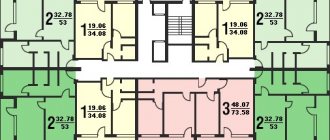

Options for redevelopment of apartments series 1-335

Photo of the house series 1-335

Plan of load-bearing walls of a house series 1-335

Description of series 1-335

When the Leningrad branch of the Gorstroyproekt Design Institute received the task of developing the cheapest possible building suitable for habitation, they set to work with enthusiasm. The result was five-story buildings of the all-Union series - 1-335 with a record of cheapness that has not been broken to this day.

Parts of the series were produced at several DSK of the USSR Ministry of Transport from 1960 to 1968 and were delivered to the capital region for assembly. That is why the series did not become widespread in the Moscow region, however, a significant number of houses of the 1-335 series were built. There are no more buildings of this series in Moscow; in the near Moscow region, houses of this series are now being actively demolished, and in the regions attempts are still being made to reconstruct and restore them.

Series 1-335 was most often built in a five-story version, but there are also lower buildings, and in all versions there were residential premises on the ground floor.

Balconies started from the second floor, bathrooms in all apartments were only combined. The apartments had storage rooms.

| Area m² | General | Residential | Kitchen |

| 1 sq.m. | 30-31 | 18-19 | 6.3 |

| 2 sq.m. | 41-45 | 26-35 | 6.3-7 |

| 3 k. sq. | 55-58 | 42-48 | 6.3 |

The ceiling height is 254 cm, which is slightly higher than the industrial minimum.

There are no elevators or garbage chutes.

Building materials:

The external walls were made of two-layer reinforced concrete 30 cm thick or expanded clay concrete 40 cm thick.

The partitions between rooms and apartments in the house were made of gypsum concrete panels 8 cm thick, but between the apartments they were installed in 2 layers with an intermediate gap.

According to residents and experts, 1-335 is the most unsuccessful of all Khrushchev buildings. The reason is the extremely low thermal insulation of external walls, fantastic audibility, leaking seams, cramped kitchens and bathrooms.

After the first problems that arose in five-story buildings in the USSR, they moved on to the construction of the modernized series I-335K, I-335A, I-335AK and I-335D, which were produced until the end of the 1980s. Some versions became 7 or 9 storeys, acquired an elevator, but the comfort of housing still remained at a low level.

Source

Khrushchev 45. Series LG 502,504,507

So, by popular demand, we are moving to the City on the Neva.

The mass series in St. Petersburg are different from those in Moscow, but they are also very different from the all-Union ones. The reason for this was that Len ZNIIEP, unlike most design organizations outside the Moscow Ring Road, was engaged in its own developments, which, by the way, were implemented not only in Leningrad and the region... So, with the presence of K7 in the development, modified 468 and 335 th series, the most common series are LG, 50*, 60* and series I-528, 527. Later there were 111, 114,121 and 137 episodes. I will briefly go over them in this and subsequent “St. Petersburg” posts. By the way, from an article about LenZNIIEP:

LG502 series

So the classic 502.

The series turned out to be extremely good, for those years, of course... However, LenZNIIEP, as you know, did not stop there.

Series LG502B And already in 1965-66 the Series LG502B

Unlike its predecessor, it is produced by DSK-2. The panels were finished with ceramic tiles and there was a loggia at the end.

Plus all sorts of little things discovered during the operation...

But otherwise everything remains the same:

In the early 70s, this version of the 502 was also produced:

I was unable to find any additional information on it. Series LG-507

Approximately simultaneously with 502B, the LG-507 series appeared, which was even produced in a variation of 7 floors with an elevator, but never became widespread, but became the prototype, both planning and constructive, of the LG504 , which also inherited the planning solution...

LG507-7

The only thing that is clear from the analysis of the 504th series is that 507 is also a series with longitudinal load-bearing walls and is covered with tent flooring, which differs unfavorably from its Moscow product I-515, which has round-hollow floors. External walls are load-bearing.

I don’t have plans for it, just a few photos.

Series LG -504

Let me quote from the same article: That is, apart from the hipped ceilings, the series is an analogue of the Moscow 515 series in its 9-story incarnation. Well, I already wrote about the delights of tent slabs...

Panorama of the 10th entrance house of the 504th series:

The entrance itself. And the kitchen.

Floor layout:

The modern appearance of the series is as follows:

The LG 504 series turned out to be the most durable of all 500 Leningraders and in the 1-Lg504D2 -10 variation was built until the mid-80s.

The main advantage of the series is the ease of reconstruction and visually high ceilings.

Sources:

1. Forum MGSU-MISI. 2 Series of houses of the universe

Useful links:

1. The ever-hanging post “All Series” 2. Accidents of Civil Buildings. 3. Redevelopment in buildings with longitudinal load-bearing walls. 4. Search for a house by series, series by address

Previous series: 44. Khrushchev 44. Plattenbau and Panelak. _________________ No comments

Characteristics of the layout of the Khrushchev house

Wide double-leaf, square-looking windows of the apartments, an iron 4-slope roof (something like a technical floor), it can also be completely flat and without an attic (there is no technical floor), or flat-pitched (some kind of hybrid).

Windows on the outer end panels. The fire escape, without a common fire balcony, is adjacent to the end of the Khrushchev-era building. The layout of the house provides for the location of four apartments on the site. Apartment layout: 1-room, 2-room. 3-room apartments with a ceiling height of about 2.55 meters.

The layout of the apartment is designed so that it is always a walk-through. The toilet and bathroom in the Khrushchev building are combined. Heat supply and water supply are centralized. The layout of the house does not provide for a garbage chute and an elevator. The number of floors of “Khrushchev” buildings - in addition to 5 floors, there are also 7 and 9 floors; houses with 3 and 4 floors are less common.

The kitchens of Khrushchev houses have gas stoves and sometimes gas water heaters. The ventilation provided for by the layout of apartments in Khrushchev-era buildings is natural exhaust. The layout of the house includes balconies.

In addition to the balcony, one of the advantages of the apartment layout is the storage room. Thermal insulation is not very good, because... The panels from which the house is assembled are hollow, filled with glass wool. The number of entrances in the house provided for by the layout is from three.

All apartments, except the corner ones, according to the layout of the house, face one side. The exterior design of the house is either covered with small ceramic tiles (color options: white-blue, light gray), or not covered (color options: gray, white, yellow, beige).

External view of the house layout of series 1-335 “Khrushchev” photo:

For reference

During the Soviet period, in 1961, the cost of constructing large-panel frame houses with the Khrushchev layout was the lowest in history and amounted to 96 rubles per square meter.

The layout of the Khrushchev houses of the 1-335 series was considered by some experts to be the most unsuccessful of all those developed under Khrushchev.

Source

How to improve

Brezhnevka's apartment design

depends on the preferences of the owners.

There are many modern, varied options. To better understand how everything can be arranged, it is worth studying the photo of Brezhnevka

.

Insulation and sound insulation

It was noted that Brezhnevka can be cold. The choice of materials for sound and thermal insulation depends on the preferences of the owner. But special attention should be paid to the seams that run in the area of ceilings and walls.

Leveling walls and floors

Leveling the surfaces will improve the condition of the apartment and get rid of problems during further cladding. More often it is enough to use putty. But in particularly difficult cases it is necessary to use sheets of plasterboard.

Advantages of zoning

Among the advantages of zoning it is worth noting:

- Selection in one room of several functional segments for various purposes;

- Space saving;

- The ability to visually change the room;

- Increasing the comfort and convenience of the room.

Decorating the living room kitchen in Brezhnevka

Brezhnevka design with 2 rooms

may imply the need to install a geyser. It is best to build it into a closet. This will effectively hide it without compromising ease of use. You must first consult with a professional and obtain his permission.

The best place to place the refrigerator will be a corner. This will make good use of space and conveniently install equipment. You can place storage shelves above it. An area near the door would also be a suitable place.

The headset should be as compact and convenient as possible. Therefore, the following options are suitable:

- Linear;

- L-shaped;

- U-shaped. For this option, you can build part of the set into the window sill, making it a work area.

Furniture placement

Small space must be used as rationally as possible. Only necessary furniture is used. It is better to choose multifunctional options. You need to arrange the furniture so that it is convenient to move, and nothing interferes with movement.

Typical house series I-335 with apartment layouts

Houses of the I-335 series were built from 1958 to 1966 and are an example of a five-story panel Khrushchev housing type of construction.

The series was not popular with developers, and therefore had many different modifications I-335K, I-335A, I-335AK and I-335D, which were produced until the end of the 1980s and in some cities grew to 7 or 9 floors . The color scheme of external walls: is formed by applying cladding with small square tiles, so houses are usually white or gray, and those that are left without cladding are yellow or beige. In the houses of the I-335 series, the number of floors is about 5, in the older versions there are 3 or 4, with the first floor being mainly residential. The number of sections/entrances varies from 3. All houses do not have an elevator. There are four apartments on each floor. Balconies are available in all apartments.

One-room apartments have a living area of 18 m², a kitchen of 6 m²; in two-room apartments, living area 26-35 m², kitchen 6-7 m²; in three-room apartments, living space is 42-48 m², kitchen is 6-7 m². In three-room apartments, the central room is a walk-through room.

The bathroom is combined, the bathrooms are standard, but not sit-down. Ventilation is natural exhaust through a ventilation unit in the bathroom. There is no garbage chute. Stairs without fire balconies.

Internal walls: brickwork 51 cm thick. External walls - two-layer reinforced concrete panels, thickness varies from 30 cm. Partitions are gypsum concrete panels 8 cm thick. Floors are solid reinforced concrete slabs 10 cm thick. Load-bearing walls are all columns and external ones.

Advantages: good size of apartments, balconies and storage rooms. Disadvantages: low thermal insulation, combined units, thin interior walls.

Some of the I-335 series homes are on the "Demolition" list.

Source

House series 1-335. Layouts with dimensions, redevelopment of apartments.

The result of the design of a temporary prefabricated residential building at the Leningrad branch of the Gorstroyproekt Design Institute was the 1-335 (I-335) series. The building, erected using a semi-frame scheme, became a record in terms of low construction costs.

It was assumed that the five-story houses in the water used during the mass construction would be used for no more than 15 years, and then their parts, after dismantling, were to be assembled in another place as two and three-story buildings for another 10-15 years or used in one-story construction on the village is already immediately like permanent structures.

Photos of houses series 1-335

Many design decisions in the 1-335 series were made to facilitate the installation and disassembly of these structures. As practice has shown, the idea of operating five-story buildings with a service life of even 30 years was utopian. The design defects of the series led to the fact that after a dozen heating seasons, irreversible damage occurred in the outer panels and seams.

Where houses of semi-frame construction of the basic series 1-335 still stand, there is a danger of accidents due to corrosion of reinforcement and metal embedded parts.

Houses of the 1-335 series were built from 1958 to 1966, and parts were delivered to Moscow by transport, which explains the small number of these houses in the capital. In total, less than 70 were collected in Moscow and currently all of them have been demolished.

Layout and construction of houses of series 1-335

Balconies always started from the second floor, and bathrooms in all apartments were only combined. The first floor was always residential.

The apartments do not amaze with space: the living area of a one-room apartment is 18-19 square meters. m.; two-room apartments 26-35 sq. m.; three rubles – 42-48 sq. m.

The total area is: 1 sq. m. – 30-31 sq. m.; 2 sq.m. – 41-45 sq. m.; 3 k. sq. – 55-58 sq. m.

Kitchen area in the range of 6.3-7 square meters. Ceiling height 254-256 cm. Elevators and garbage chute were not provided initially.

Construction and demolition of houses series 1-335

In addition to insufficient strength, leaking seams and low thermal insulation of external walls, residents began to complain about the sound transmission of houses in all directions, cramped kitchens and bathrooms.

In total, the defects led to the fact that the construction of houses in this series was completely prohibited without changes to the design, and the series was recognized as the most unsuccessful of all Khrushchev’s series of residential buildings.

Modifications of the series with a modified supporting system were available until the end of the 70s, but in the capital they were abandoned in favor of other projects.

Source

TechLib SPB UVT

Polina Dedyukhova

Series 1-335 with an incomplete frame is a residential building of 5 floors with longitudinal load-bearing walls. The structures were manufactured at prefabricated reinforced concrete factories of the USSR Ministry of Transport. Designs of the 335th series were produced at DSK from 1960 to 1968.

The series is widespread throughout the former USSR. The first house in this series was built in Cherepovets. In Moscow, the 335 series was built from imported structures; in block buildings it is found in the form of separate inclusions.

The largest number of houses in this series were built in St. Petersburg, where they were produced by Polyustrovsky DSK - 289 buildings, a total of 1,442 sections in the Krasnogvardeisky and Kalininsky districts of the city. In Omsk, 170 houses of the I-335PK series with an incomplete frame are in operation (more than 2% of the total volume of this series in the country). The most massive series of residential buildings in Kazakhstan.

In Tula, it was initially decided to build houses of a personalized series; the builders encountered a number of technological difficulties. Therefore, it was decided to introduce our own panels for construction, and thus the 1-335AT (Tula) series was born. Panels for it were produced at two factories - Aleksinsky Concrete Products and ZKD (Large Parts Plant). The first district where these houses began to be built was Proletarsky.

The appearance of 1-335 is characterized by wide apartment windows (double-hung ones look square), elongated windows on the staircases, almost the entire height of the panel. The end walls consist of 4 panels with windows on the outermost ones. Usually there is an external fire escape at one end of the house. For houses built in Moscow, a 4-pitched iron roof is typical. In another modification, including the one built by Polyustrovsky DSK (it is also found in the Moscow region), there may be a flat roof without an attic at all.

Load-bearing walls are longitudinal (as indicated by the I in the series title). The number of sections in the original modification is 3,4,5,6,8,10. There are 4 apartments on the site. The apartments are 1,2,3-room, ceiling height is 2.55 m. The central room in the 3-room apartment is a walk-through. Combined bathroom. Water and heat supply is centralized. There is no elevator or garbage chute.

Specifications for Series 1-335 Partial Frame

| Wall material | panel |

| Number of sections (entrances) | from 3 |

| Number of floors | 5, less often – 3, 4. First floor residential |

| Ceiling height | 2.54 m. |

| Elevator | No |

| Balconies | in all apartments |

| Number of apartments per floor | 4 |

| Years of construction | 1958-1966 |

| Total number of houses built | about 500 (in Moscow – 76 with a total total area of apartments of about 200 thousand sq. m) |

| Most of the houses of the 1-335 series were built in Leningrad (primarily the northeast of the city: Grazhdanka, Okhta, Polustrovo), etc. Dachnoe. Several blocks were built in the years. Cherepovets, Ulyanovsk, Volgograd, Novosibirsk, Omsk, Krasnoyarsk, etc. (including in several cities of Belarus). The series was built in less significant volumes in Moscow: 3-5 houses in the districts of Perovo, Sokolinaya Gora, Babushkin, Degunino, Kuntsevo, 1-2 buildings in a number of other districts. In the cities of the Moscow region, houses of the 1-335 series were built in single quantities, most of them in the cities. Shcherbinka and Podolsk | |

| Demolition of houses of the 1-335 series has been carried out in Moscow since the late 1990s. selectively (formally, the series is not included in the list of those to be demolished in the first place, since it is not among the most common series of “Khrushchev” buildings in Moscow, and in the BTI databases, 5-story buildings of the 1-335 series are often mistakenly listed as buildings of the undestructible series 1-515/5). The demolition of all houses of the 1-335 series in Moscow will be completed, according to experts from www.RussianRealty.ru, in 2015-2017. | |

| In St. Petersburg, houses of series 1-335 are undergoing sanitation (overhaul), some blocks are planned for demolition | |

| Areas of 1-room apartments | total: 30-31 sq. m., residential: 18 sq. m., kitchen: 6.3 sq. m. |

| Areas of 2-room apartments | total: 41-45 sq. m., residential: 26-35 sq. m., kitchen: 6.3-6.9 sq. m. |

| Areas of 3-room apartments | total: 55-58 sq. m., residential: 42-48 sq. m., kitchen: 6.3 sq. m. |

| Since 1964, modified versions of the 1-335 series have been introduced: 1-335A, 1-335K, 1-335AK, 1-335D with improved apartment layouts, improved design (full frame, better thermal insulation of external walls) and 9-story versions. No houses of modified versions were built in Moscow | |

| Bathrooms | combined in all apartments |

| Stairs | without a shared fire balcony |

| Garbage chute | No |

| Type of stove: gas. Ventilation: natural exhaust, units in sanitary cabins (bathrooms) | |

| Walls of houses of standard series 1-335 | External walls: two-layer reinforced concrete 30 cm thick or single-layer expanded clay concrete 40 cm thick. Floors: solid reinforced concrete slabs 10 cm thick. Interior partitions are made of gypsum concrete panels 8 cm thick, and inter-apartment partitions are made of the same panels in 2 layers with an air gap between them equal to 4 cm |

| Load-bearing walls | columns and external walls (partial frame) |

| Type of sections (entrances) | row (ordinary, set of apartments on the floor: 3-2-1-3, 2-2-3-2), end (set of apartments on the floor: 1-2-2-3). All apartments, except corner ones, face one side |

| Number of steps in a section (entrance) | 7 (in row sections), 6 (in end sections). Step width (distance between two adjacent load-bearing walls, floor span width): 260 cm, 320 cm. Body width: 11.6 m. |

| Cladding, plastering of external walls | facing with small square tiles (St. Petersburg), unveneered (Moscow, St. Petersburg, other cities) |

| External wall color options | tiles: blue-white, light grey, untiled: grey, white, yellow, beige |

| Roof type | 4-slope (Moscow), flat and flat-slope (other cities) |

| Distinctive features | 5-storey panel houses of the standard series 1-335 are recognizable by large, full-height panels, windows made of 4 horizontal sashes on the stairs, ends of 4 panels with 2 rows of windows |

| Advantages | availability of balconies, storage rooms |

| Disadvantages (in addition to the standard disadvantages of Khrushchev buildings) | extremely low thermal insulation of external walls, thin interior partitions, combined bathrooms even in 3-room apartments |

| Manufacturers | Polyustrovsky DSK (Leningrad), Vologda DSK, Petrozavodsk DSK, Tula ZKD, Large-panel parts plant No. 6-DSK-1 (Novosibirsk), Krasnoyarsk reinforced concrete plant No. 1, Omsk precast concrete plant No. 6, etc. |

| Designer | Design Institute "Gorstroyproekt" (Leningrad branch) |

| Varieties of standard projects of the 1-335 series (they differ only in the number of sections): | 1-335-1, 1-335-2, 1-335-3, 1-335-4, 1-335-30, 1-335-30sh |

| Cost of construction 1 sq. m of living space for frame-panel houses of the 1-335 series was 95 rubles. in 1961 prices - the lowest figure in the entire history of industrial housing construction in the USSR | |

| According to a number of experts, 1-335 is the most unsuccessful of all all-Union Khrushchev series | |

| 1-335 is the only series of houses found in both Moscow and St. Petersburg (the façade and roofing solutions differ significantly) | |

| RussianRealty.ru rating of type series 1-335 | 2.9 (on a 10-point scale) |

In support of the thesis that in frame-panel buildings it does not matter what parts and elements the frame is made of, and the standard durability will be determined by the attachment point of the horizontal structures to the fence itself, let us consider the example of a large-panel building of the 1-335 series with an incomplete frame. In appearance, it belongs to the industrial series with a durability of 150 years. However, the very design of such residential buildings, built since the early 60s of the last century, and most importantly, the qualities demonstrated during long-term operation, make it possible to classify such structures into the “Frame-panel” capital group.

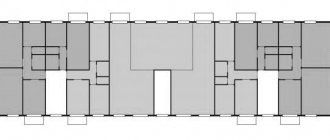

| Appearance of the 1-335 series with partial frame | Plan of a typical end section with latitudinal orientation |

| Plan and section of series 1-335 with incomplete frame | Plan of an ordinary typical section with latitudinal orientation |

During the implementation of complex development in the 60s of the last century, these buildings were erected as a frame for the residential area being built up, they were also placed inside the microdistrict, but in place of the high-rise dominant - future 9-story buildings with elevators and garbage chutes, the mass commissioning of which started in 1968.

In the 60s of the last century, during the Cold War, there was a state housing program, during which each settlement, except for the mobile resettlement fund, had a set of structures for large-panel housing, assembled according to the frame-panel type.

It was believed that five-story structures used during mass development would be in use for no more than 15 years. Then they had to be dismantled and reinstalled in another place with a reduction in the number of storeys - as three-story buildings.

After 10 years of use, they were to be transported to the countryside and assembled into semi-detached single and double storey cottages with a lifespan of 150 years.

In order to facilitate installation and disassembly, columns were not installed on the outer longitudinal walls in these houses. A number of columns for supporting the crossbar of the floor slabs ran only along the internal longitudinal wall.

Thus, the crossbars, resting on the columns of the inner row with one end (highlighted in red in the figure), rested directly on the fence panel with the other end.

This needs to be sorted out. Why does the frame-panel system in Russia (where the heating season is on average 9 months) have such a low standard durability, regardless of the fact that in this case it is assembled from fully prefabricated durable elements designed for three cycles of installation and dismantling.

As we know, heat in a room rises. Thermal engineering calculation comes down to determining the thickness of the fence behind the end of the floor structures.

In this case, two-layer panels 150 mm thick were used as enclosing structures. Which did not meet the requirements of thermal engineering calculations. The "crossbar - outer fencing panel" assembly was constantly frozen. The calculation was that over the planned durability, the physical wear of the fencing panels during the “freezing-thawing” cycles would not exceed the permissible repairable level.

However, in practice it happened differently. The changed policy did not allow the planned operation of these unique “prefabricated” structures to continue. At a construction site, where the Soviet-era estimates included articles “Temporary buildings and structures,” which included buildings up to three floors, it is customary to say: “There is nothing more permanent than something temporary.”

Of course, the original idea of housing resettlement in 15-10 years was in itself utopian, given that the main instrument of housing policy was buildings with a standard durability of 150 years.

As a result, structures with a durability of 30 years, which should have been dismantled and reassembled back in the mid-70s of the last century, still stand among the structures with normal durability, not differing in any way from them in appearance.

There are 46 such houses in Izhevsk, they stand right among similar houses, where columns are placed on the outer walls, so their standard durability is far from exhausted, and the building itself has a normal microclimate.

Today, residential large-panel buildings with incomplete frames pose a huge threat to residents.

All these structures were already in a pre-emergency condition by the end of the 80s. The destruction of these buildings can occur at any time according to an unpredictable scenario - due to the brittle destruction of metal embedded parts that have significantly corroded over the period of operation. This kind of building was supposed to be reconstructed primarily in the mid-80s of the last century.

At present, they have not yet been reconstructed, although all permissible deadlines have been missed. At the same time, the authorities are deliberately demolishing not these houses, but similar ones that have a standard life of 150 years, but are located in places that are more attractive for modern development.

According to the results of external inspections carried out back in Soviet times, the standard durability indicators for horizontal protruding elements were significantly reduced - up to 25 years. These are canopies, balconies and loggias.

In the first mass series, metal fencing was used at the protruding elements. Practice has shown that during the heat exchange process, it is at the contact with the “cold bridges”, which will be all metal structures, that the main concentration of freezing condensing moisture occurs. When freezing, condensate droplets expand, forming shells and cavities. After 10-15 heating seasons, irreversible damage occurs.

Without taking this data into account, today attempts are being made to strengthen protruding reinforced concrete elements using metal parts and reinforcement structures.

Main advantages of the 1-335 series

- The minimum number of load-bearing internal elements, which allows the principle of “flexible planning” to be implemented;

- High technological effectiveness of manufacturing and installation of structures;

- Design of a technical underground, which allowed housing to be put into operation rhythmically throughout the year in the northern regions of the country.

| View of the balconies of a large-panel residential building built in 1962. Izhevsk, 2007 |

General information about houses of series 1-335

| Purpose | Residential building |

| Number of storeys | 5 floors, ground floor, basement |

| dimensions | 67.2 m / 12.0 m |

| Spatial rigidity | Longitudinal direction – longitudinal load-bearing walls, floors. Transverse direction – external end, transverse walls |

| Wed. apartment area | 39.7 m2 |

Description of load-bearing structures series 1-335

| Foundations | Prefabricated reinforced concrete strips |

| Walls | Double Layer Heavy Concrete Wall Panel |

| Partitions | Plaster t=80 mm |

| Floors | Reinforced concrete hollow slabs |

| Coating | Pitched, on wooden rafters made of boards “on edge” |

| Stairs | Prefabricated reinforced concrete marches |

Disadvantages of the 1-335 series

- Insufficient rigidity of the assembly of the balcony slab in the wall panel, floor slabs;

- Incorrect arrangement of layers in a two-layer wall panel;

- Unreliable waterproofing of the seams of the wall panels, as a result of which leakage of the seams was confirmed by inspection;

- Inconsistency of space-planning and design solutions of apartments with modern requirements.

At the moment, these structures can no longer be dismantled and require urgent reconstruction measures to strengthen the entire building as a whole:

- External frame devices with unfastening of the crossbar support unit to strengthen and unload the existing building frame;

- Cutting worn balcony slabs;

- Expansion of openings in external wall panels, sealing of vertical and horizontal platform joints in them;

- Replacement of floors, window frames, door frames.

In addition, the planned reconstruction of the entrance areas with the installation of ramps for children and wheelchairs, installation of attached passenger elevators and garbage chutes is necessary.

During the reconstruction work, all residents would receive significant benefits, except for those living on the first floors. For them, back in Soviet times, special reconstruction projects were developed with the construction of separate entrance groups.

It is easy to notice that the installation of attached entrance groups with elevators and garbage chutes, attached loggias along the contour of the building - expands the building, allows you to unfasten the frozen joint of the crossbar to the fence.

This solution allows not only to strengthen an incomplete frame, but also to create new thermally efficient enclosing structures, dry and repair old fencing structures, and restore a normal microclimate in the building.

Redevelopment projects of the 1-335 series with an incomplete frame during reconstruction with the installation of attached entrance groups with elevators and garbage chutes and attached loggias

There are various solutions that involve partial dismantling of the fencing panels and the installation of attached structures that expand the body of the structure along the entire longitudinal contour. There are also more economical options, where only attached entrance groups and attached loggias are built, reinforcing the incomplete frame of the building from the outside.

| Reconstruction project for a large-panel house of series 1-335 built in 1964 in Izhevsk on the street. Vorovsky with the installation of elevators, garbage chutes, strengthening and expansion of the building, and the addition of the attic floor |

When expanding the building, problems arise with insulation of the premises due to the low floor height of the first mass series. However, this issue is resolved by constructing two-level apartments with a hall that has a “second light.”

| A project for the reconstruction of a microdistrict of large-block houses built in 1964 in Izhevsk with significant densification of the development by connecting three residential buildings in the most worn-out end part - into a single residential ensemble with two-level apartments | |

The current approaches to the reconstruction of large-panel buildings with external insulation have not yielded positive changes. In buildings, there was an increased growth of black mold in the upper corners of residential premises, that is, the process of freezing and destruction of structures did not slow down, but intensified.

Attempts to strengthen the angle of support of the crossbar on the outer panel of the fence from the inside, with a device similar to the internal frame, also did not yield results. In Soviet times, there were attempts to strengthen these nodes with the help of logs installed in the corners.

The internal frame, which does not have its own foundation and rests on floor slabs, only cosmetically solves the problem of frostbite, provided that it is covered with sheets of plasterboard. It should be taken into account that the majority of the examined crossbars had an unacceptable deflection back in the 80s.

In semi-frame structures of the 1-335 series, during the installation of attached loggias, it was planned to install a fastening unit for the head of the crossbar to transfer the load from worn units to the outer frame along the perimeter of the entire structure. Due to the fact that the reconstruction measures planned for the late 80s were not carried out, currently, during the reconstruction activities, the balcony slabs and canopies must be dismantled.

The installation of heated loggias had to perform the following functions:

— creation of an additional thermal protection belt before repairing and sealing panel joints; — improvement of insolation of interior spaces due to three-sided natural lighting; — increasing the comfort of living quarters; — creation of a rigid outer frame around the entire perimeter of the building.

All these measures must be carried out in a short time with the complete resettlement of residents on a permanent or temporary basis. Their implementation would help reduce social tension in society and solve the housing problem in an economical way beneficial for all participants in the reconstruction process.

Posted in Capital Group “Frame-panel”, Design of buildings and structures, Thermal engineering calculations, Technical typology, Technology of strengthening building structures

"Design of launch complexes at the Vostochny Cosmodrome"

Large-block buildings »

Design features, solutions for houses of series 1-335 and 1-335a

The design of the houses of the 1-335 series is based on a two-span design with columns running along the middle longitudinal axis of the building at intervals of 2.6 and 3.2 m, and with transverse girders supported by columns and load-bearing panels of the longitudinal external walls. The spatial rigidity of the building is ensured by the walls of the staircases, end load-bearing walls and transverse walls of ventilation blocks, which are also supports for the floors (Fig. 3-15).

The external walls of the building are designed in two versions: in the form of two-layer ribbed reinforced concrete panels made of concrete grade 200, insulated with non-autoclaved cellular concrete grade 10 (the main option), and in the form of single-layer panels made of lightweight concrete (expanded clay concrete, thermosite concrete, aerated concrete, etc.). The thickness of single-layer panels, depending on the climatic conditions of the construction area, is taken from 35 to 50 cm. Double-layer panels for all climatic regions have a thickness of 30 cm. The insulation made of cellular concrete is protected on the inside by a cement layer, and the front surface of the outer panels either has a textured layer of white or colored concrete, or painted with perchlorovinyl or stable silicate paints.

The panels of the external walls are connected to each other by welding metal plates, which are support sheets for the transverse girders of the interfloor floors; the ends of the purlins are insulated with slag wool. The vertical seams between the wall panels are caulked with tarred tow ropes and filled with expanding cement mortar. The nests in the wall panels necessary for welding are sealed with foam concrete chips and a small amount of cement mortar. Installation of wall panels is carried out over a layer of cement mortar 10 mm thick, while on the side of the facade edge on the panel before spreading the mortar, a rope of tarred tow or poroisol is laid.

Rice. 3-15. Large-panel houses series 1-335 and 1-335a

a - section of series 1-335; b - the same, 1-335A; c—conjugation of columns, purlins and interfloor panels: 1—colony; 2—run; 3 - floor panel; 4 - weld; d - coupling of external wall panels with the purlin and floor slab; 1 — mastic isol: 2 — poroizol; 3 - cement mortar; d - interface of panels on the end wall: 1 - wall panels, 2 - floor panels

The internal frame of the building consists of one-story high reinforced concrete columns made of grade 200 concrete and transverse reinforced concrete girders of rectangular cross-section made of grade 300-400 concrete. For the installation of floors, reinforced concrete flat hollow-core panels made of concrete grade 300, room size, 10 cm thick are used. The connection of the frame elements to each other and to the floor panels is carried out using welded metal parts embedded in reinforced concrete products. After installation, all metal surfaces are coated with an anti-corrosion compound, and the seams between reinforced concrete elements are sealed with a mortar of expanding cement.

The foundations for load-bearing walls are designed in two versions: a strip structure made of concrete blocks or a columnar structure made of enlarged prefabricated reinforced concrete elements in the form of separate supports mounted on pads. The foundations for the columns are made of glass-type reinforced concrete shoes. With columnar foundations, the lower part of the walls is assembled from plinth panels, and with concrete block foundations, the plinth part is assembled from large hollow blocks with a length equal to the pitch of the transverse load-bearing structures.

Interior partitions are made of gypsum concrete panels 8 cm thick, inter-apartment partitions are made of the same panels, but in two layers with an air gap of 4 cm between them. Sanitary units are designed in the form of prefabricated thin-walled reinforced concrete cabins of factory production. Staircase structures are made in cassette forms from grade 300 concrete and consist of flights with half-platforms.

The combined roof has two solutions: in the form of a ventilated and non-ventilated structure. The basis for the roof is reinforced concrete slabs 4 cm thick, laid on reinforced concrete linings (joists); roof insulation - from autoclaved foam concrete; the roof is made of three layers of roofing felt over glassine and bitumen mastic.

Residential buildings of the 1-335 series have significant planning disadvantages: apartments with walk-through rooms, with entrances to the kitchens directly from common living rooms, with combined bathrooms, with narrowed front rooms; The facades of the houses are designed in a monotonous manner with reduced heights of window openings. There are also shortcomings in design solutions: anti-corrosion protection of embedded parts is not provided; at the points where the purlins are supported on the external walls, there is no necessary sealing of the joints of the external panels; the thermal insulation qualities of external walls are insufficient for areas with low design temperatures; in a number of nodes, individual areas froze; the channels in the smoke ventilation units have insufficient cross-section; water flows from balconies and cornices into the joints of external wall panels.