With the advent of various modern flooring materials such as laminate, porcelain stoneware or PVC tiles, wooden flooring has ceased to be used everywhere. On the one hand, parquet or solid boards are certainly more expensive than laminate, on the other hand, such a floor will fit into absolutely any interior: from minimalism and Scandinavian style to classics. Architect Pavel Gerasimov told The Village about the pros and cons of wooden flooring, what determines the final cost of such a floor and how to care for it.

Pavel Gerasimov

architect, co-founder of Geometrium studio

If we talk about using wood as flooring in an apartment, then first of all it’s worth remembering the tactile sensations: walking on a wooden floor barefoot is much more pleasant than walking on tiles or laminate. There are, of course, many stereotypes about the impracticality and fragility of a wooden floor, but it should be noted that the wear and tear of wood only makes it look better. If you pay attention, for example, to a wooden floor in a restaurant, you can see how it “lives”: all its acquired abrasions, on the contrary, give it a certain aesthetics and uniqueness. And a restaurant is a public place where a large number of people pass by in street shoes every day. This definitely won’t happen in an apartment or house, so you shouldn’t worry about excessive wear and tear on the wooden floor.

Features of the floorboard

The advantage of floor boards is that they are made from solid wood, while parquet boards are created in layers, thereby being inferior in strength to floor boards.

Floor boards must meet certain requirements:

- The surface should not have knots. Fully sanded and smooth.

- The boards must be dried at the factory. The boards must be dry. If you use damp boards to lay the floor, they will dry out and quickly become unusable.

Floorboards are made from various types of wood; the most popular are boards made of oak, elm, beech, ash, maple, pine and larch.

The most durable type is considered to be floorboards made of oak and beech. They are the most durable and at the same time the heaviest. To install them, there must be strong fastenings. The high price is due to the long service life.

Floor boards made from larch and pine are considered lighter and cheaper. They are lighter than oak, but due to this they have a shorter service life.

Flooring rules

The process of installing wooden flooring consists of several stages.

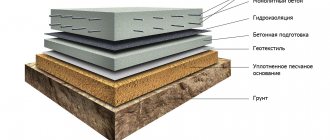

Preparing the base

The board must be ventilated, so it is not laid on a solid base, but on joists or beams. They must also be dry and thick enough to support the load.

The following are used as support beams:

- thick boards placed on edge;

- bars;

- debarked round timber with the top side beveled into a plane.

The cross-section of the logs depends on the installation method - on a solid concrete base or on support posts. And also on the length of the span between them. Exact numbers can be found in SNiPs and reference literature.

Before laying the logs on brick or concrete columns, they are covered with a double layer of roofing material for waterproofing. You can place cuttings of boards under the logs to level them horizontally. Both joists and linings are impregnated with antiseptic before installing plank floors.

Advantages and disadvantages of plank floors

Of course, one of the main advantages of a wooden floor is its safety and environmental friendliness. The benefits don't end there. A wooden floor will last you a long time.

The wooden floor has its own pattern; it also adds ambiance and comfort.

Wooden floors also retain heat well. It can be repainted in different colors depending on your desires.

- The disadvantages include the fact that wooden floors are exposed to moisture. It can harbor various bacteria and fungi. Wood is one of the objects that can catch fire. Installing a wooden floor requires a lot of effort.

- Floorboards are sold in their pure form. The finished floor is already covered with various varnishes or paints. This can be considered a plus, since after losing its appearance, you can sand the floor and apply a new, fresh coating.

Before installing the floor, it is necessary to coat the boards with water-repellent compounds.

How to care for wood flooring

Of course, a wooden floor most often has to be protected from water, which is somehow absorbed into the wood. Because of this, it is recommended to use only engineered or solid wood in the kitchen or hallway. Traces formed as a result of water ingress can be removed by restoration.

Also, you should not drop anything heavy on a wooden floor, and if this does happen, then there is simple advice: treat small dents and scratches on the wood calmly. A wooden board acquires its truly natural appearance during use. True, not everyone shares this opinion, so whether to put a wooden floor in your apartment or not is up to you to decide.

Manufacturers recommend treating wood with oil, since in case of damage it will be enough to restore only the damaged fragment of the floor. If you cover the board with varnish, then during restoration you will have to remove all the varnish and re-treat the entire surface of the floor - for a uniform coating.

Photos: cover, 3 – Katya Zaklivenets, 1 – Olya Shangina, 2 – Yasya Vogelgardt

Types of boards

There are several types of floor boards. Each of them is suitable for a specific construction purpose. There are terrace, parquet and floor boards. Let's consider the scope of application of each of them.

Parquet board

This is a type of floorboard that is a board glued together from three layers of wood.

- First layer. It serves as a substrate. It is made from coniferous wood.

- Second layer. The second layer is necessary to ensure strength. Durable types of wood are used to make it.

- Third layer. The outer layer, which is made from expensive types of wood: oak, alder or ash.

- The parquet board is impregnated with water-repellent compounds to increase its service life.

- The final and fourth layer can be considered varnished boards. This is necessary to maintain the appearance of the board.

- The thickness of the parquet board can vary from 7 to 25mm. The 7mm thickness is the least in demand, since due to its small thickness it cannot be updated.

Parquet boards with a thickness of 15 to 20 mm are considered the most suitable for laying floors in residential buildings. Since it matches in strength. It can be restored and given a fresh look.

For public places, parquet boards with the greatest thickness are used; it can withstand heavy loads and the flow of people.

Terrace board

It is used to cover floor surfaces outdoors with high humidity levels. Compared to parquet boards, the surface of the decking boards is rougher and more ribbed.

This acts as a plus. This type of board is used to lay the floor next to swimming pools. Recesses in the decking board also cause inconvenience when cleaning it. The most common thickness is 3.5 cm.

Batten

A type of floor board that is made from natural wood; the front side of the board is smooth and without knots. It, in turn, is divided into two types. Tongue-and-groove, a type of board that is equipped with fasteners for installation. And a regular board without additional fastenings.

- For installation of rough work, ordinary boards are used, as they are much cheaper. They can also be used to build baths.

- It is better to use tongue-and-groove boards for facing work. They make floor installation fun and easy.

The size of the floorboard can be very varied; the most optimal size is 2.5 cm. When purchasing a floorboard, take into account how well the board is dried and what kind of wood it is made of; the service life directly depends on this.

Criteria for use.

Most importantly, the material must have the following quality indicators: strength, moisture protection, wear resistance, low thermal conductivity, and environmental friendliness.

Types of wood and their main characteristics:

Pine is a soft species, characterized by high strength, lightness, and lends itself well to working and impregnation. Virtually no deformation when drying. Widely used in furniture making.

Spruce is a soft species, difficult to process and practically cannot be treated with antiseptics. But unlike pine, it is much easier to glue and dry. Used in construction and furniture production.

Larch – has medium density, high strength, and resistance to decay. The material is quite heavy, therefore prone to cracking, and has a characteristic turpentine odor. Tree rings are visible in all sections.

Ash – has a beautiful structure, flexibility, and is resistant to rotting. The only drawback is that it is poorly impregnated with antiseptic materials.

Birch – has sufficient hardness and can be easily painted, impregnated and polished. The biggest drawback is that it is susceptible to rotting in a damp room.

Beech is a hard wood that is malleable in processing and impregnation. But it also has a tendency to rot, and when it dries out, deformation is possible.

Oak - has continuous advantages - durability, strength, flexibility, beautiful texture, resistance to rotting.

As you can see, each type of wood has its own clear advantages. In addition to natural solid boards, more than 20 types of wood-based materials are actively used.

Of course, a natural solid board is much better than a glued one; the main advantage is that its surface can be sanded repeatedly. And another advantage of natural material is that there are no synthetic fumes.

Influence of wood species. It is customary to lay plank coverings both inside the house and on verandas, balconies and terraces. In adverse conditions, boardwalks made from exotic wood have proven themselves well. Due to their climate-resistant properties, their service life outdoors is at least 20 years.

The most common breeds are:

- Bamboo;

- bunga;

- merbau;

- sukupira;

- zebrano;

- rosewood;

- Siberian larch.

For interior work, the following materials are chosen:

- pine;

- larch;

- oak;

- ash;

- birch;

- elm;

- aspen;

- Linden.

If the room is expected to have a lot of traffic, it is better to choose hardwood. Coniferous wood is recommended for use in rooms with high humidity. Soft wood is used to decorate recreation areas.

The optimal air humidity for wood is 9%, and in no case should it exceed 12%.

Excessive moisture will lead to deformation of the material. Additional treatment with special compounds extends the service life of the material.

Board sizes

There are various sizes of flooring boards available for sale.

When choosing a size, consider:

- Room size. If the room is quite large, it is better to use a long and wide board.

- For which room equipment are you purchasing boards?

- The degree of load on the finished floor.

The thickness of the boards is selected based on the upcoming loads applied to the floor. The greater the load, the greater the thickness of the board.

How to calculate quantity

All materials are sold in cubes. This means that you need to calculate the amount of material that will be suitable for your home per cubic meter. The first thing to do is calculate the volume of one board. To do this, you need to multiply the dimensions of the lumber among themselves: width by thickness and length.

For example, if the size 25 x 100 x 6000 mm is used. All this data is converted into meters: 0.025 m, 0.1 m and 6 m. The volume will be as follows: 0.025 * 0.1 * 6 = 0.015 cubic meters. m.

In one cubic meter of material there will be: 0.015 cubic meters - 47.61 pieces.

For any shipment, the number of boards is rounded down. When purchasing, it is better to buy 15-30 percent more material, as some will be rejected. It is better to initially stock up on a large quantity of products, since wood from another batch may not be suitable.

How to choose a floorboard

The choice of boards is no less important; the correct choice depends on the durability of the structure. You can answer the question which floorboard is better to choose.

First of all, the choice of boards is based on the type of structure.

- For outdoor purposes, it is better to use a terraced dock. It is less susceptible to moisture. Due to the texture of the coating, water does not accumulate on the floor covering.

- For residential premises, tongue and groove boards made of oak and alder are used; they are distinguished by their appearance and long service life.

- A more budget option is flooring made from coniferous trees. You can combine different types of wood to implement design solutions.

Ordinary floorboards are used for rough work.

If you decide to build a bathhouse, it is best to use larch boards. Boards made from coniferous trees are not suitable for building a bathhouse. When heated, they release resin and are highly susceptible to moisture, which means bacteria and fungus can grow there.

Quality classes of floor lumber

The following types of wood are used for arranging the floor surface:

- Extra class. Wood of this class is mainly used for finishing flooring. There are no defects or knots on the canvas, the surface is smooth and has a uniform shade.

- Class A. There are no cores, cracks or chips on the surface of the material. Resin and knots can be located at a distance of 1.5 meters from each other. Used for finishing flooring.

- Class B. Acceptable at a distance of 1.5 meters are 4 knots, minor damage and 2 non-through cracks. Used as finishing floor coverings.

- Class C is a low class of wood. Most often used as a rough coating. The canvases have visible defects: cracks, chips, knots.

Photo of the ideal floorboard in the interior

Production

The production of floorboards is on a grand scale, because the popularity and demand for this material is growing every year. To produce high-quality flooring material, different types of wood are used. At the production stage, logs undergo several stages of processing; knots, branches, and mechanical damage are removed from them.

A large log is cut crosswise and then processed. After this, the blanks are sent to the workshop, where they are cut into individual boards. Of course, the technological process is wider and more complex; we are talking only in general terms about the production of floor coverings.

Lumber shop

Attention! For the manufacture of flooring, it is better to use coniferous wood; this option is attractive both in terms of price and quality. Although it is permissible to use maple or birch wood.

As already mentioned, not every type of wood is suitable for making floorboards. The most valuable species are larch and oak. But linden and poplar are generally not used for this purpose, because they do not have sufficient strength. Aspen and pine are suitable for floorboards, but these species are not used so often. Although pine produces high-class products. After the boards are processed, they are sent to the sawmill, then they are fed to a special four-sided machine for the production of floorboards, after which the finished product is again processed and dried.

Wood for lumber production

Wood defects

We invite you to familiarize yourself with our range of materials

Floorboard – Prima grade

Wood Larch Width 120 mm Thickness 27 mm Length 3 m Qty.

in pack 4 things. 3000 rub/m2Floorboard - Extra grade

Wood Larch Width 120 mm Thickness 27 mm Length 3 m Qty.

in pack 4 things. 3400 rub/m2

Shipping and payment

We deliver lumber using our own vehicles throughout Moscow and the region (the vehicle is selected based on the volume and maximum length of the purchased products).

Pickup from our warehouses and delivery to other regions by transport companies is possible. Payment Methods:

- Cash payment.

- Cashless payment (invoice with VAT).

The materials necessary for loading lumber and preserving their presentation are also provided free of charge - spacers, bars, packing tape, etc.

Road map

1 You leave a request for consultation with a specialist Or call us at +7 (495) 765-26-38

2 You receive a calculation of the cost of the order, we prepare the documents

3 We reserve goods in the warehouse

4 Choose delivery or pickup from our warehouses

5 Decide on the payment method

6 You receive high-quality lumber on time