Ceramic block is often called porous or warm block.

This is a modernized hollow brick, which in some aspects is similar in its properties.

Currently, ceramic blocks are a popular material for construction. Various objects are built from them.

Read about the advantages and disadvantages they have, as well as how real people and builders speak about them.

Advantages of warm ceramics

Although quite recently this material was used exclusively for the construction of small one-story buildings in the countryside, modern porous ceramics make it possible to build beautiful houses with 2-3 floors. They meet both the requirements of reliability and stability, as well as comfort. The main advantages of warm ceramics are:

- High thermal interstitivity. As the name of warm ceramics suggests, living in such a house will be very warm. Moreover, this does not require the installation of additional insulating boards or special impregnations.

- Good vapor permeability. This is especially noticeable in contrast to wooden buildings, which, without proper waterproofing, tend to absorb moisture from the air and subsequently rot. Warm ceramics release steam from the interior to the outside, which creates an optimal indoor climate inside the house.

- Excellent sound insulation. The porous structure prevents the penetration of sound waves into the house, which will be a very good option for private construction within the city, or in the presence of noisy neighbors.

- Very light weight. Ceramic blocks, as a rule, are made in large formats, and about 70% of their content is air. A brick of the same volume weighs about 5 times more. This greatly facilitates the delivery of material to the construction site, speeds up the work itself and makes it easier to construct the building yourself.

- Environmental friendliness. Ceramics is one of the oldest natural materials that was used not only for construction, but also for the manufacture of kitchenware, toys, and furniture. Ceramics do not emit any substances harmful to humans even when heated, and their houses are very pleasant to live in - time-tested.

- Speed of construction. In addition to their light weight, blocks made of warm ceramics have fewer seams than brickwork, which is compensated by their ribbed surface, and all this together will allow you to get a turnkey house from a ceramic block much faster than from other materials. Projects of houses made of warm ceramics in some construction companies involve the construction of a completely finished building in just 3 months.

- Stability of masonry. Asymmetrical recesses in ceramic blocks allow them to be stacked together like parts of a construction set, thereby achieving a strong “adhesion” between its individual parts (the so-called tongue-and-groove system).

- Unmatched durability. According to studies conducted by the Central Research Institute of Building Structures, such houses can last up to 200 years without major repairs.

- Fire resistance. Many insulation materials are quite flammable and spread fire. For ceramics, this is not at all scary - firstly, it usually does not contain additional insulation, and secondly, ceramics itself does not burn at all, which is confirmed by the technology of its manufacture itself.

- Saving. Unlike brick or concrete, ceramic blocks do not need additional insulation, and unlike wood, it does not need to be treated with fire retardants or antiseptics, which will avoid unnecessary costs.

To select a contractor who is ready to provide professional assistance in preparing documents on a land plot and a house construction project, we recommend using the company search in the Building Companion catalog. In the contractor’s profile, you can view reviews, portfolios, and request an estimate of the cost of the work. Get advice from specialists on preparation for construction »

Comparison of ceramic blocks from different manufacturers

Let's compare materials from different manufacturers according to their main characteristics. For ease of comparison, let’s take a ceramic block of one of the popular sizes, 380x250x219mm, also known under the technical name 10.8NF*.

| Manufacturer | Brand | Thermal conductivity, W/m °C (λ) | Frost resistance, cycles (F) | Strength grade (M) | Weight, kg |

| Wienerberger | Porotherm 38 | 0,145 | 50 | 100 | 15,5 |

| Porotherm 38 GL (Green Line) | 0,166 | 50 | 100 | 12,0 | |

| Porotherm 38 Thermo | 0,123 | 50 | 100 | 14,5 | |

| Gzhel brick factory | Gzhel | 0,13 | 100 | 100-175 | 13,6 |

| Brick (LSR Group) | LSR | 0,105 | 100 | 100 | 15,0 |

| Nikolsky Brick Plant (LSR Group) | LSR | 0,18 | 100 | 100 | 17,0 |

| Brick Factory Braer | BRAER | 0,14 | 50 | 100-125 | 17,0 |

| Slavic brick | POROMAX-380 | 0,189 | 50 | 100 | n/a |

| JSC "BIOTECH" | THERMOBLOCK 38 | 0,16 | 50 | 100 | 17,5 |

| SKKM | KERAKAM 38 | 0,19 | 50 | 100-150 | 19,0 |

| KERAKAM 38 Thermo | 0,15 | 50 | 75-100 | 16,7 | |

| KAIMAN 38 | 0,084 | 75 | 75-100 | 14,54 | |

| "Amstron" | PORIKAM 10.7 NF | 0,16 | 50 | 100 | 18,7 |

| PORIKAM 10.7 NF (PG) | 0,19 | 50 | 10018,0 | 18,0 | |

| PORIKAM 10.7 NF V | 0,16 | 75 | 75-100 | 17,4 |

* All data is taken from the official websites of manufacturers.

Disadvantages of warm ceramics

There is not a single construction material that does not have its drawbacks.

The main disadvantages of warm ceramics are, of course:

- The fragility of the material itself. You need to be careful with ceramics both during construction and during subsequent use. Sawing or trimming ceramic blocks, as well as drilling or tapping walls should be done extremely carefully. Although, by choosing the right fasteners and proper work, this drawback can be leveled out: it is quite natural that a concrete dowel will not hold in ceramics. For ceramic blocks, you need to use special anchor bolts equipped with small antennae, which ensure reliable fastening into the material without destroying it.

- Lack of ideal geometry. Of course, everything here depends on the manufacturer, however, in the fit of the blocks as a whole there may be a small (up to about 0.5 cm) error. However, uneven masonry can be smoothed out due to a high-quality seam, so this minus cannot be considered fatal either.

- Fragility in relation to dynamic loads. Yes, ceramic blocks do an excellent job of withstanding statically pressing weight. However, with the slightest movement of the ground or errors in design, the blocks risk breaking, which threatens the collapse of the entire building. The same applies to construction in regions with high seismic activity.

- Price. Despite the absence of many additional works, warm ceramics are still a rather expensive material. It will cost about 10-15% more than gas blocks and many other building materials.

Importance of solution

Ceramic material will fully perform its functions only if it is laid correctly and the mortar is selected correctly. Otherwise, the interblock seams will facilitate the passage of cold flows and reduce the thermal insulation properties of the material. In addition, an incorrectly chosen or poor-quality solution can “fall” into the voids of the blocks and form gaps between the elements.

Construction technique

One of the mentioned features of ceramic blocks is their lightness, which allows the use of inexpensive types of foundations, which also makes such houses very budget-friendly, despite the cost of the material itself. A shallow (above the soil freezing level) strip foundation is quite suitable. A pile foundation would also be an excellent option, but here it is especially important to correctly calculate the load on it. In general, of course, you need to pay attention not only to the weight of the future house, but also to the type of soil - if it is rich in groundwater and is not solid, you need to lay the foundation deeper than the freezing level of water.

The first layer of ceramic blocks is laid on a cement-sand mortar on top of the foundation. At this stage, any unevenness on the foundation slab is smoothed out, which makes it possible to maintain an even line of masonry in the future. Subsequent rows are laid on a special solution with the addition of perlite. At this stage, the recesses available in the structure of the blocks will be useful - it is into them that the solution is poured, the excess of which is subsequently removed with a slider. The ribbed structure of warm ceramics adds strength to the masonry. It is also important that different solutions are used for the construction of external and internal walls. If the mentioned “warm solutions” are suitable for the first, then for the second they use a classic cement-sand mixture.

To strengthen the structure, metal mesh is often used. Also, we must not forget about waterproofing. It must be carried out between the foundation and the first layer of the wall.

Material composition and production technology

The following materials can be used as materials used in the production of ceramic blocks:

- clay

- siliceous rocks,

- industrial waste (coal, ash),

- mineral supplements,

- water.

Upon receipt of the material, the feedstock is subjected to the following stages of processing:

- clay and other components of the mixture are thoroughly crushed;

- the resulting mass is moistened and mixed;

- the resulting solution is poured into molds;

- at the next stage, the products are dried in molds;

- After drying, the products are annealed.

Is it worth building a house from warm ceramics?

Of course, when making such an important decision as the choice of material for construction, many more factors need to be taken into account. Aesthetics cannot be ruled out - some will like large dark red ceramic blocks, while others will prefer a classic log house. The initial construction budget also plays an important role. After all, as we have already found out, given the relative high cost of warm ceramics, in the future it can save considerable money - these are not only the costs of insulation, but also the installation of heating communications and their further payment.

To choose the right foundation contractor, use the convenient builder search on the Building Companion website. You will find examples of completed projects and customer reviews for each contractor and can request an estimate of the cost of the work. Find a builder to arrange the foundation of a turnkey house »

We were also convinced that the notorious fragility of ceramic blocks is a myth - they cope well with their function, namely the construction of low-rise country houses, and proper operation during the work and the use of suitable tools will allow you not to spoil the material and enjoy living in such a house for many years.

Summarizing all that has been said, we add that there are no right or wrong, bad or good materials, there are only those that are suitable or unsuitable for you. A house made of warm ceramics is definitely worth building when you are ready to incur some expenses during the construction stage, but then save yourself a lot of hassle, and also if you are not planning to build a very large-scale building above three floors.

The article uses photographs from the site

.

Main mistakes

Now we get to the essence of the story. Since the material is quite new on the modern building materials market, even experienced builders can make inaccuracies and obvious mistakes when working with porous ceramic blocks. Among them:

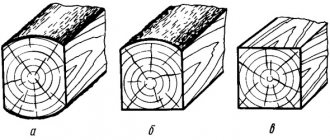

- Laying porous blocks along the wall with the grooved, long side. Such laying is not allowed even for the construction of internal walls, because it can disrupt the adhesion of the blocks. In addition, the thermal insulation properties of each block individually in the perpendicular direction are much less, and the amount of plaster for finishing work will be almost twice as much.

- Combining blocks with bricks and other building materials with higher thermal conductivity is not allowed! This always leads to condensation of moisture on the walls, to the appearance of fungi and mold, and so on.

- Laying rows of ceramic blocks without dressing is also unacceptable! This will significantly reduce the strength of the masonry.

- Different thicknesses of seams between individual rows are not allowed. In this case, the geometry of the walls is seriously disrupted, in the structure of which unevenly distributed loads arise. In this case, thick seams will become potential cold bridges during operation, which will significantly reduce the thermal insulation properties of the walls.

Brick characteristics

It is quite possible that, having learned everything about the disadvantages and advantages of aerated concrete and warm ceramics, you will still decide that brick is best. It is reliable because it has been tested more than once.

But when choosing a brick, you also need to know many nuances. To ensure that the brick meets all your requirements, look for a good manufacturer and never buy bricks secondhand.

Naturally, the brand of brick must meet the requirements. By the way, in modern construction it is allowed to use different materials when constructing one building, so you can combine brick and aerated concrete or brick and warm ceramics.

For example, you can make a load-bearing wall from brick the old fashioned way, and use ceramic blocks inside. Naturally, your imagination must be supported by accurate calculations.