- What is double beam

- What buildings are being built using this technology?

- Features of the technology

- Advantages and disadvantages

- 3 popular misconceptions about construction using double timber technology

Finnish double timber construction technology has been used in our country relatively recently, but is finding more and more adherents.

The popularity of the technique is explained simply - houses made of double timber are durable, environmentally friendly and warm. At the same time, they surpass traditional wooden buildings in terms of performance indicators. Such houses are designed for decades of impeccable service, look attractive, and meet all modern requirements for comfort, coziness and practicality. True, buildings also have disadvantages - for example, the difficulty of repairs when structural elements fail.

Our article contains the whole truth about double beam technology. You will find out what kind of houses are built using this method, what are its pros and cons, features and nuances.

What is a double beam?

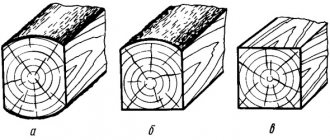

The principle of building a house using this technology is to tie individual wooden blanks (thick boards or truncated beams) into a tenon, thereby forming a double-walled mirror structure. The cavity between the walls is then filled with sound, heat and vapor barrier materials, ensuring the maintenance of comfortable living conditions in the house.

The main task of the developers of this technology is to try to unify the construction process through the use of a prefabricated structure, the parameters of which would be selected taking into account the individual requirements of the customer.

At the same time, the latter could independently determine the required wall thickness, as well as select the appropriate insulating material (including the number of its layers).

Schematic design of a double timber house

Manufacturers of such structures intended to use mineral wool (ecowool) as a filler for inter-beam cavities. Polystyrene foam, penoplex or polyurethane foam can also be used.

Thanks to the versatility of this technology, you can build buildings of almost any profile, from a small cozy bathhouse to a permanent two-story house.

Communications: well and sewerage

During the production of the wall set, we laid communications.

A drilling company was invited to construct a well. In our area, the water lies at a depth of 25 meters. After drilling the well, the pump was lowered inside. Then, using an excavator, they dug a hole around the hole in the ground to install a reinforced concrete ring. A hatch with a cover was installed on top of the resulting structure. They laid a water pipe to the house. Spent 1 day.

- The water well cost 48,000 rubles.

Specialists were also called in to install the sewer system using an excavator. The first step: we dug a trench from the point of entry into the house to the cesspool. Second step: we dug a hole 1.5×1.5×3 m to install reinforced concrete rings. Third step: installed reinforced concrete rings with a bottom on a concrete solution in the pit. Fourth step: coated all seams with bitumen mastic, installed a hatch with a cover. A HDPE sewer pipe was laid in a dug trench on a sand bed. A 20 cm layer of sand was poured over the pipe. Then everything was covered with soil remaining after digging the trench and hole (3 cubic meters).

- 23,800 rubles on sewer installation

- Communication costs RUB 71,800.

Benefits of technology

The advantages of the “double beam” technology include:

- versatility, you can choose the composition and type of protective layer at your discretion;

- excellent thermal insulation characteristics. In terms of thermal insulation, a double wall is equivalent to a 40 cm thick timber structure. Have you ever seen such a wall? No? I didn't see it either.

- since mineral components are used as insulation, such timber is fire resistant (does not propagate combustion);

This is, frankly, a weak advantage. Adding mineral wool will not make a house comparable in fire resistance to a concrete one. However, residents may have a couple more minutes to leave the premises.

- due to the design features, material consumption is reduced, and the lightness of the walls will allow you to save on a lightweight version of the foundation;

- with this method of home improvement, you can do without additional finishing of its walls (both external and internal);

- the absence of any chemical components (adhesive compositions, in particular) significantly increases the environmental friendliness of the structure.

Strictly speaking, double timber does not belong to the category of materials from which you should build with your own hands. For this material, it is better to find a supplier who will make all the necessary parts from dried material with furniture-quality fitting. The buyer will only have to assemble the product on the site.

Assembly in progress: the main thing is to do it before the rain

If you decide to build it yourself, before starting construction work, the prepared material should be thoroughly dried, which will protect it from deformation and cracking. Only after this can you begin the actual assembly of the structure. Double timber is more sensitive to cracks than solid or glued timber.

As a cavity-filling thermal insulation material, I advise you to choose an environmentally friendly filler - ecowool, produced on the basis of natural cellulose. Among other things, this material is resistant to fire and absorbs extraneous noise well. In addition, it reliably protects structural elements from fungi, mold, rodents and other destructive factors.

If you use ecowool, you can do without special vapor barrier protection.

The only obstacle between you and ecowool may be the lack of suppliers in the region. In this case, mineral wool is also suitable; you can purchase and install it yourself. If possible, choose mats with a high density and be sure to use fixing fittings. Polyurethane foam is also suitable in terms of characteristics, but many experts have a strong prejudice about its compatibility with wood: the fact is that it does not “breathe” and can cause wood to rot if there is residual moisture in it.

Electrical wiring

Since the power grid in the SNT territory is “weak”, they decided to connect to the city network. I had to install a pole on the site.

- Supplying electricity costs 16,500 rubles, the process took almost 2 months (due to red tape with the energy company).

The electricity was turned on after all, and all we had to do was install the wiring inside the walls of the house.

Wiring inside walls

Junction Box

Used:

- more than 300 m of cable and corrugated HDPE/NG;

- 100 installation sites;

- distribution boxes;

- socket boxes, small consumables.

- Posting RUB 34,000, 2 days.

Disadvantages of double timber

Along with positive assessments of this product, a number of users also have certain doubts about its operation, expressed in the following:

- since the material, new to Russian conditions, has not yet passed the testing stage, there is still no complete confidence that all its characteristics correspond to the declared indicators;

In Russia, other methods of building a house from wood are still widespread (using profiled timber, for example).

- many users have doubts about the insulating layer, which, according to reviews, is prone to shrinkage with the loss of all the thermal insulation properties declared by the manufacturer;

Another difficulty is that it is difficult to control the condition of the internal cavities of the walls. Is moisture getting in there? Has rotting or mold started to form there? Are there any uninvited tenants there?

- uncertainty regarding the issue of repairing double beams. Of course, as a last resort, you can always turn to specialists, but this call will cost you a lot of money. You can't patch up a house like this on your own with jacks.

The specifics of the double timber structure require a special approach to organizing its production, ensuring unique operational parameters.

Design. House kit cost

We found a manufacturer of house kits with a good reputation in the neighboring region. Together with the manager, we drew up a sketch, after which we signed a contract for the design of the log house.

3D model of a house

We were completely satisfied with the finished project. The price of a cube of finished timber from the company is 17,500 rubles; according to the report, it should have taken 28.98 m3 per house.

- Design RUB 16,500

- House kit 507,000 rub.

We could only wait until the specialists prepared the material - sawed it, dried it, cut grooves and tenons, and cut out cups. The manufacturer reported a readiness time of 1 month.

Design features

When you carefully study the “double beam” technology, you will immediately notice some features of its implementation related to the design of prefabricated elements. First of all, what is striking is that it is based on a system reminiscent in its structure of standard sandwich panels. In this case, the wooden sidewalls of the frame base mirror each other, and insulation in one or several layers is placed between them (selected depending on the region of residence).

Hidden communications can be laid

The thickness of the timber sidewalls usually does not exceed 70 mm, but you can choose this value at your discretion (it should also be tied to the climatic conditions in your area).

The versatility of this material is also manifested in the fact that using the “double timber” technology it is possible to erect buildings with a wall height of up to 10 meters and a thickness of up to 340 mm.

Exceeding the specified thickness is allowed, but there is no point in this, since in a building with such indicators, comfortable living conditions are provided by the wall structure itself

Insulation

Next, the walls were insulated using ecowool (finely shredded paper with the addition of boric acid and fire retardant).

Before starting work, we installed door and window frames and used the material left over from the ceiling and framing.

We calculated the insulation taking into account the required density (55-65 kg/m3). The volume of the walls is 30 m3, 30*65 = 1950 kg of wool. The mixture is sold in briquettes of 15 kg, 1950/15 = 130 briquettes.

- The price of insulation is 33 rubles/kg, 1950*33 = 64,350 rubles.

- To blow in the cotton wool, we rented a unit for 6,000 rubles and insulated the house for 3 days.

The house was insulated using a dry method, without water or glue. At the first stage, the apparatus and insulation briquettes were lifted into the attic. Next, the cotton wool was poured into the loosening tank of the installation, a long hose was lowered inside the wall to the floor level of the 1st floor, and turned on. First, the unit fluffed up the cotton wool, then, under strong pressure, fed it through a hose. All that remained was to control and direct.

Insulated floor of the 2nd floor

All walls were consistently insulated. The ecowool still remained and was used to insulate the floor of the 2nd floor.

Areas of use

Naturally, you may have a question about what else (besides residential buildings) is allowed to be built using the technology we are considering. The answer is the following list of its possible applications:

- construction of baths and similar health complexes;

- organization of recreation areas, including a barbecue with a gazebo;

- arrangement of modern children's playgrounds and sandboxes;

- production of wooden canopies in summer cottages;

- organization of parking spaces for vehicles;

- production of special furniture samples.

We will separately consider the nuances of producing blanks for this technology.

Ready-made “double” house

Roof structure

The next stage was the installation of rafters, sheathing, corrugated sheeting and roof insulation.

For the rafters we used a 50x200 mm board, for the sheathing - 15x100 mm (treated with OBZ).

- Boards 20,000 rub.

The rafters were attached to the side walls and the ridge wall using metal corners, in increments of 0.6 m. The sheathing was screwed on top of the rafters using self-tapping screws.

Next, corrugated sheeting for the roof was attached to the rafters.

- Corrugated sheeting and fasteners RUB 40,000.

We attached waterproofing from the inside and laid Izospan insulation (roll, 200mm).

- Roof insulation RUB 25,000.

- Total cost 85,000 rubles, time – 3 days.

Finishing

- The ceiling on the first floor was covered with clapboard 13,000 rubles, 1 day.

Double timber does not require finishing as such; it is necessary to lightly sand the surface and cover it with oil or paint. We chose a 2 in 1 impregnation – antiseptic and transparent strengthening paint.

- Impregnation 15,000 rubles, 2 days.

- The floor of the 1st floor was covered with linoleum, 20,000 rubles, 1 day.

Heating and plumbing

For heating, we purchased a 9 kW electric boiler (3 heating elements of 3 kW each, can be used separately), a pump, metal-plastic pipes, bimetallic radiators, fastenings, and fittings.

We stretched the pipes along the 1st floor, attached radiators to the walls, and connected them to the boiler.

We installed a pressure maintenance station and a water heater, laid pipes for cold and hot water.

- Heating 50,000 rub., 1 day.

- Water supply RUB 25,000, 1 day.

Installation of windows and entrance door

Since the attic windows are non-standard, the order had to wait longer than usual (3 weeks); mounting plates and foam were used to secure the windows.

One side of the metal plate was attached to the casing, the other to the window, the space between was filled with polyurethane foam

- Windows 61,000 rub., 1 day.

We ordered a metal door. The installation didn't take long. The door was secured with wood groins to the casing, and the remaining space between the jamb and the frame was foamed with polyurethane foam. We assembled the door hardware.

- Door 15,000 rub., 3 hours.