Michel

21236 0 24

Michel July 31, 2016Specialization: plumber with 10 years of experience, computer repair specialist, powerlifting coach. I have extensive experience in construction, interior decoration, and making homemade furniture. Hobbies: sports

In this article I am going to talk about indoor and outdoor gas pipes. We have to figure out which pipes can be used for gas, how to install them correctly and check for leaks, how to calculate the flow rate when a gas pipeline ruptures, and according to what regulatory documents the pipe for its installation is produced. So, let's go.

Gas wiring is made of copper.

What is a gas tank?

The simplest and most economical way to heat a country house is not with electricity, but with the most common gas. But connecting directly to a centralized supply system for this type of fuel is not possible everywhere, and sometimes costs a lot of money. The time required to connect to such networks can sometimes be quite long; they depend on the remoteness of the highways, as well as on the complexity of the terrain where the house itself is located. Also, do not forget about the preparation of a number of documents - bureaucracy is thriving here. Sometimes, just because of the need to fill out the necessary papers, you have to wait for years for gas to arrive in the house.

Gas holder for a private home

In this case, the easiest way is to think about the possibility of autonomous gasification. One of the elements of such a system is a gas tank , which will allow you to have gas on your site without connecting to centralized systems and without serious red tape, and will also make it possible to always have gas in your home.

Liquefied gas from a gas tank is used for heating the house, heating water

A gas holder is a fairly capacious metal container designed for storing gaseous substances, mainly (in domestic terms) to save a mixture of butane and propane, that is, the same gas that is used to operate kitchen stoves and the heating system in the house. You can call a gas holder a large gas cylinder, from which it differs only in its very large dimensions and is installed once, regularly performing its task for many years. This “cylinder” does not even need to be taken to a gas station - just call a special gas station attendant who will come and fill the container with gaseous fuel.

The principle of operation of a gas holder in a private house

On a note! Special structures for gas storage appeared in Europe in the 19th century. True, gas was stored in them only on an industrial scale. Now such containers can be placed right next to the house.

The gas holder is usually made of high-quality steel with a thickness of at least 5.5 mm (this indicator is taken from GOST), treated with special compounds that prevent corrosion. Thus, the tank will last a very long time, about 20 years. The gas holder also has special sensors that will show how much gas is in it at the moment, what is the pressure in the cylinder. The equipment has a filling valve, a tank filling sensor and valves for connecting gas distribution. Thanks to a well-designed system, the gas holder is completely safe for home use.

The gas holder is completely safe for home use

The gas tank is always located outside the residential building, at a certain distance from it. Gas is supplied through laid pipelines to the house, where it is used to operate a heating boiler, gas furnace, etc. Typically, the gas tank is buried underground and does not even take up space on the site. It is capable of containing several thousand liters of gas liquefied under pressure of 6 atmospheres.

On a note! For a private home, a gas holder with a volume of five cubic meters is most often purchased. This volume is enough to heat a 150 m2 house all year round.

Dimensions of VPS gas tanks

Main classification of gas pipelines

The category of a gas pipeline, depending on the gas pressure, is one of the most important criteria that has a significant impact on the choice of pipe material.

There are 5 main categories of gas network:

- I-A - design with the highest pressure exceeding 1.2 MPa. The diameter of the pipe is 1000-1200 mm, the purpose is to connect thermal stations, turbines and steam plants.

- I - system with high pressure, ranging from 0.6-1.2 MPa. Its purpose is to transport gas and arrange gas distribution points.

- II - pressure is lower than in the previous category, but is still considered high. It fluctuates in the range of 300-600 kPa. The diameter of the pipe is 500-1000 mm, the purpose of the gas pipeline is to deliver gas from gas distributors to industrial facilities, residential and social buildings.

- III - medium pressure design with values of 5-300 kPa. The use of pipes with a diameter of 300-500 mm is allowed. Its purpose is to transport gas from the pipeline to gas distribution points, which are located near residential buildings.

- IV - system with minimal pressure (less than 5 kPa). The diameter of the pipe does not exceed 300 mm, the purpose is to deliver gas from the inlet gas pipeline to residential buildings and directly to the final gas consumption devices.

In addition to the category of the gas pipeline and the pressure value, the choice of pipes is also greatly influenced by the features of their installation and operating conditions - external or internal installation, above-ground or underground.

If they are laid in the ground, then you will have to take into account such factors as the depth of freezing, the density and thickness of the soil layer, the likelihood of corrosion processes, and the presence of stray currents.

A ground or air gas pipeline is characterized by ease of installation work to create it, but additional care is required for reliable operation

To ensure stable and long-lasting operation of the gas pipeline, it is necessary to take into account the features of installation and operation at the stage of preparatory and design work, and perform all the analyzes that require gasification standards.

Advantages and disadvantages

A gas holder is a convenient piece of equipment, the advantages of which have already been appreciated by many users. It boasts the following advantages of use:

- it is economically beneficial (gas heating costs are low);

- gas is an environmentally friendly type of fuel (does not leave behind combustion products);

- The home gas supply system operates silently;

- servicing a gas tank is relatively cheap;

- Often you won’t have to fill the tank with gas if the volume is correctly calculated;

- gas tank - safe equipment;

- it is usually located underground and does not take up free space on the site (you can even organize a garden on top of the gas holder).

A gas holder for a private home allows you to supply gas to any room

The gas holder also has disadvantages of use. So, installing the tank itself is still quite expensive, but you will have to spend more money on supplying gas to the house. A gas tank is expensive, but the costs pay off very quickly. It is also important to understand that the equipment must be installed correctly, otherwise it will not be safe for the user. So it is better to entrust all the work to specialists. It is also important to understand that it is not easy to find high-quality certified fuel to fill your tank in all regions.

Horizontal underground gas tanks

Important! You should not buy a used gas tank. This is due to the fact that used equipment does not exclude the possibility of gas leakage.

Brands of polymer pipes

The most common types of plastic pipes for gas include:

- High and low pressure polyethylene pipes

. The brand of products intended for gas transportation is indicated by a yellow stripe. The products are suitable, in addition to gas transfer, for the installation of sewerage circuits and cold water supply. - Polyvinyl chloride pipes

. They are distinguished by greater strength compared to the previous type. Suitable for gas supply and sewerage systems. They are not used as water supply elements, since upon contact with incoming water they release chlorethylene, which is hazardous to health. - Polypropylene pipes

. Polypropylene is the best option for making gas pipes. It is tougher than polyethylene, does not emit toxic substances like polyvinyl chloride, and does not interact with most aggressive environments. Thus, products made from this material can be used in almost all types of home communications.

The listed materials have their advantages and disadvantages.

For example, small-diameter pipes made of polypropylene and polyethylene are produced 50-500 m long in the form of coils; they weigh 2-4 times less than steel products.

Selecting a gas tank: types of equipment

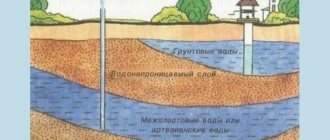

Gas tanks can be divided into several types depending on how and where they are installed. So, the equipment can be both underground and aboveground , and the first option is much more popular than the second, since it will not interfere with the site and freeze. The underground tank is installed underground so that the layer of soil above it is at least 60 cm. Otherwise, there is a risk of freezing of the equipment or the possibility of causing mechanical damage to the cylinder. You can easily install a tank with a volume of 1.5-10 thousand liters underground, which will not even be noticeable. Only the neck remains on the surface, and this is the main advantage of such models.

Underground gas tank

Aboveground gas tanks can also be large, but they will definitely spoil the appearance of the site, and therefore are usually small. However, in some cases the installation of such equipment is justified - for example, when for some reason the tank cannot be installed underground, but you want to have an autonomous gas supply system. An above-ground tank must be able to withstand high temperatures because it may be exposed to direct sunlight. But it is still recommended to keep the equipment out of harm’s way.

On a note! If you plan to install an above-ground gas tank, but large volumes of gas are needed, then the easiest way is to install several cylinders of modest size and connect them together into a single system.

Aboveground gas tank

Gas tanks are not only stationary, but also mobile. True, their volumes are small (only 500-700 liters). But such a tank can be transported by a regular car and even taken to a gas station yourself. Usually used in dachas or where people live temporarily. Gas holders can also be vertical or horizontal.

Table. Types of gas tanks by design.

| Type of equipment | Description |

| Vertical | This type of model allows you to save space on the site. But the pit for such equipment will have to be dug very deep (it is important to remember that there may be groundwater underground). But the gas in such containers, due to their large depth, is well cooled in the summer, and, on the contrary, does not freeze in the winter. It is important to remember that for normal gas supply, its temperature must be above zero. |

| Horizontal | Such tanks take up more space, but are easier to install, since you don’t have to dig a deep pit for them. Not the best option for a modest-sized area, although a lot depends directly on the volume of the tank itself. |

Scheme of using a gas holder

You can also divide gas tanks into two types depending on the type of neck:

- high neck (Russian standard);

- without neck (euro).

Equipment without a neck is cheaper, but abandoning it is not always justified. The presence of a neck will allow you to install the platform with the reinforcement as high as possible, which will protect it from moisture. If water gets into the reducer, the gas supply will be stopped. There are also gas tanks without a neck, but their fittings are located on high tubes, and you don’t have to worry about water getting into them.

Cylindrical gas tanks

Nuances of constructing a copper gas pipeline

Copper pipes relatively recently began to be used for the installation of gas networks. It is allowed to use drawn and cold-rolled copper pipes with a wall thickness of at least 1 mm for internal wiring.

Copper is a rather expensive material, however, its use is justified by the ease of installation work and the ability to create lines of complex configurations.

Properly connected copper pipes not only ensure complete tightness of the joints, but also fit perfectly into the interior of any room

Another indisputable fact in favor of copper pipes is their attractive appearance. Since the gas pipeline cannot be hidden in niches in walls and ducts, steel structures can easily spoil the appearance of the room, while copper pipes will only enrich the interior.

Copper products have the following positive qualities, which may be decisive when choosing them for a gas duct installation:

- high plasticity, which makes it possible to lay lines of complex configurations;

- simplicity and ease of installation work, the product is easy to cut, pipes are connected by using press fittings or soldering;

- attractive appearance;

- durability - service life, subject to technology, reaches 100 years;

- resistance to mechanical damage and resistance to the effects of chemically active compounds.

Copper pipes also have their weaknesses, the main one of which is high thermal conductivity, which contributes to the formation of condensation. And also their strength is much lower than steel, and the price is much higher.

The following article will introduce you to the technology of soldering copper pipes, which ensures a hermetically sealed connection, which we recommend reading.

Select the volume and calculate the costs

To choose the right gas tank, it is important to decide what volume it should be. This figure can be calculated taking into account gas consumption per 1 m2 of living space. In warm regions, consumption per 1 m2 averages 25-30 m3, and where it is cold - at least 35 m3. The need for gas can be calculated as accurately as possible by focusing on the power of the heating boiler - about 100 liters of fuel are consumed per 1 kW per year. You can also calculate the volume of the container in another way: if cylinders were used, then you need to estimate how many of them were spent per month and multiply the resulting number by 12.

How to position the gas tank correctly

Important! It is worth understanding that the cylinder is not 100% filled with gas. Approximately 15% of the volume must be free to allow gas to expand when heated.

The market for such equipment offers tanks of various volumes - from 2 to 10 thousand liters. It is important to choose a container that will need to be refilled no more than twice a year. For example, for a building with an area of 100 m2, a gas holder with a capacity of 2700 liters is sufficient . A tank with a volume of 10 thousand liters is suitable for a house of 300 m2.

Table of the ratio of the heated area and the optimal volume of the gas holder

The cost of gas is low, but it is important to understand that when refueling equipment you will have to immediately pay for a large volume. So, in the spring, gas costs less (about 15 rubles per liter), in the winter it gets a little more expensive - up to 20 rubles, because the demand for it grows at this time of year. That is, to refill a 4800 liter gas tank you will have to spend at least 58,000 rubles. in spring, and in winter - all 80,000 rubles.

Advice! If possible, it is better to choose a gas tank in such a way that you do not need to fill it often and fill it during the period when gas is the cheapest.

How else can you choose the volume of a gas tank?

The operating temperature range for the equipment is -40 – +40 degrees. But for a reservoir that will be located underground, these data are not critical - such indicators are not found in the ground. But if the system is installed incorrectly in winter, the gas supply may stop (this is due to freezing of the communications supplying gas to the house).

Prices for gearboxes for gas tanks

Reducer for gas tank

Calculation

- How can you find out how much gas can pass through a hole of a known size in a unit of time?

In the simplest possible form, the outflow of gas from a pipe is described by Torricelli’s formula.

The master left us a gift - a simple and easy-to-use formula.

For gas it looks like this:

V=√(2g*Dp)/ λ. In it:

- V is the speed of the outflowing gas in meters per second;

- g—gravitational acceleration (9.8 m/s2);

- Dp is the pressure difference between the gas in demand and the atmosphere in kg/m2 (as a rule, the pressure of household gas exceeds atmospheric pressure by 0.2 kgf/cm2, or 2000 kg/m2);

- λ is the gas density. At room temperature it is approximately equal to 0.72 kg/m3.

For a liquid in an open vessel, the formula is noticeably simplified.

The formula describes the outflow of flow from a container or pipe whose dimensions significantly exceed the size of the hole. The gas flow through the pipe cut will noticeably decrease due to friction of the flow against the walls.

Knowing the flow rate of the outflowing gas and the diameter of the hole, it is easy to calculate the flow rate per second. To do this, you need to multiply the speed in meters per second by the area of the hole in square meters.

The area of a circle is calculated using the formula πr^2, or πd^2/4. r is the radius of the circle, d is the diameter.

Calculation of the area of a hole based on its diameter.

Let's do the calculation for a hole with a diameter of 15 mm.

The flow speed is √(2*9.8*2000)/0.72=275 m/s.

The area of the hole in square meters is 0.015^2*3.1415/4=0.000176709375.

The gas consumption in cubic meters per second will be 0.000176709375*275=0.048595078125. To calculate the consumption per hour, you need to multiply the resulting value by 3600 (the number of seconds in an hour). In our case, 0.048595078125*3600=175 cubic meters of gas will enter the atmosphere in one hour.

The consequences of such a leak can be very serious.

Installation of equipment: rules and regulations

It is necessary to install a gas tank in accordance with certain norms and rules. Thus, an underground type container must be located at a distance from a residential building (at least 10-12 m, according to SNiP - at least 10 m) and must be in stable soil. It is also prohibited to allow any utility lines to be located near the gas tank.

Do not use used, homemade or other containers that do not meet the standards.

Ground gas tanks should be installed in the shade at a distance of about 2-3 m from the border of the territory and at least 20 m from the house itself (according to SNiP). Trees should be no closer than 10 m. There should also be a well with water located not far from the equipment (no more than 15 m). It is important to understand that in winter, an above-ground gas tank in Russia will not work due to harsh climatic conditions, and you need to buy and install a special evaporator.

Gasification at home

If all installation rules are followed, gas tanks do not pose any danger to residents of the house and users of the equipment. The gas inside is stored without air access, and if the cylinder depressurizes, no explosion will still occur - the gas will simply escape into the atmosphere and dissipate. By the way, one of the safety measures is the location of the tank outdoors and not indoors. This is necessary in case a fuel leak does occur. Gas accumulation may occur in the room. And to avoid excess pressure, the gas tank is equipped with a special safety valve, which, if necessary, will simply release excess pressure (for example, in the case of gas heating).

Alternative options

What are the positive features of gas communications based on plastic pipes?

Such a gas pipeline is better than a metal one in that:

- The service life of the structure under discussion significantly exceeds that of a metal structure.

- Products of this type do not conduct electricity, which plays an extremely important role in many situations.

- Due to the low weight of polyvinyl chloride structures, the construction of various objects using them is carried out quite quickly.

- The construction of any communications using the pipes in question in domestic and industrial conditions is an optimization of the estimate; the use of the same amount of metal parts will cost much more.

For a more in-depth study of the characteristics, it is best to read the article devoted to this issue on our website - Temperatures, pressure, what it consists of, and more.

Gas tank installation

The installation of a gas tank itself is not difficult; its connection itself will cause more complications. That is why it is important to entrust the work to professionals. But in general, you can try to understand the system on your own. However, you can definitely do the installation of the tank yourself.

Step 1. First of all, you need to dig a pit suitable for the size of the gas holder. Before installing the gas pipeline, it is important to lay a warning tape that has an indelible inscription indicating the presence of gas.

First you need to dig a pit

Step 2. Next, you need to arrange a gravel bed by pouring gravel onto the bottom of the pit. It is also important to take care of creating a concrete base - it can be poured, or you can simply lay a concrete slab on the bottom of the pit.

Preparing the pit bottom

Laying a concrete slab

Step 3. After this, it is enough to lower the gas tank itself to the bottom of the pit and be sure to secure it with metal pins and cables.

The gas tank itself is lowered

It is important to secure the tank well

Step 4. Next you need to make a trench from the gas tank to the house. Pipes will be laid in it to supply fuel to the residential building.

Digging a trench

Step 5. You need to lay a gas pipe in the trench and bring it to the house.

Pipe laying

Prices for multilayer pipes for gas

Multilayer gas pipe

Step 6. One of the important stages is the installation of the gas supply system. Here it is better not to act on your own, but to call a specialist.

It is better to entrust the installation of the gas supply system to a specialist

Gas supply system being installed

Step 7. After installing all elements of the system, you need the technician to check its tightness using a special solution.

Checking the tightness of connections

Step 8. Then you need to connect all the devices and test the system for functionality.

System testing

Step 9. Only after this can the pit with the gas holder be filled with soil. It is recommended to fill it with sand.

A pit with a gas holder is filled in

Vertical or horizontal

Gas tanks that are installed vertically are of more interest to owners of small plots: this way they can comply with all placement requirements and save precious space. This is the most important advantage of vertical gas holders, and for this reason they are so popular in European countries.

In our country of large territories and high groundwater levels, the horizontal option is more common.

Andrey2 Member of FORUMHOUSE

It is cheaper to bury a horizontal one, but if the groundwater level is high, then the vertical one is more difficult to install.

About the fact that “vertical gas tanks have a small evaporation mirror, and with a large analysis there may be a lack of gas fraction” - on the portal there are quite a few owners of vertical tanks who did not feel any inconvenience at all from the small evaporation mirror.

Preparation for installation of polymer pipes

When deciding whether gas can be carried through polypropylene pipes in a particular case, you should consider a number of installation recommendations:

- The pipes must run deep into the soil. PVC products expand slightly when heated, so they can be laid in concrete or adits.

- During the design phase, care should be taken to avoid using too many fittings or welds.

- If fittings have been chosen to connect products, you should prefer pressed or crimped ones, as they provide the greatest reliability of the connection.

Methods for welding elements of polymer pipelines

The most popular and effective method of connecting pipes is welding.

Welding methods are divided into three types:

- Butt - the simplest, suitable for pipes with a diameter of 5-16 mm.

- In the socket - in most cases it is used for the installation and subsequent repair of sewer and water supply circuits. Suitable for polymer products whose diameter is in the range of 15-90 mm.

- Electrofusion - using an electric coupling, the current passing through the contacts of which melts and welds the plastic pipes inserted into the coupling with the product material. This is a particularly successful method for arranging gas supply systems made of polyethylene and polypropylene.

Polyvinyl chloride products are not soldered. To connect them, a specific glue is used - “cold welding”. The strength and durability of a correctly made connection is not inferior to that of hot welding. In addition, to perform such a joining, you do not need to look for a welding machine.