sensor that measures the carbon dioxide content in the room.

Cost: 14,000–16,000 rubles.

Blauberg Fresher 50 1000045121 Pros

- high degree of protection;

- several operating modes;

- low cost of the model;

- energy saving.

Minuses

- Thick walls are required for installation.

Aeropac SN

This model is universal. The device can be used both in an apartment and in a residential building. This ventilation is used less often in offices. The housing of the air handling unit is very durable. The model is able to withstand falls or loads. The device can be mounted next to the battery (to increase the room temperature in winter). Installation on an air duct is also possible. The mechanism has a fairly low level of electricity consumption.

Cost: 18,000–21,000 rubles.

Aeropac SN Pros

- the model has a long cord;

- can work on filters from other manufacturers;

- strong, durable construction;

- You can make a hidden installation.

Minuses

- not controlled using the remote control.

Tion Lite

The model is small in size; among the entire Tion line, this model is the smallest. The device can be mounted into the wall at any angle - this does not affect its performance. You can also select the filtering level. In total, the model can operate at six speeds. The display of the device reflects all the most important information - full climate control is provided.

Cost: 23,000–25,000 rubles.

Tion Lite Pros

- small dimensions of the model;

- there is the possibility of hidden installation;

- heater power is 850 W;

- can be installed at any angle.

Minuses

- insufficient quality of noise reduction.

VAKIO Lumi

This model can be mounted on walls with a thickness of 15 cm or more. The model is small-sized. Ventilation has a high degree of filtration. The installation efficiently cleans the air from street dust or harmful substances. The model has three modes of operation: supply, exhaust, and can also be used as a passive valve. The device perfectly dampens noise coming from the street. The mechanisms can be combined into a joint group of 10 installations.

Cost: 20,000–22,000 rubles.

VAKIO Lumi Pros

- possibility of combining into one cluster;

- control can be carried out from me on the case or using the remote control;

- inexpensive maintenance;

- Can be installed on thin walls.

Minuses

- The kit does not include a heater (additional purchase required).

The best premium air handling units

In this section we have included air handling units with a price starting from 45,000 rubles. These mechanisms are capable of providing hundreds of square meters of space with fresh air. They usually come with many different sensors and more options available.

AIRNANNY A7 BabyCare H11

This device was created specifically to control the climate inside a children's room. The model continuously introduces fresh air into the room, monitoring the state of the environment: humidity, temperature and other indicators. The mechanism can be configured to operate automatically. The device has a robust design that can withstand mechanical damage or loads. The model is also resistant to hypothermia – it can function at a temperature of -20°C.

Cost: 47,000–49,000 rubles.

AIRNANNY A7 BabyCare H11 Pros

- withstands negative temperatures;

- favorite among ventilation for children's rooms;

- there is no sound or light alarm - nothing will interfere with the child’s sleep;

- many different options.

Minuses

- large dimensions of the model.

Tion 3s Plus

The model can immediately supply fresh air and filter it. The model perfectly cleans the air flow from dirt and dust. The device collects and displays several environmental parameters at once: it shows air temperature, humidity and carbon dioxide concentration. The product has six different speeds for operation. Maximum productivity is up to 140 cubic meters/hour. Depending on the selected power, the noise level from the installation ranges from 19–47 dB.

Cost: 50,000–53,000 rubles.

Tion 3s Plus Pros

- 6 speed modes;

- energy efficiency;

- controlled remotely (via smartphone using Bluetooth function);

- filters are easy to replace.

Minuses

- There is no control panel on the ventilation itself.

Ventmachine Satellite

The device has excellent performance, but at the same time produces a low noise level during operation. There is also the possibility of installing a model with wiring for several rooms. That is, one such installation can easily replace several cheaper options (the price of this model is quite high). The device has a long service life. Ventilation can serve its owner for decades.

Cost: 150,000–155,000 rubles.

Ventmachine Satellite Pros

- a sufficiently high coefficient of suppression of external noise (coming from the street);

- high service life;

- many functions included (fire sensor, carbon dioxide sensor);

- Durable stainless steel construction.

Minuses

- high cost of the model. Further maintenance will also cost a pretty penny.

Problem Analysis

So you bought a breather or air purifier. How do you know that it is working and cleaning the air? Without a measuring device - no way.

Before solving a problem, you need to learn how to measure it.

Metrics

I decided to find a device to measure CO2 and air pollution.

Air pollution is most often measured using the PM2.5 metric.

This is the content of particles <= 2.5 microns in size in the air. For comparison, the thickness of a human hair is 50 microns. Why this size? In my opinion, for convenience: particles of this size are the most common and harmful to health. What other metrics did I use?

- PM10 - content of particles <= 10 microns in size. The size was chosen specifically: the natural filters of the nose only retain particles > 10 microns in size.

- HCHO - formaldehyde, emitted, for example, by furniture.

- VOCs are volatile organic compounds found, for example, in exhaust gases.

We do not consider rare metrics - NOx, SO2, CO - since the instruments for measuring them are not widespread.

Below we consider only PM2.5 and CO2.

For CO2, the recommended level indoors is 500-800 ppm, typical outdoor levels are 400-500 ppm.

With PM2.5 it is more difficult. In Australia, by law, the annual average concentration must be no more than 8 μg/m3. In Europe - no more than 25 μg/m3. In the USA - no more than 12 μg/m3. Does this mean that values below the threshold are safe? No. Every 10 µg/m3 of PM2.5 concentration increases the risk of lung cancer by 36% . The only safe level is 0 µg/m3. Read more about health hazards in this article.

I set myself target values for CO2 metrics - 700 ppm, PM2.5 - 8 μg/m3.

Disadvantages of PM2.5 Reduction

Reviews sometimes write that lowering PM2.5 levels relaxes the immune system, but I have not found scientific evidence for this.

Measuring instruments

I bought an Air Quality Pollution Monitor for $130 to measure. But it showed zero PM2.5 levels all the time. I haven't figured out how to calibrate it correctly.

So I bought a separate AirVisual Pro for $270 to measure PM2.5. After a year of using it, I am completely satisfied with it.

The large number on the green background on the left (13) is the US AQI level. In this device it is just a different scale for PM2.5. The small number on the black background on the left (3) is the PM2.5 concentration. On the right is the carbon dioxide level (982).

I took photos of the devices at the same time. It can be seen that AirVisual Pro detects PM2.5, but the first device does not.

Operating principle of the AirVisual Pro device

AirVisual Pro uses a laser to calculate PM2.5. There is a constant flow of air through the device thanks to the fan inside. The laser emits a beam through a stream of air. The beam is reflected from suspended particles in the air. Only that part of the laser radiation that is reflected from the particles reaches the photometer. Thus, the device calculates how much was suspended in the air flow. This mechanism is capable of detecting particles from 0.3 µm to 2.5 µm. The resulting values are calibrated against temperature and humidity.

An infrared lamp is used to calculate CO2. The principle is similar: the lamp emits infrared light into the air stream. Carbon dioxide particles absorb it, so not all the light reaches the detector of the final radiation. The carbon dioxide content is calculated from the fraction of light that reaches it.

Read more about the AirVisual Pro device here.

We measure the air

With CO2, everything is easy: we close the windows, go to bed with my wife, and after a couple of hours the level of carbon dioxide rises from 600 to 1200 ppm. I wake up at ~1300ppm. With the windows slightly open, it’s cold, noisy and ~600ppm.

Volunteers with AirVisual Pro instruments share PM2.5 data. This data is collected on a map here, and there is also such a map. Typical PM2.5 levels in my area are 12 µg/m3 or 50 US AQI. On weekends there are often spikes in PM2.5 levels up to 20-30 μg/m3 - most likely these are emissions from enterprises.

Inside my apartment the PM2.5 level is 10-20% lower than outside at the same time. Why? I don't know, maybe there is a device error.

How else were PM2.5 measurements useful to me?

- When my wife and I were choosing an apartment, we went with the device. If the environment is important to you, this is an objective way to measure it. In articles “The 10 cleanest areas of the city” there is often bullshit.

- When turning on the humidifier, we noticed that the PM2.5 readings were rising sharply. It turned out that ultrasonic humidifiers should only be filled with distilled water. Otherwise, the humidifier will release impurities from the water into the air. This is harmful to health, so we no longer use an ultrasonic humidifier.

- When we iron clothes, PM2.5 levels rise. There is research on this topic. It’s not clear what to do about this, but we know that the procedure is harmful to health

I realized that there were definitely problems in my area and my apartment. The air is dirty and CO2 accumulates quickly.