Leaving a vehicle for a long time in the open air is fraught with corrosion of its metal parts and damage to rubber and plastic elements. In addition, the car in this case is an excellent target for persons committing thefts and thefts. If you have become the happy owner of a small plot of land, the size of which allows you to build a garage, then there is nothing to think about - you need to build. The easiest, fastest and most inexpensive way is to make your own garage from sandwich panels yourself.

Advantages and technological features of the design

Before using a panel sandwich, you need to understand its technological features and main advantages.

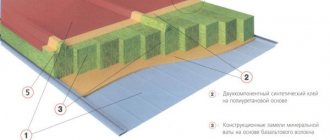

A sandwich panel is a building material that can be used to quickly build a small structure. Such panels consist of a thermal insulation and two facing layers. In the manufacture of the material, magnesite plates and PVC are used, and to create a layer responsible for insulation, the following is used:

- high-density polyurethane foam;

- Styrofoam;

- mineral wool.

Thanks to their multilayer nature, SIP panels have a high level of density, since their thickness is 10-20 centimeters. The width is in the range of 120-130 centimeters, and the length is 5-10 meters. These dimensions make it possible to construct buildings from this material without the use of additional seams.

The main advantages of building sheets include ease of use and speed of construction of buildings. It takes 2-3 hours to build one wall. However, they also have other advantages, which include:

- Heat retention. Panel structures with wall thicknesses of more than 250 mm perfectly retain heat even in regions with low temperatures.

- Small mass. Structures made from sandwich panels are lightweight and therefore do not require an additional foundation.

- Soundproofing. Inside the panel garage you can hardly hear any extraneous sounds from the street.

Disadvantages include poor load-bearing capacity of structures. Tall panel buildings gradually deform due to heavy loads. Therefore, experienced builders advise using materials with a length of two meters when constructing garages.

Prices

If you build a garage yourself, its construction will cost the owner much less than using standard materials, and the building will last from 30 to 50 years.

The average price for sandwich slabs varies from 920 rubles. up to 4200 rub. for 1 m2 . The greater the parameters of the elements (thickness, width, length), the higher the price. This cost must be multiplied by the area of the garage walls and subtracted from it the sizes of windows and gates. Roofing panels will cost about 2000 - 4000 rubles.

To the costs you also need to add the price of the foundation, fastening elements (if they are not included in the package of the panels), gates, windows, tools for work.

What materials are used for construction

In the manufacture of sheets, various materials are used that have certain distinctive features. Therefore, it is recommended to understand in advance what the panels are made of. The following are used as cladding:

- Metal. The metal frame is made of stainless or galvanized plates that are protected from corrosion. Their surface is covered with polyester or a thin layer of pural. Some manufacturers apply aluminum foil for additional protection.

- Drywall. Such cladding is less reliable, and therefore plasterboard panels are used only for the construction of partitions indoors. They are not suitable for external use, as the material quickly deteriorates due to temperature changes and high humidity.

- PVC. This material, like drywall, is only suitable for indoor use. Most often, partitions in buildings or doorways are made from it.

- Paper. Sometimes the panels are covered with paper, to which foil and polyethylene are added. Some material manufacturers use paper that is completely impregnated with bitumen. Builders advise using such panel sheets when insulating a foundation or roof.

The thermal insulation layer of building sheets is made from materials such as:

- Mineral wool. It has good thermal insulation properties and therefore is often added to sandwich panels. Cotton wool is also resistant to high temperatures and practically does not burn.

- Glass wool. The characteristics of this material are in many ways similar to mineral wool. The main distinguishing feature is that glass wool is more elastic and durable. Many people do not advise buying such sheets, as they emit particles that are harmful to human health.

- Expanded polystyrene. It is considered the highest quality material, as it is resistant to mold, low temperatures and high humidity. Thanks to this, expanded polystyrene panels do not deteriorate for several decades.

How to calculate the quantity?

To calculate the required number of sandwich panels for building a shed, you need to take into account a number of facts, including :

- Roof features: single-pitch or gable.

- Dimensions of the building: width, length, height to the roof and to the ridge.

- Number of windows and doors.

- The thickness of the panels for walls and roofs, their width and length.

It is difficult to perform accurate calculations on your own. As a rule, panel sellers do this after providing them with the necessary characteristics. As a last resort, you can use an online calculator by entering the required data in the appropriate columns.

Accurate calculation is very important. It will allow you to avoid unnecessary expenses and immediately purchase additional elements of the required size.

It will not be possible to use only solid panels. They will have to be cut, so you need to take care of the necessary equipment in advance.

Types of garages made of sandwich panels

There are four types of garage spaces, which are made from sandwich panels. It is recommended to familiarize yourself with their features in advance in order to choose the most suitable type of construction.

Cassette

Over the past few years, garages made from cassette-type panels have become popular. Their main advantages include:

- low cost, which allows you to save money on building a garage;

- high density of the structure;

- ease of installation, thanks to which a person can build a garage on his own;

- reliability of the design.

Also, the walls of buildings made of cassette sheets are resistant to mechanical damage and adverse weather conditions such as hail, snow or rain.

Modular

People are building modular garages to quickly acquire a vehicle storage space. A distinctive feature of the modular construction of buildings is that during construction, modules manufactured in special factories are used. A person simply needs to connect them together to build a frame for a garage.

The disadvantages of modular garages include:

- Fragility. The service life of such buildings is several times less than that of brick buildings.

- Poor thermal insulation. Modular buildings require additional insulation.

Frame

Frame structures are popular because of their simplified design, which saves time and money on garage construction.

Builders prefer to make frame garages, as they have the following advantages:

- high strength;

- ease of construction;

- the opportunity to do everything yourself.

The main disadvantage of frame buildings is their flammability. To protect the structure from fires, you will have to treat it with antiseptic compounds.

Collapsible

A prefabricated garage is considered the simplest structure that can be built to store a car. The advantages of structures of this type include:

- Ease of construction. Even a person who has never been involved in construction before can build a prefabricated garage.

- Speed of building creation. It will take 2-3 days to completely build a prefab garage.

Barn project

Design is one of the important stages. All work will be carried out on the basis of this documentation. The project also takes into account the costs and construction time.

When designing, be sure to take into account the purpose of the building. It is necessary to comply with legislative norms and requirements for the maintenance of cattle, dairy, etc. Select the optimal options for flooring, placement of stands, feeders, cleaning, engineering and other systems

In general, as you understand, there is a lot of work and it is important to carry it out correctly. Our employees have designed many objects, accumulated vast experience and will competently draw up all project documentation

At the design stage, you can follow one of the following paths:

- Select a standard barn design. This option has already been implemented and worked out. Construction based on it will save time and money on its development.

- Develop an individual project from scratch. If for some reason the standard options are not suitable for you, an original design solution will be developed for you. The cost of the service is from 250 rubles/m2.

Drawings and diagrams

Before starting construction, drawings and diagrams of the garage structure are developed. To do this, you will have to familiarize yourself with the dimensions of one-story and two-story garages.

One-story

Most motorists build one-story buildings for long-term car storage. Moreover, the optimal size of such a structure is 7 x 4 meters, and the height is two and a half meters. However, it is not necessary to adhere to these parameters. When determining the most suitable dimensions for a garage, the dimensions of the vehicle are taken into account.

Two-story

Some people try to save space on their land and build two-story garage buildings in which vehicles are stored on the first floor and living rooms are located on the second. Experienced builders advise building a building no smaller than 8 x 8 meters in size with a height of about 7-8 meters.

For 1 car

When building a garage for one car, you can save building materials, since such a building is the most compact. When determining the size of the garage space, take into account the make of the car that will be parked inside and its dimensions. For example, the minimum garage size for a Ford Focus is:

- length - five meters;

- width - three meters;

- height - two and a half meters.

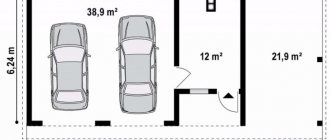

Project for 2 cars

Owners of two cars will have to build a large garage from SIP panels. Its width should be 7-9 meters, length - 5-6 meters, and height - 2-3 meters.

Direct construction

Even a small utility block can cause many difficulties during construction. The event therefore welcomes the following sequence of actions:

- Clearing the area for the structure;

- Carrying out measurements;

- Digging holes or trenches for the foundation;

- Filling the trenches with a drainage cushion of sand and crushed stone;

- Installation of formwork for a strip foundation or ready-made pillars for a block analogue;

- Installation of reinforcement under a cement strip foundation or backfilling of blocks with drainage;

- Filling the reinforcement with cement or laying roofing felt on top of the blocks;

- Organization of the lower trim from metal channels or wooden logs with a cross-section of at least 150x100 mm;

- Construction or assembly of walls from piece building materials or finished panels, respectively;

- Organization of the top trim from lightweight wooden logs with a cross-section of at least 100x100 mm;

- Installation of rafter sheathing;

- Laying roofing;

- Installation of doors and windows.

If you want to build a utility block with a toilet and shower, you will have to supplement the structure with a partition. Such a project welcomes the organization of a pipeline for water supply and sewerage at the foundation construction stage.

When organizing a utility room with a cellar, you will have to dig a large pit and fill its bottom with a drainage pad. The latter will serve as the basis for the construction of the basement foundation.

Stages and technology of DIY construction

In order to build a high-quality structure for storing cars, you will have to familiarize yourself with the main stages that make up the construction.

Required tools and materials

First, you should understand the basic materials and tools that will be useful when performing construction work. Some people use a grinder or an electric jigsaw when working with panels, but this should not be done. Such tools damage the surface of the protective coating.

To create a garage foundation, you will have to prepare in advance:

- roulette;

- sand;

- containers for preparing cement mortar;

- wire;

- shovels;

- fittings

When building the frame use:

- self-tapping screws;

- screwdriver;

- drill bits.

Pouring the foundation

The basis of any building is the foundation on which the frame will be installed. Before creating the base, the area is marked, during which intermediate stakes are installed and a marking rope is pulled.

After marking, a pit about 50 centimeters deep is dug. It is covered with a low layer of sand, after which the bottom is compacted with a vibrating plate. Formwork made of wooden beams and boards is installed on the compacted surface. Then the foundation is filled with concrete mixture.

Frame installation

After laying the foundation, the frame of the structure is created from vertical posts. There are two main methods for installing frame supports:

- partial recess into the ground;

- fastening to the foundation using anchors.

Many people prefer to make the frame frame using the first method. To do this, all the racks will have to be deepened by a third into the ground so that the metal garage made of panels is more reliable.

Wall installation

Before installing the panel sheets on the frame, mounting holes are made on the panels into which self-tapping screws will be inserted. When installing the walls, carefully ensure that they lie evenly. To do this, apply a level or bubble-type level to their surface.

The gaps between the panels are completely covered with silicone for additional sealing.

Roof covering

When re-roofing, it is recommended to adhere to certain rules that will help get the job done. Fastening horizontal sheets begins from the extreme corner of the frame. In this case, the panels are placed in such a way that their groove is located at the bottom. This helps rainwater drain from the garage roof.

Gates

Before installing the gate, you will have to make a metal frame on which they will be attached. To attach it to the garage wall, you can use reinforcing rods, which are welded to the frame and inserted into sandwich panels.

When the iron frame is installed, hinges are welded to it, on which the gate leaves are hung.

Choosing a foundation

If there is a slope on the site, it is recommended to install a pile-screw foundation for the foundation of a stationary utility block. Installation of such a base is carried out mechanically and takes one day. This technological option has additional advantages:

- Installation is carried out year-round ; The technology is used on all types of soil.

- The process is not accompanied by excavation work ; it does not include pouring concrete mixture and removing soil.

A feature of the technology is the need to install a floor and decorative cladding of the base (on an uneven landscape). Unlike a pile-screw foundation, a slab foundation is a solution with a finished floor. Pouring the slab at the base of the utility block is carried out on any soil and also has its own characteristics:

- Installation takes one to two days , but the concrete sets within three weeks.

Pile-screw foundation Source tovarim.ru

- The method includes excavation work . It will be necessary to arrange formwork and remove excess earth.

- The method depends on the weather and is not suitable for sloping areas.

Insulation works

To keep the garage room warm, you will have to insulate it. Foam plastic is used as the main insulating sheathing, which covers the walls from the inside.

First, the walls are sheathed with wooden blocks to which the insulation will be attached. Then the beams are sheathed with the first layer of foam. The second layer is laid on top of the first so that the seams of the sheets do not match. The foam is covered with plywood on top, puttied and painted.

Top trim device

Before you begin attaching the material, you must complete the process of constructing the frame. The final stage is the top trim. It is recommended to lay the boards or bars used for this purpose on the top of the vertical support. This will allow you to evenly distribute the load during snowfalls. Also, the supports will take the weight from the roof, and the SIP panels will not be subject to deformation.

Garage Doors

An important detail is the garage door. They provide safety and comfort of use. Gives a completed look to the building.

Popular types: — Roller shutters — Sliding — Swing — Sectional

All options have insulation in the form of foam filling. This gives additional heat and sound insulation properties. You can choose almost any color, in combination with the main one.

Can be equipped with automatic remote opening. Only in swing gates this will be more difficult to implement.

Why us?

Our company can guarantee that all work will be completed as professionally, efficiently and without violating the agreed deadlines. Our specialists have not only the required skills, but also extensive experience in the construction of such structures. We can implement even the most complex project without using the services of intermediaries, which is achieved by having:

- own production;

- a bureau whose employees can develop any project that meets your wishes and current requirements;

- our own fleet of vehicles to deliver all the required materials to the site where construction is planned;

- qualified team of builders and installers.

By contacting our company, you will receive attractive prices and the highest quality work. You will receive a garage that will meet all requirements, and the cooperation will leave only pleasant impressions.

More :

Choosing a size

The size of the garage is determined by the size of the area allocated for it. On a plot near a private house, you can afford a larger garage if there are any plans for it - for example, equipping a workshop, a paint booth, etc.

There is another factor that influences the size of the garage - the number of cars. The standard size traditionally used for the construction of such buildings is 6 m by 4 m; for 2 cars they usually build 6 m by 6 m.

NOTE!

Practice shows that, if possible, building a more spacious garage is always very useful - who knows what kind of car will be parked in it tomorrow, maybe a very large one?

Advice from the experts

- When installing panels, you can slightly improve the quality of the locking connection. To do this, a tape of insulation (you can use polyurethane foam) is placed in the groove of the mating part, preventing the joints from blowing through and condensation or freezing appearing on them.

- If a horizontal type of installation is used, it is recommended to lay a strip of foam plastic under the first panel. This will help retain heat in the room, seal the joint and prevent rain or melt water from entering through the cracks.

- Before cutting the panels, it is necessary to determine what type of insulation is inside. If there is mineral wool, you have to cut it in a respirator. If it is glass wool, glasses, gloves, and closed clothing are required.