Correct installation of the door structure will provide the proper level of protection. This will also guarantee optimal heat and sound insulation. Let's figure out how to install the front door, what is needed to achieve the best result. We will familiarize ourselves in detail with all stages of work - from dismantling to finishing. We will also consider how to soundproof a metal entrance door.

A door installed according to all the rules always looks beautiful Source potapenkov.com

Dismantling operations

Installation of the front door begins with dismantling work. During the work, you don’t have to worry too much about the integrity of the canvas (when its further use is not planned). But it is important to take care of the safety of the opening. The less it suffers during the process of removing the frame, the easier it will be to install a new door.

Dismantling work is carried out in the following sequence:

- Removing the door leaf . To remove it from its hinges, you need to lift it a little using a crowbar. The collapsible hinges are untwisted, after which the canvas is removed from the opening.

- Removing a threshold . For ease of removal, it is cut into two parts, after which it is knocked out with a heavy hammer.

- Removing the box . This process starts from the side. To make the box easier to dismantle, several horizontal cuts are made. If the side elements of the box have been removed, the upper part will be removed very easily.

Dismantling the old box Source prom.st

- Cleaning the opening . In order for the subsequent installation of a metal door to be successful, the old opening is cleared of plaster and foam. Fasteners are removed.

Dismantling work becomes more complicated if the door frame is metal. First, determine the location of the fasteners. They are removed, after which the box is removed from the installation site without significant effort.

Dismantling a metal door frame Source tildacdn.com

Finishing

When the door is installed, the slopes and the adjacent part of the wall remain uncovered (platbands are needed). In addition, for economy class doors, the inside of the door leaf requires further finishing: powder painting or paneling made of veneer or plastic.

Slopes can be installed from gypsum plasterboard (the process is described in detail in the work: “How to make slopes on plasterboard windows?”), plastic, or sealed with putty. But the most popular option is to finish it with additional trim. The manufacturer can supply the accessory complete with the door.

Attention: for more information about installing the additional strip, see the following material.

Preparing the opening

When studying the recommendations of experts on how to properly install a metal entrance door in a private house, you should not neglect the stage of preparing the opening. If there are pieces of plaster that may fall off, it is better to get rid of them. If large voids are identified, it is recommended to fill them with bricks set on sand-cement mortar. Small potholes can be skipped as they will later be filled with polyurethane foam.

The condition of the floor must be assessed. If necessary, a wooden block treated with impregnation is placed in the opening. Brick can also be used to level the base; minor defects are filled with mortar.

Preparing the opening for subsequent installation of the box Source ytimg.com

Determining factors

The installation features of outdoor metal doors are influenced by the following factors:

- Model design.

- Purpose (for a house, apartment or entrance).

- Type of opening (material, condition).

- Installation method.

The main criterion for the correct installation of the front door in the house will be maintaining the balance of the door block at any opening angle. Errors in installation can ruin all efforts to choose a high-quality and beautiful door, so such an important process requires careful preparation.

Installation

To figure out how to install a metal entrance door, start by leveling the frame. The prepared structure is installed in the opening. The lower part of the box is installed on special pads. By adjusting their thickness, they ensure that the structure stands level. When the loot is aligned horizontally, it is aligned vertically. This process is also controlled using a building level.

The position of the door frame is checked in all planes Source goodoors.ru

Once the box is in the optimal position, it is wedged. Use plastic or wooden wedges. Three fixing elements are installed vertically, and two horizontally. The wedges are placed close to the fastening points.

When the box is exposed, they proceed to fixing it. There are several methods for installing a metal door:

- For the eyes . The simplest and most popular method. A hole is made through the eyelet. An anchor is inserted into it, which is subsequently tightened.

- Through the canvas . The structure can be fixed through special holes that are provided in its design. The wall is drilled through them with a hammer drill, after which anchors are installed.

Fastening through the canvas Source rabotai-sam.ru

See also: Catalog of companies that specialize in doors, windows and related work

- Grips . The method is used when performing installation in a house with reinforced concrete walls. The structure is held inside by special hooks.

After securing the box, install the canvas. If there is a non-separable mechanism, it is simply hung on the hinges. It may also be necessary to adjust the door so that the process of closing and opening it occurs as smoothly as possible.

Installation of accessories

Manufacturers of door hardware do not install only handles - they may be damaged during transportation (the locking mechanism itself is already installed). They must be assembled before installing the frame - you need to check the movement of the door leaf, the operation of the locks and the geometry of the exposed frame.

Assembly of locks.

Handles can be installed on sockets and bars. The former are currently popular.

To install a door handle with a rosette, you must perform the following operations:

- twist the decorative strip (rosette) from both handles;

- insert a square into the door;

- put the handles themselves on the square from the outside and inside;

- Use special self-tapping screws (with sawn heads) to screw the handles to the door leaf;

- insert a threaded pin from the outside to fasten the handles together - prevents the handles from being removed from the corridor side;

- screw in the sockets.

Finishing work

If after installation of the main structural elements no problems are identified, proceed to finishing work:

- Polyurethane foam . All remaining space between the box and the enclosing structure is filled. Polyurethane foam acts as filler and insulation, preventing the penetration of cold air and extraneous sounds from the street into the room. To ensure that the material fills all the voids, the opening is cleared of dirt and moistened with water. The remaining foam is cut off after it hardens.

The entire contour of the doorway is filled with polyurethane foam Source krovati-i-divany.ru

- Finishing . The gap between the box and the wall is carefully leveled. Putty is used, which is applied in several layers.

- Installation of platbands . Such decorative overlays significantly improve the appearance of the opening. The trims are attached to the outside of the door structure.

- Slope finishing . Plastic strips and drywall are used. The slopes can also be puttied and painted.

Opening before and after finishing Source rabotai-sam.ru

- Handle and lock . After installation, functionality is checked. If necessary, the opening mechanism is lubricated with special oil.

Useful tips for beginners from experienced ones

Another portal participant did not photograph the process, but his observations will be useful to anyone who is planning to start making a door.

outsiderForumHouse Member

I also welded the doors; I didn’t take any photos during the process, but I’ll tell you the details. I did this with my father-in-law, they welded a bunch of these doors as a sub at the factory.

DIY metal door, life hacks and conclusions:

- It is better to take hot-rolled iron for cladding; cold-rolled iron has tight geometry and right angles;

- To weld the hinge plate to the box with a clamp, you need to hold it lightly and immediately release it. When the seam cools, the plate will bend with the required gap. All loops are scalded after fixation;

- If you make a special device (as in the figure), pressing the sheet to the corner during welding will avoid “bubbles”;

- To prevent the door leaf from touching the frame during operation, the hinges are welded so that the hinge axis is on the edge of the sheet;

Intermediate draft result in the photo.

Master81 welded two metal doors - double and single (255x110 mm and 210x0.72 mm), and, looking at his creation, it is clear that he is “on the short end” with metal.

The box was welded from a corner five millimeters thick, six is possible, but four is undesirable, the frame is made of a 40x20 mm profile pipe. The manufacture of the structure did not cause any difficulties.

Master81FORUMHOUSE Member

I measured the doorway, minus a centimeter from the width and length, cut the corner straight with a grinder, first assembled the frame, then the frame for the door.

Another of our craftsmen, a FORUMHOUSE member from Moscow with the nickname oss, has already made the sixth metal door, if you count garage doors. The canvas is three millimeters thick, the frame is made of a 50x40x3 mm profile pipe, like most, but he approached the issue of safety thoroughly. Armor plate, internal plate, lever lock with four bolts, protective curtain in the hole. These improvements have increased the cost of the product, but peace of mind is more valuable. What oss lacks in photos, it makes up for with an optimized assembly process and helpful tips.

ossFORUMHOUSE Member

Before this, I made doors using different techniques, including first tying, and then tacking and assembling the frame. The sequence chosen this time seems more optimistic.

The optimized version looks like this:

- I started with the front vertical profile, made a frame, secured the lock in the frame, checked how it worked;

- I made a rear vertical profile, immediately welded the anti-pullers (behind the hinges);

- I assembled the entire frame from profiles using tacks;

- I cut out the trim along the frame (with an overlap of 20 mm);

- “I baited” the sheet, scalded it with oven mitts in increments of 150 mm;

- In the racks of the box (trimming) I cut out grooves for the crossbars and anti-removals;

- I welded a box with gaps (3 and 5 mm);

- Welded the hinges.

Oss recommends installing one combination door lock instead of two different types.

Features of installation in a wooden house

When installing a door in a building with wooden enclosing structures, it is unacceptable to attach the frame directly to the wall. Be sure to use a frame in the form of a beam. It is attached movably, which leaves the possibility of moving the log house as a result of drying out. In this case, the tongue-and-groove connection type is used. The pigtail is held in a given position due to elastic force.

Rigid fastening of a door in a wooden house is unacceptable. At first, the openings in such a building are not filled at all due to too much deformation. To install the door, a groove is cut out in the selected location. Perform a T-shape. The width of the groove is slightly less than the thickness of the tenon. This ensures reliable fixation without the use of additional fasteners. During installation, the casing is inserted into the tenon and driven in with a sledgehammer until it stops.

Casing in the opening Source dvervdome.ru

Conclusion

We will not say that installing iron doors is a cakewalk, but if you follow all the above recommendations, then a person who knows how to hold a drill and a hammer in his hands can cope with such a job.

Doors installed by yourself will be your pride.

If you need to purchase spotlights, then on the page https://ledin.kz/ru/catalog/prozektora today every modern consumer has the opportunity to get acquainted with one of the most practical, reliable and attractive solutions.

Features of work in a building made of aerated concrete

Aerated concrete blocks are not as strong as brick. Therefore, when installing a door structure in such a building, it is necessary to additionally strengthen the opening with a corner.

Strengthening the doorway with corners Source roomester.ru

The fastening of two corners installed at the edges of the opening occurs with vertical jumpers. They should be located in the places where the door frame fasteners will be placed.

Articles on the topic

Preparing a brick surface for plastering - rules, instructions, advice from masons

Cladding windows with bricks - options, stages of implementation, instructions, advice from masons

How to make a roof on a brick house - varieties, strengthening, instructions, advice from masons

Brick sides - what they are called, characteristics, instructions, advice from masons

Heating in a brick house - air, radiator, instructions, advice from masons

Brick ceiling - how to make, options, strengthening, instructions, advice from masons

Insulating a house made of sand-lime brick - stages of work, instructions, advice from masons

Brick partitions - preparation, construction, instructions, advice from masons

Reviews ()

Increasing door sound insulation

Failure to comply with installation technology leads to the fact that the sound insulation of the front door is very low. This problem occurs if gaps occur while filling the gap with polyurethane foam. Noise insulation is reduced if the seal is placed incorrectly (different degrees of tension). Also, the ability of a door to transmit sounds is influenced by the material from which they are made - the type and thickness of the filler, the type of cladding.

To solve the problem, you can choose several options:

- Replace the seal or install it along two contours, which will improve the fit of the door to the frame.

- Install special threshold slats.

- Take care of slope insulation. This will prevent sound waves from penetrating through microcracks in the wall or gaps in the foam.

Door slope insulation Source stroy-podskazka.ru

Soundproofing process

The door is soundproofed after it is removed from the frame. It is necessary to remove the external fittings and lay the canvas on a vertical surface. The subsequent technology for performing the work depends on the design of the door - collapsible or not. In the first case, all decorative elements of the product attached with nails, rivets, and screws are carefully removed. The metal panel from the room side is removed. The internal space of the canvas is first filled with vibration-damping materials based on bitumen (Guerlen), after which sound insulators are laid.

Laying insulation Source aviarydecor.com

To soundproof a non-removable structure, a frame is installed on the surface of the door for subsequent fixation of soundproofing materials. Subsequently, the product is covered with decorative panels. Soundproofing of interior doors is carried out using a similar algorithm.

To perform these works, the following types of fillers are used:

- Minvata . The material is affordable and durable. The filler is fireproof, but when wet it loses its insulating properties.

- Foam sheets . Easy to install, do not absorb moisture, and insulate well. Polyfoam is inexpensive and has a long service life. Disadvantage: flammability.

- Polyurethane . It is not afraid of moisture and is lightweight. Effectively absorbs noise and safe. The disadvantages include the relatively high cost of the material.

- Foampropylene . It is lightweight and works effectively as a sound insulator. The material is resistant to various chemicals, but is classified as flammable.

The variety of insulating materials on the market is encouraging Source krovlyaikrysha.ru

The procedure for manufacturing metal structures

A do-it-yourself iron door, regardless of its diagram and drawing, is assembled according to one algorithm. Initially, individual elements are made.

Box

There are no problems with it, but provided that all measurements and cutting of blanks are made correctly, in strict accordance with the drawn up drawing. It is not difficult to weld individual parts into a single structure of the correct geometry. You just need to work on a perfectly flat, hard surface and constantly monitor the angles. Once the jamb is assembled, all seams are carefully polished with a diamond disc.

It is mandatory to weld hinges and fastening strips with drilled holes to the box. Using the final details, it is fixed to a wall made of any material.

Door leaf

- The frame manufacturing technique is absolutely identical.

- For reinforcement, stiffeners are installed according to the selected pattern.

- A groove is cut for the lock tongue.

- Frame sheathing on one side. It is produced by fastening steel sheets by welding, with a slight overlap. In the area of the hinges it is about 5 mm, along the length of the frame it is about 10 - 15. It is recommended to “tack” the cladding with several seams, no more than 40 mm in length. To ensure reliability of fastening, the intervals between adjacent sections are selected within 20.

- Depending on the design, at this stage of assembling a metal door, the lock fastening elements are installed, the hinges are welded (those parts that are attached to the leaf) and a window for the peephole is cut out.

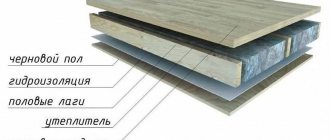

- If it is planned to insulate the sash, then heat-insulating material is immediately laid; it is placed between the stiffening ribs, which prevents it from sagging under its own weight.

- All that remains is to weld the second sheet of metal to the wrong side of the frame and also cut a hole in it for the peephole and the lock cylinder.

- The last thing to do with the sash is to carry out a control check of its geometry and sand all joints, welds and paint with primer to prevent metal corrosion.

If the “one and a half” scheme is chosen, then all technological operations for the small blade are absolutely identical, with the exception of the peephole and the door lock. But upper and lower stops should be provided for fixation in a stationary position.

Briefly about the main thing

Door installation begins after the opening is cleared. The installation of the box is carried out strictly according to the level. The structure is fixed in the design position through special holes, behind linings or grips. After installing the canvas, the resulting gap is filled with special foam, finishing and fittings are installed.

In a wooden building, doors are installed after preliminary installation of the frame. In an opening made of aerated concrete, it is necessary to carry out additional reinforcement of the structure. When installing doors, it is also important how well they cope with sound insulation. If necessary, the canvas can be additionally insulated using polystyrene foam, polyurethane and other materials.