Projects of wooden houses made of profiled timber have a number of advantages. This includes the appearance, the internal atmosphere, environmental friendliness, the cost of construction, and other advantages. The technology also has some minor drawbacks. For example, a log house shrinks, requires special operating conditions and does not forgive unprofessionalism during the assembly of the log house.

What is profiled timber?

Glued profiled timber

This modern lumber is made using industrial equipment. During production, it is subjected to several types of processing, resulting in the wood acquiring its final shape and unique characteristics.

The production of profiled timber is mainly carried out from the following types of wood:

- pine;

- spruce;

- cedar;

- aspen;

- larch.

In private housing construction, pine is usually used, as it is cheaper. Baths made of profiled timber are often built from cedar or aspen. Both breeds tolerate temperature fluctuations and high humidity well. Larch has a long service life, but is expensive.

Spruce is considered the least preferable. It is susceptible to rotting, but has a beautiful appearance, so it is used mainly for internal partitions and decoration.

An important feature of profiled timber is the presence of a profile, which is located on both sides. This element provides good fixation and reduces the number of blown zones in the wall. In addition, the profile speeds up the construction of the building and allows you to save on insulation.

Production is carried out in accordance with GOSTs (8486-86, 8242-88, 24454-80, 11047-90). State standards establish technical requirements for lumber intended for construction.

Profiled timber production

It happens in several stages:

- Selection of wood. This stage determines the future characteristics of the product.

- Selection of section. The market offers square, rectangular and rounded sides.

- Rejection. Lumber with defects is removed.

- Calibration The remaining ones are grouped depending on size.

- Drying - natural or chamber. Natural drying takes several months, chamber drying - 2-4 weeks.

- Some manufacturers at this stage saw the material so that it does not crack, and treat it with antiseptics and fire retardants.

- The lumber is then planed and profiled.

Possibilities of external and internal decoration of the house

External cladding for such a building is not mandatory. Treatment with antiseptics and fire retardants will be sufficient to prevent exposure to external negative factors. The building will look beautiful from the outside; smooth wooden walls can be painted in any color or covered with transparent varnish. There are many special compounds that provide excellent protection for wood, but at the same time preserve its natural pattern.

Interior decoration also depends only on the wishes of the residents in terms of decorative qualities. The natural color of wood may seem boring to some, but this material opens up wide possibilities for design. Several popular interior finishing options:

- The walls are sometimes sheathed with plasterboard sheets and covered with wallpaper, but in this case all the decorative advantages of a wooden house are lost. You can paint them with special compounds: paints and odorless translucent azures do not cover the natural texture, so the rooms will be beautiful.

- It is not advisable to cover a wooden ceiling with plaster, since due to the shrinkage of the wood it will begin to crumble over time. You can choose the appropriate coloring and filing option: the floor beams can be left visible and painted - this allows you to create an unusual, stylish decor.

- The floor can be finished using parquet, special floorboards, or parquet boards. Natural materials will look most harmonious in the interior and will also provide additional thermal insulation. The parquet will be warm and pleasant to the touch.

One of the advantages of building a house from profiled timber is the opportunity to significantly save on finishing. The wood does not need to be leveled, plastered, or covered with plasterboard - just choose the appropriate coloring option to create a cozy and modern interior.

Pros and cons of profiled timber

Main advantages

Profiled timber has many advantages compared to other materials:

- attractive appearance (houses made from it do not require additional finishing);

- ecologically pure;

- low thermal conductivity, allows you to reduce the cost of heating your home;

- there is no need to seal the walls, since the crowns fit tightly to each other;

- high strength;

- treated with agents against fungi, mold and fire;

- maintains original dimensions;

- ease of assembly;

- quick installation;

- long service life;

- does not crack;

- after assembling a log house from dried profiled timber, slight shrinkage of the house occurs;

- the house is lighter than other materials, so it does not require a massive foundation. Can be installed on a columnar or strip foundation.

Profiled timber - disadvantages

Profiled timber has several disadvantages:

- Frequent manufacturing defects.

- Profile defects are often encountered.

- It is not always sufficiently dried, as a result of which the shrinkage period increases.

- High flammability. Requires compliance with fire safety standards and requires special treatment.

- The need for additional insulation. It occurs when the thickness does not correspond to climatic conditions or the construction technology is not followed.

- Wood darkens over time.

- After construction is completed, it is difficult to change the layout of the premises.

Preparing the area and purchasing materials

Construction work must begin from the site preparation stage. First you need to get rid of all the plantings in the area and foreign objects. When purchasing the right materials, you need to determine what exactly is needed.

For construction you will need the following material:

- A profile with dimensions of 20 by 20, or larger for the first crown;

- Profiled timber with dimensions of 15 by 15 for partitions and walls;

- Tow or moss will be needed for insulation. These materials are laid between the beams;

- Metal or wooden dowels;

- Reinforcement brackets for fixing several perpendicular logs.

A batch of timber must be prepared in advance long before the construction process begins. This is due to the fact that the material must be dried as much as possible, since wet wood will dry out after some time. This can lead to very undesirable consequences.

Types of profiled timber

Classification is carried out according to the following characteristics:

- front side view;

- dimensions;

- profile type;

- type of drying;

- structure.

Front side view

She may be:

- Straightforward. The most popular is timber with straight sides. This form is convenient for subsequent wall finishing; it is the cheapest.

Straight profiled timber

2. D-shaped. The outer side has a curved shape, like a rounded log, while the inner side is straight. A house made of such lumber does not require additional external finishing.

"D" shaped profiled timber

3. O-shaped. The most expensive type. With this profile, you don’t have to do any cladding either inside or outside the house.

O-shaped glued profiled timber

Profiled timber - dimensions

Typically, the thickness of timber for external walls is from 100 to 200 mm.

The most common sizes (mm): 100x100, 150x150 and 150x200.

For houses built according to individual projects, manufacturers produce products with dimensions that correspond to the features of a particular structure.

The area of use depends on the thickness of the material. 100 mm timber is used for light buildings (gazebos, cottages) or internal partitions. A thickness of 150 mm is suitable for residential buildings, and 200 mm is used for the construction of expensive cottages.

Profile type

Profiled timber is available with the following types of profiles:

- Single-spike. The presence of one ridge eliminates the possibility of water accumulation at the joint. Characteristic for naturally drying materials.

- Double (two-spike). This type provides a more secure hold. Thanks to two spikes, thermal insulation is increased.

- Multiple (comb). This type has from 3 to 8 spines. Compared to other types, the comb provides the most reliable fastening and maximum thermal insulation.

- Beveled chamfers. This type is one of the varieties of double profiles. Due to the beveled chamfers, less water accumulates at the attachment point, making caulking of the walls easier.

- Finnish (Scandinavian) type, which has two ridges with beveled chamfers, located at a large distance from each other.

Type of profile of profiled timber

In this case, profiled timber can be either glued or regular.

Timber drying type

Materials highlighted:

- natural drying;

- chamber-drying profiled timber.

Moisture content determines the performance characteristics of the material.

The first type of timber is dried naturally. Lumber is laid in a place protected from water and sun so that air circulates between them. To achieve the desired level of humidity, the products are aged for several months. The disadvantage of this method is long drying and shrinkage.

When chamber drying, the workpieces are placed in special chambers - ovens, which reduces production time. This material is more expensive, but shrinkage occurs quickly and is very small.

After drying is complete, the wood retains a certain amount of moisture. Material that has undergone natural drying has a moisture content from 22% to 40%. When chamber drying - 18-20%.

Profiled timber: price

To make profiled timber, much more time and skill is required. You also need special professional equipment and the ability to handle it.

It is logical that such material is noticeably more expensive than simple smooth material, even if it is processed. But the profile significantly simplifies construction. The walls fold up like a construction set, saving labor and time. Less insulation required.

Dry profiled solid timber is usually 30% cheaper than laminated timber. This is due to the peculiarities of the technologies used to create products. In the case of laminated veneer lumber, the buyer is freed from the need to additionally sand the facade before starting painting. This allows you to save on costs.

The cost of finished houses is approximately the same for both types of materials. Therefore, the choice is made precisely on the basis of operational characteristics.

When purchasing, it is important not to skimp on really high-quality wood, harvested according to all the rules. There are cases when an unscrupulous manufacturer neglects technology in order to save money. It is better to purchase profiled timber from a well-established manufacturer.

German and Finnish profile types

German has another name - comb. It is created by selecting grooves and tenons in the required quantity. This makes it possible to protect the building from wind, low temperatures and avoid the use of insulating materials. When the tenon is tightly installed in the groove, a reliable and warm inter-crown connection is obtained, which prevents cold air from penetrating into the room.

The Finnish one has a wide groove at the bottom, and small tenons about 1 cm high on the sides. This allows you to increase the size of the supporting platform and improve the fit of the crowns. This type of section prevents the penetration of cold and ensures uniform shrinkage. Due to the side spikes, the insulation laid in the inter-crown seams will not be noticeable.

But it is worth noting that profiled timber may lose its thermal insulation qualities if storage conditions are not met. If the material is exposed to sunlight, rain, or snow for a long time, the interlocking joints may become deformed or swell. After such storage it will be impossible to pack the crowns tightly.

Structure of the timber material

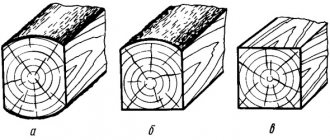

Depending on the design features, lumber is divided into two types:

- from the array;

Solid planed timber

Such a beam is made by simply removing the cylindrical part from four sides. Rough boards with a semicircular convexity on one side come out of the scraps - slabs. The result is a material with a cross-section of a regular quadrangular shape.

Typically, it is not additionally sanded or dried before being sold. Therefore, it has a low cost.

Sometimes solid timber is planed or sanded, adding beauty.

Solid timber is usually made from softwood. It is environmentally friendly and requires less production time and costs. It has a lower price.

- laminated veneer lumber;

Glued beam

Glued laminated timber is a high quality lumber. It is assembled from thin wooden slats, which are pre-dried to the required humidity, eliminating knots and any possible defects. This technology eliminates the possibility of deformation during shrinkage and reduces the amount of waste during construction. To achieve the required properties, craftsmen glue lamellas from different types of wood. Glued laminated timber consists of several dried and processed lamellas glued together. It is characterized by increased resistance to rotting and burning, as well as a higher price.

Glued laminated timber has interesting differences. Both types mentioned above are suitable for its manufacture. In this case, the tree undergoes serious processing. Using special equipment along the entire length, a tenon is machined on one side and a groove on the other. During construction, they are connected and form a thermal lock. It does not eliminate the need to insulate the joints, but significantly reduces heat loss.

Reviews of timber baths on official websites

The high quality declared by the development companies is confirmed by the huge number of reviews from their clients on official websites. But think about why there are so many positive reviews and not a single negative one? Of course, the vast majority of reviews are generated by employees themselves.

Naturally, you shouldn’t paint everyone with the same brush, but we still recommend being wary if there is not a single negative review from customers. Before believing positive reviews, it is better to pay attention to whether the site offers videos or photos of ready-made baths.

A company that monitors its reputation invites clients not only to read reviews, but also to personally go to the construction site, talk to the owners, and see everything with their own eyes. However, the bulk of the reviews that you read on official websites are aimed only at attracting the attention of the consumer, nothing more.

Production of solid profiled timber

A typical workpiece is prepared as follows:

- They take a log of wood and process it using special machines.

- The result is a product with a rectangular or round cross-section.

- Special grooves with tenons are cut out on the technical sides. This allows you to create a locking connection for further construction.

When producing profiled timber, they try to preserve as much as possible the natural pattern on the surface characteristic of natural wood. The main material is the core part of the tree trunk, so you don’t have to worry about the strength of the finished product.

Construction from profiled timber

When building walls from smooth timber, quite a lot of time is spent fastening the crowns together. For this purpose, dowels are used - special wooden nails. They are driven into holes pre-drilled every 1.5-2 m, and the next row is planted on top.

Cutting out the bowl for the corner joints is also a labor-intensive task. It is better to perform this delicate work using high-precision equipment. This is what they sometimes do when making profiled timber. And the tenon and groove successfully replace dowels in fastening the crowns and create a windproof seam.

Appearance

Untreated wood looks untidy. The situation is aggravated by tow fibers protruding from the wall. If a house is built from simple timber, usually only the part that will be facing inward is processed. Or use lumber for decorative finishing:

- lining;

- eurolining;

- imitation timber;

- siding;

- block house.

Marking and foundation

The essence of marking is to mark the location of the future structure in the selected area. For this, wooden pegs and ordinary rope or fishing line are often used. An ideal rectangular trench for the foundation will only be possible in a situation where the diagonals of this figure are the same.

To equip the foundation you will need the following materials:

- Concrete;

- Sand;

- Crushed stone;

- Wooden formwork;

- Ruberoid;

- Materials for insulation.

For a bathhouse, you can equip a strip or columnar foundation. The load-bearing capacity of such foundations will be quite sufficient for the construction of even a large building made of timber.

For the foundation, you can equip formwork or do without it at all. Sometimes it is enough to simply equip a trench, put a cushion of sand and crushed stone on the bottom, and then pour concrete. The width of the foundation must be suitable for installing the timber.

Glued laminated timber

Sometimes a person who wants to build his house from profiled timber is faced with a choice: which timber is optimal for construction?

How laminated veneer lumber is produced

Glued laminated timber

To produce laminated veneer lumber, a more complex method is used. The following several stages are expected:

- The logs are sawn into boards, which are then dried using special chambers.

- Before and after the drying process, sorting must be carried out.

- Gluing the boards to the desired size is done after drying.

- Aging under pressure and profiling are the last stages of processing.

- After this, the product is released onto the market, ready for further use.

Strength

When a profiled solid beam is produced, the outer part of the wood is cut off from the log. And it is usually stronger compared to the internal one. Therefore, laminated laminated timber is superior in this parameter to profiled solid timber.

Pressing, gluing and drying are the main steps in creating laminated veneer lumber. Additional processing is carried out to provide reliable protection from any influences. That is why the glued variety of material is more resistant to damage of various types.

Humidity and shrinkage of profiled timber

Glued laminated timber initially has low humidity levels, up to 11-14%. Therefore, shrinkage produces a result of only 1%. The drying rate of the main structure in this case will be almost zero.

Uniform humidity within 20-22% is typical for profiled solid timber. Such results can be achieved through the use of modern drying technologies.

Environmental friendliness

Profiled solid timber does not have any additional elements in its composition. It is coated with special compounds. But the material remains absolutely safe both for the buildings themselves and for those who are constantly inside.

When connecting laminated timber elements, additional components are used, which can be divided into three groups:

- Safe.

- Potentially dangerous.

- Generally unsuitable for residential premises.

The main indicator is the amount of formaldehyde used in the production process. If its level does not exceed 0.5 mg/liter, the material is considered safe and suitable for use.

Glued laminated timber may become deformed if low quality compounds were used during gluing. The glue itself costs differently, depending on the initial characteristics of a given component.

Fire and biological resistance

Any type of massive timber is vulnerable to environmental impacts. After all, before building a house from timber, special compounds are used to treat the material antiseptically. Over time, they are washed out and weathered, which is why resistance to such types of damage decreases.

Fire safety also remains low for all types of structures.

G4 is a standard marking that is used for products. It persists even after additional processing. In the case of laminated timber, the safety indicator is average. The material is quite dense, which is achieved through pressing. But it is still not possible to completely get rid of flammability.

Aesthetic component

Glued laminated timber has a perfectly flat surface that does not require further cladding. There are also no holes from old knots on the material, which only improves the appearance.

But when using profiled solid timber, such ideal smoothness cannot be achieved. There may be various holes from old knots and cracks.

Important features of laying communications

One of the most important disadvantages of houses made of timber is the fire hazard. This is what is taken into account when laying communications. All wires must be laid in metal pipes so that the slightest damage to their integrity does not lead to a fire.

The next thing that is taken into account is the low ability of wood to withstand moisture and the shrinkage of the new building.

When laying sewerage, it is necessary to leave compensation holes. The water supply should be laid below the freezing level of the soil.

The exit point needs to be insulated. It is permissible to install the heating system only after complete shrinkage. A water type of system with liquid circulation through pipes and radiators is recommended.

Only taking into account the pros and cons of profiled timber can you decide on its use for building a house. The type of material is determined depending on the region, the purpose of the building, and the characteristics of a particular project.

Cost of the bath

For small buildings, such as bathhouses, the cost of construction from logs or timber does not differ very significantly and depends on the specific project. In general, bathhouses made from hand-cut logs processed with a planer are slightly more expensive than bathhouses made from rounded logs, which in turn exceed the cost of buildings made from timber.

In general, the cost of a particular material depends on the region. Thus, in areas where there are no wood processing plants nearby, the price of timber is higher than that of regular logs due to delivery costs.

In our catalog of bathhouse projects, on the page of each project there is a calculator that shows the cost of construction from various materials.