Sometimes, when planning to build your own house, circumstances develop in such a way that the usual, reliable and relatively inexpensive strip foundation scheme becomes simply impossible. Typically, such conclusions are reached in cases where an assessment of the condition of soils on a site indicates their insufficient bearing capacity or a pronounced tendency to frost heaving. You can, of course, lay a deep tape, lowering its base below the freezing level of the soil, but this extremely complicates the project and leads to a large increase in the cost of its implementation. In addition, this may be hampered by the location of underground aquifers being too close. As an alternative, the option of constructing a shallow slab foundation is being considered.

Slab foundation thickness calculation

This type of foundation has another common name - “floating”, which quite accurately characterizes its features. Indeed, the uniform distribution of the load from the building and the mass of the slab itself over a large area leads to the fact that the specific pressure is minimal, and the reinforced concrete foundation of the building seems to “float” on the surface, without settling deeper and repeating seasonal vertical vibrations of the soil. But this significant advantage is only fully revealed when the dimensions of the slab foundation, and in particular its thickness, correspond to both the actual operating conditions of the building and the parameters of the building erected on such a foundation.

Let's take a closer look at this issue: slab foundation thickness calculation, depending on the conditions of the construction site, and on the specifics of the building planned for construction.

Cement prices

cement

Kinds

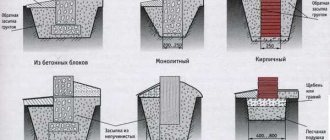

A slab foundation is a reinforced concrete slab located under the entire area of the structure and buried to varying depths in the ground. It is divided into several varieties according to design and construction technology.

According to execution, there are 2 types:

- Monolithic, reinforced concrete slab. It is made by pouring concrete mortar over the entire area of the house with laying metal reinforcement.

- Prefabricated structure. The base is assembled from several ready-made reinforced concrete slabs, the seams between which are filled with concrete. To level the surface, a cement-sand mortar screed is poured.

The following foundations differ in design:

- Solid base. The surface of the slab acts as a subfloor. A typical example is the Swedish stove. It can be manufactured in a monolithic or prefabricated design.

- Ribbed design. Stiffening ribs are formed at the bottom of the slab, for which additional trenches are dug in the common pit. They increase the mechanical strength of the base and the stability of the entire structure.

- Box-shaped design. The foundation slab and the floor are separated by an air gap, but are combined into a single monolithic structure by pouring concrete.

The pile-slab option stands out separately, when a combination of pile and slab foundations is used.

The piles are made using bored technology, and a reinforced concrete slab is laid on top of them. This design has maximum load-bearing capacity.

Pile-slab foundation

Based on the depth of immersion of the slab into the ground, the foundation is divided into 2 types:

- Shallow type. The slab is immersed in the ground to a depth of 30-50 cm. It is used for small buildings.

- Recessed (deeply recessed) type. The lower surface of the slab is located below the freezing depth of the soil. The height of the foundation can be 1.2-1.5 m. Such a powerful foundation is necessary when constructing large structures of several floors.

Important! The choice of slab foundation design depends on the soil structure, moisture content, operational loads and the design of the building itself.

Cutting rods

The easiest way is to cut the rods using a template.

To do this, you first need to cut all the longitudinal pieces of both belts, and then prepare all the transverse rods. The easiest and cheapest way to cut is using a regular angle grinder (angle grinder) with a metal disc. Thanks to this machine you can cut rods of any size.

You can also use:

- Hydraulic metal shears (bolt cutters). However, they are only suitable for rods with a diameter of 6-8 mm and will be very expensive.

- Gas cutter. In this case, you will have to obtain a permit that will allow you to perform dangerous work.

At the same stage, it is necessary to prepare and cut pieces of reinforcement for the stands.

When is this type of foundation used?

A slab foundation is considered a rather expensive and labor-intensive structure, and therefore its use is necessary.

The main purpose is the construction of houses in problematic soils, where other types of foundations are unsuitable or unreliable:

- Weak soils with a bearing capacity not exceeding 2.6 kg/cm2. These include sandstones, dust compounds, clays and loams, and peat bogs. Due to the large base area, the structure does not sag during long-term use.

- Soils with high moisture content. Shallow slabs (“floating” type) can also be used in swampy areas. A slab foundation is suitable for areas where groundwater comes close to the surface.

- Soils with high seasonal heaving. A durable slab is able to withstand dynamic loads that occur during seasonal changes in such soils.

- Rocky outcrops and coarse soils. It is extremely difficult to dig deep pits or trenches in them, as well as drive piles. At the same time, these structures have a high load-bearing structure, and the slab base simply distributes the load evenly. The slab does not need to be buried deeply to ensure the necessary stability of the house.

Deep-buried slab foundations have a special purpose . Their construction is justified when building on bulk soils, when the lower surface of the slab reaches the main (solid) soil. Another option is mixed soils, when their bearing capacities differ sharply in a small area. The increased depth allows for stable formations to be reached.

The box structure is intended for the construction of a house with a basement in areas where groundwater rises almost to the surface of the earth. Another typical purpose is the construction of dachas, outbuildings, bathhouses and other small houses.

In this case, it is enough to lay a slab 20-30 cm thick, which eliminates the need for a large amount of excavation work. And you can build a slab foundation on almost any type of soil.

Study of soil characteristics

Before starting to calculate any type of foundation, the characteristics of the foundation under it are determined. The main and most important points include:

- water saturation;

- bearing capacity.

When constructing large facilities, before starting the development of project documentation, full-fledged geological surveys are carried out, which include:

- drilling of the wells;

- laboratory research;

- development of a report on the characteristics of the foundation.

The report provides all the values obtained during the first two steps. A full range of geological surveys is expensive. When designing a private house, it is most often not necessary. Soil studies are carried out using two methods:

- pits;

- wells.

The cutting of pits is done manually. To do this, dig a hole with a shovel, 50 cm deep below the expected level of the base of the foundation. The soil is studied by section, approximately the type of bearing layer and the presence of water in it are determined. If the soil is too saturated with water, it is recommended to use pile supports for the building.

The second option for studying the characteristics of the foundation for a house is carried out using a hand drill. The analysis is carried out on pieces of soil on the blades.

Important! When conducting events, it is necessary to select several points to study. They should be located under the building site. This will allow you to study the soil type most thoroughly.

Having decided on the base, the optimal specific pressure on the ground is determined for it. The value will be required in further calculations, an example of which is presented below. The value is taken according to the table.

| Type of soil being tested | Optimal specific ground pressure, kg/cm2 |

| The sand is dusty and fine | 0,35 |

| Medium sand | 0,25 |

| Sandy loam* | 0,50 |

| Loam | 0,35 |

| Plastic clay | 0,25 |

| Hard clay* | 0,50 |

*With this type of foundation soil, the strip option may be more economical, so you need to calculate the estimate for two types of foundation and choose the one that will cost less.

Advantages and disadvantages

The slab foundation has a number of undeniable advantages:

- increased load-bearing capacity superior to other types of foundations;

- possibility of construction on any type of soil, incl. on problematic soils, where other options are ineffective;

- uniform distribution of soil loads over the entire area of the structure;

- high durability exceeding 150 years;

- the foundation slab can act as a subfloor (concrete screed) without additional leveling;

- the possibility of arranging a full-fledged semi-basement (basement) room;

- simplicity of construction technology, which does not require highly qualified workers;

- reduction in the volume of earthworks;

- preventing insects and rodents from entering the room from below.

Houses of different designs and number of storeys can be built on a slab foundation. Walls can be built from wood, brick, concrete, panels and gas blocks.

The slab provides a reliable foundation under the entire surface of the house, which simplifies the installation of internal partitions after construction is completed.

Some disadvantages of slab construction should also be noted:

- high cost due to high material consumption (concrete, reinforcement);

- difficulties during construction on sloping terrain, where there is a risk of a heavy structure gradually sliding down during operation;

- increased requirements for waterproofing;

- increased labor intensity associated with a large volume of concrete work.

Important! When constructing small structures, almost all the disadvantages are leveled out, which gives noticeable advantages to the slab foundation over other options. Problems with slippage are mitigated by the formation of a ribbed slab.

What thickness should it be?

The thickness of the slab depends on:

- design loads,

- concrete grades,

- reinforcement schemes,

- hydrogeological and climatic conditions within a given project.

When the calculation of a parameter is carried out according to the current conditions of SNiP, it is necessary to simultaneously carry out calculations for both strength and resulting deformations.

An unprepared builder can easily make mistakes in calculations, which will lead to premature destruction of the building, so it is advisable to turn to professional designers.

But such services are often unavailable to individual developers due to the high cost, so the thickness of the slab foundation is chosen according to generally accepted recommendations, taking into account the minimum requirements.

What thickness should a monolithic foundation slab be for a one-story and two-story house:

| Type of structure | Plate thickness, mm |

| lightweight structures and extensions | 100–150 |

| one-story frame-panel houses | 150–200 |

| one-story buildings made of aerated concrete | 200–250 |

| brick one-story houses, frame and aerated concrete two-story buildings | 250 |

| two-story houses made of logs, timber, concrete | 250–300 |

| brick two-story houses | 300–400 |

Rules for drawing up a slab foundation plan for a private house

The simplicity of the slab foundation design is quite deceptive. To ensure reliability, it is necessary to correctly calculate the main parameters and select the optimal design option.

When drawing up a foundation project, you must:

- calculate operational loads from the entire structure and climatic influences;

- take into account the structure and composition of the soil, the level of freezing and the depth of groundwater;

- take into account the terrain and develop measures to form a perfectly flat area;

- choose the optimal design (type) of the slab base;

- choose the right grades of materials (primarily concrete and reinforcing elements) taking into account SNiP and GOST standards;

- calculate the required depth of the slab;

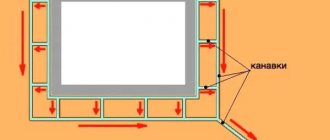

- develop a drainage system plan.

When making calculations, it is necessary to determine the total loads, which consist of the weight of the entire structure of the house and the foundation slab itself, the weight of all utilities, operational loads (furniture, interior decoration, stoves and fireplaces, household appliances, residents and guests), climatic influences (wind, snow). accumulation).

All factors are taken into account at maximum values with a certain margin of safety.

Main elements of a tiled monolithic foundation

Let's consider the main elements of a monolithic foundation in the form of a slab:

- cushion, the calculation of which will be based on factors such as soil heaving (freezing depth, presence of groundwater, soil type);

- the base, which will include the calculation of the distance between the reinforcing mesh, since according to the technology there should be two of them, as well as its total thickness.

Before starting the construction of the structure, it is necessary to stock up on reference books and information about the climatic conditions of the area where the construction of the house will take place.

Load safety factors.

Device

A standard monolithic slab has a pie-shaped structure with the following layers:

- Compacted soil surface (base of the “pie”). It is prepared by carefully leveling the site and compacting the surface layer.

- Geomembrane separating soil and slab. It is not considered a mandatory element, but increases resistance to the effects of ground changes. Geotextiles are usually used.

- Pillow. It is made by filling with sand and crushed stone or small pebbles with compaction. The standard thickness of the cushion is 25-30 cm. For particularly weak and heaving soils, the thickness increases to 40-45 cm. When backfilling, the sand is moistened for better compaction.

- Footing. This layer is made as follows. Geotextiles are placed on the pillow. A layer of M100 grade concrete up to 2-2.5 cm thick is poured onto it. The hardened concrete base is impregnated with a composition with waterproofing capabilities. A mixture of diesel fuel and bitumen in a ratio of 3:2 is popular.

- Waterproofing. The most commonly used roofing material is laid in 2 layers. The stripes overlap. You can use thick polyethylene film or modern polymer waterproofing materials.

- Insulation. For this layer it is best to use rolled, extruded polystyrene foam. Sheet insulation sheets are used. Another protective layer of polyethylene film is laid on top of the thermal insulation.

- Main reinforced concrete slab.

When making the main slab, special attention is paid to reinforcement . The reinforcing frame is made in the form of 2 horizontal contours made of steel reinforcement. Linking them into a single structure is ensured by vertical rods from A3 reinforcement and transverse elements from A1 reinforcement.

The diameter of the rods for the contours is selected taking into account the thickness of the slab and is 1/20 of it. The distance between the rods is 20-22 cm. The slab itself is made by pouring concrete of a grade not lower than M300 (B22.5) with compaction with a vibrator.

Recently, the Swedish stove has gained popularity. Its main difference from a standard slab is the presence of “warm floor” elements in the design. Heating cables or water heating pipes can be built into the concrete slab.

Dimensions: maximum and minimum thickness

The thickness of the foundation slab is calculated taking into account the bearing capacity of the soil and the total load on the foundation . Building codes set minimum dimensions.

For light buildings (wood, cellular concrete), the minimum thickness of the slab is 20 cm, and for houses made of brick and concrete - at least 25 cm. On excessively moist and heaving soils, it increases to 30-35 cm.

The minimum thickness of the slab must ensure the fulfillment of an important condition . The distance from the surface of the slab to the reinforcing contour (lower and upper) must be at least 5 cm. The distance between the tiers of the frame is chosen to be at least 7 cm. In addition, the diameter of the reinforcement should be taken into account.

The maximum size of the slab is calculated taking into account the bearing capacity of the soil. The weight of the foundation is added to the total load from the structure, and therefore cannot exceed the permissible value.

For example, if for loam the load-bearing capacity is 3.5 kg/cm2, and the total load from the house is already 3 kg/cm2, then the load on the slab remains no more than 0.5 kg/cm2, which limits its weight, and therefore thickness.

How to calculate?

The simplest way to calculate the thickness of a slab base is based on the summation of three parameters:

- the gap between the reinforcing belts;

- rod thickness;

- thickness of the protective concrete layer around the frame (from 4 cm)

The rules for reinforcing reinforced concrete foundations are regulated by the relevant paragraphs in SNiP 52-01-2003 and SP 52-103-2007.

A more reasonable calculation is made based on the loads from the future structure . For example, for a light agricultural building, a slab with a height of 0.1 m will be sufficient, and for a country house - 0.2–0.3 m.

In this case, it is necessary to take into account the features of the structure. For example, a long and narrow foundation for a house with a minimum number of internal partitions will be subject to bending loads, which may result in cracks in the foundation slab approximately in the middle. To avoid this, the thickness of the monolith is purposefully increased.

Initial data for calculation

Thus, to determine the thickness of the slab, the developer must have the following information:

- know the type of soil and, as a result, the optimal value of the distributed load;

- know the structural parameters of the future structure and the types of materials involved in order to calculate the design loads;

- choose the optimal reinforcement scheme for the given conditions, namely: rod diameter, cell size, distance between chords, etc.

Sequence of calculations

The slab thickness is calculated using the following algorithm:

- Determination of total loads.

- Calculation of specific pressure on the ground by dividing the total pressure by the area of the base. The size of the slab must exceed the dimensions of the structure itself by at least 10 cm on each side.

- Comparison of specific ground pressure with the optimal table value.

- The resulting difference as a result of the calculations from point 3 is compensated by the mass of the reinforced concrete foundation slab.

- Knowing the mass of the monolith and the density of reinforced concrete, the volume of the structure is determined.

- Find the required height of the slab by dividing the volume by the area of the base.

Analysis of results

If the value of the slab height found using the algorithm described earlier is in the range from 0.2 to 0.35 m, then the result obtained is considered optimal. As a rule, the value is rounded up or down to a multiple of 50, and for reliability, the load is recalculated to compare with the recommended reference value (the difference should not be more than 25%).

If the height of the slab is more than 0.35 m, then the developer has reason to assume that the slab under the given conditions is not the most economically feasible solution and it makes sense to consider options with a strip or column base.

The thickness of the monolith can be reduced by designing stiffening ribs that will prevent horizontal displacement of an excessively light foundation. In this case, it is impossible to do without calculations that can only be carried out by highly qualified specialists.

If the thickness of the slab is less than 0.1–0.15 m, then most likely the designed structure is too massive for a slab foundation and experienced specialists should be invited to participate in the soil study and design of the load-bearing structure.

Calculation example

Specified conditions:

house 2 floors with an area of 6 by 9 m;- walls made of gas silicate blocks;

- load-bearing partition – one;

- wall thickness – 0.3 m;

- height of the structure – 5.5 m;

- pediment height – 1.0 m;

- roof – roofing tiles;

- load-bearing layer – clay (reference specific pressure – 0.25 kg/cm2).

First of all, find the total weight of the structure, namely:

- the total area of all walls (with gables and partitions, but without window and door openings) is 182 m², and their total weight is 182 × 180 = 32,760 kg;

- the area of the monolithic floor excluding the staircase opening is ~ 50 m². Then the total mass will be 50 × (500 + 210) = 35,500 kg;

- the attic floor area is 54 m2, then the mass is 54 × (150 + 105) = 13,770 kg;

- operational load of the 1st floor – 54 × 210 = 11,340 kg;

- roof area - 71 m2, then the mass together with the weight of the snow layer is 71 × (30 + 100) 9,230 kg;

- the total mass of the structure obtained by summing up the results of previous calculations (102,600 kg).

The masses are calculated based on the dimensions and specific gravity of the building materials used (reference information).

Next, based on the project conditions, find the area of the monolith (54 m²) and divide the total weight of the house by it:

(102,600)/54=1900 kg/m^2 or 0.19 kg/〖cm〗^2

The recommended specific pressure for soil is 0.06 kg/cm2. Find the mass of the slab by multiplying the resulting value by the area of the base, which is converted to square centimeters:

0.06×54×10,000=32,400 kg

Find the volume of the slab by dividing the mass by the density of reinforced concrete:

(32,400)/(2,500)=12.96 m^3

The required height is determined by dividing the volume by the area of the base:

12.96/54=0.24 m or 24 cm

For given conditions, two options can be considered, when the height of the slab will be equal to 0.2 or 0.25 m. In the first case, its mass will be 27,000 kg, which means that together with the foundation the building will exert a pressure equal to:

(27,000+102,600)/(54×10,000)=0.24 kg/〖cm〗^2.

The difference with the recommended value will be:

(0,25-0,24)100/0,25=4%.

The obtained result satisfies the design conditions and allows saving on the amount of concrete, so the slab height is taken to be 0.2 m.

Design advantages

When pouring a monolithic slab, you can immediately install a heated floor system

In addition to being economical, a big plus of this type of base is the large surface area of the slab. Due to this, the pressure on each square centimeter of soil is reduced, which prevents deformation processes and uneven settlement. Other advantages include:

- Possibility of installation on different types of soils, including those characterized by increased mobility or high water rise. If you have to build a house on “inconvenient” soils, slabs are an excellent option. However, on a slope it is difficult to make a reliable foundation of this type; here it is better to choose piles.

- Excellent insulation ability. If the foundation is made in accordance with the technology, good protection against heat loss is achieved. It also does not allow moisture to pass through.

- Durability: A solid slab can last more than a century without signs of deterioration.

- Rigid design thanks to a reinforced frame, large dimensions and a structure that does not include suture elements. This makes it suitable for buildings made of brick, aerated concrete and other materials that react negatively even to minimal movements.

Depth of depth

The depth of a slab foundation is less dependent on design and geological conditions than other types of foundation.

In this case, the depth of laying the sole will be determined:

- type of soil;

- total loads;

- soil freezing level;

- depth of underground sources.

When choosing a parameter for a foundation for a house made of aerated concrete, they are guided by the following current standards:

- For loose soils prone to heaving and movement, the depth of the base will be 0.2 m (floating slab).

- For dense and stable rocks – 0.5 m.

- Peaty soils must be completely removed, then the depth of the pit can reach one meter or more.

Pile

Recently, the use of . It is similar in design to a columnar structure, but instead of pillars, piles or supports are used. Unlike pillars, piles are narrower, longer and are divided into the following types:

- screw;

- bored;

- driving.

— iron pipes with blades at the bottom for easy entry into the ground. The shallow installation method allows you to screw them in with your own hands; for greater depth you will need to use a special device. The inside of the piles is filled with concrete.

Wells are prepared for bored piles. A reinforcement cage is inserted inside the pipes and concreted. In practice, screw and bored piles are more often used. The tops of the installed piles are combined with a supporting structure, which allows masonry to be carried out. It is unstable to ground movement, so this type can only be used on dense soils.

USP at a price of 3,000 rubles per m2 - reality or magic

I don’t know how, but here is a real person, Alexander Dobrynin, who could do this. I quote:

In 2022, I built a USHP for myself. Followed all the rules described in the Dorocell cards. Area with terrace 146 m2 All materials and delivery cost 430 thousand, that is, 3 thousand rubles/m2 for materials.

Here's the full calculation:

- The tractor dug a pit, buried water pipes, then leveled the sand and pulled away the selected soil for 11,000

- Then three workers leveled the pit and dug a trench for drainage for 8,000

- Purchased 200 m2 of geotextile 150 for drainage and 200 m2 of geotextile 300 for the slab for 13,800

- 70 meters of drainage pipe 7000

- 5m3 of crushed stone for filling a drainage pipe - 7500

- Drainage wells, covers, various gaskets and transitions for 12725

- Drainage pump and hose - 2000

- The first layer of ASG - 45 tons - 19500

- Filling the rest of the cushion with sand 90 tons - 42000

- Buying a tamper - 25,000, after filling I sold it for 20,000. Total I write 5,000

- Sewer pipes and fittings – 6780

- Eps TechnoNIKOL CARBON ECO SP 12 packs - 32820

- PSBs-25 GOST 21 cubic meters or 105 sheets for 44940

- Adhesive foam Tytan 5 cans and gun for 2172

- Flat slate 8mm - 10 sheets for 4400

- Reinforcement 12 - 400 kg, 6 - 600kg, 8 - 100kg for 42560

- Knitting wire 20kg – 2037

- Hooks 2 pcs – 326

- MP water supply pipes - 7880

- Mushrooms for fastening L-blocks 10-180 - 500pcs - 2340

- Chairs with supports – 750pcs for 3930

- Heated floor pipes 4 coils of 200m each - 17824

- Various ties 2000pcs approximately 1500

- Insulation for pipes - 1000

- Manifold for 8 outlets with flow meters, with Eurocones and delivery of TC from MSK - 15100

- Rack profile Knauf 50-50 - 19 pieces - 4250

- Concrete pump - 13200

- Concrete B25 M350 P4 - 19m3 - 89300

The total is 420,884. I’ll add all sorts of little things, screws, lace, delivery, maybe I forgot something. Let it be 430,000 rubles. The total area of the house with a terrace is 146.6 m2, the price is 2,933 RUR/m2. If you don’t count the terrace, then the area is 124 m2, the price is 3,468 RUR/m2

Required Tools

To arrange a slab foundation that meets the requirements of GOST, you will have to rent lifting equipment and prepare the following set of tools:

- for preparatory work - shovels, crowbars, picks, devices for compacting pillows;

- for installation work - a grinder, hammers and sledgehammers, scissors, pliers, a sharp knife;

- At the concreting stage, you will need a trowel and trowel, usually a spatula, a construction mixer, and a grater.

The quality of the work performed is checked by the construction level. In addition, a tape measure and a metal ruler will come in handy.

Monolithic slab for a house made of aerated concrete - construction technology

The procedure for constructing a monolithic slab is as follows:

- Prepare the site.

- Make markings.

- Dig a pit.

- Form a pillow.

- Install the formwork.

- Lay waterproofing.

- Install insulation.

- Assemble the reinforcement grid.

- Perform concreting.

When performing each stage of work, you should be guided by the requirements of a previously developed project.

Calculation of a slab foundation based on load with an example

There are only two types of foundations that are suitable for the construction of almost any building: pile and slab. They allow the construction of buildings on soils with poor characteristics at minimal cost. It is worth choosing a monolithic slab as a foundation for many reasons, but in order for it to be strong and reliable, it must be properly calculated.

Installation of a slab under a garage

There is nothing difficult in doing the work of installing a monolithic slab for a garage box yourself; you just need to have minimal construction skills and sufficient funds (a monolithic concrete slab is a rather expensive type of foundation).

Preparatory work, site planning

Before starting concrete work to pour a slab base under the foundation, it is important to carry out preparatory planning work with special care. The area should be cleared of debris and large stones, tree stumps should be uprooted, overgrowth of trees and shrubs should be removed, and the area should be leveled

The marking of the future foundation is carried out directly on the construction site after planning work. The corners of the building are marked with pegs, between which strings are stretched. The length and width of the slab are measured with special care - any discrepancy in size can cause distortion in the structure of the foundation and the garage building built on the slab.

In order to check the size compliance, it is worth pulling the string diagonally across the area - the measurement results should be absolutely identical.

Excavation work for the installation of a monolithic slab

To install a concrete cushion, it is necessary to dig a pit, which usually has a depth of 30 to 50 cm. In some cases, the thickness of the slab has to be made larger, but it should be remembered that the cost of such a foundation increases sharply.

The bottom of the dug pit is filled with crushed stone, which is laid out in an even layer on the ground and thoroughly compacted. The height of the crushed stone base can be from 10 cm.

The preparatory layer of crushed stone is filled with coarse quartz sand, which is leveled over the area of the pit and the height must correspond to the thickness of the crushed stone preparation. The sand layer must be compacted; if compacting is difficult, add water and then repeat the operation.

Formwork work and reinforcement cage production

Wooden formwork is erected along the perimeter of the pit, the height of which should be slightly higher than the thickness of the supporting monolithic slab. The construction of the formwork begins at one corner, into which the first support peg is driven

Pegs are placed around the entire perimeter at equal distances, and it is very important to ensure that the vertical position is maintained. The formwork boards are fastened with self-tapping screws; when installing them, it is important to fasten the boards with the smallest gap between them

After installing the formwork, you should begin constructing a frame made of reinforcement. It is allowed to use reinforcement with a diameter of at least 12 mm to reinforce a monolithic slab foundation. The frame is knitted using knitting wire or welding. The cell size should not exceed 20 cm.

When choosing between the welded method of manufacturing a reinforcement frame and the method using knitting wire, it is worth noting that both methods have their advantages and disadvantages, but the second is more reliable.

Pouring concrete mixture

The quality of the foundation largely depends on compliance with the technological process of pouring concrete. It is allowed to use concrete not lower than M-250, the ideal option is M-350. It is best if the process of filling the prepared formwork with concrete is continuous - thus, uneven setting of the concrete mixture and the formation of cold bridges can be avoided.

It is best to order concrete mixture, which is supplied in special mixers. Filling the formwork begins from one corner, the concrete mixture is distributed throughout the structure, with constant compaction by vibrators

It is very important to avoid voids when pouring a slab base; their presence will significantly weaken the bearing capacity of the foundation cushion

When making a concrete mixture by hand, it is important to place concrete mixers on different sides of the foundation, filling the formwork from opposite corners, and it is very important to thoroughly compact the concrete mixture with vibrators. Watch the video on how to properly install a slab under a garage:

Watch the video on how to properly install a slab under a garage:

Calculation of the area of load-bearing walls

It remains to calculate the area of the load-bearing walls of the building and compare it with the result obtained above.

If it is smaller, the thickness of the slab can be reduced, for example, to 25 cm and the calculation repeated. This way you will reach the optimal thickness of the monolith. In this case, you should adhere to the following recommendation: if you are building a house yourself, you should not go beyond the range of 15-35 cm when determining the thickness of the slab.

If you are interested in other types of foundations, then read the articles in the relevant sections using the links below:

Video about foundation calculations.

Source