Work associated with the formation of dust, the release of toxic gases, and fumes requires the installation of an exhaust system in the workplace and room. In most cases, do-it-yourself ventilation in the workshop is the most affordable way to solve the problem.

There are various options for constructing air exchange systems. We will help you navigate their diversity and consider the features of building ventilation for each type of workshop. Let's look at the most effective and affordable options for self-installation.

Chip extraction from the sewer riser

To make a chip extractor from plastic sewer fittings, you will need the following tools and materials.

Read also: The lead angle of the thread is

Materials

- PVC Sewer pipe ø 100 mm;

- PVC pipe ø 40 mm;

- hose;

- rivets;

- glue stick;

- fixing rings - clamps;

- two 2-liter bottles;

- 5 liter eggplant.

Step-by-step instructions for assembling a chip ejector

- The neck of the sewer riser is cut off, leaving a section 1 m long.

- The plastic bottle is cut, leaving a part of the cylinder with a cone, neck and stopper.

- Holes are drilled in both plugs. The plugs are glued together with a gun and tightened with a clamp.

- The cut bottle is inserted into the lower hole of the riser. The connection is sealed with hot glue and tightened with a clamp.

- A hole ø 40 mm is cut into the side of the PVC pipe. A pipe 70 mm long is inserted into it. The joints are sealed.

- 3 circles ø 100 mm are cut out of tin using a jigsaw.

- A hole ø 40 mm is cut in the center of each circle.

- The resulting disks are cut in half.

- The halves are sequentially connected to each other with rivets, resulting in a screw.

- A PVC pipe ø 40 mm is threaded inside the spiral. The pipe is connected to the screw with hot melt adhesive.

- The entire structure is pulled into the riser so that the upper part of the pipe protrudes 100 mm above the riser opening. In this case, the auger must remain inside the cyclone body.

- The neck and bottom of a 5-liter eggplant are cut off so that the lower part of the cone fits tightly onto the upper end of the sewer pipe. The outer diameter of the connection is glued with a gun.

- The upper hole of the neck is glued to the outlet of the inner pipe.

- A storage bottle is screwed into the bottom cap.

- Hoses are inserted into a horizontal pipe, the second end of which is connected to the nozzle of the shavings and sawdust collector of a woodworking machine (circuit saw, router or other equipment).

- The vertical outlet is connected to the branch pipe by the hoses of the vacuum cleaner. The chip ejector is ready for use.

Cyclone assembly

The design of the chip ejector must include the use of a cyclone filter.

Cyclone assembly:

- Installation of a ring for fixation;

- Side pipe fastening;

- Assembling a figured insert;

- Making a cyclone.

Metal drawing and its types

Setting up a workshop with your own hands

The main types of rotary metal drawing:

Step molding

A sheet blank in the shape of a circle is fixed between the mandrel and the support. The mandrel must match the internal configuration of the product. The drive begins to rotate the blank, and controlled forming pressure is carried out by a special passive roller driven by the rotation of the blank. Pressure is applied in both longitudinal and radial planes. The roller presses the metal against the mandrel and moves along a complex curve, either towards the edge of the blank or back.

The clamping is carried out in several passes, in steps. At the end of the treatment, a series of smoothing movements of the roller are carried out with reduced pressure to obtain a high-quality surface.

Projection - One-Pass Molding

Extraction is carried out in one pass. The roller moves parallel to the mandrel, depending on the angle of its installation, the wall of the blank is thinned more or less, its material moves under the influence of the roller in the axial direction.

Projection - One-Pass Molding

The method is characterized by efficiency and dimensional accuracy, as well as a high class of the resulting surface.

Rolling with or without mandrel

In this case, the outer diameter of the workpiece is reduced with a simultaneous thickening of its wall due to the redistribution of the material. Rolling is carried out towards the center, in several passes.

Rolling with or without mandrel

As an option, the part is formed by individual segments of the mandrel using a roller with an offset center. Cutting, additional profiling or flanging are carried out as final operations.

Combined

For parts with complex configurations, stepwise forming, rolling, profiling and cutting are used together in various combinations.

Sales organization is the key to a successful business

Finished wood products

To begin with, you can contact construction and repair companies, providing your price list and indicating the delivery time of the goods. A commercial proposal should be sent to organizations that are interested in purchasing wooden products. For example, restaurants, hotels, and recreation centers stylized as Slavic antiquities can be considered as potential buyers. The interior of such establishments always contains wooden pieces of furniture and decor. Buyers of the products can be stores - hardware stores, building materials stores, furniture stores. If you plan to participate in government tenders and enter the international sales market, it is better to open an LLC. In this case, the purchased equipment in monetary terms can act as the authorized capital.

Operating principle of aspiration units

How to update a kitchen set with your own hands: options for restoring old furniture

The aspiration system of a woodworking shop has a complex structure, each element of which is subject to precise calculations during installation. A standard aspiration system consists of the following parts:

- Dust fan (creates draft, increases pressure);

- Large chip catcher (usually implemented using a cyclone);

- Pollution removal system;

- Bag filters that pass through air from which contaminants have been removed;

- Containers for collecting contaminants.

How does a wood waste aspiration system work? The air flow, forced by the fan, pulls out sawdust and directs it into the sorting compartment of the system. A large particle catcher separates them from the air flow and discharges them into a storage hopper, where they are formed into blocks for subsequent disposal. Air containing fine dust particles passes through a dust extractor and filters, where it is cleaned of impurities. The purified air masses are removed outside the workshop or returned to the premises through a recirculation system.

The design of the aspiration installation for a woodworking shop is developed based on several factors:

- number and location of machines;

- energy consumption of devices;

- climatic conditions;

- required power.

The calculation of the system and its installation should be carried out by specialists in this field of technical support for enterprises. Only they will be able to take into account in detail all the conditions of the workshop and select the necessary design elements.

What to choose?

Under what circumstances should supply, exhaust and supply and exhaust ventilation be installed?

Forced ventilation

Supply ventilation is provided by supplying fresh air into the room. It creates increased pressure, displacing exhaust air that is removed naturally - through openings, leaks in enclosing structures or technological hatches and openings.

In most cases, an influx is needed to dilute the released harmful substances to a possible concentration. It is provided by a fan that supplies flow inside through a duct system.

Exhaust ventilation

Exhaust ventilation removes the waste stream to the outside. It is produced by a suction fan; air is drawn in using air intake grilles and a system of air channels.

Due to the active removal of air flow in the room, a reduced pressure occurs, which is compensated by inflow through openings, leaks or other openings. The hood is used to select and remove released pollutants with guaranteed efficiency and prevent the spread of unwanted components inside the building.

Supply and exhaust ventilation

A supply and exhaust ventilation system is the most common option. It is capable of supplying a certain, pre-calculated amount of air inside and out.

This allows you to set the necessary air exchange modes and organize low or high pressure indoors as needed. The performance of the supply and exhaust lines must match each other so that it is possible to create the most comfortable air exchange for people and technological processes.

Under what circumstances should supply, exhaust and supply and exhaust ventilation be installed?

Car strobe light is a simple circuit for DIY assembly. powerful strobe with your own hands, how to make a strobe with your own hands using simple spare parts

To choose forced ventilation, you need to know what it is intended for and what harmful factors are found in your room that ventilation will eliminate.

| Forced ventilation | The supply air undergoes special cleaning, heating or cooling and humidification. This type of ventilation is designed to reduce or increase the temperature in the workplace and to supply clean and fresh air to workers. Air conditioning in apartments and private houses is a special case of forced ventilation. | For this function, supply ventilation is used in most cases in residential areas, cottages, houses, but not in workshops. Suitable for apartments and workshops such as art and framing. | Advantages: Provides clean air at the desired temperature, easy to install, regulates the microclimate. Disadvantages: does not provide complete air recirculation. More expensive in maintenance and initial cost than exhaust ventilation. Does not provide a microclimate for large rooms. Does not remove harmful substances. |

| Exhaust ventilation | Exhaust ventilation in workshop-type rooms is necessary to remove harmful fumes, such as: - dust; - warm; - smoke; — gas. To prevent the appearance of harmful substances, local suction is used. | This type of ventilation is widely used in rooms where hazardous work is performed. Painting shop, laboratory, welding station, sandblasting room, etc. Suitable for workshops associated with hazardous production. | Advantages: Quickly removes harmful substances from the room. Easy to install, maintain and cheaper than other systems. Disadvantages: does not provide complete air recirculation. Does not provide a microclimate for large rooms. Does not remove harmful substances. |

| Supply and exhaust system | when constant filtration of exhaust air in production is necessary; — if necessary, heat and purify the air at the same time; — supply and exhaust ventilation systems are also installed to humidify the air, which is carried out using the air that enters the supply air masses. | Used for large rooms with few windows and doors. Suitable for private homes and all types of workshops. | Advantages: Regulates the microclimate in any size room. Provides complete air recirculation. Provides removal of harmful substances. Disadvantages: More expensive to maintain and initial cost than other systems. Energy consumption is higher than other systems. |

Useful tips from the experts

- If the walls of the building are made of brick, then the design and installation of channels should be carried out simultaneously with the construction of the house

- To create air ducts with the same cross-sectional diameter, it is convenient to use cardboard or wooden templates.

- The internal walls of the ventilation duct are made of solid brick with high-quality sealing of all junction points.

- It is convenient to equip the ventilation outlet to the roof with asbestos-cement pipes, connecting it to the wall ventilation duct and properly securing the structure with cement mortar.

Common Misconceptions

- Ventilation problems in the room are easily solved by installing air conditioning equipment. An air conditioner can affect the temperature and humidity of the air, but is not able to saturate it with the oxygen necessary for breathing.

- Periodic ventilation of the room or setting the windows to micro-ventilation mode is sufficient to ventilate the room. This statement can be called valid only for the warm season. In the winter cold, the room will quickly cool down without having time to receive the required amount of oxygen.

Peculiarities

Typically, the air flow is cleared of debris by passing it through a fabric filter or a container of water. This is quite enough to retain dust and small household debris.

The vacuum cleaner for shavings and sawdust has a different design. There is no fabric filter in it, because it only creates unnecessary resistance to air flow. Dust, shavings and sawdust are removed from the air flow in a centrifugal filtration apparatus, the so-called cyclone.

In large industries, industrial vacuum cleaners-chip exhausters are used to suck out shavings and sawdust from the working area of a woodworking machine. These are large, powerful machines, but they are designed in the same way as small carpenter's vacuum cleaners.

Rating of the best devices

Professionals have compiled a rating of the best models, taking into account the characteristics of the devices and their cost.

Scheepach (Woodster) HD 12

One of the most popular German-made units, which can be used not only at home, but also in production. The device is equipped with a powerful motor. The unit quickly removes chips of various sizes and also purifies the air from the smallest particles.

Advantages:

- Powerful engine.

- High suction speed.

- Volume bag for chips.

- Convenient handle that makes it easy to move the device.

- Compact dimensions.

- Light weight.

No shortcomings were found in the unit.

Metabo SPA 1200

This is another unit made in Germany. The device is characterized by high motor power, as well as a long operating period without any malfunctions.

The tool is small in size and has wheels, which allows it to be quickly and easily moved from place to place in the workshop.

The tool can be used for any sawing and grinding machines. It quickly and efficiently gets rid of both large chips and the smallest howls.

Advantages:

- Relatively silent operation.

- Availability of an effective filter.

- Durable housing, resistant to mechanical stress.

- Great warranty – 3 years.

Flaws:

Poor performance.

FDB Maschinen ST 300S

This is a powerful unit that is recommended for use in production. Up to three machines can be connected to the device simultaneously. At the same time, the equipment has small dimensions. The main feature is the ability to use for a long time without interruptions, overheating and reduction in size.

Advantages:

- High power and performance.

- Possibility of using three machines simultaneously.

- High suction speed.

- Can be used for a long time.

- Long operational period.

Flaws:

- Large dimensions.

- High price.

FOX F50-841

This model is equipped with a powerful engine that guarantees good performance. The device can be used both at home and in production.

Advantages:

- Powerful motor.

- High quality filter.

- Volume bag for chips.

- Easy filter replacement.

Flaws:

Weak traction.

Scheppach (Woodstar) ha 1000

This is a device for home use. The machine is equipped with a metal body, which has increased strength and resistance to mechanical stress.

The chip evacuation bag has a volume of 50 liters. This allows the master to rarely shake out the chips.

Advantages:

- Increased body strength.

- Versatility - can be used to remove dry and wet stains.

- Convenient handle that allows you to quickly rearrange the unit.

Flaws:

- Low power.

- Can only be used for small machines.

Proma OPM-150

A lightweight and compact unit that can be used at home even in small spaces. The body is equipped with small wheels to ensure mobility of the unit. The motor has good power and is relatively quiet.

Advantages:

- Compact dimensions and light weight.

- Large diameter exhaust fitting.

- High performance.

Flaws:

A small and inconvenient bag that is difficult to shake out.

JET DC-900

This is a Swiss made portable chip extractor that can be used for any woodworking machine. It does not have a very powerful engine and is not very efficient. That is why it is not recommended to be used for production, but only at home.

The device has small dimensions and light weight. The tool body is equipped with wheels that allow you to move the unit from place to place.

The device bag has a large volume of 55 liters. It can be easily cleared of debris.

There is a filter at the outlet of the device. It is he who frees the air even from small dust.

Advantages:

- A new generation filter that effectively purifies the air.

- Easy to remove and install the bag.

- Convenient transportation with handles and wheels.

Flaws:

Low power and performance.

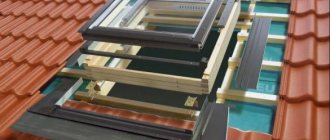

The nuances of ventilation depending on the type of garage

Before carrying out ventilation, you need to take into account a number of nuances.

Natural ventilation replaces air masses due to the difference in temperature outside and inside the garage. To effectively move air, you need to make 2 ventilation holes. It is better if ventilation is provided before the construction of supporting structures.

To keep your garage well ventilated, you need to follow these rules:

- The inlet opening must be at least 10 cm above the floor surface. To prevent debris and dust from penetrating into it, the hole is covered with a mesh. To protect against snow in winter, the air duct on the street is placed at least 30 cm from the ground.

- The exhaust hole is placed in the upper corner opposite the supply hole (preferably diagonally or as far as possible from the inflow), 10 cm from the ceiling. The air removal pipe is installed 50 cm above the roof level and protected from above with a “fungus”.

- Grilles are built into the gates as supply openings. In this case, effective air exchange is possible only if the size of the installed grilles is 2-3 times larger than the cross-section of the required exhaust pipe.

- Removing dirty air will be better if you install a deflector. It creates an area of low pressure. To prevent condensation from appearing on the deflector, it must be well insulated.

The good thing about this kind of garage ventilation is that you don’t need to spend a lot of money on it. Of the minuses, it should be mentioned that due to unstable weather (changes in pressure, temperature and strength of air flows), it will not be possible to fully control the quality of air exchange.

Depending on the material

In a metal garage, condensation always appears on the walls, and in winter, ice forms on the roof, damaging the coating. Condensation must be dealt with, because high humidity causes metal corrosion and, as a result, rapid wear of the car.

In a garage, condensation occurs due to two factors:

- Lack of ventilation or errors in its design.

- Lack of room heating or poor insulation.

You can prevent condensation yourself; you just need to provide good ventilation and reliably insulate the garage. If there is ventilation and it works as it should, but condensation appears, then you need to think about cleaning its channels - perhaps they are forgotten by garbage. Over time, ventilation becomes contaminated with oily deposits and dust, which can harm human health.

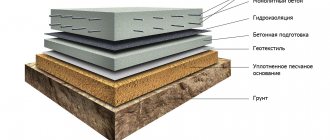

With a basement

Using a basement for storing canned food and vegetables is only permissible if the ventilation system is working properly. Almost all ventilation systems are applicable in the basement. But usually for such an area there is enough natural ventilation, for the production of which sewer plastic pipes are used.

When planning the design you need to consider:

- The cellar ventilation system should be made with a minimum number of bends and turns of pipes.

- The exhaust pipe must be well insulated to prevent condensation.

- The diameter of the pipes cannot be changed in any section.

- External ventilation inlets must be protected with special caps to protect against precipitation.

When creating ventilation in the basement, you need to place the exhaust pipe under the basement ceiling and lead it to the roof of the garage, and the supply pipe - 0.5 meters above the floor.

With a pit

If your garage has an inspection hole, then it is advisable to ventilate it separately from the rest of the garage. Condensation often accumulates here and, as a result, fungus, mold and even insects appear on the walls.

To ventilate the pit, natural air circulation is enough. This is not difficult to do. Gaps are left along the edges of the flooring (about 10-15 cm wide). Where fresh air will enter, the gap can be doubled, which will significantly increase traction. We must remember that it is undesirable to park the car over a hole with the gap open.

Hood as a supplier of cold to the workshop - what to do about it?

We have a workshop at home, we have allocated a small room for the workshop. From the hood there is a 20 cm thick corrugation going through the wall to the street, i.e. such a decent hole. When the hood is not working, a decent flow of cold air flows through it from the street.

Who solved this situation? I suspect that some kind of curtains should be sold for installation on the street side of the pipe, so that when the hood is not working, the hole is closed. But I couldn’t find one for my diameter on sale. Maybe the workshop could invent some kind of plug?

Typically, such hoods are equipped with fans with a check valve, which allows air flow in only one direction. Type “fans with check valve” into a search engine and you will be happy. As far as I know, their sizes start from 100 mm in increments of 50 mm

Everything is correct. In the simplest case, you can install a check valve. In essence, it represents a round curtain that rotates on an axis inside a piece of pipe. When air flows from the hood, it rises and allows air to flow freely. When the hood is turned off, it lowers under its own weight and blocks the access of air from outside.

It is better to install two such valves - one at the very exit to the street, the second not far from it (25-30 cm), so that cold air does not enter directly into the pipe itself and condensation does not form outside the pipe or corrugation.

For clarity.

She herself worked in a ventilation company. That's right - you need a check valve that will not let in cold air from the street. As an additional means, you can also insulate the corrugated air duct itself.

When we built the house, we also made fairly large holes for ventilation, but during finishing we encountered a problem like yours

, I had to fill and plaster part of the hole inside the bathroom and attach a standard fan with plastic curtains, connect it to the switch and, in addition, pull the string every time so that the curtains close. In 6 years, three fans have been replaced, the curtains break.

Maybe a check valve would be better? On the hood in the kitchen, he really doesn’t miss anything.

Firstly, there are very simple fans with a valve, as they said. But you, in all likelihood, already have some kind of fan, you worked somehow before. So there is no reason for you to install another one. Just don't laugh. I remembered our Magadan Khrushchev house, in which we once lived for 8 years. So, in such houses, apartments, and in all of them, according to some idea of the architect (the houses are old), there were round holes in the wall in the kitchen, about 10 cm in diameter, maybe a little more. The yard was visible through this hole (I suspect that this was the ventilation by design). For all of them, these holes were closed with something like “plugs”. In my case, it was a wooden “plug” with rags (to fit more tightly and without cracks). Come up with something too. Well, for example, in your case it could be some kind of small cylinder made of thick cardboard, perhaps filled with polyurethane foam. To make it fit more tightly, use a backing for Lenolium, thin foam rubber, etc. In a word, you understand the essence, but what you will adapt for this purpose - see for yourself (what is available and what is more convenient and handy for you). Sit down at the burner, remove the plug, do some work, close it. The advantage of such a device is its thickness and compactness. It's just that the valve will protect less from the cold, I think.

The importance of preliminary calculations

Ventilation of the shower is necessary if it is installed in a concrete building or in a wooden house. It prevents the negative impact of high humidity on the integrity of plumbing equipment and building materials.

It is necessary to follow SNiP standards, which will serve for the safe operation of the room in the future. Before equipping a room with ventilation with your own hands, you must have a drawing of the shower stall, as well as the dressing rooms available in the room.

Removing excess moisture helps increase the life of all metal plumbing fixtures and some building materials. For normal human well-being, humidity should not exceed 65%. If this indicator is too high, staying in the shower can negatively affect the health of its visitor.

SNiP standards introduce the concept of “air exchange rate”. It represents the ratio of the volume of air entering or leaving a room to the volume of the room itself. The minimum indicator according to SNiP is 50 m3/hour. For public showers – 75 m3/hour.

The minimum “air exchange rate” according to SNiP in a public shower is 75 m3/hour

Rules for selecting ventilation for a workshop

Every consumer often wants to get the desired maximum result at a minimum cost. To do this, you must first study all the factors that will help or influence such a result. To select the most optimal ventilation system option, it is necessary to take into account the following components:

- the material from which the room will be constructed;

— cleanliness of the environment.

Another very important component is the required amount. Remember that we recommend not saving on the ventilation system, because this will ultimately affect your comfort, and most importantly, your health. Now let's talk about the types of ventilation in more detail and tell you about their advantages and disadvantages.

Now let's talk about the types of ventilation in more detail and tell you about their advantages and disadvantages.

Forced ventilation

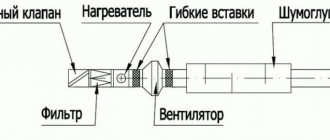

Sometimes a workshop needs a huge number of tide valves. In this case, it is best to give preference to a forced ventilation system. Assembly is carried out on absorbent fans. The ventilation system kit includes a ventilation network and ventilation equipment. Installation of flow-exhaust ventilation allows for the presence of the following components:

- Heater;

- Filter;

- Noise suppressor;

- Air valve;

- Fan.

The ventilation equipment design must include an air intake grille, air distribution devices and air ducts. Air distribution devices should include anemostats, grilles and diffusers.

This is what the forced ventilation operation diagram looks like:

The filter is designed to clean air flows from dust; the heater, in turn, heats the absorbed air if ventilation is used in winter. A heater can be installed, but it is not required. Its action comes from water or electricity. The first option is more expensive, since during installation you need to make a hydraulic connection. When the system has an exhaust hood, and ventilation operates due to the supply and exhaust flow, it is necessary to install a recovery system, which will make it possible to reduce the energy consumption for heating the passing air.

Natural ventilation

A natural ventilation system in production should be implemented in the following cases:

— clean outdoor atmosphere;

— if the building materials include the following elements: gas block, cinder block, wood, foam block, metal, expanded clay block, adobe, monolithic expanded clay concrete, ceramic block.

Natural ventilation of the workshop is a very effective and less labor-intensive method compared to forced ventilation. It is often carried out in separate buildings that are made of metal materials and which often have long gaps between the walls and the roof.

Pre-launch tests

After assembling the entire ventilation complex and connecting all elements, its functionality is checked.

Pre-start tests at maximum power are necessary to ensure the following:

- all systems work correctly;

- design performance has been achieved;

- air exchange is carried out according to planned design standards, that is, the conditions for air distribution in individual rooms are met;

- smoke removal is effective;

- no vibration;

- fastening to the wall and ceiling did not reveal any flaws;

- electrical circuits do not spark, do not heat up, or short circuit.

- Heating elements change temperature evenly.

In accordance with the rules of SNiP, a trial run and adjustment of the equipment are carried out to confirm the design parameters of the system. Typically, pre-commissioning tests of a ventilation system are carried out before its industrial operation. Sometimes such launches are carried out after the completion of installation work of individual blocks or cycles. The results of intermediate checks must be recorded in reports, which upon completion will be included in the package of documents for the ventilation system.

Before a trial run, specialists must check the technical documentation to ensure that the following criteria are met:

- the equipment actually installed coincides with that stated in the project;

- installation work was carried out in accordance with technical specifications and standards;

- the degree of readiness of the installations corresponds to the operating instructions from the manufacturer;

- all deviations from the project are documented in the designer’s supervision book or other act, agreed upon and meet the requirements of SNiP;

- all identified defects were eliminated by the time of launch, as evidenced by the attached acceptance certificates.

If pre-launch tests reveal a discrepancy between the actual data and the design data, then after identifying the reasons, adjustment of the devices is necessary. The removal is carried out by the contractor installing the ventilation.

The following discrepancies are acceptable.

- A deviation of 10%, both plus and minus, in the indicators of the volume of air that passes through the head general exchange sections of the ventilation unit.

- Deviation of the volume of air flow passing through the dispensing or receiving units is in the range from -20% to +20%.

- Deviation of air volume indicators is ±10% entering special purpose buildings. These include medical institutions, in particular operating rooms, museums, control rooms and other premises where precise air conditions are required.

In the next video you will see the installation of ventilation in the kitchen.

Types of chip ejectors

There are three types of such machines:

- portable

- stationary

- mobile.

The category of portable dust collectors includes small-sized dust collectors. Installation and disassembly of such devices is easy to carry out in a short period of time. They are light in weight and can be placed on a table. They are used in cases where the operation of other types of equipment is impossible or difficult. This happens due to the small area of the room or for technical reasons. It is worth noting that portable devices do not always remove waste efficiently due to their low power and, consequently, low productivity.

Mobile dust collectors can be placed near the machine. They take up little space and dismantling will not take much time either. To move, you will need a cart or standard casters. With the help of mobile dust collectors, two machines can be serviced in turn. However, the following condition must be met: the machines must operate at different times. Some models of such chip ejectors have a two-stage air filtration system.

Stationary chip ejectors are installed in a permanent place, without the ability to move. They have a higher power level compared to previous options.

Which fans to choose?

Selecting fans is a serious task, the solution of which is determined by the configuration of the workshop, the number of compartments, additional rooms, and rooms. A complex and extensive duct system requires a powerful fan that can overcome the resistance of the ducts. In this case, the best option would be to use radial (centrifugal) ventilation units. They have high performance and at the same time are able to create sufficient pressure for the air duct system.

Design and principle of operation

In terms of its tasks, this device resembles a vacuum cleaner. An important difference between the chip ejector is the presence of a special element called a cyclone. The composition of such units includes the following elements:

- electric motor (its power must exceed 3.5 kW);

- impeller (to create the required air flow speed);

- cyclone (produces high-quality cleaning of the supplied air from existing chips);

- container for collecting dust and chips;

- cleaning filter (it is advisable to install a multi-stage filtration system);

- electrical switching system for switching and control;

The impeller is located in the sealed housing of the chip ejector. Air is supplied during chip removal through an air duct through a side hole in the housing wall. Purified air is released through the second hole. Their size depends on the diameter of the selected air ducts. Collectively, such a system is called a cyclone. It works on the principle of separating heavy particles due to the centrifugal force generated when the impeller rotates at high speed.

The chip suction cyclone has a fairly simple design and can be made with your own hands from existing available tools. This is an ordinary large round container (barrel or bucket). You can make it yourself. The incoming air flow begins to flow into the upper part of the container, and at the same time the air stream is directed along the wall. Thanks to the impeller, the flow twists in a spiral. The speed of the moving flow causes chips and debris to move towards the wall of the container. After this, they settle to the bottom of the tank or the garbage bag located below.

The necessary vacuum inside the chip ejector is created due to the rapid removal of purified air. At the outlet, the air is cleaned of sawdust, dust and shavings. This allows it to be sucked out using a regular household vacuum cleaner. The higher the power of the vacuum cleaner, the more productive the chip extractor will be. The industrial chip ejector uses a specially manufactured high-power centrifugal pump.

Conclusion

A vacuum cleaner for collecting chips is an integral part of any carpentry shop or workshop . It protects the room from cluttering with wood processing waste and facilitates the collection of chips for subsequent disposal.

After reading the article, you learned:

- principles of operation of various devices used in aspiration systems;

- the advantages and disadvantages of various types of these devices;

- optimal configuration of the ventilation system.

In addition, the process of making such a system with your own hands became clear.

Vacuum cleaner for workshop

The process of mechanical processing of wooden workpieces is always accompanied by the release of dust or the scattering of shavings and sawdust. Modern power tools provide the ability to connect any installations for the collection and disposal of wood waste, but purchasing them for household needs is not always justified. At the home level, a homemade device successfully copes with the problem of dust removal. Let us consider in detail the procedure for making a vacuum cleaner for the workshop.

Required materials and tools

The basis for the project is an old household vacuum cleaner, from which the following components are used: •Motor part; •Power regulator; •Power supply wire; •Suction hose; •Attachments.

For the homemade body, select a polyethylene barrel with a capacity of 50–80 liters, always with a fixed lid. You will also need: •A piece of plastic sewer pipe with a diameter of 50 mm; •Plywood 5–10 mm thick; •M6 bolts and nuts – 14 pieces each; •Strip of galvanized sheet; •Air filter from a minibus; •220 Volt switch; •Threaded rod with washers and nuts; •Construction sealant; •Sandpaper; •Glue rods; •Drain corrugated hose for washing machine; •Electrical installation corrugation HDPE 32.

Docking units are made of plastic tubes and fittings, selected depending on the size of the pipes on the tools and the diameters of the vacuum cleaner intake hoses. List of tools used: • Glue gun; •Drill; • Locksmith keys; •Screwdrivers; •Pliers; •Electric jigsaw; •Sharp knife; •Files; •Sealant gun.

The process of making a vacuum cleaner for a workshop

Stepping back approximately 100 mm from the top, mark a hole on the wall of the barrel for the inlet pipe and drill it using a drill. Then use a knife to give the hole an oval shape so that the inner end of the pipe is placed close to the wall and points down at a slight angle. Degrease the surfaces to be joined and, using a glue gun, fix the pipe in place.

Using the same “hot” method, an adapter for the suction hose is attached to the outside of the pipe.

Using a jigsaw, cut out two circles from plywood with a diameter slightly smaller than that of the barrel lid. First, two holes are made in the blanks for bolts and the parts are secured on both sides of the cover. Next, drill the remaining holes, remove the circles and remove the burrs with sandpaper. Apply sealant around the perimeter of the workpieces, place the parts on the lid and fully install the fasteners. A hole is made for the pin in the center of the plywood circles, and a little to the side for the air intake of the motor block.

Remove the metal mesh from the air filter with pliers, otherwise it will become clogged with sawdust and interfere with cleaning the vacuum cleaner. One end of the cylinder is covered with a plywood plug.

The prepared filter element is secured to the stud with a wing nut.

The motor part, as a rule, has a round shape. Therefore, for ease of installation, the plastic parts in which the motor was located are cut out from the body of the old vacuum cleaner. Thanks to them, to secure the unit to the barrel lid, you only need one clamp, made from a strip of tin.

A switch and power regulator are placed next to the engine, placing the latter in a suitable box. All that remains is to connect the elements together with wires and connect the cable with the plug. After making sure that the connections are correct and that there are no exposed contacts, apply power and check the operation of the device.

The standard suction hose of a household vacuum cleaner is too short; it is extended with a corrugated tube for laying wiring or another similar product.

Manufacturing of nozzles and adapters

Cleanliness in the workshop begins with the workbench. To clean the workplace, use a standard brush that comes with the household appliance.

The nozzle is connected using a rubber adapter cut from a tube of appropriate caliber, for example, from a pipe of a car’s cooling system.

One of the most littered power tools is the power planer. The outlet fitting of the tool is large enough; most likely, the vacuum cleaner hose will connect without problems.

For a manual surface grinder, you will need to make an adapter that is soldered to the dust bag clamp.

In this case, a thinner hose from the washing machine drain and the ability to electronically reduce the suction power of the vacuum cleaner so that the body does not shrink will come in handy.

The same corrugation is suitable for suctioning chips from the working area of a manual router.

Using the selection method, the corresponding parts are also found for the pallet of the circular saw.

Top outlet mounting

- The entries are drilled in the center of the bottom of the small bucket.

- The plastic pipe is attached to a sheet of plywood with a prepared hole equal to the thickness of the pipe.

- The structure is screwed from below with four screws.

- Fill all formed joints with sealant. In addition to tightness, it gives the assembly additional strength.

The insert is attached to the outer wall of the filter using self-tapping screws.

Machines for rotary drawing of metal

To implement the technology, the following types of machines are used:

- Pressing and rolling machines for rotary drawing of metal.

- Rotary forging machines.

- Round cutters.

On manual lathes, molding is performed by the muscular strength of the worker. Used to produce unique products or especially small series. For medium and large series, pressing and rolling (rolling) machines with numerical control are used. Hydraulic or electric drives, controlled by a controller according to a program loaded into the central CNC unit, allow precise control of the force and direction of the clamp, as well as the direction of movement of the roller, including the most complex curved trajectories

Such machines ensure absolute identity of products in a series, which is especially important for jet engine parts and other high-tech products

Scheme of forging on rotary machines

Rotary forging machines allow you to form conical-shaped products from pipes by crimping the pipe with a special tool - a forging die. The peculiarity and main advantage lies in the unique ability to produce products that have:

- the length is many times greater than the diameter.

- along the length, the diameter and opening angle of the cone can be repeatedly changed.

- knurling of stiffeners is required.

Round cutters

Circular cutters are designed for cutting rolled sheets into flat pieces in the shape of a circle or ellipse. Also used are both manual and electro-hydraulic.

Kinds

Portable

These are small-sized products that are quickly installed and disassembled. The tools are lightweight. They can be placed on the table for ease of use.

Portable chip ejectors are recommended for use in cases where it is not possible to use other units. Most often this happens if the machine is installed in a small room and for technical reasons.

They have a large number of disadvantages, namely:

- Low power.

- Poor performance.

- Poor waste disposal.

Expert opinion Dmitry Konstantinovich Levin

If it is possible to use other types of chip ejectors, then the use of portable devices is abandoned.

Mobile

Such devices are placed near the machine. To move the device from place to place, you will need a cart or other similar device. These tools can be used to service two machines, but only in turn and the equipment must operate at different times.

Advantages:

- Small dimensions.

- Good performance.

- Quick assembly and dismantling.

Flaws:

It is not always convenient to use, since sometimes there is no space for the unit near the machine.

An advertising campaign will help you find more clients. Experts advise creating a company website and groups on popular social networks. At the same time, advertisements are placed on thematic Internet sites and forums. Another direction of the advertising campaign is the printing of flyers and leaflets that are distributed in crowded places, near new buildings. Participation in thematic exhibitions and fairs is mandatory, where manufacturers exhibit samples of their work. As marketing activities, you can consider additional free services, for example, delivery of ordered products to the address, assembly of furniture. As part of your marketing strategy, you should pay attention to the positioning of products. For example, to focus the attention of potential buyers on the quality of raw materials and the finished product: “We use solid oak and teak for production,” “We will develop a design taking into account the interior concept.”