When the question arises of what to build from, many people are confused due to the wide variety of materials, further methods of finishing them and construction technologies. Surely many in the process of choosing materials will hear about profiled timber. In this article you will learn what it is, all the intricacies of assembly, pros and cons, as well as recommendations for selection and construction. Unlike other wooden materials for the construction of buildings, construction from profiled timber is facilitated by the fact that it has ridges, locks and grooves. This allows you to stack the beams together very tightly, saving on thermal insulation. By the way, you can make a beautiful and practical gazebo from timber.

[contents]

Types and sizes of profiled timber

The appearance of the profiled timber and its other technical qualities must comply with GOST 8242-88. In this regard, the variety of options can be divided as follows:

- by size;

- by structure;

- by appearance (sides);

- profile type;

- humidity.

The dimensions of the profiled timber are made according to the needs and whims of the customer. As for the standards, the beams go on sale with a thickness of 100, 150 and 200 mm. Standard sizes of profiled timber according to GOST: 100x100, 100x150, 150x150, 150x200, 200x200.

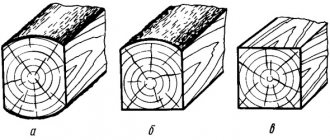

According to the structure, profiled timber can be:

- made from solid logs;

- glued;

- warm or double (glued with increased thermal insulation, suitable for latitudes with low temperatures down to -50. The price is lower than that of glued. This is a new product on the building materials market).

By appearance:

- straightforward;

- one of the sides is D-shaped. It creates an imitation of a rounded log.

Profiled timber can have the following profile:

- from one thorn;

- of two thorns;

- with beveled bevel;

- with a comb (many spikes);

- Finnish It has a wide groove at the bottom and two tenons at the top. Thanks to this, insulation is practically not required and is not visible, the house is well protected from winds and frosts.

Comb profile.

For houses, it is advisable to use profiled timber with a comb or Finnish profile. For lighter structures for household purposes, beams with 1-2 spikes are suitable.

In terms of humidity, profiled timber can be:

- dried;

- natural.

The shrinkage of profiled timber with natural moisture content is much higher than that of dried timber. But many people buy it because of the lower price. Dry, chamber-dried profiled timber is processed and does not crack; houses made from it can be put into operation immediately after the construction of the structure.

Glued laminated timber

Glued laminated timber consists of lamellas glued together, which are well dried and free of defects. Thanks to this, there is practically no shrinkage after the construction of the house and you can move into it in the same season, without waiting for the material to dry out and shrink.

Additional benefits:

- attractive appearance, no additional finishing required;

- high thermal insulation of the material;

- impregnation against rotting;

- impregnation against fire;

- has the best performance characteristics among all lumber;

- may have a D-shaped side for rounded timber.

The price of a house made of solid profiled timber with natural humidity of 75 m2 starts from 1.5 million Russian rubles. The same area, but made of laminated veneer lumber will require a cost of 2 million Russian rubles. The difference will not be too big after the solid beam is insulated and the finishing is done. All this is not required with glued profiled timber.

Warm (double) timber

Warm (double) timber is in many ways similar to laminated timber, since it also contains multi-layer dry lamellas, but between them there is extruded polystyrene foam. Thanks to the gluing of these materials under high pressure and their properties, a unique building element is obtained that looks like an ordinary profiled beam, but has much higher thermal insulation. Such houses are not afraid of temperatures down to -50, so the material can be used even in the Far North without large additional costs for insulation and with low heating costs in winter.

The price of such double timber is lower than that of glued timber, but there is also a small “but”: not everyone agrees with the name, since the structure of the material is closer to sandwich panels than to timber, and is not 100% environmentally friendly. Another important point: you should take a responsible approach to the choice of material so that it is well dried.

Advantages and features

The advantages of profiled timber include:

- Price. Profiled timber with natural humidity has an acceptable cost. And the need to wait for shrinkage allows you to divide the total costs into parts according to the time they are needed.

- Long service life.

- Durability and reliability.

- The structure of the log with a profile greatly simplifies construction and reduces insulation costs.

- Breathability. Solid wood timber does not lose its characteristics during processing. But when purchasing laminated veneer lumber, you should make sure that the adhesive base is safe.

- Natural, environmentally friendly material. Allows you to create a unique microclimate in the room; tar vapors have a positive effect on residents.

- Aesthetics. Due to the fact that the material has a smooth and even surface, the corner elements harmoniously complement the overall appearance of the log house - the log does not require the use of decorative finishing inside and out.

- Low thermal conductivity, provided the assembly technology is followed and high-quality insulation is used.

- Uniform shrinkage and resistance to deformation.

- A reduced percentage of humidity and making logs from the core part of a tree trunk can reduce the number of cracks during shrinkage.

- Easy to assemble at home. The tongue-and-groove connection simplifies the process and allows you to assemble the house in 1 - 2 months.

- Corner joints made under production conditions reliably secure the crowns.

- Possibility of building structures of various shapes and sizes. Standard bars are made 6 meters long, but can be made to the required length upon request.

- Repeated caulking of the walls is not required, because the ridge lock eliminates the possibility of gaps appearing between the crowns.

- The construction of houses from profiled timber can be done on a columnar or shallow strip foundation.

- The laying of communications (electrical wiring, pipes) can be provided for at the manufacturing stage. For this purpose, technological holes and channels are drilled using special machines.

Disadvantages of profiled timber:

- Long shrinkage period. At the same time, the use of heating and heating devices can lead to uneven shrinkage and an increase in the number of cracks.

- When cutting a log, the structure of the growth rings is disrupted and if they are not treated with antiseptics, the process of rotting may accelerate.

- Formation of cracks during drying. On a square-section log, they appear on all sides, and if the cross-section is rectangular, then mainly on the wide sides located inside the wall.

- Low resistance to insects, fire and weather conditions. The problem is easily solved by using fire-retardant impregnations. After complete drying, they do not emit toxic compounds and pose no danger to humans.

- Material, even with a cross-section of 200 x 200 mm, when used in winter or in northern regions, requires additional insulation from the facade.

- The need to use insulation in inter-crown seams.

A significant disadvantage of a house made of profiled timber is the impossibility of carrying out redevelopment or superstructure work.

When choosing a material you should remember:

- timber structures are more durable than those made from profiled timber;

- the evenness of the sides, to check it is enough to place the beam on a flat base;

- the intervals between annual rings should be equal, this will avoid deformation;

- uniformity and uniformity of surface color. If there are darker areas, this may indicate the presence of internal tension and a possible change in shape in the future.

Analyzing the described pros and cons of profiled timber, we can say that in comparison with similar wood materials, it is very popular due to the optimal combination of quality characteristics and affordable cost.

Disadvantages of profiled timber

Profiled timber has much fewer disadvantages than advantages:

- It takes quite a long time to dry out (shrinkage). This delays the moment of using the house. The use of additional heating devices will make the shrinkage uneven and increase the number of cracks.

- As it dries, cracks appear. This is especially noticeable on square beams - they form on all sides, while on rectangular beams this problem is noticeable only on the wide side, which is usually located on the inside. But this does not impair the thermal insulation properties of the profiled timber.

Chamber drying

Typically, chamber drying requires additional equipment and strict technical compliance with all production rules. The chambers in which the material is dried must be equipped with special heaters, as well as fans. These conditions are the most optimal for drying timber.

All drying work is fully automated and for any section or type of wood, its own specific mode is set. Any mode has a separate temperature and a separate time period. The master only sets the initial moisture content of the wood and the section with the final moisture content that needs to be obtained. A specialist, namely a technologist, constantly monitors the process and measures the moisture content of the wood from time to time. It should not exceed 20%.

Chamber drying technology is used with success, both in Europe and here in Russia. This method has proven itself excellent among many specialists working with wood. It is possible to dry profiled timber using a chamber method in just 3 weeks. If the manufacturer claims that this work can be done in 20 hours, then this is complete absurdity.

How to choose high-quality profiled timber?

A house made of profiled timber is not a cheap pleasure, so you don’t want to get into trouble because of low-quality material. How to choose?

Firstly, we advise you to immediately refuse the services of intermediaries. They are not responsible for the quality of materials, but add their percentage to the cost. How to determine that you are communicating with the manufacturer?

- You are invited to watch the production without any problems.

- They can show objects under construction or already constructed.

- A large selection of types of profiled timber, the ability to order individual sizes and voicing the price per cube in this case.

- You are warned about the disadvantages of profiled timber with natural moisture.

- When purchasing, an agreement is concluded with clauses on quality guarantees and liability on the part of the seller.

Secondly, when purchasing profiled timber, you should pay attention and choose:

- size. The larger the diameter of the timber, the better it will protect from the cold;

- type of wood;

- quality of equipment from the manufacturer. This can best be assessed by the finished objects made from profiled timber from this sawmill.

Thirdly, before buying materials, you should pay attention to:

- production location. If it is far away, then transportation costs will be very high;

- licenses, quality certificates, diplomas and diplomas;

- production of products in accordance with GOST or TU;

- reviews about the manufacturer from real customers.

A few more secrets on how to choose high-quality, inexpensive profiled timber with natural humidity. To do this, pay attention to:

- evenness of all surfaces of the timber. This is easy to check: place it on a flat surface with all its edges. If there are no curves then everything is fine;

- the distances between the annual tree rings must be the same, otherwise it will bend during the drying process;

- The color of the surface should be uniform and uniform. The presence of color contrast indicates internal tension, which will lead to deformation.

It is impossible to determine humidity by eye or touch, but if you see that the profiled timber is completely fresh, just cut and meets the above parameters, then buy it and dry it yourself. To do this, it is necessary to stack all the beams in rows with veins for air blowing. The material must be protected from moisture from below and above. Additionally, it is advisable to whiten the ends and protect them from direct sunlight - this will protect them from the occurrence of a large number of cracks.

Briefly about the important

For the construction of houses from profiled timber they use

coniferous wood - pine, cedar, spruce. In this case, it is better for the tree to be cut down in the northern regions, because... The peculiarities of the northern climate reduce the natural humidity of the material. Which will further lead to a decrease in drying time and a decrease in the number of cracks on the surface.

A distinctive feature of profiled timber is the presence of auxiliary fastenings on the technical sides, made in the form of ridges, grooves or locks. Due to them, a reliable connection of the links, their tightness and thermal insulation are ensured.

When choosing a wooden material, special attention should be paid to humidity, because... this can have a significant impact on the quality of the building and the method of construction. The process of shrinking timber with natural moisture can last from several months to two years.

Lumber that has undergone fire-bioprotective treatment in production in a high-pressure chamber is less susceptible to negative influences and will significantly increase the service life of the house.

Assembly of houses and baths from profiled timber

A bathhouse made of profiled timber or a house is built in 4 stages:

- Construction of the foundation. Profiled timber is not a very heavy material, so a shallow concrete strip or a bored-in-place foundation will suffice. Reinforced concrete slabs, blocks and screw piles are also used. The latter option is popular due to the fact that it does not require additional waiting for the foundation to completely harden.

- Wall installation. At this stage, we will dwell later in a little more detail to explain the technology of assembly from profiled timber. During the construction of the walls, waterproofing of 1 crown and insulation of the structure is done.

- Installation of sheathing under the roof and installation of the roof. The technology is no different from any other design. The main thing is to correctly calculate the load.

- Finishing. This includes the installation of doors and windows, installation of floor coverings, supply and connection of communications. Decorative finishing is practically not required. This is done only at the request of the owner.

For what purposes is it suitable?

For the construction of a wooden house, chamber-drying timber is considered preferable, since it practically does not create shrinkage and is less susceptible to warping than untreated timber.

These characteristics save time, since it is possible to begin finishing the premises immediately after installation.

Territory of use of chamber timber in house construction:

- house building frame;

- external walls with load-bearing characteristics;

- columns and other supporting elements;

- roofing system;

- interfloor covering;

- interfloor stairs.

Additionally . Chamber timber is often used as interior and exterior home decor. It is used in finishing, so it must be grade 1. In order to preserve the presentation of the product, it is transported in a protective film and closed trucks or other transport cargo equipment.

Technology for assembling profiled timber

The main advantage of profiled timber is the ease of assembly of the entire structure and reduced costs for thermal insulation. However, in order to build a house from this material, you must understand the process and know its features.

The assembly of profiled timber begins with the installation of the first crown - the basis of the entire structure. In order for it to last as long as possible in its original form, waterproofing should be done between it and the foundation. Another good option for the durability of the first crown is to use expensive but very durable wood, larch.

After waterproofing, but before the first crown, you should put one more protection - a lining beam. Its width should correspond to the width of the beams used, and its thickness should be 100 mm. It is also advisable to use larch for it and must be treated with anti-rotting compounds!

The lower crown is beams with a flat bottom side and a profiled top side. A 5 mm jute seal must be placed between the beams.

During the construction of the structure, all horizontal wooden planes should be treated with an antiseptic! The insulation is laid after it has dried.

The connection of profiled beams is carried out using dowels. This allows the beams to be well bonded to each other and achieve uniform shrinkage, which is very important when using materials with natural moisture.

The dowel (spike) can be used with a round or square cross-section. Wood, plastic and metal are available for sale. For profiled timber, it is best to use wooden dowels.

When connecting profiled beams with dowels, you should adhere to the following recommendations:

- connect no more than 2 bars;

- distance between elements – up to 1.5 meters;

- the pins should be arranged in a checkerboard pattern;

- holes for the tenon are drilled vertically clearly along the diameter of the dowel itself (the maximum allowable gap is 1 mm) and along the length of about 1.5 beams, so that the house does not warp when shrinking (the difference between the length of the hole and the tenon is from 20 mm).

It is better to rest the floor beams on the foundation. This will make it easier to replace the first crown if necessary in the future. If larch is used, the floor beams can be cut into the first crown.

A little about the shrinkage of profiled timber

The most accurate data on the percentage of shrinkage of profiled timber can be gleaned from GOST 6782.1-75. To make shrinkage more gentle, it is recommended to build a house or bathhouse in winter. Then the drying of the logs will take place under softer conditions with minimal deformation of the beams.

Technical characteristics and parameters

Dry lumber has better stable characteristics than untreated wood. In addition, it is much less susceptible to warping and splitting during use.

In higher grades of wood, especially hardwood, the drying process improves its basic characteristics: increased rigidity, bending strength and compressive strength. The frost resistance of the timber is very high; material with a thickness of more than 150 mm does not freeze in the harshest Russian winters .

Main characteristics of chamber timber:

- humidity, not higher than 12%;

- thermal conductivity coefficient from 0.1 to 0.4 kcal/m*grad*hour, depending on the thickness of the timber;

- shrinkage is not higher than 2% of volume versus 8% of lumber with natural moisture;

- strength 420 or 280 kgf/cm2, respectively for pine or spruce.

Ways to save on construction from profiled timber

To make construction from profiled timber cheaper without sacrificing quality, use the following tips:

- the cheapest and most quickly erected suitable foundation is on screw piles;

- do not forget about insulation of the roof and ceilings. For this you can use 50-100 mm mineral wool;

- install wooden windows instead of plastic ones;

- use profiled timber 100-150 mm thick.

To economically operate such houses year-round, it will be necessary to reduce heat loss. The facades will need to be insulated. This is done 1.5-2 years from the moment the house is put into operation (after initial shrinkage). Most often, siding or lining is used for cladding.

There are other ways to save money, which, however, can negatively affect the quality of the structure (corners without tenons, assembly with nails, unqualified carpenters).

To ensure that your home lasts for many decades and you are completely satisfied with it, choose high-quality materials and qualified construction teams who will complete everything on a turnkey basis in a short time.

Main advantages and disadvantages of the material

When choosing profile timber for building a house or cottage, the important advantages are undoubtedly:

- Easy and straightforward assembly, requiring minimal labor.

- High quality buildings with low financial costs for home insulation.

- Conscientious sanding of the wood is sufficient to finish the outer surface of the timber.

- Environmental friendliness of timber.

The disadvantages include:

- When working with such material, not every design idea is feasible. In addition, once the construction work is completed, it is no longer possible to redesign the rooms.

- Under the influence of sunlight, light wood can darken; to avoid this effect, it is necessary to periodically impregnate the material with solutions.

- In frosty zones, where temperatures reach low levels, profiled (dry) timber requires mandatory insulation on the outside of the house.

Often, mineral wool and lining or siding are used as additional wall cladding.

Environmental Safety

Home is, first of all, a place where we feel completely safe. And in this case we are talking not only about the fact that the house must be strong and reliable enough so that we can not be afraid of the visit of uninvited guests or the rampant elements. Being within our own walls, we should not fear for our own health.

Wood has always been and still remains a symbol of environmental friendliness. It is quite predictable that houses built from edged or profiled timber will be out of competition from the point of view of environmental safety. The ventilation of such a house is natural (subject to the use of natural sealing materials, for example, jute), it is very easy to breathe in it, and the humidity in the room will always be optimal.

The use of laminated veneer lumber in the construction of residential buildings gives rise to a lot of controversy and discussion. Firstly, glue is used in the production of such timber. As a rule, for these purposes, adhesive compositions based on PVA are used, which, unlike phenol-formaldehyde resins used in the production of wood-based panels, is considered harmless to health and the environment.

Despite the fact that the adhesives used comply with various standards, from the point of view of environmental friendliness, such timber is inferior to conventional timber, which does not contain any adhesives in principle. In addition, it would not be a bad idea to ask yourself the question: are you sure that the manufacturer of the timber, the batch of which you are going to purchase, did not violate technology in order to reduce the cost/speed up the process?

Secondly, during the production of laminated veneer lumber, lumber is impregnated with various antiseptic, insecticidal, fire retardant and other compounds. Of course, you will have to treat the walls of a house, even built from edged or profiled timber, with these protective impregnations in order to prevent its premature destruction as a result of exposure to adverse external factors. However, there you will apply protective compounds for the most part to the outer walls, but here the timber is saturated with them in its entirety.

Thirdly, due to the tight joining of the beams and the absence of gaps between them, due to the multidirectional arrangement of wooden fibers and the use of glue, the natural air exchange in a house made of laminated veneer lumber is disrupted, and the vapor permeability of the walls is reduced. To improve the indoor microclimate, it is necessary to equip the house with wall inlet valves or a forced ventilation system.

In a word, despite the compliance of laminated veneer lumber with European standards and Russian GOSTs, there is still room for doubt. If your family has small children, allergy sufferers, asthmatics, or people with other chronic diseases, give preference to edged timber or profiled timber, which is definitely better in terms of clean air inside the house.

Edged and profiled timber lead the list of environmentally friendly materials. In this regard, many complaints can be made about laminated veneer lumber.

Work of qualified specialists

In order not to be upset with the result later, it is recommended to abandon independent construction, the work should be left in the hands of professionals, and hire a team of builders. The cost of their work will not be as high as if you damage the material during improper construction and you have to buy everything again. What the contractor usually offers:

Professional selection of foundations for your project. There is no point in arguing that another type suits many owners and will cost much less than the recommended one. A decent builder will never undertake the construction of an initially doomed house. Surveyors have an excellent understanding of the characteristics of the soil, so they select the foundation not because of their whim, but according to generally accepted factors.