The starting profile is used during the installation of wall and ceiling cladding made of plastic panels; the element can be used when finishing surfaces with plasterboard boards, etc. Due to this element, the appearance of the tiled surface is significantly improved, work is accelerated, and the final quality is improved. The L-profile is installed in corners, near door and window openings. It is also used at the junction of wall finishing and floor coverings.

Collapsible starting L-profile

Improved starting collapsible L-profile

Ceiling mount

The ceiling frame is a mesh of ceiling profiles, fixed to the ceiling with guide analogues and U-shaped brackets. You can also use quick hangers. A natural question arises: “How to attach profile hangers? » They are mounted in increments of 500 mm under the attached supporting profile. And then their ends sticking down are pushed apart. If direct hangers are selected, then the profile is attached to them with self-tapping screws with a press washer. And for analogues with traction, it snaps onto their special protrusions.

A mesh of profile strips is mounted on one side in increments of 400 mm, and on the other - 2.5 meters. During installation, the PN is controlled by level, and the supporting profiles are attached along a tightly stretched thread. Excess sections of the profile are cut off at an angle of 45o. The installation process of the ceiling structure should begin with the corner parts, and then move on to the straight ones.

Application of products

There are two types of slopes: one of them is located outside the building, the other is located on the inside. Both types require proper finishing. The slope is intended not only to give the windows an aesthetic appearance, it performs important protective functions.

Plastic windows are attached to the opening using mounting foam. It deteriorates under the influence of moisture and is gradually carried away by the wind, which is why it is important to install a slope profile that can protect the structure from adverse weather conditions. Otherwise, the foam may become deformed and damage the window frame.

Application of F-profile for finishing the external slope

Read more on our website about the types of platbands for metal-plastic window structures. How to finish the slopes of plastic windows with your own hands, see the link. We choose the most “correct” slopes for plastic windows. Prices for different types of slopes, consumer reviews

When replacing windows yourself, do not forget about installing sills for plastic windows.

Fastening materials for guide profiles

The quality of installation of the guides depends on the chosen fasteners, because how well the frame is connected to the load-bearing walls determines almost the entire safety margin of the finish and the ability to hang additional elements on it.

The main feature is hidden in the self-tapping screw for the profile, which is not screwed in, but is driven into the attachment points like a regular nail. Why is there not a drill on the tip, but a pointed end. However, you need to select the type of fasteners in accordance with the material of the walls of the room where the repairs are being carried out. A dowel-nail cannot always provide reliable fastening in the thickness of the masonry. It is best used for installation work in rooms with concrete and brick surfaces.

Characteristics of dowel nails

Existing sizes of dowels for profile installation Today, aerated concrete and foam blocks, rather soft and fragile materials, are increasingly used for laying walls and partitions. Guide profiles are attached to such surfaces using another type of dowel - crocodile.

This is a metal type of fastener with longitudinal slots and teeth. When the mounting screw is screwed in, it opens and is securely fixed into the thickness of the wall with hooks. In wooden buildings, you can use a regular self-tapping screw of the appropriate length, without pre-drilling and driving in dowels.

Design of metal dowel nails for concrete

Design options for plastic dowels

In houses built with raw brick, the selection of fasteners is individual. Dowel-nails are definitely not suitable; most often it is better to fasten with long self-tapping screws (120-150 mm) or crocodiles, which are better fastened in such materials. The choice of fastening material should be taken responsibly, otherwise inappropriate hardware will not provide reliable fixation in repair areas, which is dangerous due to collapse of the assembled structures.

How are guide profiles attached to the surfaces of walls and ceilings and what technological nuances are observed during the work process?

PVC panel design: choice of color and texture

The advantage of plastic panels is the wide range of colors and textures. It is not difficult to choose a material that ideally matches the style of the window profile. Modern finishing technologies make it possible to produce panels with a surface that imitates natural materials - brick, stone, metal, marble, granite.

PVC can be combined with window profiles, walls or fittings. Depending on the chosen style in the room, use plain or colored materials, varnished, laminated with glossy or matte film.

Advantages and disadvantages of plastic slopes:

The disadvantages of plastic slopes are relative, because they are easy to prevent or eliminate. These include the risk of breakage as a result of a strong impact or the impossibility of local repairs: to eliminate a cut or crack, it is necessary to remove the entire panel

Installation of rack profiles for drywall

So, the guide profiles around the perimeter are fixed. Now we will learn how to attach a drywall profile to a wall. To do this, we take rack profiles 60x27 mm (CW or PS).

But before doing this, you need to saw off each such profile to size. To do this, use a tape measure to measure the distance from the guide profile on the ceiling to the guide profile on the floor and subtract one centimeter from the result obtained.

This is necessary so that the rack profiles can be easily inserted. It’s more convenient to insert from the top first, and then insert the bottom diagonally:

After the first rack profile is installed in place, we immediately grab (fix) it with hangers (crocodiles), that is, we bend them, moving them to a U-shaped position.

We move on to the next rack profile, do it in the same way: first insert its top, then insert its bottom diagonally and grab it with U-shaped hangers.

After the rack profiles are installed, stretch the nylon thread and align them on the plane. To do this, take a mounting bracket (self-tapping screw with a press washer, 4.2×13 mm without drill), attach it to the profile and screw it into the profile not completely:

We take a nylon thread and put it on the screw so that it holds.

And tighten the screw at low speeds.

Stretch the skein of thread. You need to pull it 10-15 cm above the suspensions (crocodiles). We stretch the thread, go to the other side wall and screw in the screw there a little, after which we tighten the thread.

And tighten the screw. Let's move on to the top row of hangers and do the same thing.

So, two threads are stretched. You can start installing rack profiles.

An important nuance! You need to set profiles from the last one and then everything in order

Therefore, it is important that the other profiles do not touch or pull the thread. To do this, we take two self-tapping screws, press on the profile and insert them into the side holes in the U-shaped suspension to fix the profile so that the profile does not reach the thread.

Thus the following profiles.

Now you understand: to the question of how to attach a drywall profile to a wall, you can answer that this is a rather lengthy and careful procedure that requires care and patience. But let's continue.

Now all the profiles preceding the first profile are pressed against the wall. We begin setting up the first profile. The profile should under no circumstances bend the thread.

But also he should not be too recessed in relation to her.

It is optimal if the distance between the thread and the profile is about 1 mm or even less.

Let's start fastening - we use self-tapping screws with a press washer. We insert a self-tapping screw onto the screwdriver bit. We hold the profile with one hand, and with the other we screw a self-tapping screw into the side of the profile through the hole in the suspension.

It is better to try to secure it in the middle of the profile.

We do the same on the other side of the profile.

The thread does not touch the profile, which is optimal.

We secure all subsequent profiles in the same way.

Upon completion of installation, the threads are removed. And the protruding ends of the U-shaped hangers are bent inward, but this is provided that the wall will not be insulated. If insulation is installed between the profiles, then it is too early to bend the hangers - they will still be useful.

What is the difference between an ordinary starting L-profile and a collapsible one?

An ordinary profile is made using automatic presses and consists of one continuous element. This design creates problems for builders when cladding walls; it is difficult to work with - individual panels constantly go beyond the top strip during filling, and it is difficult to insert them back there.

Starting L-profile

In addition, this procedure is performed with a metal object, most often a kitchen knife, and it can damage the front surfaces of the panels. If excessive force is applied, their attachment to the support rail is disrupted. The risk of damage increases if the fixation is made with a stapler; such fastening is not reliable. When bending the panel to fit it into the profile, the thin tongue of the panel breaks off.

Start profile

Starting profile (L)

Collapsible starting L-profile

How to mount a metal profile on a wall

Tip: Before installing a wall frame made of a metal profile, all work related to electricity is carried out: wires are supplied to switches, sockets, lighting fixtures, and all household devices.

The technology for installing a wall frame consists of finishing each wall separately.

Installation of a metal profile on the wall

The instructions for attaching the frame to walls made from a plasterboard profile suggest the following procedure for performing the work:

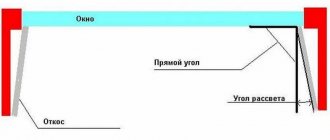

- Walls with windows require special attention when constructing the frame. If you need to insulate walls, vertical profiles are installed at a distance of 50 millimeters from the old slopes.

- The width of the window sill has an influence; when finishing the walls after its installation, the marking of the frame starts from the window. But the thickness of the plasterboard sheet must also be taken into account; it can be 12.5 or 9.5 millimeters.

- A square is applied to the frame and the required distance is measured, adding 5 centimeters on the other side of the opening. You can immediately install a PN to the “bottom” of the window sill, with a pitch of vertical posts of up to 60 centimeters.

- A building level is applied to the risks, which will help transfer them to the side planes of the window sill.

- The marks on the floor and ceiling are connected.

- The profile guides are installed along these lines:

- on the sides of the window, the verticals in this case are marked from these profiles in increments of 60 centimeters;

- one of them must be installed in the corner of the room.

- The hangers are mounted in increments of 60 centimeters, with the center strictly along the line.

- Rack profiles are installed in the guides so that their middle groove coincides with the mark on the floor and ceiling, and then they are connected to each other.

- The level regulates the verticality of the elements on the shelves and base.

- The final fastening is done with self-tapping screws.

- The crossbars are fixed using a “crab”. A horizontal lintel is installed above the opening.

- After the metal frame is completely secured to the wall, you need to sketch out the placement of the transverse and longitudinal profiles. This diagram will be required if there is a need to place paintings on the wall, an additional shelf, or attach a decorative flowerpot to the ceiling.

- In this case, so-called “umbrellas”, “butterflies” and other similar elements are used for fastening, which are fastened according to this principle: when a screw is screwed in, a plastic dowel spreads its “wings”, which ensures reliable fastening on the back side of the plasterboard sheet.

Finishing methods

There are several ways to tidy up your window. These may be the following options:

- Finishing with plaster. This method is quite old. Its main disadvantage is the complexity of the work. Plastering is time-consuming and requires careful cleaning of the area after finishing. When a house shrinks, it may crack.

- Application of drywall. This option is not bad, but it is only suitable for interior work. The room must be dry and warm, otherwise the sheet of drywall will begin to collapse.

- PVC profile for slopes is the best option. It is not afraid of moisture, temperature changes, is easy to install, and can be used both outside and indoors. This is an excellent solution for plastic windows, as it matches them perfectly in terms of material; the PVC F profile for slopes is very easy to install. It is quite possible to do this yourself. With other materials, for example, wood, the profile may not look so harmonious, although you can order wood lamination, and the differences will not be noticeable.

PVC profiles for slopes

Drywall

The main material you will have to deal with is a sheet of drywall. GKL (gypsum plasterboard sheet) can also be called Knauf-sheet (from the name of a German company whose main activity from 1959 to the present day is the production of plasterboard and its components). This company developed plasterboard technology, which is used today by all other manufacturers, from small “handicraft” factories to the largest manufacturers.

Despite the fact that the technology for producing plasterboard is the same, the quality of the finished product can vary dramatically, since it also depends on what equipment is used for drywall and what materials are used as raw materials. Therefore, if you want to achieve good results in repairs, purchase only drywall from a well-known brand manufacturer that guarantees high quality products.

The plasterboard sheet structurally consists of three layers: two outer layers made of special cardboard and an inner core made of gypsum mixture. By adding modifying additives to the gypsum composition and impregnating the cardboard jacket with special mixtures, the following types of plasterboard are obtained.

Conventional drywall (GKL) is used in domestic, office and industrial premises with normal temperature and humidity parameters.

Moisture-resistant or waterproof plasterboard (GKLV) is highly resistant to exposure to moist air. The use of such gypsum boards in rooms with high humidity guarantees the absence of warping and delamination of the sheets, and the occurrence of mold or mildew.

Fire-resistant plasterboard (GKLO) is indispensable for industrial premises where there is an increased risk of fire. In general purpose domestic premises there is no need to use such sheets, since the fire resistance of ordinary plasterboard meets all fire safety requirements.

In some cases (rather infrequently), fire- and moisture-resistant plasterboard (GKLVO) is also used. Each type of sheet has its own marking, applied to its back side and a specific color of the facing cardboard.

Currently, you can purchase plasterboard sheets in several standard standard sizes. For renovation of domestic premises, it is convenient to use plasterboard sizes of 1200*2500mm. The thickness of the sheet can also vary. When installing the ceiling, sheets with a thickness of 9.5 mm are used (the weight of a sheet of plasterboard is approximately 25 kg). For leveling or constructing walls, the recommended sheet thickness is 12.5 mm (plasterboard weight is 30 kg).

Advantages

The starting profile for PVC windows has several obvious advantages:

- Ability to resist ultraviolet radiation. The profile does not fade even for ten years.

- The material is durable, looks good, and can fit into any interior without standing out.

- Suitable for use both indoors and from the facade.

- Moisture resistant.

- The chalk content in the composition is minimal.

- The semicircular end of the tail allows you to lay the profile on the most uneven wall.

- Hides wall imperfections, levels slopes without the use of other materials.

- The plank can be safely cut, no chips or cracks will appear on it.

- Installation is carried out independently; this does not require special skills.

- No glue is used PVC windows and slopes

Installation of drywall with adhesive mixture

This assembly is the most complex and painstaking way to level walls with plasterboard without a frame. Installation is carried out in the following order:

- Inspection of the leveled surface. Includes identifying protruding areas of walls and piers. In these areas the amount of adhesive applied will be minimal. Identifying areas with swollen plaster and putty. Such places will need to be cleaned.

- Preparing the surface for installation. Mechanical removal of old wallpaper, tiles, peeling plaster. Notching sections of walls coated with oil or pentaphthalic paints.

- Primer of walls and partitions. It is better to use a deep penetration primer as a primer. For areas covered with paint, concrete contact can be used.

- Installation of beacon marks. The main task of such an event is to create support points for the back side of the gypsum board. Plastic dowel clips with self-tapping screws screwed into them can serve as beacon marks. The heads of the hardware should create a plane on which the drywall will be mounted.

- Installation of plasterboard sheets. A special adhesive mass is applied to both the wall and the plasterboard. The glue is not applied in a continuous layer, but in fragments. The distance between such fragments is 30–40 cm. The height is 15–20 mm greater than the gap between the base and the back side of the drywall. The sheet is pressed against the wall, and the correctness of its installation is checked using a rule with a level.

Walls leveled using any of the above methods are ready for finishing. Any of these methods is the shortest path to success in repair.

Window profile F-shaped, 2.5 m

Description

The profile is intended for decorative interior decoration during the assembly and installation of windows and installation of slopes. Used to close gaps or fastening elements. Size - 250 x 5 cm.

Characteristics

Product type Slope profile Manufacturer's article 10000477 Type F-shaped Material PVC Color white Length, cm 250 Width, cm 5 For panels thick, mm 10 Weight, g 150 Country of origin Russia Additional information The width of the product is composite - 50 mm (main part profile) + 10 mm (slope) Package dimensions (WxHxD), cm 8 x 250 x 5

Sources

- https://plastokonnik.com/napravlyayuschie-dlya-otkosov-plastikovyh-okon/

- https://delaydachu.ru/steny/f-profil-pvh-dlya-otkosov.html

- https://dekoriko.ru/paneli-pvh/startovyj-profil/

- https://stroy-podskazka.ru/stroitelnyj-profil/kakim-byvaet-f-obraznyj/

- https://LeroyMerlin.ru/product/profil-pvh-f-obraznyy-dlya-paneley-5-mm-18720743/

- https://www.Castorama.ru/profil-okonnyj-f-obraznyj

How to attach drywall to a wall without a profile. Secrets of the frameless method

Successful perception of the repair and construction work carried out. Even the most sophisticated finishing materials will lose all their luster against the background of depressions or bumps in the wall planes. Therefore, leveling the walls during repairs can be considered a priority. Drywall is ideal for this purpose.

GCR, as a finishing material, does not require special advertising. Moisture-resistant, regular, fire-resistant - for any room you can choose plasterboard of the required quality. For bathrooms - moisture-resistant, for the corridor - fire-resistant, common for living rooms.

Standard sizes 600x1250, 1200x2000, 1200x2500, 1200x3000 allow the use of this material with virtually no waste. After minimal processing, the surface of the sheets is ready for wallpapering, applying textured plaster, and laying tiles.

There are two ways to attach gypsum boards to walls - framed and frameless.

- The first option is much more suitable for large rooms where there is no space limit. The frame made of profiles and the drywall mounted on it take away at least 40 mm of the floor and ceiling of each wall (27 mm - profile + 12.5 mm - gypsum board).

- The frameless method allows you to attach sheets of drywall directly to the vertical surfaces of a room or office. In addition to saving space, this method is more profitable from an economic point of view. The financial component of the frame is 60% of the cost of the walls mounted from gypsum plasterboard.

There are three options for frameless installation of plasterboard sheets on walls:

- Fastening sheets with self-tapping screws.

- Installation of gypsum boards with dowels.

- Gluing drywall.

Seal the cracks in the internal slopes

When there are still cracks and they need to be hidden, the most effective and most frequently used method is to use a special putty. You should not use gypsum putties - they do not bond with plastic, they will crack and a crack will appear immediately after drying. Epoxy putties are much more effective, but the resin is difficult to remove from plastic, and sanding results in scratches.

The best putty for plastic is acrylic! This is a material that goes well with plastic, a large selection of colors to match the window sill or panel. Acrylic is sold in buckets or tubes, from which it is squeezed out using a construction syringe. The spout of the tube can be cut off depending on the width of the slit. Some craftsmen use rubber spatulas to smooth cracks. But the most convenient tool is your own index finger! To work with acrylic, the finger is moistened with water so that the sealant does not stick to the skin. Excess acrylic can be easily removed with a damp cloth. You should not work with acrylic from bottom to top. It is more convenient to first fill the gaps between the vertical panels and the top lintel, as well as the panels and the window frame. Gradually moving downwards, remove the cracks on the side sandwich panels, and finish by eliminating the cracks in the joints with the window sill.

The manufacturer indicates the period for complete hardening of acrylic on the packaging, as a rule, this is up to a day, although polymerization begins immediately, under the top layer the acrylic will remain soft for a long time. On the second day, the cracks should be inspected - sometimes they draw in acrylic and you have to apply another layer.

It is better not to sand acrylic, but to remove the old one and apply a new one.

If it is not possible to avoid the appearance of cracks at the junctions of the panels with the window sill, then the situation can also be corrected by other methods. The first way is to cut out a small piece of plastic bead covering the joint and glue it to the window sill with mounting adhesive. It is better to cut the edge facing the room diagonally, decoratively. You can use an L-shaped profile instead of a bead, but this option is worse, since the profile has low rigidity.

Types of profiles for drywall and rules for their installation

The most commonly used are the following varieties:

- Guide. Used as a horizontal base for vertical posts. It is marked with two capital letters - PN. Selected based on the following dimensional characteristics;

- Rack profile (PS). Made in the form of a channel made of galvanized sheet. The flanges of its cross-section have longitudinal grooves that provide the required rigidity. It is secured with self-tapping screws when constructing vertical frame posts for the construction of walls and partitions;

- Ceiling profile (PP). It is made of the same cross-section and from the same material as the rack-mount one. The reliability of the entire structure will depend on knowing how to properly attach a drywall profile to the ceiling. There are three longitudinal grooves in its back and shelves. The outermost ones are responsible for rigidity, and the central groove allows for precise fastening of drywall sheets (GKL);

- Angular. It strengthens the corners of the structure after the main work with drywall. It is marked (PU), made at 90o. This profile protects the outer and inner corners of the cladding from mechanical damage. It is made of galvanized perforated tape, on the surface of which there are small holes. The solution penetrates through them and ensures reliable adhesion of the profile to the overall structure;

- Arched profile (PA). It can be concave or convex. It is used not only to decorate window and door openings, but also to create complex wave-like hanging structures.

Using the listed profiles, frames are erected. They largely depend on the correct installation of the profiles. Several rules for their installation should be taken into account:

- You can attach two ends of a sheet of drywall to the profile post. The main thing is that they are located equally on it;

- screws are screwed into the profile strip near the wall to avoid them getting into the end of the material;

- Do not attach screws at an angle. Their cap should be recessed;

- if the length of the profile during installation is not enough, then it is extended using a special extension, the type of which depends on the location of the joint.

Peculiarities

The plastic starting profile for PVC panels looks like a U shape, one side of which is usually slightly shorter than the other. As a rule, installation of the entire structure begins with its installation, which is why it is also called initial. It “sets” the direction of the entire plastic finishing structure. This molding is used to cover the ends of panels, and, in addition, in cases where the PVC sheet is adjacent to the openings of windows or doors. Its use can significantly save time and materials for finishing and installation work.

Such elements have a number of obvious advantages. They generally exhibit resistance to ultraviolet rays and can avoid yellowing for up to 10 years. The material is elastic, but not brittle, so when cutting you can prevent the appearance of cracks. The composition is good because it contains a minimal amount of chalk and substances harmful to the human body.

The moldings are easy to install and, thanks to their convenient shape, fit smoothly even with uneven walls.

On which profile can drywall be fixed?

For ease of installation, you can use a plasterboard wall profile, which comes in four types:

- Two of them are used for mounting frames on walls and for making partitions.

- Two - for installing a frame on the ceiling.

The standard length of the elements is three or four meters. The thickness of the metal used for their manufacture is from 0.4 to 0.8 millimeters. The best option is with a profile thickness of at least 0.55 millimeters. In addition, two types of elements are used for finishing plasterboard surfaces.

According to their purpose, profiles are:

- Rack or PS. They have a C-shape with longitudinal grooves. The base of the element is the “back”, its width ranges from 50-100 millimeters, and the sides are “shelves”, their size is always 50 millimeters, used for installing partitions and cladding the room. Used when installing vertical racks.

- Guides or PN. Manufactured in U-shape with dimensions:

- 40 mm shelf width, always constant;

- from 50 to 100 millimeters, base dimensions.

They are used to create partitions and wall frames. During installation, it is fixed to the ceiling and floor, creating a rigid frame for the main structure.

- Ceiling or PP, with dimensions: 60x27 millimeters, have three identical longitudinal grooves. Used to construct a suspended structure.

- Ceiling guides or PNP, their dimensions: 28x27 millimeters. They are used for mounting frames on ceilings and as a vertical element for walls.

- Corner or PU, sizes that are: 31x31, 25x25 millimeters. Used to strengthen corners. They are made external or internal, which differ in parameters and purpose.

- Arched or PA have a curved or convex shape. They are used to design arched doorways and create complex suspended wave-shaped structures.

Profiles for drywall installation

The following additional elements are used:

- Connecting sleeve to increase the length of PP profiles.

- The crab is made in a cross shape and is used at the intersection of profile elements, as in the photo, which increases the strength of the structure. The two-level crab is mounted on the upper-level PP and firmly fixes the metal profile of the lower level.

A straight hanging element is attached to the surface and bent along special lines. Then the profiles are installed and fixed into the U-shaped opening. Excess “ears” are carefully bent or cut off.

Tip: When using such a fastener, it is necessary that the under-ceiling space is no more than 6 centimeters.

Clamps and rods of anchor suspensions. With their help, you can adjust the height of the inter-ceiling space in the range from 25 to 100 centimeters. The supporting part of the element ensures a stable location of the PCB.

How to choose hardware for mounting profiles

Hardware for fixing guides and hangers should be selected based on the type of surfaces for which they are intended.

- For walls and ceilings made of concrete, the profile or anchor hangers are fixed with dowels, the dimensions of which are 6x60 or 6x40 millimeters, which depends on the quality of the surfaces.

- On wooden bases, screws measuring 6x70, 6x80 millimeters are used for fastening.

- All metal structural elements, such as: straight hangers to ceiling profiles, rack-mount profiles to guides, couplings, crabs, are best fixed together with self-tapping screws with a pointed end, dimensions 3.5x11 millimeters.

- Drywall is attached to metal profiles with self-tapping screws with fine threads of 3.5x25 millimeters, made of galvanized steel. In this case, there is no need to make any holes first.

- Profile guides for making plasterboard ceiling racks can be fixed with special drop-down dowels, ensuring reliable fastening.

What tools are needed when installing profile elements?

The profile for plasterboard walls is attached to:

- Direct hangers.

- Anchor hangers.

- Crab connectors.

To install the frame and lay insulation you will need to prepare:

- Hammer for drilling holes for installing dowels.

- Screwdriver.

- Electric drill with a special attachment for fixing drywall.

- Screwdriver.

- Staple profile or cutter.

- Rasp.

- Jigsaw.

- Wire cutters.

- Construction level with magnetic side.

- Water level.

- Laser level.

- Chockline or painter's cord.

- Blue.

- Plumb.

- Metal or wooden square.

- Dowels and drills for them, 6 mm in diameter.

- Self-tapping screws, 4 mm in diameter.

- For cutting profiles, metal scissors.

- Double-sided tape.

- Protective gloves.

- A mask to protect the face when working with insulation.

Competent selection

When purchasing material, first of all, pay attention to the technical parameters. But, as a rule, all sizes are standard. Therefore, it is difficult to make a mistake when choosing. The exception is the use of custom-made cladding panels. In this case, it is necessary to check that their ends fit well into the grooves of the profile.

Types of profiles for PVC panels Source 100panel.ru

Metal profile reinforced UA

The reinforced profile for plasterboard is used to increase the strength of the structure in the following cases:

- creating a suspended ceiling with increased weight;

- fastening door and window frames;

- when you need to strengthen tall structures;

- wall decoration with placement of a large number of communications.

USEFUL INFORMATION: Butterfly fastening for drywall: sizes and types of dowels

The thickness of the metal is 2 mm, and the height of the shelf is 40 mm.