Fuel briquettes are alternative types of fuel that are used to speed up the ignition of a stove or replace wood in a fireplace. In addition, briquettes are widely used for heating greenhouses, garages, country houses or garden houses for temporary residence.

Modern technologies make it possible to produce briquettes from unnecessary materials and waste.

The main advantages of fuel briquettes include:

- The ability to make fuel briquettes with your own hands , and with simple equipment, their production can be organized as a way to run your own business.

- Compared to firewood , it has a longer burning life, with minimal sparking and smoke formation.

- Environmentally friendly , since the production of briquetted fuel mainly uses waste of plant origin.

- The cost-effectiveness of briquettes compared to coal or firewood is explained by the use of waste and the use of one’s muscular strength and simple devices;

- Non-waste use - the ash formed after combustion can be used as fertilizer.

- Practicality, unpretentiousness and economical storage - briquettes when stacked take up less space than loose firewood or coal.

- Possibility of use in any heating systems and devices, from a country fire to a boiler for an individual heating system running on solid fuel.

Do it yourself: pallets from waste paper

Do not rush to throw away old newspapers; with special treatment, they can easily turn into kindling for a fire or even firewood. Fuel briquettes made from waste paper were tested in field conditions by one of the tourists, who came up with a method for their manufacture and impregnation. With such fuel, even in the forest you won’t have to look for dry wood chips or pine cones for your mini-pinch stove.

A video tutorial in three parts will teach you the art of converting waste raw materials into effective fuel.

The first video introduces firewood from newspapers. What it is?

Next, watch how kindling made from waste paper burns.

Finally, how to make fuel briquettes at home.

In conclusion - the work of fuel in a real stove on a camping trip.

To the history of the issue

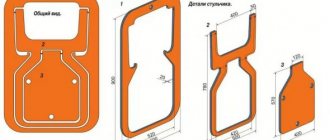

Mold making

But first you need to make a simple mold

(Fig. 1)

. Its design is a welded rectangular box with a removable bottom and lid. Individual mold details and their dimensions are shown in

rice. 2

. Of course, the dimensions of the mold can be changed either up or down - it all depends on the size of the existing heating system.

devices

and him

firebox

Rice. 1 .

Design of a mold for making paper briquettes Holes drilled in the lid and bottom serve for drainage

water

when pressing. Vertical cuts in the side walls of the box are also intended for the same purpose. If the holes in them are made round, this may make it difficult to remove the finished briquettes from the mold. And so that the cuts do not reduce the strength of the side walls, the area around them is reinforced with 10 x 10 mm corners welded on the outside.

Rice. 2 . Mold parts: 1 - side wall (2 pcs.); 2 — end wall (2 pcs.); 3 — removable cover; 4 - removable bottom

Along the lower edges of the side walls, 25 x 25 mm corners are welded on the inside - supports for installing the bottom. After preparing all the parts, the side walls are welded into a rectangular box. Relatively thin-walled parts may “lead” when welded, so it is advisable to make the seams intermittent.

It is better to weld the corners only from the outside, without leaving any protrusions or irregularities on the internal surfaces of the box that could interfere with pressing and removal of the finished product.

Features of use

Sunflower briquette

Before you begin recycling waste on your personal or garden plot and start production, you need to decide on the scope of use of briquetted fuel and calculate the need for the source material.

If briquettes are intended to be used as an alternative, additional fuel for combustion in a stove or fireplace in a country house, then any plant waste can be used as the starting material:

- Sawdust, shavings, wood chips, chopped small branches left after pruning trees.

- Agricultural waste – dry plant stems, straw, seed husks.

- Garden waste that is usually burned or composted - dry grass (weeds), fallen leaves, root crop tops.

- Household waste – cardboard, paper.

Some gardeners use plastic film as an additive to plant matter. However, there are no official recommendations on this matter and the use of plastic waste is carried out at the own peril and risk of the manufacturer and consumer of briquettes.

Clay or starch is used as a binding material.

Preparation of starting material

Briquette press

The main problem when making fuel blocks yourself is the need to grind the starting materials. Of course, when using sawdust, small shavings, or grain husks, this operation is not required. But small branches, shavings, and cardboard waste must be crushed before briquetting until uniform particles are obtained.

For crushing, you can use any household agricultural crusher, in which the hammers are replaced with cutting plates. At a rural farmstead, these devices are usually available and used to prepare feed for domestic animals and poultry.

A city dweller who has a garden or summer cottage will have to find a suitable model in a gardening store. Today, special devices designed for shredding household waste and garbage are also produced.

By purchasing this crusher, a summer resident will be able to use it not only for preparing briquette raw material, but also for other purposes.

What are they needed for

Artificial firewood in an electric fireplace

Many people will wonder why such dummies are needed? Well, firstly, it's a matter of aesthetics. And secondly, you don’t need deep knowledge of stove equipment to notice the difference between a fireplace with an electric heating element and a wood-burning fireplace.

Due to the absence of smoke and rapid heating of the room, electric fireplaces are an advantage when compared with a wood-burning fireplace. But with all this, a certain naturalness of the hearth is lost, its charm and charm are lost. If you add dummy firewood to such a design, the picture of the fireplace changes radically.

This situation is especially relevant for a city apartment, where installing a real fireplace is simply impossible.

Placing decorative firewood

Particular attention must be paid to the placement of firewood in the fireplace niche. You can do this yourself and give the hearth a more aesthetic appearance; it will become more believable. To place a fake log in the fireplace niche, you need to decide on the installation option.

- Place logs in the form of a “house”.

- Arrange the wood in a cone.

- In a chaotic order, as your imagination suggests.

Imitation of firewood looks quite impressive in combination with other decorative elements, such as stones or candles.

If for some reason it is impossible to place artificial firewood in the depths of the firebox, you can place a separate emphasis on the firewood by placing it outside the hearth.

In addition, you can build a firewood shed with your own hands, into which decorative firewood is placed.

With a harmonious selection of stove equipment and decor for it, you can turn the hearth into an object of great attention. The combination of firewood and fire, regardless of whether they are natural or artificial, will add unique charm and comfort to any interior.

Main advantages

Fuel briquettes are a modern type of alternative fuel. They can be used in any stoves, fireplaces, boilers, grills, barbecues. Eurobriquettes are cylindrical billets resembling firewood, or rectangular bricks. Small dimensions allow them to be placed in fireboxes of any size.

What are briquettes made from? Most often, wood is used (sawdust, shavings, dust), but straw, paper, peat, coal, seed or nut husks, and even manure are also used. The composition of eurobriquettes can vary significantly, depending on what technology is used in production.

At the same time, all types of raw materials from which firewood can be produced are natural, absolutely natural. Making fuel briquettes at home will allow you to create an environmentally friendly product that will burn almost completely in the furnace firebox and at the same time emit a minimum of smoke.

A home-made eurobriquette can be used to light a sauna stove or heat a home. Since the raw material is compressed quite strongly and the amount of moisture is minimal, the fuel briquette burns for a long time, constantly releasing a large amount of heat. An interesting point was noticed by people who are already actively using such fuel: if you heat your barbecue with eco-wood and fry food on it, if fat gets on the briquettes, it will not ignite.

For stoves, boilers and fireplaces that burn solid fuel, sawdust briquettes are an excellent option. They flare up slowly, but then burn for a long time and emit a large amount of heat. This is explained by the high density of the pressed wood product. The heat transfer from briquettes significantly exceeds the level of heat obtained from the combustion of even the driest firewood, the storage and drying of which took at least a year.

The humidity of fuel briquettes is 8-9%, dry firewood, in turn, has an indicator of 20%. It turns out that a briquette made from the same wood burns better than the wood itself. This effect is formed due to the fact that when burning, fuel briquettes do not need to evaporate a large amount of moisture.

The briquette burns with a stable fire, without splashes, sparks, or crackles, and the amount of smoke released during combustion can be described as small. It is extremely convenient to put such fuel into the stove, since all products have the same correct shape.

A little trick: if you want to create an intense fire with high heat transfer, you should place fuel briquettes in the firebox at some distance from each other and, conversely, to maintain smoldering, you need to tightly connect all the eco-wood in the firebox.

Like any product, fuel briquettes are not without their disadvantages:

- First of all, it is worth noting that they are very vulnerable to moisture, so they are sold in cellophane packaging.

- Briquettes are not able to withstand mechanical stress, especially products made using RUF technology that are not fired on the outside.

- If you want to start making such things at home, it will cost you a pretty penny, although there will certainly be benefits in the long run. The fact is that you will have to purchase a grinding installation, a dryer and a pressing machine in order to carry out the entire cycle of work with raw materials. With suitable equipment, it will be possible to set up artisanal production of fuel briquettes even in your own garage.

Advantages of pellets over other types of solid fuel

The wide distribution of fuel briquettes, which are also called eurowood and pellets, is due to a whole list of their advantages:

- compact size, which ensures ease of storage and transportation;

- emitting a small amount of smoke and minimal sparking during combustion;

- long burning period (when compared with ordinary firewood, pressed sawdust fuel burns at least twice as long);

- environmentally friendly (compressed from waste materials of natural origin, fuel briquettes do not emit substances harmful to humans and the environment when burned);

- low ash content (the amount of ash formed after complete combustion of pellets does not on average exceed 1% of the total mass of fuel used).

The main advantages of fuel briquettes are long burning and minimum ash

How to make briquettes from newspapers?

Tear the cardboard into pieces, shred the newspapers. Then put everything in a large container and fill it with warm water. The paper will soften and it can be beaten with a construction mixer with special. nozzle. If briquettes are made from sawdust, grinding of the husks is not required.

You can add sunflower seed husks to the newspapers. However, in winter it will be problematic to store husk briquettes. Mice love her.

Sawdust is perfect for newspaper pulp. It contains enough adhesive mass, which will serve as an excellent binder for sawdust.

Everything is thoroughly mixed with the same mixer. Then you need to let the mixture settle a little. Next, put and press under pressure.

Photo: moy-metall.ru/wp-content/uploads/2017/03/press-sokovyzhimalka-samodel-9452.jpg

Photo: moy-metall.ru/wp-content/uploads/2017/03/press-sokovyzhimalka-samodel-9452.jpg

Some people use an old garden press (juicer) for apples and grapes. I looked at Avito, where the press costs from 4,000 rubles

. You can start your business with this press, and then (as your business develops) buy a more expensive and productive one.

Someone immediately buys a press for making fuel briquettes (sold in stores of various modifications). All models solve one problem: compact the mass into a mold. The cheapest press costs from 100,000 rubles

.

So, the mass is put into the press, and excess water comes out through the holes. The result is a finished briquette made from newspapers. Now you need to dry it. This is done in the fresh air.

Image: ochg.ru/wp-content/uploads/2017/02/toplivnie-briketi-svoimi-rukami-1.jpg

Image: ochg.ru/wp-content/uploads/2017/02/toplivnie-briketi-svoimi-rukami-1.jpg

Fuel dries under a canopy for about 7-10 days

if it's sunny outside.

Pellets: what is it and how is it made?

A modern type of fuel that is used for combustion in pellet boilers. Pellets are currently an excellent alternative to gas and other fuels, but many do not know what it is. Heating with pellets is 3-4 times cheaper than gas, but so far the technology for manufacturing such a material does not make it possible to completely replace gas with it. But many people consider pellets as an alternative. Contents What are pellets? History of appearance Environmental factor Classification of pellets Production process Advantages of fuel How to choose high-quality pellets?

Pellets are considered an environmentally friendly fuel

Crushed wood used to make pellets

One of the characteristics of fuel pellets is the amount of thermal energy released, which affects the cost of raw materials

Wood pellets in a vessel near the boiler create some decor in a modern interior

Pellets: what is it?

Externally, fuel pellets look like cylindrical granules. Wood and agricultural waste is pressed into them. Their sizes are standard: Diameter – 6-8 mm. Length – from 5 to 70 mm. Humidity – 7-10%.

“Loose” granules are convenient when using feeding devices in boiler rooms. Due to this indicator, they are successfully used in pyrolysis boilers. If we compare it with firewood, the efficiency of boilers using this fuel is 1.5 times greater. But the size of one pellet depends on the material used for production, the type of raw materials and the scope of use. Note! This type of fuel is actively used abroad, especially for automated boiler houses. Pellets are widely used in both domestic and industrial use. In terms of their thermal conductivity, pellets are compared to coal. In addition, this fuel is environmentally friendly.

Well-dried pellets work more efficiently

History of appearance

Pellet boilers were first used in the USA, where the production of this material began. Although initially the idea of granulation was somewhat different, because in this way it was planned to save space when transporting waste. But quite quickly pellets began to be used as fuel. In Europe, people first started talking about alternative fuels in Switzerland in the 80s. Granules are being produced from wood waste. In the 90s, a real boom in fuel production on an industrial scale developed in Switzerland. Further development took place in Canada, Denmark, Finland, England, and Italy. At the moment, pellet production plants are located directly next to logging and wood processing enterprises. This allows fuel production to continue, and such plants often operate 24 hours a day.

Environmental factor

Buying pellets means maintaining a stable environmental background. They are the result of waste recycling, which means they will not harm the atmosphere or people. It is believed that pellets are part of the CO₂ cycle in the environment, that is, they release exactly as much as the tree absorbed during growth.

In the process of burning pellets, the same amount of carbon dioxide is released as was formed during the natural decomposition of wood . Please note! Waste is used in production, which means that every ton of such fuel keeps trees in the forest safe and sound. And the environment is not polluted by wood processing waste. What is very important is that emissions into the atmosphere from the combustion of such fuel are not as harmful as if coal and diesel fuel were burned.

The chemical characteristics of pellets depend on the raw materials from which they are made

Pellet classification

The price of pellets largely depends on the raw materials used in the manufacturing process. There is such a classification:

Variety of pellets based on the raw materials used for production White pellets - this variety is also called “premium”. They are made from waste wood without bark. The calorific value of such pellets reaches 17.2 MJ/kg. The ash content is almost zero. Such pellets make up about 95% of all that are on the market today. They are suitable for all types of boilers.

The advantage of white pellets is their low ash content. Cleaning the boiler after such raw materials is necessary no more than once a month. Industrial - they contain lower quality wood. In addition to wood waste, they may contain bark and non-combustible particles. In terms of calorific value, they are almost the same as the first type, but the ash content is slightly higher. When using them, the boiler will have to be cleaned more often.

Additional elements in the composition of industrial pellets make their color a little darker. Agropellets - they are made from agricultural waste. Their calorific value is lower - up to 15 MJ/kg, ash content is more than 4%. This means that the boiler will have to be cleaned frequently. Among the advantages of such fuel is their affordable price. They are used primarily to produce heat in large thermal power plants. They are also convenient if boilers have automatic ash removal. They cannot be used in all boilers, but only in those designed for such fuel.

An economical option for standard quality fuel, which can only be used in special boilers

Production process

Pellet production is a multi-stage process that requires both material and time costs. But first of all, raw materials are delivered to the plant. Raw materials can be: Bark, sawdust, wood chips, and other logging waste. Agricultural waste: corn, straw, sunflower husks and others.

Pellets for heating boilers from sunflower husks The production process consists of the following stages: Coarse crushing. Drying. Fine crushing. Mixing and water treatment. Pressing. Cooling, drying. Packaging.

Waste wood chips are used to make wood pellets

Primary crushing

It is also called coarse crushing. During the process, grinding occurs to dimensions of 25 x 25 x 2 mm. This process ensures rapid drying of raw materials to the required moisture content. Since such material is stored on a concrete floor to prevent mixing with sand and stones, it is fed into the grinder using a scraper device.

Shredding wood waste is the first stage in the production of pellets

Drying

Now the raw material has a moisture content of 15%, which is not suitable for the next stages, since it will not be pressed well. And pellets that contain so much moisture are not suitable for boilers. The optimal humidity range is from 8% to 12%, but the correct pellets have 10%. In order to dry the primary crushed raw materials, drum belt dryers are used. The choice of one or another drying method depends on the type of raw material, its quality and other factors.

Raw materials for the production of pellets with inappropriate humidity require additional moistening or drying. Please note! This process is energy-intensive, because in order to dry 1 ton of raw materials, at this stage you need to burn 1 m³ of firewood. In order to reduce the cost of this process, bark or sawdust is burned into the dryer firebox.

Secondary (fine) crushing

In order for the press to work, the particle size should not be larger than 4 mm, so repeated grinding is used. For this purpose, hammer mills are used, which are excellent for crushing fibrous shavings and sawdust.

Sawdust prepared for re-crushing

Water adjustment, pressing

Since the raw material was dried in the previous stages and currently has only 8% moisture, it will be difficult to glue it together. To do this, the material is moistened with water or steam. The latter is necessary when pressing hard wood waste. If the raw material is soft wood, then additional moisture is quite enough. As for pressing, equipment for pellets has different matrix shapes - flat and cylindrical. The diameter of the matrix itself is about 1 meter, and the power is measured at 500 kW.

Presses from some manufacturers do not require additional steam due to their design features

Cooling, packaging

In order to obtain high-quality pellets, they must be well cooled. This process helps dry the granules. After the press they have a temperature of +70-90 ⁰С. After this process is completed, they are sifted and packaged. Since pellets are loose raw materials, they are often stored in bulk, but this can negatively affect the quality of the material, as it will gain moisture. Therefore, manufacturers package and recommend storing fuel in large big bags. The highest quality pellets that you can buy are packaged from the factory in 20 kg bags.

The packaging of granules depends on the storage system that the consumer has: in bulk, in big bags or in small packages

Fuel benefits

Pellets have a number of significant advantages: They are environmentally friendly raw materials that do not produce increased CO₂ emissions into the atmosphere. Low risk of spontaneous combustion due to the fact that they do not contain spores or dust. The pellets are denser than wood and have lower moisture content, which provides more heat from combustion of the same volume as wood. Due to standard sizes and flowability, it becomes possible to fully automate the heating process. The most common types of pellets have little waste, which means that you won’t need to clean the boiler every day. According to reviews from those who use this fuel, cleaning is needed no more than once a month. Only at first glance this fuel does not seem to be the most affordable. In fact, if we recalculate the amount of thermal energy, then pellets will be the most efficient fuel in this regard. Easy storage of raw materials - minimum space and no odor. Simplicity and cleanliness of transportation. High boiler efficiency within 96%.

A cross-sectional example of how a pellet boiler works

Note!

If we talk about the disadvantages of the material, then this is the need to constantly keep stock in the warehouse. Also noted as a disadvantage is the danger of burning pellets if the raw materials from which they were made are taken from areas contaminated by radiation. Indeed, there is such a risk, but manufacturers who have been working in the market for a long time will not risk their image and sell frankly dangerous material. Therefore, you need to carefully choose the manufacturer of the granules.

Wood pellets are practically not subject to self-ignition, since the composition does not include dust and spores. In addition, they do not cause an allergic reaction

How to choose quality pellets?

The importance of choosing high-quality pellets is that only such pellets can provide the declared amount of heat. Their ash content parameter will also be within the presented limits. The use of low quality fuel leads to accelerated wear of the boiler.

Pellets provide high calorific value compared to wood chips or firewood. When choosing, you need to pay attention to: Size. And not only the dimensions of the pellets themselves, but also the presence of broken and crumbled ones. There should be no trash in the package, and if it is found in significant quantities, then it is not worth buying such fuel. The surface of the pellet should be smooth and shiny. If the material is of poor quality, then roughness will be clearly noticeable. Pellets must be hard and dry, only these should be used. It is difficult to break a high-quality pellet; under no circumstances should it crumble in your hands. Another way to check the quality is to throw fuel into water, and if the pellet sinks, then it’s good, but if it floats, then it’s better to look for another fuel.

The correct shape of the pellets allows them to be easily transported and reloaded, as well as poured through special sleeves. Using pellets is a convenient and environmentally friendly solution. It is not surprising that almost all of Europe has already switched to such fuel. Source: zen.yandex.ru

Production

To produce briquetted fuel for heating a summer house or garden house, you will need crushed waste and clay. They are mixed in a ratio of 10:1, adding water little by little until a paste-like mass is obtained.

The quality of combustion will depend on how evenly the initial components are mixed, so mixing is best done using a household construction mixer (concrete mixer).

Using special equipment for the production of small batches, it is necessary to make a cellular form. For trial batches, the mold can be put together from boards. The size of the cells is chosen arbitrarily, based on the desired form of briquettes.

Some summer residents press the mixture in old pots, boxes and other unnecessary household containers. However, a rectangular shape is preferable since rectangular fuel blocks are easier to store.

The wet mass is placed into the cells of the mold and compacted. The quality of homemade fuel depends on the degree of compaction.

To prevent the briquettes from crumbling and falling apart in your hands, it is advisable to lay several layers of newsprint on the bottom of the mold (or under the mold when using cells without a bottom).

Drying is done naturally in air. On sunny summer days, this process does not take much time. After removing the briquettes from the mold, they are placed under a canopy, in a stack with gaps, where they are dried in a draft.

Waste briquetting device

Homemade press

If you plan to use heating briquettes for winter heating of a country house in winter or as an alternative fuel in an individual house, it is quite labor-intensive to make them manually.

In this case, it is advisable to make a simple machine that will speed up and facilitate the work. Today, various modifications of machines are available for sale. They differ in functionality, the number of cells in the forms, and the type of drive - manual or mechanical.

All models have one thing in common - they allow you to mechanize the most labor-intensive process - compacting the wet mass in the cells of the mold.

The simplest machine is a metal frame welded from a corner, on which a wooden tabletop painted with moisture-resistant paint is fixed. A “P”-shaped bracket is welded to the frame, between the uprights of which a swinging lever is fixed - a rocker arm, the length of which determines the compression force.

A punch is hinged on the lever, the dimensions of which are slightly smaller than the dimensions of the cells. A mold filled with briquette mass is placed on the countertop and pressed with a punch until the briquettes are given the required density. Moving the mold along the tabletop, the pressing operation is repeated for each cell.

Some “craftsmen” abandon the welded structure and knock together a bracket and frame from boards and thick bars. It all depends on the volume of production.

In order for the press to last long enough, after each pressing operation it should be cleaned of adhering mass.

If the gardener has the opportunity to obtain or make a vibrating plate, then a press is not required. The sawdust-clay mass is compacted due to vibration.

Manufacturing technology

The technology for making fuel briquettes at home practically does not depend on the raw materials used for pressing:

- The raw materials from which it is planned to make fuel briquettes are cleaned of foreign impurities and crushed.

- Clay is added to the crushed raw material mass, which will act as a binder. Instead of clay, you can use wallpaper glue, soaked paper or cardboard as a binding component.

- Water is added to the raw material mass to make it more plastic and pliable for pressing.

- The mixture, consisting of the main raw material, water and a binder, is placed in portions into the matrix cavity, and then pressure is applied to it using a punch connected through a rod to a lever, screw or hydraulic power mechanism. When applying pressure to the raw material mass from which the fuel briquette is formed, it is necessary to ensure that water comes out of it (the more, the better).

- After the fuel briquette is formed, it is removed from the internal cavity of the matrix and dried in the open air to such a state that the humidity of the product does not exceed 13%.

Briquette production technology

To learn in detail how to make fuel briquettes with your own hands, we recommend watching the corresponding video.

Stage 2. Choosing a room - what should it be like?

And the room should be chosen in such a way that it can not only accommodate all the necessary equipment, but also store raw materials and finished products. The area of such a room directly depends on the scale of future production, but, for example, a minimum of 55-60 m2 is required for pressing.

Attention! When arranging the premises, carefully monitor the quality of ventilation of the area where pressing is planned, as well as the fire extinguishing system and the reliability of electrical networks.

You can make briquettes for the firebox yourself ↑

Briquettes are often made with your own hands using a simple press.

German equipment of the RUF brand for the production of fuel briquettes is widely known

The production of briquettes from waste paper and printing waste is popular:

Most often, do-it-yourself fuel briquettes are made from sawdust, straw or paper as the most common and therefore affordable types of raw materials.

This topic of making homemade fuel briquettes is of particular interest to gardeners - many are not averse to heating their greenhouses and garden houses in this way, especially since pasture is usually available in garden plots.

Necessary equipment

Despite the relative ease of obtaining fuel, you still have to acquire some equipment. Or adapt existing ones to new needs. What you will need:

- Chopper. You can’t do without it, because the finer the raw material, the denser the finished briquette. And when making it with your own hands, materials of various fractions are used. You won’t have to spend money on purchases if your farm has a device that chops vegetation to send it to compost. Inventors with skillful hands adapt an old activator-type washing machine for a shredder - they change the activator itself with knives;

- Any container where the raw materials will be mixed before being placed in the matrix. It would be a good idea to supplement the “trough” with a miniature concrete mixer or construction mixer. In the absence of both, get ready for hard physical work of kneading raw materials;

Fuel briquettes made of paper ↑

We often have waste paper accumulating in our house, which we don’t know what to do with. Of course, you can sell it for 2 rubles per kg. But this money is unlikely to be enough for you to buy fuel for the winter. But from the same paper you can make excellent fuel in briquettes with your own hands.

The technology for making paper briquettes for fuel is simple, it is well developed and tested. The burning duration of such briquettes is about 2 hours; as for the calorific value, it is even significantly higher than that of coal briquettes. And there is very little residue in the form of ash after combustion - approximately 5% (versus 80% that remains after burning simple newspapers). So, as we see, there are only advantages. Unless it will require time and some of your own labor.