What is it like to live in a house without corners, straight lines, or partitions? Some people believe that round and cylindrical houses are the ideal place to live. We will introduce you to the most original round house projects.

Round-shaped structures have been known to mankind for many centuries. It all started with caves and yurts, then watchtowers and observation towers, lighthouses and, finally, experimental residential buildings appeared, devoid of sharp corners and strict forms. It is believed that in their style such buildings are closer to natural beauty, since they are devoid of straight lines, which are rare in nature. They resemble tree trunks and look more organic in any landscape.

Advantages and disadvantages of round houses

Round houses are considered more durable and earthquake-resistant, and can withstand winds of any strength. They are installed in areas where storms, hurricanes, tornadoes and tsunamis are not uncommon, but a common occurrence. Flat or sloped roofs of cylindrical houses are less likely to be blown off by the wind, and they do not “fold” even during earthquakes.

The unusual shape of the housing helps to save on building materials. According to experts, a round house requires 15-20% less building materials than a rectangular house of the same area.

Cylindrical houses have completely different acoustics. Sound waves travel evenly throughout the building, allowing voices and music to be heard softer and clearer. But external noises barely penetrate into the building, so cylinder houses are ideal for anyone looking for silence and unity with nature.

The main disadvantage of a round house is its unusual shape and the lack of corners and partitions. However, not so long ago cylindrical houses were developed, equipped with interior partitions. A group of Polish architects managed to create the Standard hOuse, which can rightfully be considered the standard for round houses.

Randy Colwell project by Monticello Custom Homes and Remodeling

0

There are plenty of round grain bins in the US state of Missouri. Local farmers dry their wheat and corn there, and the McDowell family lives there. Mark and Kelly are designers, the husband does furniture, the wife does interiors. Initially, the couple wanted to build a guest house from an old bunker, but later the plan changed - they bought a new bunker, and made the house not a guest house, but a master’s house. A metal cylinder with a cone-shaped roof is the center of the building and the actual living area, with various utility rooms located around it. The total area of the complex is almost 200 square meters.

Polish project Standard house

The biggest problem is not only the unusual shape and interior space of such houses, but also the fact that it is very difficult to find appropriate furniture for a round house. Polish experts from KWK Promes Konieczny Architects decided to give the rooms a trapezoidal shape using interior partitions. Furnishing such a room with familiar furniture is much easier than a room without corners.

According to the creators of the project, adherents of minimalism who do without bulky interior items and, for example, paintings, will feel best in such houses. They just need to paint the walls in light colors and enjoy life in their own “capsule”.

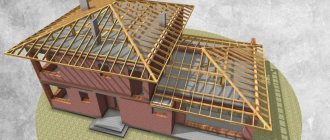

Preparatory work

At the preparatory stage, the following must be done:

1. Project selection. The following points should be displayed in the project drawings: - the shape of the building; - square; - number of rafter elements; — cell parameters; — number of connectors, etc. 2. Selecting a location. At the chosen location for building the dome, markings should be made in accordance with the dimensions of the future building. 3. Manufacturing of necessary products for construction. Based on the drawings, you need to make your own connectors, rafters and plywood elements. 4. Materials processing. Wood naturally needs to be treated with an antiseptic; if metal connectors are used, they are treated with anti-corrosion substances.

Construction instruction

Country house Villa Nyberg

For those who value the picturesque view from the window more than any painting, the Swedish studio Kjellgren Kaminsky Architecture has developed a project for a country house in the shape of a multi-stage cylinder. The total area of its premises is 156 square meters, and the building itself is made using energy-saving technology.

The builders gave the “drum” shape only to the first floor of the building. The second floor forms a semicircle, equipped with panoramic windows and several terraces, which offer stunning views of the nearby lake.

Building options

A one-story house with a bay window looks preferable in an open area, in a forested area; it personifies the landscape with interesting views. It turns out to be practical to build houses from timber using ready-made standard designs. They are more easily modified to meet the needs of the customer and the owners of suburban areas. They quickly adapt to a forest, an open clearing, a meadow, or a view near a pond. They also combine other features of individual solutions.

Houses from abandoned towers

A separate category includes residential buildings that were created during the conversion of abandoned silos and water towers, as well as gas tanks. These are very serious projects, the implementation of which requires a lot of effort and money. After all, it is not enough to find an unnecessary building, you also need to make sure that it is suitable for habitation (which is rare). It needs to be re-equipped, further strengthened, insulated, and window and door openings made. But the end result is a comfortable and original home.

Blind or opening windows

Since the vast majority of these models are made to order, the client can independently determine the opening method. Usually the choice is made from 4 options:

- Blind

- this design eliminates the possibility of opening the window. When using this technology, double-glazed windows are inserted into frames and pressed with glazing beads. This glazing method is chosen in cases where a room with a round window has other sources of fresh air. - With opening sashes

- to implement this method, the window is divided into separate segments by vertical and horizontal imposts. The most common option is dividing it into 4 parts by perpendicular jumpers. In this case, the active elements of the window have the shape of a quarter circle. - With an opening top or bottom

- windows of this type are functionally reminiscent of transom models, in which the sashes are tilted or raised in a vertical plane. To ensure this method of opening, the internal clearance is divided by a horizontal impost. - Middle-hung

- this technology is based on the rotation of the active sash around its axis. Depending on the attachment points of the fittings, such windows can open in a vertical or horizontal plane. During movement, the sash can rotate 180°. To ensure safe operation of mid-mounted models, the fittings are additionally equipped with special braking devices. With their help, the movement of the active leaf is controlled.

When considering the functional characteristics of models with opening doors, it is recommended to focus on the data from the table.

| Opening type | Individual characteristics |

| With opening top or bottom of the window | They allow you to ventilate rooms and, thanks to the additional jumper, have increased rigidity. However, during operation it is not always convenient to lower or raise the active sash. Also, with a large structure, it may be difficult to access the entire outer part of the glass unit when washing windows. |

| With swing doors | This round window functions almost the same as a regular rectangular model. The number of active sashes is determined by the customer. It is possible to integrate rectangular vents into a round structure. It should be taken into account that a large number of vertical or horizontal imposts reduces the light transmittance of windows. If there is an insufficient number of active sashes and their small sizes, access to the outer part of the double-glazed windows is difficult. |

| Mid-suspended | A convenient model that allows you to easily ventilate the premises and wash the double-glazed windows. Thanks to the improved fittings, even large doors move easily when opened. Such models provide ideal air circulation when ventilating rooms. |

If you decide to choose a model without active sashes, you must take into account that blind structures can only be washed from the reverse side. It is also undesirable to make a round dormer window blind - read more about this on OknaTrade.

Fairytale Hermit's Tower

Japan is one of the most densely populated countries in the world, and carving out some free land and space here is very difficult. However, even here you can find a secluded corner and arrange it at your own discretion. Just like one of the local residents did, who built a cozy “tower”. The entrance to it is located on the second floor, a spiral staircase leads to it. But the main surprises are hidden inside.

The interior is divided into several zones by four vertical parallelepipeds. Each of the blocks hides a staircase leading to one of four rooms on the first floor - a bathroom and three bedrooms. For those who don't like labyrinths, there is also a regular door leading to the first floor.

Cylindrical houses can be different - large and small, laconic and fantastic. This is an excellent option for those who value comfort, economy and eccentricity. Start with small shapes—a turret-shaped house extension or a cylinder-shaped summerhouse—to see if you like rounded shapes or if you miss angles and straight lines.

Materials

Nowadays, metal-plastic profiles, aluminum systems and laminated wood beams are mainly used. To give each of the listed materials a radius shape, appropriate technologies are used, which is why the finished structure has its own characteristics.

PVC blocks

The most popular option, due to the well-known practicality of plastic, relatively affordable cost and ease of manufacture. The production technology of round PVC windows consists of preliminary heat treatment of the profile, after which it is given the appropriate shape. The actual heating is carried out in a special chamber. The bending radius is calculated in advance, a template is created, according to which the frame circumference is formed. After cooling, the plastic retains the forum and all the positive properties characteristic of this material:

- Low sound transmission;

- High energy efficiency;

- Service life more than 50 years;

- The block turns out to be quite sealed;

- PVC is resistant to atmospheric conditions, changes in temperature and humidity, as well as UV radiation.

The main disadvantage of the round design, in comparison with traditional rectangular analogues, is the lack of reinforcing reinforcement. The temperature at which PVC softens to a plastic state differs significantly from that for metal. Therefore, it is impossible to bend polyvinyl chloride reinforced with an iron profile. It will also not work to install a ready-made radius element of additional rigidity into an already formed part. Thus, all the loads are taken by the plastic, which is not critical for relatively small blocks, but will have consequences as the size increases. The outer frame is fixed in the opening and is practically not subject to any critical loads. But the doors of opening structures can become deformed, which in turn will lead to loss of tightness.

It is still possible to further strengthen the round plastic block. This is a fairly expensive technology, and instead of metal, a composite polymer is used as reinforcement.

It is heated to the required temperature, given the appropriate radius and inserted into the prepared plastic profile.

The manufacturing process in the following video:

Aluminum windows

One of the properties of aluminum is high thermal conductivity. Because of this feature, the most common is the so-called cold aluminum glazing. This type of glazing is relevant in rooms where energy efficiency is of secondary importance, for example, on unheated balconies or loggias. The possibility of producing warm aluminum structures also exists. To do this, they use complex profile systems in which metal elements are separated by a special thermal insert - a polymer with low thermal conductivity.

Profiles for round aluminum windows, both cold and warm, are made on profile bending machines. A flat workpiece is passed through rollers several times, deforming it in a given direction. The procedure is repeated until the part takes the required shape.

The positive aspects of aluminum windows:

- The maximum service life among all available materials (100 years or more).

- The aesthetic appeal of glazing on the facade of a building.

- The weight of aluminum blocks is less than that of plastic or wooden models. At the same time, the design is characterized by high mechanical strength, which makes its use most preferable if the block is subject to strong wind loads.