Modern materials and construction technologies are literally transforming the concept of “own home.” Until relatively recently, such methods for creating beautiful and comfortable homes simply did not exist, but today people not only have ample opportunities to create housing from scratch, but can also modify existing buildings by adding an attic made of composite panels, increasing the comfort of life. The most advanced technology is a house made of SIP or, as they are also called, sandwich panels. Structurally, these are particle boards that, under pressure and exposure to high temperatures, are glued on both sides to a layer of expanded polystyrene. The resulting material is not only light and durable, but also opens up the widest possibilities for the construction of non-standard building structures.

Advantages of sandwich panel structures

If you are considering a house and an attic made of sandwich panels, the choice of this particular material is determined by its very attractive characteristics:

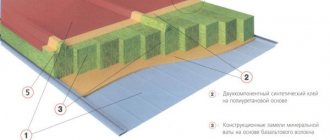

- high thermal insulation rates, which improves living in spring and autumn and reduces heating requirements in winter;

- the strength of the attic walls is such that in most cases a separate load-bearing frame is not required;

- construction can be carried out on any type of existing structure, since SIP panels are lightweight;

- there are no special requirements for the roof; in addition, by using sandwich panels for the roof, you can significantly reduce heat loss in the attic.

When building an extension on an existing structure, it is advisable to follow several options that will allow you to both save effort when creating an attic and receive cost savings and other useful benefits.

Typical projects

The most common option that duplexes have on the market are two-family houses, when the apartments are located next to each other and have a common wall. Such a one-story building is covered with a gable roof, the design of the building is simple, it is possible to accurately divide the space (including the area of the land) between the living families.

Duplexes can be very different. Projects with attics for the area of each of the living families, two-story options, small boarding houses where the number of apartments can be quite large, a dozen or more, are common.

Preparation for construction

Often, an attic made of composite panels is built on a building that has a standard pitched or gable roof. This design does not provide enough space for future rooms, so the most advisable step would be to disassemble it. The resulting structures (beams and intermediate floors) can be used to erect a roof on a new attic.

Important to know: What types of cottages are made from SIP panels?

Depending on the wishes of the owner, the ceiling of the lower floor can also be dismantled. Sometimes it is advisable to do this, since an attic made of panels makes it possible, without large financial investments, to get a new, high-quality ceiling, which will be the floor of the extension.

Connection options

There are several options for joining sandwich panels to each other:

Locked open connection type. This is the most common option because it is lightweight and effective. It consists in the fact that, from one end of the first slab, the outer layer of sheathing is inserted into a groove provided in the filler of the second slab. Tightness and waterproofing are not affected here, because the sheathing of the first slab fits tightly into the space between the insulation and the metal covering of the second slab. The groove size is made taking into account the expansion of metal under the influence of high temperatures.

Locked closed type. Its distinctive feature is its stepped design. There is more free space here compared to the first option, which facilitates the removal of moist air and reduces heat loss.

Thermal lock. This option has the most complex configuration of all presented. This is a variation of the classic method, but with additional features. So, on one side of the panel there is a longitudinal protrusion, and on the other there is a groove. The connection is carried out according to the “groove-tenon” principle, which ensures maximum strength: the elements are securely fastened and do not separate even under heavy loads. This method is applicable when constructing buildings in regions with unfavorable climatic conditions and high wind loads. The thermal lock is called an energy-saving fastening method because it prevents heat from escaping from the building.

These methods are used for fastening wall panels, and there are options for roofing panels:

The metal covering of the first slab covers the skin of the second slab. The joint is completely closed, external moisture does not pass through, but this does not negate the final treatment of the sealant. The metal sheathing, made in the shape of a wave, overlaps the sheathing of the adjacent slab, made in the same shape.

So, the construction of sandwich panels is a fairly simple procedure, which is why it is widely used in the construction of industrial and residential buildings. However, here too there are rules and subtleties that you need to know in order to ensure a long service life of the structure.

Formation of a new gender

Creating an attic floor from SIP panels may be required when the house or floor underneath is covered, for example, with logs. As a result, the surface does not meet the rigidity requirements and may not guarantee strength when placing furniture. In this case, proceed as follows:

- a timber frame is formed around the perimeter of the future attic;

- The floor is laid out from SIP panels using intermediate strapping beams.

As a result, they solve two problems at once: they obtain a durable, high-quality covering for the attic floor and ensure that the existing ceiling of the lower floor will not take on excessive loads.

The same applies if an attic is built on a house without a roof. Simply put, on a box, supported by the ends of the walls. This is the most cost-effective and time-saving project. The opening for the stairs to the attic is created in one ceiling, exactly where it is needed - in a field assembled from panels.

Projects of houses made of vulture panels with an attic in Krasnoyarsk

I hereby freely, by my own will and in my own interest, give my consent to IP Tsurikov Alexander Evgenievich, located at 627750, Tyumen region, Ishimsky district, Plodopitomnik village, st. Svetlaya, 2, 1 (hereinafter referred to as the Operator) for automated and non-automated processing of their personal data in accordance with the following list:

- name, telephone number, email address and other individual means of communication specified when filling out all forms on the website https://stroy-dom-krk.ru (hereinafter referred to as the Site), namely:

- Other feedback services;

- source of access to the site and information from the search or advertising request;

- data about the user device (including resolution, version and other attributes characterizing the user device);

- user clicks, page views, field completions, impressions and views of banners and videos;

- data characterizing audience segments;

- session parameters;

- information about the time of visit;

- user ID stored in cookie

- for the purpose of providing information, providing relevant advertising information and optimizing advertising.

I also give my consent to the Operator providing my personal data to third parties, including the Tenant of the site https://stroy-dom-krk.ru, as well as to the cross-border transfer of personal data to achieve the stated purposes of processing personal data.

In order to ensure the implementation of legal requirements in the field of personal data processing, the Operator can:

- carry out the processing of personal data by collecting, storing, systematizing, accumulating, changing, clarifying, using, distributing, depersonalizing, blocking, destroying personal data;

- use an automated method of processing personal data via the Internet;

This consent comes into force from the moment of confirmation and is valid for 5 years, unless otherwise provided by the current legislation of the Russian Federation.

Withdrawal of consent to the processing of personal data is carried out by sending a written application to the legal address of the Operator.

I confirm that I am aware of the right to withdraw my consent by drawing up an appropriate written document that can be sent by me to the Operator. In the event of my withdrawal of consent to the processing of personal data, the Operator has the right to continue processing personal data without my consent if there are grounds specified in paragraphs 2-11 of part 1 of article 6, part 2 of article 10 and part 2 of article 11 of the Federal Law of July 27, 2006. No. 152-FZ “On Personal Data”.

Erection of a structure on an existing building

In this case of construction, after dismantling the roof, an attic from panels is erected, supported by timber framing. The latter can either be located on the walls or go beyond them, for example, when you want to change the house and also get a comfortable veranda.

The project can use both horizontal and vertical panel layouts. The latter type of construction is considered the standard type, since it has the maximum strength characteristics of the finished walls. If construction with a horizontal arrangement of panels is chosen, timber must be placed between the rows to achieve rigidity and ensure that the attic walls will support the weight of the roof.

Price, dimensions and weight of sandwich panels

The cost of sandwich plates is determined by several factors:

- the thickness of the sheet protective layer, on which the strength of the products depends;

- color spectrum;

- polymer coating used (pural, plastisol, polyester, PVC);

- sandwich panel thickness, minimum 50, maximum 250 mm;

- quality of insulation material;

- order volume - the more products are ordered, the cheaper the batch will cost.

As for dimensions, manufacturers provide a variety of products. The length of the panels can reach 18 m. The width is not so varied. You can find two options on sale: 1 m and 1.2 m. The thickness of the material depends on the layer of insulation used in production.

The weight is influenced by the type and thickness of the thermal insulator layer. The thinnest and lightest of them is EPS (expanded polystyrene). According to standards, the thickness and weight of sandwich panels are strictly regulated. They are: with a thickness of 150 mm - 25 kg/m, with 80 mm - 20 kg/m.

As you can see, sandwich panels, their sizes and prices are interrelated. You need to calculate everything before you buy a batch.

Roof structure

An attic made from composite panels is strong enough to withstand any type of roof. The most convenient way is the following:

- after installing the panel gables, the upper ridge beam is located directly on their upper part;

- if it is necessary to obtain a roof with a complex configuration, all the necessary elements are also attached to the front panels.

Important to know: Features of houses on stilts made of SIP panels

However, the most convenient way is to form a roof from SIP panels. The project and subsequent construction using this technique have the following advantages:

- the roof does not require insulation;

- the roof surface is very strong and smooth;

- the resulting roof can be covered with any material.

The construction of a simple version of the roof, both single-pitch and gable, is not difficult at all. If you want a roof with a complex configuration, with skylights and several ridges, you should order a project from a specialized company.

How to carry out construction quickly and at the lowest cost

When constructing an attic, there are several stages when it is advisable not to do everything yourself, but to turn to contractor companies. Although the project can be drawn up independently, it is always cheaper to order constructs from specialists. In fact, today you can purchase SIP panels of standard sizes, but this is not always profitable, as it can lead to the following inconveniences:

- working with large structures, giving them the required dimensions is quite troublesome;

- the number of connections and joints increases, which negatively affects the strength of the structure;

- financial expenses will increase, since structural remains will inevitably be formed;

- more timber and other auxiliary material will be required to create load-bearing frames.

Therefore, the best option if you decide to build an attic from SIP panels is to order the production of structures from a responsible contractor company. In this case, a standard project can be used, and all assembly work is carried out independently.

Consequences of incorrect installation

Sometimes, after the wall sandwich panels are attached, the general curvature of the building is revealed. It is not the wall structures that can be oblique, but the entire frame. In this case, it will no longer be possible to correct the error.

If you store the panels incorrectly, leave them in the sun, or walk on them, they will begin to deform. When installed, it will affect the entire building. The tightness and load-bearing capacity will be compromised.

Overtightened screws reduce the load-bearing capacity of the structure, leaving dents on the surface. The tightness of the building is compromised.

Loose fasteners cause holes to form. Moisture remains on the mineral wool, which causes a decrease in energy efficiency.

Subtleties and methods of installing sandwich panels:

How to purchase quality material

Here is an excellent video with personal experience about building a house from sip panels, in which, dear author, he also shares tips on how to purchase high-quality material:

When building an attic with your own hands, there is a risk of purchasing unreliable material . The construction market often offers homemade panels that do not have the required properties and have unacceptable gluing quality.

This material is cheaper, but it is dangerous to use. Even one low-quality panel can cause irreparable harm. It is not always possible to get rid of defective goods and return the money spent.

You can only buy the material from a seller who has a certificate indicating the manufacturer and information about the components of the sip panels: OSB, PSB and glue. Documents must confirm the product’s compliance with the standards.

The quality of expanded polystyrene in panels for construction is one of the decisive factors. It must be manufactured in accordance with GOST and have a 25 grade. You should not purchase material with expanded polystyrene made according to specifications and having grade 15.

How to install an attic

Side rafters are not required to build the roof. Due to their strength, panel gables are able to withstand all necessary loads. A ridge beam is attached to the top of the gables .

The bottom of the roof slopes rests on the Mauerlat, and the top on the ridge beam. If necessary, horizontal beams-purlins are cut into the sides of the gables, which provide support for vertically laid panels.

This is how the installation of sip panels is carried out.

SIP panels can also be horizontal. In this case, support beams are installed at certain intervals connecting the ridge beam and the mauerlat.

The panels are mounted using appropriate technology. The tenon-groove principle ensures the strength of the assembly. All connecting places are foamed. Self-tapping screws are used for fastening.

The planned window openings are cut out before assembly. The completed roof does not require additional insulation. To protect against moisture and give a decorative effect, one type of tile is usually used.

An attic made from sip panels looks something like this

OSB boards

OSB boards were developed in the United States in 1980 as an analogue of chipboard. OSB boards are a product made from deep processing of wood by pressing rectangular chips under high pressure using a waterproof adhesive resin.

It should be said that OSB was the first board of wood origin and developed exclusively for construction purposes. Today, OSB has found its wide application in the manufacture of furniture and, thanks to its excellent characteristics, it is gradually replacing plywood and chipboard from this industry.

OSB boards are the best option for insulating the attic. In addition, decorative material can be immediately applied to the OSB board, which will significantly increase the aesthetic appeal of the room.

In order to ideally insulate the attic, a sandwich panel made of polyurethane foam and OSB is suitable. Sandwich panels made on the basis of OSB are lightweight, have low thermal conductivity and a perfectly smooth surface, which will give enormous scope for design ideas in terms of floor design.

A number of facts support the choice of OSB sandwich panels.

- Availability. A sandwich panel made of polyurethane foam and OSB is a relatively cheap material that has excellent thermal insulation properties and is ideal for insulating an attic from the inside.

- High thermal insulation characteristics. This material, due to its multilayer structure and manufacturing materials, has low thermal conductivity, which allows you not to use other materials when insulating the attic from the inside, thereby simultaneously saving on finishing work, since these slabs already have a perfectly flat and smooth surface.

- High water-repellent characteristics. Of course, sandwich panels made on the basis of OSB are not suitable for installation in rooms with high humidity, but for insulating the attic from the inside they will come in absolutely handy. This material owes its high water-repellent properties to a polyurethane foam core and water-resistant resin used for gluing wood chips.

- Fire resistance. Sandwich panels of this type have excellent fire resistance and belong to the group of materials that, even when ignited, do not release harmful substances into the environment.

- Environmental friendliness. Thanks to the materials used - wood and polyurethane foam - this material is absolutely environmentally friendly and suitable for insulating residential premises from the inside.

- Light weight. Due to their low weight, these sandwich panels do not cause a significant increase in the weight of the roof, so they can be used both for insulating the inside of new and used roofing structures.

If you carefully analyze the costs of heating the attic floor, then the need for high-quality insulation becomes more than obvious. When finishing an attic space with sandwich panels, in order to achieve maximum high-quality insulation, you must follow some rules.

Why PremierSip?

Cooperation with us has a number of advantages:

- We carry out all the work ourselves, without involving intermediaries, which reduces the cost and allows us to control the entire work process;

- we use high-quality Green Board panels;

- During construction, we protect the house from precipitation using special coatings;

- We work not only in Moscow and the region, but also in other regions.

At any time, you can read a large number of reviews about our work and make sure of the reliability of cooperation with us.