If a person has to think about building his own house, then first of all he needs to decide on the choice of material for walls and ceilings, construction technology, and also select a suitable layout. If an architect can cope with any layout, then the choice of construction technology depends on your preferences and financial capabilities. If you prefer buildings made of stone, then you should pay attention to houses made of concrete panels. The main thing is not to succumb to established stereotypes, because if, in fact, the same technologies are used here as in the construction of multi-story buildings, then the qualitative methods for constructing houses have improved significantly.

Modern house made of reinforced concrete panels Source strcomfort.com

What is a modern reinforced concrete panel for the construction of a private house

Even judging by the name alone, a reinforced concrete panel is a concrete slab, inside of which there is steel reinforcement, which improves the concrete's resistance to mechanical stress and increases strength under lateral loads.

All panels are divided into three types :

- External.

- Internal interior slabs.

- Floors.

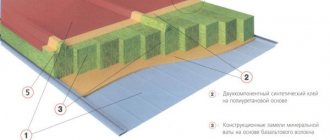

External walls can be one, two or three layers. In the latter version, the inner layer is insulation, and the outer surface of the slab is made of high-strength concrete.

Wall panels, in turn, are divided into the following types :

- Bearers.

- Self-supporting.

- Hanging slabs.

From the name it is clear that the initial ones are the basis of the building. The following panels are independent elements and they are fixed to the load-bearing walls and floors of the house.

A reinforced concrete house is assembled from slabs for various purposes, which optimizes the overall cost Source mypresentation.ru

DIY frame construction

To build a concrete foundation for a building, you need:

- carefully inspect the area for the presence of unnecessary materials that interfere with construction;

- mark where the structure will be;

- carry out excavation work;

- create reliable formwork;

- clearly arrange the reinforcing bars;

- pour the concrete mixture.

Before construction begins, the soil is examined, then the dimensions of the structure are indicated with signs and the thread is pulled. Then they dig trenches. You will need a shovel, hammer, and sledgehammer. The dimensions of the trench are 60 by 70 cm. This is influenced by the quality of the soil where the structure is being built.

When work with the trench is completed, it is compacted and laid with layers of crushed stone and sand. Then they begin to assemble the formwork. For this you need wooden blocks, a hammer, nails, a file, and a drill. Having folded the formwork, the reinforcement is prepared. You will need a grinder and welding. The reinforcement is laid in grids measuring 20-40 cm.

After installing the reinforcement frame, the preparation of the concrete mixture begins. Concrete is selected according to the size of the building being built. To create a concrete solution, cement, sand, water, and crushed stone are used. The grade of cement used is higher than the grade of the mixture. To prepare the mixture, use a concrete mixer. The finished concrete mixture must be poured gradually and evenly. There is no need to fill in parts, as joints will form and the structure will become fragile.

Return to contents

Advantages and disadvantages of modern panel house projects

There is no perfect way to build a home that suits everyone. Therefore, before making the final choice, you need to evaluate the advantages and disadvantages of the technology.

Advantages

As a result of regular improvement, the use of new materials and technologies, a house made of panels can be built relatively cheaply, quickly and with high quality.

For buyers of a house or cottage, 3 aspects have priority: the layout of the premises, the price per square meter and the construction period:

- Variety of design solutions . Reinforced concrete panels manufactured according to the project allow you to create buildings of various shapes, sizes and with different layouts.

Thus, panel cottages today are presented not only as economical housing, but also as houses with spacious rooms reserved for a living room, children's room, kitchen and bathroom.

Reinforced concrete houses allow you to implement almost any architectural design and can be used in both classical and modern styles Source m.shianwang.com

- Price . Prices for turnkey projects of houses made of reinforced concrete panels are significantly lower than the cost of a brick or monolithic building. Thus, the price per square meter in a panel house in the Moscow region will be from 44 to 70 thousand rubles, and in a monolithic one at the same time - from 70 to 90 thousand rubles.

- Construction speed . A house made of panels, compared to a brick one, is built several times faster. Thus, the box of a two-story house made of reinforced concrete panels, with an area of 170 sq. m., is erected in four to five days (without foundation and finishing).

This is achieved due to the fact that all panels are brought to the construction site in finished form: the external structures have openings for windows and doors, and the internal partitions have ready-made hidden channels for electrical wiring. We must not forget about the conditions for assembling a house - a monolithic one is created at the construction site, and a panel one is created at the factory.

Flaws

The disadvantages include the following parameters of the slabs:

- Soundproofing . If the house is built of one or two-layer panels, then extraneous noise from the street may be heard in such a building.

If you save on three-layer panels, then in the future you may have to spend money on sound insulation Source magnat4.ru

- Reinforced concrete surface . To attach or hang any objects on the wall, you have to use a hammer drill every time.

- Inability to change layout . The walls are not removable, so they cannot be moved.

Features of the combination of materials in the construction of combined houses

Modern combined houses are made of various modifications of stone or concrete on the first floor, and wood on the second.

Traditionally, the ground floor is made of natural or artificial stone, foam or gas blocks, monolithic reinforced concrete structure, brick and even frame-panel construction. The latter option belongs to the economy class category, and has reduced strength, making the construction of buildings higher than 3 floors unacceptable. The first floor of combined houses of the middle price category is used to accommodate utility rooms: kitchen, boiler room, garage. If the owners are planning a fireplace design, it is also recommended to place it on the ground floor.

Technical structure of the basement floor of a combined house Source eurobeton61.ru

Living rooms are traditionally located on the second and third floors, made of natural wood. Popular materials for fireproofing and anticorrosion treatment of wood retain the pleasant appearance and functionality of the material. Therefore, finishing work is most often limited to covering the walls with transparent varnish, as well as installing additional decorative elements.

See also: Catalog of combined house projects presented at the Low-Rise Country exhibition.

Common combinations of materials for such houses

A combination of a reinforced concrete structure, trimmed with stone, at the base of the house, in which the ground floor is arranged, and a superstructure made of rounded logs. This combination not only looks respectable, but also ensures durability and environmental friendliness of the entire building. Houses made of timber and stone are the most durable and expensive construction option.

A house made of timber and stone is a reliable building for a harsh winter Source vsemixfight.ru

A more aesthetic and expensive option is a combination of smooth timber and a brick plinth, located on a strip or slab foundation. The large weight of the final structure requires serious investment in the construction of a slab or strip foundation structure. Such houses are suitable for construction on heaving soils, and if a slab foundation is created, the housing will withstand construction near bodies of water.

A budget option for building a combined house is a combination of foam blocks and natural wood. Such materials require careful finishing of the first floor, taking into account the additional waterproofing required for the use of blocks.

Projects of such combined houses are most in demand on the modern market due to their affordable price and durability.

Design differences between panels

Building slabs are large-sized elements and are made from reinforced concrete in a factory.

The production of slabs occurs with the maximum degree of readiness, that is, with door and window openings. They also often arrive at the construction site with the exterior finishing completed and the interior surface prepared for wallpaper and painting.

In terms of construction, all panel houses are divided into three types :

- Panel-frame . The base and panels are single structures; in the second case, the load is shifted to the frame, and in the third, all the weight from the slabs is transferred to the panels.

- Frame . They are used in houses with complex and non-traditional structures.

- Frameless buildings . They come with load-bearing longitudinal and transverse walls.

The load-bearing external wall of a panel house is being installed Source reformtheweb.com

Advantages of frameless reinforced concrete houses :

- No oversized protruding elements inside the house.

- Easy to install.

- Savings when building a box.

Depending on the purpose and type of panel, the weight of the walls can be completely distributed over the frame of the house (hinged), accommodate only their own weight (self-supporting) and withstand the weight of the floors (load-bearing). Based on their composition, the panels can be divided into one, two and three-layer.

See also: Popular designs of houses made of reinforced concrete panels

Monolithic housing construction

Initially, monolithic construction meant only the construction of structures made of reinforced concrete, since there was simply no alternative to a reinforcing frame and cement-based mortar with aggregates. When pouring, prefabricated formwork is used. Not so long ago, monolithic construction was widespread only in industrial quantities, for the construction of multi-storey buildings, public buildings or industrial facilities. But gradually the technology began to spread into the private sphere, which is due to a number of advantages of monolithic houses.

Immelnikoff

In my opinion, the trick of monolithic reinforced concrete is as follows:

- thin load-bearing walls (120-140 mm);

- high strength of the entire building, hence safety;

- seismic resistance;

- fire safety (all electrical wiring is laid inside the formwork before pouring);

- good “air” sound insulation (shock insulation is poor);

- high heat capacity of the house;

- durability (100-150 years);

- stable geometric dimensions of the house - optimization of interior decoration;

- versatility - any interior decoration without restrictions;

- psychological comfort from the knowledge that nothing in the house will collapse, that the insulation will not get wet, that no person will break through the walls, that the house is a real centuries-old fortress.

This is my list.

Of course, the monolith has its share of shortcomings.

jtdesign

This technology requires qualified builders and the presence of concrete plants in the area, so as not to transport concrete further than 50 km. It is also unreasonable to build without a detailed design (reinforcement diagram, formwork diagram). So this may be one of the obstacles to the widespread adoption of this type of private home.

But any material has disadvantages; it’s another matter that their number does not outweigh. A concrete mixer plus modifying additives - and you can fill it with self-mixed concrete. Ideally, any construction process requires qualified performers, but in reality, our craftsmen have repeatedly proven that self-builders will give many “pros” a head start, since they build for themselves. If you have the desire, you can learn anything.

ffdgdvasc45fg4

I am interested in monolithic construction on my own (without reference to deadlines) of a two-story house for permanent residence measuring 10x10 m. I am considering different types of monolith, but my priority is reinforced concrete. I will build it alone, slowly, step by step, in general, long-term construction, I have no experience in construction, but the most important thing is that I have the desire, and this is very motivating.

Build it yourself or order a turnkey service

Today, many people dream of owning their own home - this means freedom, complete isolation from noisy neighbors behind the wall, and live communication with nature in their garden.

To fulfill your desire, there are two options: build a house yourself (even with the help of hired workers) or order the work from a professional construction company. At the same time, the price of the issue at first glance seems completely different, but where you will find it and where you will lose it needs to be examined in more detail.

Building a new house yourself

It is simply impossible to build a house from reinforced concrete panels on your own, so we will simply compare the stages with the construction of an ordinary cottage.

Initially, you will have to order a house project. This is not just a layout drawing, but technical drawings that indicate the location of the house on the site, calculate the forces of the floors and other data according to which the house can be built.

You must understand that the layout and appearance are only an architectural project and it is still impossible to build a house based on these data Source pinterest.com

Next, you will have to organize the purchase and delivery of building materials. In addition, you will have to choose these materials yourself, which can be quite a difficult task for a person without construction experience.

Even now, the construction of the house has not yet begun, since many issues will need to be “sorted out,” in particular, to obtain a building permit (here, by the way, you will also need an approved project)

When the paperwork is resolved, construction can begin. Here everything depends on whether you will build completely yourself or attract additional labor. There are pitfalls here and there. If you look for workers, then the first question is their qualifications, which, let's face it, is a matter of chance. In addition, the workers will have to be constantly monitored, and since you have other things to do besides construction, it’s simply not possible to keep track of everything.

In any case - during independent construction or when involving workers, if after some time any defects appear, then you will have to correct them yourself, since the “gray” construction team will not give you any warranty obligations. And even if he does, in a year or two where will we look for these workers?

Not all builders’ shortcomings can be noticed immediately Source anayemeni.net

As a result, it is almost guaranteed that the cost of a house when erected on your own will be significantly higher even during construction, compared to the initial calculations. And this does not take into account the costs of correcting possible defects that will appear after some time (if they can be corrected at all without dismantling the house).

Turnkey construction

Even if you just go through the points listed, the difference will already be quite noticeable:

When you order, a serious construction company will make you a house design for free. In addition, this project will be read by builders without any problems, because despite standardization, even a specialist will have to understand an unfamiliar project. Plus, designing a private panel house is relatively simpler, and therefore faster.

The construction company takes care of all the accompanying documents and permits, which saves you time.

The selection of workers is also the concern of the construction company and they treat this issue responsibly, because the built house is guaranteed.

When ordering turnkey construction, you only need to approve the project you like Source stroika.proraion.ru

Another advantage of the contract is that it states a fixed estimate, which means that everything after signing the document will only have to be paid for the pre-agreed amount.

In addition, the construction of a turnkey cottage from concrete panels will not take long - in fact, a construction crane will arrive and with its help the designer will assemble it. It is clear that the designer’s parts will be assembled at the factory for some time, but all deadlines are in any case specified in the contract and the house will be ready on the agreed date.

See also: Catalog of companies that specialize in the construction of turnkey country houses from reinforced concrete panels.

Reviews about the technology

Many residents who have built a monolithic frame house give only positive reviews, that the apartments are distinguished by a more competent layout, or the ability to do it yourself, the high-quality condition of the walls, delivered “turnkey,” uniform shrinkage of the premises and heat retention in the winter season.

Construction organizations do not recommend using lightweight concrete in buildings with more than three floors and not saving on concrete as the main component in construction of any level of complexity.

Design of a house and utilities

The design of a cottage made of reinforced concrete slabs is developed down to the smallest detail, and the dimensions are agreed upon with the manufacturer. This is of particular importance, since the slabs will no longer be processed.

It will be almost impossible to change the layout of a reinforced concrete house in the future Source firstcostconceptz.com

When developing a project, it is imperative that special attention be paid to the following points :

- The location and number of door and window openings, their configuration and dimensions.

- The presence of technological channels for wiring, ventilation, etc.

- Number of rooms and their parameters.

- Compliance of components.

To develop a project for the construction of a private house or cottage, you can use one of two options:

- Use standard projects that are always available from any construction company.

- Order an individual project, but in this case you will have to wait until the panels are made for it at the factory.

Purpose of concrete columns

The element takes on and transfers to the foundation the load from higher structural parts. Reinforced concrete pillars become the support of the floors, connecting the structure between the base and the ceiling surface. The pillar supports a variety of terraces, balconies, porches, ceilings, making it possible to implement any design idea and significantly increasing the service life of the entire building.

If we are talking about decorative design, then in this case concreting columns acts as a means of decorating the facade and interior. They are often made with column sills, consoles, capitals, decorated with stucco molding, original patterns, and various types of material processing.

Video description

For an analysis of one of the typical designs of reinforced concrete houses, watch the video:

Foundation

Most often, a strip or monolithic concrete base is used for a panel house. Sometimes a pile foundation can be used, but since piles are expensive for heavy houses, such decisions are made in very rare cases.

Otherwise, the stages of work are standard: marking, digging a trench below the freezing depth of the soil, then formwork is done, reinforcement is performed and concrete is poured at least grade M 400.

Panels and ceilings

The next stage in the construction of a building is the installation of walls and ceilings. The construction of a house from reinforced concrete panels is carried out by a professional construction team using a crane. Wall slabs are fastened together by welding to a reinforcing frame.

Comparison of frames

The work of creating a monolithic concrete structure is voluminous and depends on the weather. At construction enterprises, such frames, of course, are created faster and are of higher quality. However, the cost of this product is many times higher. You will also need to deliver it to the construction site and find the necessary equipment.

Prefabricated frames are less material-intensive than monolithic ones. A monolithic frame requires less material and reinforcement. These frames are installed immediately at the construction site, thereby reducing energy costs, eliminating column joints, reducing the cost of technological equipment, and familiarization with new construction technologies.

A prefabricated frame requires more materials for fabrication such as steel, inventory decks, support devices. But the frames do not need to be delivered, but can be assembled immediately on site, rather than in production. Less energy is spent on construction and no welding is required. Today these frames have become available.

Return to contents

Prices for houses made of reinforced concrete panels in the Moscow region

The market offers suburban housing made from reinforced concrete panels of all types and in a variety of price segments. Premium monolithic :

- Project up to 200 m²: 4.2-4.6 million rubles.

- Project up to 300 m² with a garage for 3 cars: 7.2-7.5 million rubles.

- Project up to 400 m², 2-storey, with a garage for 2 cars: 9.3-10.5 million rubles.

When calculating per 1 sq. m . The cost of business class cottages is as follows:

- A two-story house with a flat roof for a recreation area: 44.7-45.8 thousand rubles.

- Two-story house with a second attic floor: 43.4-44.2 thousand rubles.

- House with an attic, one-story: 39.2-40.2 thousand rubles.

In the economy segment, a house made of reinforced concrete slabs costs 1 sq. m. costs :

- With interior decoration: 24-31 thousand rubles.

- Without interior decoration: 13-21 thousand rubles.

Conclusion

Everyone’s preferences and capabilities are different, and everyone proceeds from their own goals, however, the technology of monolithic house construction is quite viable in the private sphere, which has been repeatedly proven by the example of the participants of our portal.

An example of independent construction of a reinforced concrete house that does not require additional insulation is in the material about monolithic foam concrete. Another article is about monolithic expanded clay concrete. More information about simultaneous pouring and insulation can be found in the article on permanent formwork. The video is about a monolithic house for two.

Subscribe to our Telegram channel Exclusive posts every week