Every developer wants to get a warm house that will be heated with minimal investment. The widespread use of modern technologies and the construction of lightweight houses have led to the fact that not every foundation is able to withstand the load that a massive brick oven will produce. They have been replaced by lightweight structures that can provide heat even to houses with an area of over 200 square meters. In this case, to remove combustion products, the construction of a heavy chimney is not required, but you can limit yourself to a light-weight system, the elements of which are reliably connected to each other. Let's figure out how to properly install a sandwich chimney with your own hands in order to produce a high-quality installation and avoid unnecessary installation costs.

Sandwich chimney with external installation Source torgpoliprom.ru

Design Features

The reliability of the design of lightweight systems is ensured through the use of several layers of modern building materials. The design is called “Chimney Sandwich” in honor of the English sandwich, in which several ingredients are combined in layers. It consists of two pipes made of high-quality steel alloy.

The diameter of the outer pipe is significantly larger than the diameter of the inner one. A layer of thermal insulation material is laid between them, usually non-flammable stone wool. The outer pipe provides protection against damage and mechanical stress. The inner tube can withstand high temperatures. A cushioning layer of mineral wool compensates for the difference in temperature conditions. The thickness of the thermal insulation layer depends on:

- differences in diameters of the inner and outer pipes;

- temperatures during operation;

- the diameter of the stove opening to which the chimney is connected.

Important! Stone wool is a non-flammable material. Therefore, in the event of deformation of the internal steel contour, it will be able to protect against combustion products from entering the chimney.

Sandwich chimney pipes Source i1.wp.com

The principle of assembling a chimney is identical to that of a constructor. You can invite a specialist, but after learning how to make a sandwich pipe for a chimney with your own hands, you can carry out a complex of work yourself. The system consists of parts that are equipped with fasteners for a strong connection with each other. The elements have two types of connections that allow installation using:

- corrugated end elements, which allow easy assembly, but require the use of expensive sealant;

- socket connection, complex due to the need for careful adjustment of parts, but more airtight if installed correctly.

A properly installed sandwich chimney will last 15 years or more. But you need to remember that to prevent soot outbreaks, the system must be cleaned regularly.

Assembling a sandwich chimney with your own hands Source klimatlab.com

Advantages and disadvantages

Technological progress has made it possible to move away from the use of heavy foundations when building a house and to build on prefabricated pile-screw and drill-fill foundations. And if previously heating a house could only be done using a heavy Russian stove or fireplace made of brick, now they have been replaced by modular structures made from a portal with a firebox weighing about 500 kg.

Sandwich chimney in a bathhouse Source spskamin.ru

When wondering how to assemble a chimney for such systems, you need to know the advantages and you need to know their advantages and disadvantages:

- When used, only the internal part of the system becomes very hot. Thanks to the compensation layer of mineral wool, the outer pipe has an acceptable temperature, which significantly reduces the risk of burns;

- after heating the chimney, the draft increases significantly;

- the steel surface of the chimney is not susceptible to soot settling as in systems made of brick or ceramics;

- due to the rapid removal, combustion products do not accumulate in the chimney, which does not lead to the accumulation of condensate on the walls;

- the design of the chimney provides maximum protection: on the outside it is protected by the outer diameter of the pipe from deformation under direct influence, the inner pipe does not allow heat and combustion products to pass through, and mineral wool is a protective layer from fire since it is not hot;

Installed sandwich chimney Source petropech.ru

Since the sandwich chimney system is relatively light in weight, its installation does not require the installation of a special foundation. It is advisable to strengthen the structure of the subfloor with additional lags, but if this is not possible, this may not be done. With proper care, the system will last a long time, but after about ten years, areas with partial depressurization may appear in the seam area.

How to protect a country house from fire when installing a stove

Fire regulations require protection of walls and floors made of combustible materials when using solid fuel heating equipment. Fire prevention measures include:

- Use of thermal insulation materials with a high degree of fire resistance to protect walls and ceilings at the installation site.

- Application of fire protection: impregnations and mastics.

Safe installation of the furnace and the use of fire prevention products are a mandatory requirement for the operation of furnace equipment.

How to cover the walls and ceiling when installing an iron stove

The part of the ceiling located above the stove and at the point where the chimney passes, as well as the adjacent walls, experience severe thermal stress. The following fire safety conditions and measures are considered mandatory:

- The ceiling is made of non-combustible materials. The use of wooden and plastic panels is not allowed. It is optimal to use gypsum fiber boards treated with gypsum putty for painting.

- The walls are protected with basalt cardboard followed by sheathing with steel sheets. For convenience, we use ready-made protective decorative wall screens made of stainless steel, which have a beautiful appearance and provide a high degree of safety. The walls are protected with plaster with a thickness of at least 3 cm, as well as brickwork.

Fire safety requirements for installing a metal stove in a wooden house are described in detail in SNiP 31-05-2003 and SP 118.13330.2012.

Fire retardant treatment of wooden structures

Where the stove is installed, wooden walls are protected using fire retardants: mastics and impregnations. Load-bearing structures and beams must be processed. Fire retardants are applied to the walls and floors where the furnace equipment is installed.

Mastics and impregnations have been developed for protection. The former provide better fire protection, the latter are almost colorless.

The order of installation regarding fire safety measures specified by the manufacturer is specified in the technical documentation. Fire protection work is carried out by representatives of the Ministry of Emergency Situations. You can take measures to prevent fire yourself, but before putting the stove into operation, you will need to obtain a certificate from the inspector of the Ministry of Emergency Situations about the fulfillment of all requirements of the safety regulations.

Detailed parameters for installing a solid fuel heating country stove are described in the technical documentation attached to the heaters of leading European and Russian factories. Compliance with the described rules is mandatory.

Small brick stoves without a foundation are great for country houses or temporary buildings, especially if the building is already ready, and there is no way to build a foundation for the stove in it. You can install a small stove on a regular floor, even a wooden one, as long as it is made of thick enough boards. Being equipped with a cast iron hob, it can be used not only for heating, but also for cooking. At the same time, this unit is more convenient to use than steel stoves, since it emits heat softly and can accumulate it in sufficient quantities (you have to add firewood less often).

It is not always possible to allocate space for a stove foundation, but there are stove options where a foundation is not required.

Many owners of already built country houses do not dare to build such a unit due to reluctance or lack of opportunity to build a foundation for the stove. In such a situation, you can build a miniature brick oven without a foundation.

Calculation of sandwich chimney pipe sizes

Diameter

To determine the optimal pipe diameter size for a sandwich chimney, you need to know the conditions under which the operation will take place. The heating power of the furnace depends on how large the area is, as well as what the planned temperature range is.

As a rule, in order to heat 10 square meters they take 1 kW. Accordingly, in order to heat an area of 100 square meters, you need to purchase a 10 kW stove. Having decided on the power, you can choose a model for individual parameters.

Chimney facing the street Source santehnika-otoplenie.ru

If a system is needed to remove combustion products from a heating boiler, then you need to know the type of fuel and the power of the boiler itself. The higher the temperature of the gases passing through the chimney, the stronger its heating will be. The lowest temperature is for gas boilers, which heat up from 120C to 200C, and the highest for coal boilers, where the temperature of combustion products reaches 700C.

The choice of sandwich should begin with the diameter of the inner pipe. The more powerful the stove is planned to be installed, the wider the diameter should be. For example, if a 3.5 kW oven is installed in a room of 4 square meters, then the width of the outlet from it will be 158 mm. And for an area of 90 square meters with a 9 kW oven, a hole of 220 mm is suitable.

Despite the fact that open fireboxes are not currently recommended for installation, they also have their own standards. The outlet channel in this case should be no more than one hundredth of the total volume of the boiler. If this rule is not observed, the draft in the system will be weak with potential turbulence of air masses with combustion products.

Sandwich chimney inside the house Source pechivrn.ru

Height

To ensure safe removal of smoke away from people, it is necessary to maintain height standards. The total length of the structure should not be less than 5 meters. If the condition is not met, reverse draft may occur, as a result of which the residential area will be subject to smoke. In addition to the overall length, you must also follow the rules for venting the chimney through the roof.

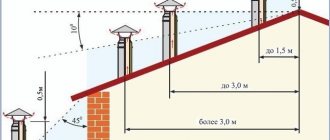

If the roof is pitched, then the upper edge of the chimney should be at least 0.5 meters above the ridge if the middle of the pipe is at a distance of 1.5 meters or less from it. At a distance from the chimney of 1.5 to 3 meters, the chimney should end at the same level as the ridge in a horizontal plane. When removed by more than 3 meters, the top edge should be 10 degrees below the ridge.

Rules for installing a sandwich chimney on the roof Source stroy-good.ru

If the sandwich system is installed on a flat roof, then the height of the upper edge should be located at a distance of 0.5 to 1.5 m. Since the total size of the chimney should not be less than 5 meters, if the dimensions are insufficient, you can increase the length of the outlet through the roof to 30 cm, making sure to use special reinforcement braces.

Life time

The service life of chimneys depends on the designs and materials from which they are made.

A ceramic chimney will last up to 40 years. Manufacturers declare 50 years or more, but no one has checked it yet. A brick one can last longer, but stainless steel liners will have to be replaced after 15-20 years.

The service life of the liner primarily depends on the thickness and grade of steel. The thickness of the liner steel should not be less than 0.8-1.0 mm. Galvanization will not last long.

A good quality sandwich will last for 15-20 years or even more. The service life depends on the material and thickness of the inner liner - a good stainless steel inner liner with a thickness of 1 mm will last 20 years. Enameled liner made of carbon (“black”) steel – 15 years.

The service life of the liner depends on the type of heating unit (more precisely, on the type of fuel and the heating temperature of the exhaust gases).

The shortest service life is for chimneys for fireplaces and coal boilers, which release very hot gases during intense combustion. The service life of chimneys from boilers and fireplaces using peat, briquettes and wood is slightly longer. Chimneys for pellet and gas boilers will last the longest.

How to choose

Since different boilers produce different combustion temperatures, in each case the composition of the steel from which the inner and outer pipes are made can play a role. After burning, sulfur, sulfuric and hydrochloric acid may remain on the walls of the chimney. Temperatures also differ depending on the type of fuel used.

Sandwich chimney details Source www.stroimdom.com.ua

When learning how to properly assemble a chimney from sandwich pipes for a home or bathhouse, you need to know that different grades of steel react differently to aggressive influences. The most common:

- AISI 304. High temperature resistant steel alloy. It has a high content of nickel and chromium. It is used at elevated temperatures up to 1000C, since at low temperatures around 600C it becomes brittle;

- AISI 316. High alloy molybdenum stabilized alloy that is acid resistant. Characterized by the absence of corrosion;

- AISI 321. High alloy steel alloy stabilized with titanium. Suitable for use in the average temperature range, up to 800C. Corrodes when interacting with sulfur;

- AISI 430 . It is used at low temperatures, as it has a low level of resistance to aggressive influences. May be corroded. It is used in the use of inexpensive budget models.

Sandwich chimney components Source www.rus-dimohod.ru

Since it is most often impossible to determine the type and grade of steel with the naked eye, a magnet can be used to determine the type. When learning how to properly assemble a chimney from sandwich pipes for a stove or boiler, it is necessary to take into account the characteristics of steel. If the steel is of high quality, then it will not be attracted, but if the alloy is of low quality, then attraction will arise.

Type of chimney placement

If you are interested in how to assemble a chimney from sandwich pipes, you need to carefully analyze the place where you plan to install it. Depending on the area of the room, the location of the furniture, the level of humidity and other factors, it is necessary to choose the type of placement of the sandwich chimney. Installation is possible indoors or outdoors.

Outdoor installation

A chimney that is assembled from the street side significantly saves space inside the house or bathhouse. Having studied how to install a chimney in a bathhouse from sandwich pipes, you can assemble such a structure with your own hands. There is no need to make a decorative box for it, which significantly saves money.

Main types of chimney assembly Source otopleniehouse.ru

The system consists of assembled elements of the required length, which are connected to a structure located indoors with a special through pipe. To ensure good traction, it is necessary to follow the rules when the length of the passage section should not be more than 100 cm.

During installation, a technological slope of 3 degrees must be observed so that condensate does not accumulate in the boiler or furnace. In this placement, the roof must be more than 50 cm from the edge of the steel outer pipe. The best answer to the question of how to properly install a sandwich pipe in a bathhouse, outside or inside, would be installation from the street side.

Important! If continuous use is not planned in winter, it is advisable to insulate the chimney to avoid freezing and deformation from temperature changes.

External installation of a sandwich chimney Source fluesystems.ru

See also: Catalog of companies that specialize in the installation of stoves, fireplaces, grills and barbecues.

Indoor installation

The chimney, which is installed in the room, consists of an internal part of the system, located perpendicular to the floor, and an external part, discharged through the roof. The structural parts must be joined together in open areas so that inspection can be carried out. A joint located in the interfloor ceiling does not provide such an opportunity and is considered a potential fire hazard, since if the seal is broken, the wooden floors, floor materials of the second floor and ceiling of the first will overheat.

The placement in a completely vertical position gives a good level of draft, and in addition, such a chimney is easy to maintain. If during installation it turns out that when installed vertically, the chimney rests on the ceiling or rafter, then in order not to interfere with the structural part of the house, it is better to bend the pipe using special connecting elbows.

Where is the best place to put a stove in a wooden house?

The installation location of the stove in a wooden house is determined as follows:

Principle of operation :- Air-heating furnaces, operating like the Russian “Burzhuika” or the Canadian “Buleryan”, are installed in a place where convection currents move unhindered. If it is planned to heat adjacent rooms, the structure is built into the interior partition, or air ducts are connected.

- A stove with a built-in water heat exchanger is installed so that the circuit in the stove is the lowest point of the heating system. The location is not critical and is determined only by fire safety requirements.

- Connecting a chimney - installation of a heating stove and chimney in a wooden house are closely interconnected. The stove is located where it will be easier to connect the chimney in compliance with fire safety requirements.

- Ease of maintenance - to fire and clean the stove, you will need a sufficient distance towards the opening of the combustion chamber door. Furnace equipment with panoramic glass provides the opportunity to admire a live flame; this feature is also taken into account when choosing a location

- Fire breaks - from the heating surfaces of the stove body to the walls made of combustible materials, leave a distance of 110-125 cm. In the direction of the opening fire door, at least 125 cm.

A rational installation is important, taking into account the optimal location of the furnace, ensuring better heat transfer, safety and ease of use.

Sandwich pipe connection options

If you are interested in the question of how to assemble a sandwich chimney, another question will probably arise: how to join the system pipes together. There are two possible options, and each of them has its own name:

- “By smoke”, when the lower pipe goes inside the upper one. In this case, combustion products have no way out and are freely discharged upward;

- “Ppo condensate”, when the inner upper pipe is inserted into the lower one. External pipes are assembled with the top side facing out.

It is believed that in the second case the risk of moisture getting into the insulation is reduced, but if the tightness is broken, then some of the combustion products may enter the room.

Connection for smoke and condensate Source www.rusovent.rf

Sandwich system kit details

Once the location of the chimney has been chosen, whether outdoors or indoors, you need to understand what parts will be needed to understand how to properly assemble the chimney. To compile a list of the necessary parts, you can independently contact a specialized store or request a commercial offer via the Internet. But it’s better if you have an independent understanding of the process and what parts will be useful during assembly.

Manufacturers produce chimneys with all the necessary components so that a full assembly cycle can be carried out. If there are differences between manufacturers' models, they relate to decorative or connecting functions. The list of elements is usually the same. Therefore, having decided on the names, you can choose a manufacturer based on the criteria of reliability or availability.

Sandwich chimney parts Source pech-kamin.ru

Where to put a metal stove?

Ideally, you should choose a location for a steel stove after windows have been installed and doorways have been erected. Then it becomes clear how the air flows inside the room will be directed. To achieve the most efficient operation of the furnace, it should be placed where there is not too much air movement.

- Narrow rooms are not a suitable place to install a stove. According to fire safety rules, there must be at least 130 cm to the wall opposite the firebox.

- In addition, the stove itself should be 110-125 cm from the walls, and when using insulation made from non-combustible materials - 40 cm.

- It is also not possible to install a stove in a room that is too small: heating equipment that runs on wood is allowed to be installed in rooms with an area of at least 16 m2.

If the device is equipped with a hob, then you can safely install it in the kitchen. For example, among the Teplodar stoves, the Matrix, Vertical, Meteor and other models have this design. These stoves can operate for up to 8 hours on one load of wood thanks to an effective two-channel afterburner system.

Owners of two-story buildings should take into account that to heat the second floor they will need another metal stove.

Required Tools

After carrying out all the necessary calculations and deciding how to make a chimney pipe yourself, you need to prepare all the required elements. In addition to the list of parts of the sandwich system itself, you need to have on hand a list of the following items:

- clamps for tightening;

- support brackets;

- necessary hardware fasteners;

- heat-resistant sealant;

- grinder, metal scissors;

- spatula for sealant;

- roulette;

- square;

- screwdriver;

- drill and hammer;

- building level.

You also need a marker or construction pencil for marking. When assembling, the joints of the parts must be secured with clamps. The entire resulting structure is fixed vertically along the wall using brackets in increments of 1.5 to 2 meters.

Chimney assembly

If you decide to implement the question of how to make a sandwich chimney correctly with your own hands, you need to once again make sure of the quality of the system and check the availability of the passport before starting the installation. This document must be handed over upon purchase and it indicates a possible assembly diagram, as well as some technical parameters of the composition of the chimney.

When the heating device is already installed, you need to insulate the wall with calcium silicate or mineralite. This must be done immediately, since after installing the chimney there will be no access to the wall. Also, you immediately need to mark and drill holes for the bracket for connecting the mono-pipe and pipe.

Elements of a sandwich chimney assembly Source pandia.ru

When starting assembly work, you need to coat the parts of the outlet of the heating device with sealant. After this, a tee is connected to the boiler or furnace pipe, which contains a plug and a device for collecting condensate.

On the opposite side, a mono pipe is connected to the tee. After the tee is firmly seated on the pipe, it is pushed in all the way and tightened tightly with a clamp. After screeding, you need to apply a building level and if everything is normal, then you can secure the first element with a support bracket to the wall.

Next, the pipes are connected to each other in the chosen way: “through smoke” or “through condensate.” All joints between parts are fixed with heat-resistant sealant. To apply it you need to use a spatula. After application, the composition is distributed in an even layer over the entire surface of the edge of the element.

Support bracket Source topijar.ru

The sequence and list of necessary parts depends on how the chimney will be located. When the installation is carried out indoors and in a vertical position, it is advisable to install a tank for heating water or a specialized mesh heater.

If you place the sandwich elements at once, then exposure to high temperatures may cause the thermal insulating mineral wool layer to sinter, which will cease to perform its functions. The steel can subsequently burn out quickly.

If the question arises of how to assemble a chimney from sandwich pipes into a bathhouse and the system must be taken outside, then first a pipe is installed, and after it a section is immediately placed in a horizontal plane. The passage section must not be installed in a completely horizontal position or with a slope towards the premises, as accumulating condensate can get inside the heating device, which can lead to its deformation.

Chimney indoors Source dizajninterer.ru

Do I need to make a foundation for the stove?

Installing a stove in a wooden house may require the presence of a foundation. However, a permanent foundation is required for a metal stove only if its weight exceeds 750 kg. Typically, steel stoves weigh much less (up to 300-400 kg). But if the equipment is covered with brick, then the weight of the entire structure will be very impressive.

When the stove weighs up to 80 kg, a foundation is not needed; the device must be installed on a solid, non-combustible base.

Another way to determine whether a foundation is needed is to consult a professional stove builder. This must be done at the stage of designing a wooden house, since the foundation for the stove is built during the creation of the foundation for the house. If the building has already been built, then the flooring at the installation site will have to be dismantled. After this, you will need to remove the soil and make a foundation for the stove.

Roof passage

When learning how to properly assemble a chimney from sandwich pipes for a bathhouse or home, special attention should be paid to the place where the sandwich chimney passes through the roof. It is extremely undesirable to crash into the rafter structure as this can negatively affect the roof structure as a whole. The holes should be:

- with a pitched roof of oval or round shape;

- on flat roofs or sheathing with frequent square or rectangular pitches.

The opening is cut with a jigsaw after applying the appropriate markings. The distance from the wooden roof elements should be 13 cm or more. If the chimney gets into the rafter, then you need to use your knees to take it to the right place.

Passage through the roof Source stroy-podskazka.ru

After the chimney is brought outside, there will be a gap between the roofing material and the sandwich pipe, which must be securely and hermetically closed. For this, the best option would be to use a master flush. Its design includes a flanged base reinforced with aluminum for a complete seal and a silicone cone-shaped cuff located at the top.

After installation, the master flush will reliably protect the roof and under-roof space from precipitation and dust. For maximum tightness, before installation, you need to trim the top part so that it is 20% smaller than the chimney pipe.

After this, the master flash is put on the pipe, lowered down to the roof and fixed with silicone glue. Then the upper edge is tightened with a clamp, and the lower edge is treated with sealant. To complete the installation, a head is placed on the upper edge of the pipe and secured with self-tapping screws.

Do it yourself or order it?

You can only make a brick chimney yourself or a structure from an insulated single-layer steel pipe.

But laying smooth and beautiful walls of a brick pipe is more difficult than laying just a brick wall, and you must have the skills of an experienced mason. Single-layer pipes will have to be insulated; the quality of self-insulation is much worse than that of ready-made factory-made pipes.

You can independently install a chimney made of ceramics and sandwich pipes. It is impossible to manufacture elements of such chimneys on your own, but the industry produces many modules that allow you to assemble a pipeline of any design.

The question of whether to install a pipe yourself or hire a team of professionals is quite complicated.

Installing a chimney is quite a complex job, and it is worth thinking about and carefully assessing your capabilities: is it possible to take prefabricated scaffolding or scaffolding of the appropriate height, will you have assistants, do you have the skills to install building structures, how do you react to height.