The foundation on screw piles is considered the most universal: it is suitable for most soils. And in difficult areas - swampy, with uneven terrain or heaving soils - it is preferred as the most stable and economical. But when it comes to the construction of fences or not very important outbuildings, most homeowners think about how to make a screw pile themselves and save on buying factory-made products. In what cases is this desire justified and how to realize it, this article will tell you.

For areas with a slope, a pile-screw foundation is the fastest and least expensive option Source svaisad.ru

What you need to know about screw piles

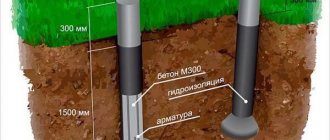

Piles are not only steel screw, but also concrete. In some cases, especially during the construction of large and heavy structures, preference is given to the latter, as they are more reliable and durable. But before you make a pile foundation with your own hands from concrete, you should carry out geological surveys and engineering calculations to ensure that the decision made is correct.

However, such costly measures are usually carried out when building a house made of bricks, concrete blocks and other massive materials. Lighter wooden, panel and frame buildings can be placed on a base of screw piles on any soil except rocky.

But if we are talking about a permanent structure, calculating the parameters of the piles is still necessary. It can be neglected only when constructing secondary structures - gazebos, sheds, bathhouses, fences. And only for such structures can you use homemade screw supports.

Metal fence on screw piles Source spravka-region.ru

Pile components

Externally, the screw pile resembles a garden drill and consists of the following parts:

- steel pipe barrel;

- sharp cone-shaped tip;

- blade (screw);

- head.

The main difference from the drill is the perpendicular position of the blade relative to the trunk, which allows it to enter the soil without loosening it or disturbing its density.

The second difference is the cap in the upper part of the structure, intended for tying all installed elements and grillage installation, since it is impossible to make a pile foundation without such support platforms.

In factory conditions, piles are made either by casting or welding using professional equipment. They can be of different lengths, differ in blade diameter, trunk diameter and thickness. These parameters are selected depending on the calculated load on the foundation and the depth of dense soil layers.

In addition, during production, all products are coated with a layer of anti-corrosion coating, which prevents the destruction of metal that is in constant contact with a humid environment.

Factory-made pile Source www.balticdom.ru

Differences between handicraft and factory designs

The production of foundation piles is regulated by regulatory documents. In particular, GOST 8732 determines the quality of the metal for the barrel, and GOST 9.307-89 determines the quality of the zinc coating. They specify the grade and thickness of steel, its chemical composition and other characteristics. When deciding how to make screw piles with your own hands, it is advisable to study these documents in order to obtain high-quality products.

Not having the opportunity to manufacture them themselves, but wanting to save on supports, some developers buy them from “handicraftsmen” - craftsmen who produce metal structures in conditions far from factory ones. Of course, they do not give any guarantees, and it is impossible to verify the quality of such products before construction begins.

In particular, both homemade and handicraft products may not have the necessary strength, the blades may be deformed or torn off when screwed into dense soil, and the lack of high-quality anti-corrosion treatment can lead to destruction of the metal and weakening of the foundation.

The destruction of just one support will lead to weakening and distortion of the foundation Source tverstroy.rf

However, the question of how to make screw piles yourself remains relevant for many due to the high cost of certified products. Experts allow the use of homemade supports, but only when erecting lightweight buildings, the reliability and durability of which are not of decisive importance. The foundation for residential buildings, permanent outbuildings, brick and stone fences must be built from factory piles produced in accordance with regulatory requirements.

See also: Catalog of companies that specialize in foundation repair and installation of metal structures of any complexity

Advantages and disadvantages

Pile foundations have a number of advantages:

- The technology allows you to build a building on any soil.

- Minimum amount of excavation work at the preparation stage.

- Save time. Installation takes 2-3 days.

- Possibility of construction in areas with difficult terrain.

- Saving money. A pile foundation is 20-40% cheaper than a strip foundation.

- High strength and long service life.

- Possibility of manual installation without the use of specialized construction equipment.

- Modernization of the building can be carried out after the foundation has been erected (laying utility networks, changing the layout of the house).

A pile foundation allows you to build a building on any soil.

There are several disadvantages to a pile foundation, but they can be minimized:

- On rocky and rocky soils, installation work is extremely difficult.

- The metal is susceptible to corrosion, so waterproofing and storm drainage will be required to protect it from moisture.

- With such a foundation, the construction of a full-fledged basement or basement is impossible, but it is still necessary to close the beams from the outside.

- To insulate the floor in the building, additional funds will be required.

Manufacturing process

Before you make foundation piles with your own hands, you need to stock up on all the necessary materials.

Choosing a barrel pipe

The base of the screw pile is made of a hollow steel pipe with a thickness of at least 4 mm. Steel grade in terms of strength – St. 20 or more.

Note! The thicker the pipe wall, the stronger the trunk will be. But when manufactured in artisanal conditions, it will not be easy to form a sharp conical tip from thick metal.

The trunk is made of durable steel pipes Source minteko.net

The length of the trunk is selected based on the depth at which dense, non-freezing layers of soil lie at the construction site. Such data can be obtained from the local geological survey service or by asking nearby neighbors who built houses according to a project tied to the area. Another option is to do test drilling.

To this value you need to add 30-50 cm for penetration into the load-bearing layer and the height of the trunk remaining above the ground. It is advisable to make a larger reserve, otherwise if there is not enough length, the pile will have to be increased by welding a piece of pipe to the upper end, which will weaken the structure.

Please note that industrially manufactured extension cords do not have this drawback. A 20-25 cm coupling is welded to a pipe of the appropriate diameter in the factory, which is placed on a screw pile installed in the ground, then the joints are additionally welded and primed to avoid corrosion. Due to the design features, the connection point is thicker than the pipe itself, so if you have a task to build up screw piles, it is better to use factory-made extensions.

Anzhelika Avdeeva

Head of Sales Department, KZS LLC

It’s easier to cut off the excess length by leveling all the piles after installation Source vladimirsvai.ru

The diameter of the trunk is also important for the strength and load-bearing capacity of the foundation. It is regulated by building codes and regulations. In order not to waste time studying specialized literature when figuring out how to make a pile foundation with your own hands, focus on the following values:

- posts for light fences are made from pipes with a diameter of 47-76 mm;

- more massive fences, bathhouses, gazebos and other outbuildings are installed on a base of piles with a diameter of at least 89 mm;

- for the construction of a frame country house or a building made of timber, supports with a diameter of 108 mm or more are used.

It is not recommended to make more massive products, since it is impossible to ensure proper quality for them at home.

History of appearance

The widespread use of pile foundations became possible in the early 50s. The development of this construction technology was due to the advent of equipment for screwing in supports.

After numerous experiments, the scientific work TUVS-55, prepared by domestic scientists and builders, was published in 1955.

This work contained a large number of technical instructions on the design of pile foundations. Since then, these developments have been adopted as standards.

Screw piles are widely used for foundation construction.

The norms and rules used in the 21st century have changed somewhat, but many provisions were borrowed from TUVS-55.

Video description

The process of making a pointed tip is shown in the video:

A paper template - a sheet of paper the length of which is equal to the circumference of the pipe - will help you accurately mark. This length is divided into 4-6 parts depending on the number of segments, their height is determined and the designated points are connected. The cut out “crown” is applied to the pipe and traced along the contour.

An example of a finished cut for further production of a cone Source kzs.ru

After removing excess metal with a grinder, the remaining petals are bent towards each other using a hammer. It will be easier to bend them if you make small horizontal slits at the junction of the petals, which will also need to be boiled later.

And this is an example of welding a previously made workpiece into a pile cone Source kzs.ru

Making a screw

Another type of material that must be purchased before making piles with your own hands is sheet carbon steel grade St.3, the thickness of which must be at least 5 mm. The main working element is made from it - a spiral blade.

For normal passage through the ground, one turn of the spiral is enough, so the blank for making the screw will be a circle cut out of steel with a hole in the center. Its outer diameter is selected in accordance with the diameter of the trunk. The dependence of these parameters is reflected in the table.

External screw size depending on the diameter of the pile shaft Source remont-book.com

DIY pile reinforcement

You need to prepare everything you need to make a metal frame in advance. To install bored supports you will need the following tools and materials:

- grinder for cutting metal rods;

- welding machine for installing a reinforced frame;

- vibration device for compacting concrete mortar inside the pile;

- drilling machine;

- concrete mixer;

- shovels;

- ready-made concrete or its components: sand, cement, crushed stone;

- metal rods, corrugated and smooth;

- roofing felt;

- wire.

Step-by-step instructions for reinforcing piles with your own hands:

- Steel rods are cut into pieces of the required length using a grinder.

- For transverse jumpers, sections of rods are bent to obtain a rounded shape or 4 pieces are prepared, which are subsequently welded to the sides of the longitudinal frame.

- The required number of longitudinal rods are laid parallel to each other, their upper, lower ends and the middle are connected by transverse jumpers.

- The second part of the frame is assembled. They are connected to each other with a double weld.

- Treated with anti-corrosion compounds.

- The reinforced frame is lowered into the prepared hole.

- Fill with concrete mortar and compact it with a vibration installation.

Video description

The following video shows in detail the screw manufacturing process:

The finished blade is welded to the end of the pile, trying to ensure that the plane of the screw is perpendicular to the trunk. Apply a suture on both sides, without gaps. The strength of the entire structure depends on its reliability.

Final processing

After completing the welding work, remove scale from the seams and grind them thoroughly. Then the entire product is cleaned of rust, degreased and an anti-corrosion coating is applied. This can be a high-quality metal primer or ship paint. They should be applied in at least two layers, allowing each to dry before applying the next.

Paint will protect metal products from corrosion Source i.ytimg.com

Final works

After installing all elements of the pile field, the following work must be carried out:

- Place the design level level on each pile and mark it with a marker.

- Trace the mark with a marker around the circumference of the body. To do this, use thick paper.

- Cut off the excess using an angle grinder strictly according to the mark. If there are any unevenness or burrs on the top, sand it down.

- Prepare a funnel, cement mortar or concrete using fine crushed stone, fill the pile cavities to a level 20 centimeters below the head. As you pour, compact the concrete with reinforcement.

- After the concrete has set, mount the heads and weld them to the body of the piles. If the project provides for an upper channel frame, no caps are needed.

A few final tips:

- If there is an obstacle in the ground, and the bottom of the pile remains in the freezing zone or groundwater, it is necessary to remove the stone or add two more elements at a short distance along the axis. This will reduce the load on the pile. If it is the support for the internal axis, then a simple displacement of the pile will necessitate changing the position of the remaining piles of the internal axis and the design of the house as a whole.

- The load-bearing capacity of piles can be determined by the amount of torque using a device that determines the force when turning.

- After concreting the cavity, fill it to the top with a dry cement-sand mixture; it will absorb the remaining moisture when the concrete hardens.

- Clean the seams from slag and coat them with anti-corrosion compounds.

Foundation structure

To screw the screw support into the ground, two holes are cut opposite each other in its upper part by welding. A crowbar or a pipe of suitable diameter is inserted into them, forming levers for rotation on both sides of the pile.

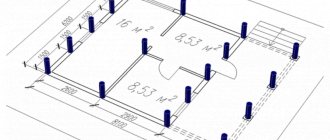

When screwing in, it is necessary to constantly monitor the vertical position of the support in the ground. After screwing in all the piles, they are cut at the same level so that the ends protruding above the ground lie in the same horizontal plane. Then a concrete solution is prepared and poured into the pipe cavity.

Comparison with other options

In addition to screw structures, there are several other types of piles. They differ in materials of manufacture and installation methods. The visual difference can be seen in the diagrams and photos.

Pile-tape construction

The pile-strip structure refers to a bored pile foundation. To install it, a hole with a hemispherical base is drilled in the ground, a frame made of a metal rod is inserted into it and filled with concrete. The columns are tied with a reinforced concrete grillage.

Pile-tape structure - bored foundation.

This design has increased strength, but is not used on swampy, silty and rocky soils.

Reinforced concrete piles

Such products are reinforced concrete pillars with a square section. They are installed without preliminary earthwork using a specialized device. Disadvantages include the impossibility of deepening on your own and lower strength compared to screw supports.

Video description

How to prepare concrete and how to pour piles under the foundation with your own hands is shown in the video:

After the concrete hardens, caps are welded onto the piles - metal platforms on which the grillage will be attached. There are two ways to do this.

- Weld triangular gussets to the end of the pipe on four sides, and secure the pads to them by welding.

- Make heads from scraps of pipe of larger diameter, put them on the ends of the piles and weld them in a circle.

Overhead heads with a platform drilled for fasteners Source svai-kirov.ru

Final works

After installing all elements of the pile field, the following work must be carried out:

- Place the design level level on each pile and mark it with a marker.

- Trace the mark with a marker around the circumference of the body. To do this, use thick paper.

- Cut off the excess using an angle grinder strictly according to the mark. If there are any unevenness or burrs on the top, sand it down.

- Prepare a funnel, cement mortar or concrete using fine crushed stone, fill the pile cavities to a level 20 centimeters below the head. As you pour, compact the concrete with reinforcement.

- After the concrete has set, mount the heads and weld them to the body of the piles.

If the project provides for an upper channel frame, no caps are needed. Trimming the head to the design mark.

A few final tips:

- If there is an obstacle in the ground, and the bottom of the pile remains in the freezing zone or groundwater, it is necessary to remove the stone or add two more elements at a short distance along the axis. This will reduce the load on the pile. If it is the support for the internal axis, then a simple displacement of the pile will necessitate changing the position of the remaining piles of the internal axis and the design of the house as a whole.

- The load-bearing capacity of piles can be determined by the amount of torque using a device that determines the force when turning.

- After concreting the cavity, fill it to the top with a dry cement-sand mixture; it will absorb the remaining moisture when the concrete hardens.

- Clean the seams from slag and coat them with anti-corrosion compounds.

Cut the stripes

With the help of competent design of steel strip cutting, the amount of waste can be significantly reduced.

The width and length of the strip must be a multiple of the outer diameter of the blade blank:

- It is necessary to lay a large template along the width without any allowances. For example, in the case where we have a diameter of 200 mm, the strip width should be 200 mm;

- The strip must correspond in length to the diameter of the template multiplied by the number of blanks (and without any allowances for the gaps between the blanks).

In order for all the blades to be the same size, it is necessary to correctly draw the strip: for this you need to draw the horizontal axis along its length, and the vertical axis, in turn, with a step that will be equal to the diameter of the blade. Moreover, the first vertical must be marked from the short side of the strip at a distance that will be half the diameter of the workpiece.

Using templates, circles are marked. Moreover, these operations can be performed in any order - first large (external), then small (internal) or vice versa.

In the event that you decide not to apply axes to the strip, you need to start marking from the outer contour of the workpiece.

What solutions apply in this case?

With such soil conditions, the most effective solution is to build on a pile foundation.

Foundation piles are rectangular, pyramidal, round, solid or hollow. The materials for their manufacture are reinforced concrete, concrete, wood, metal.

The pile structure is also distinguished by a vibration protection mechanism, which is installed on top.

Existing installation options:

- retaining piles. They stand on solid ground at a great depth of burial. The technology is characterized by a complete absence of shrinkage;

- hanging piles. Used when it is impossible to reach solid ground. They are firmly driven into the moving layer and held by friction forces.

- drilled and driven piles. Installed in pre-dug holes;

- piles with driven elements. Pointed piles are driven with a special installation designed for this work;

- screw piles. They are screwed into the ground like a huge screw, either automatically or manually.

What are the advantages and in what cases are they installed?

- Of all the listed methods for installing a pile foundation, the fastest is the pile-screw method.

To carry out the work, no preparation is required before screwing the piles into the ground.

If the piles are no more than a meter long, they can be screwed in manually using a barbell or a wrench.

The use of high-quality piles from reliable manufacturers in the pile-screw method is highly valued by construction specialists.

For example, the German company Krinner produces a large number of elements of improved shape, adapted to various foundations and soils.

Such piles are used almost everywhere; they can be easily installed even in permafrost conditions, which has made them very popular in the far north.

Correct cone design

In the construction of screw piles, the design of the cone is important.

Using the template, you need to mark 4 sectors. After this, you need to cut them out from the body of the pipe using a grinder.

The triangles that remain on the pipe must be carefully knocked down using a sledgehammer, and in the direction of the center of the cross section until they are completely closed. Then you need to carefully weld the joint lines using a continuous seam. The quality of the weld is of great importance. In this case, the number of sectors can be increased.

Fine sands

This type of soil has a number of features that will have to be taken into account when working with it. Due to the weak water throughput and the ability to increase the volume when moisture freezes, it is best to add a drainage layer to such a base, which will interrupt the capillary rise of moisture to the foundation.

The second way to protect the future foundation from the heaving ability of fine-grained sand is to install piles under a strip frame. They can be installed either manually or screwed in using a special machine.

Which method to choose is up to the developer to decide based on his financial capabilities. The piles should be installed so that their upper part protrudes at least 10 cm above the bottom of the trench. To save on the number of piles, it is better to make calculations so as not to install unnecessary ones. Before installing the formwork, it is necessary to backfill the base with coarse-grained material, and also lay a layer of rolled waterproofing.

If the developer does not want to do extra work with fine-grained sand, you can build a foundation on bulk soil, for which a layer of old soil is removed and coarse-grained material is laid. It should be noted that all inert materials are well compacted under their own weight, therefore, if you fill the new base with a layer of small thickness and leave it for a long time (for example, for a time when it will not be possible to carry out work due to seasonality), then later you won’t even need to add it thicken.

Step-by-step instructions for making metal piles

For example, let’s take the simplest version of manufacturing products, but the screw blade has a rather complex geometry. This results in the following advantages.

- The blade is welded to the tip - the twisting force is reduced, and the pile goes into the ground more easily.

- The bottom rib has a special geometric shape that easily cuts the soil. There are options when the edges are made sharp, but professional builders do not advise doing this. The reason is that thin edges quickly bend, which increases the resistance significantly. Instead of making screwing easier, the opposite situation occurs.

Thick wall pipes with a wall thickness of 6 mm and a diameter of 50 mm are used for the products. Used pipes, which significantly reduces the cost of materials, while the quality and all physical parameters are at the proper level. Protecting surfaces from corrosion is done with bitumen mastics.

Step 1

. Using a basic template, mark the end of the pipe. It is necessary to cut out the so-called crown; after bending it, a sharp end is formed. It is needed to make it easier to screw the pile into the ground. The template can be made from durable cardboard or a piece of linoleum. The process consists of several stages.

- Cut a piece of linoleum. The width should be equal to the circumference of the pipe, and the length should be twice the diameter. In our case, the width is 50 × 2 = 100 mm, and the length is calculated by the formula C = πD = 3.14 × 100 = 314 mm .

- We will make four teeth, the width of each at the base is 100:4 = 25 mm. Place dots at these deletions.

- Draw the axes of symmetry and connect them with lines to the vertices of the triangles.

- Cut out the triangles, you should end up with a crown, this is the template for all the piles.

What can result from incorrect backfilling?

You need to know how to fill the foundation correctly and competently. This is also explained by the fact that incorrect execution of this operation can lead to the fact that the waterproofing system of the building’s foundation will be nullified. It is also necessary not to forget that there are other problematic situations that can be caused by excessive overloading of the backfilled soil.

It is necessary to install pile supports under the first floor of the building. Their purpose is that they will take on most of the load. Thus, the filling itself will remain intact.

It is also necessary to pay attention to the drainage system. This is due to the fact that groundwater, which can rise from time to time, destroys the fill under the foundation

In order to eliminate such situations, the equipment of a special buffer cushion is required.

This component must be located between the foundation and the base of the building. The buffer is made from either crushed stone or gravel material. Such a component is filled with a layer of fifteen centimeters, with a deviation of 5 cm allowed. Such a structure helps drain groundwater from the foundation.