- Causes of cracks in the toilet

- What to do to prevent cracks from appearing on the toilet and cistern

- Where do cracks mainly form on the toilet?

- Ways to get rid of cracks

Modern earthenware is made of quite high quality, so it lasts for many years, but the well-known property of ceramics is great fragility. With a certain mechanical impact or impact, plumbing fixtures can be damaged, so we all sometimes face the question of how to repair a crack in a toilet. In this article we will try to understand this issue in detail.

How to glue correctly at home

Difficulty in gluing a toilet cistern arises due to the fact that cracks and chips on the surface of earthenware and porcelain do not have a smooth texture. Because of this, the adhesive composition holds the parts of the broken device together less well. Therefore, this procedure often has to be carried out two or more times.

What you will need

To glue porcelain and earthenware products you will need:

- fine sandpaper;

- acetone (gasoline), which is needed to remove grease from the toilet;

- glue;

- scotch.

You will also need wipes to remove excess adhesive. Before you begin gluing, you must turn off the water supply and drain the tank.

Surface preparation

The procedure for preparing the surface for restoration work depends on the nature of the defect. This procedure will require more effort for deep cracks that run on both sides of the tank.

Unilateral damage

In case of one-sided damage, the cracks must first be cleaned of dirt (a brush with stiff bristles is suitable for this), and then wiped of grease using acetone or gasoline. Similar actions need to be carried out in relation to the breakaway part.

Bilateral cracks

Before you start cleaning the surface and gluing the tank, it is recommended to use a thin ceramic drill to make a hole at the end of the crack. This is necessary in order to prevent further divergence of the defect and splitting of the plumbing fixtures. Then you need to use a grinder to widen the crack and process the internal surfaces according to the described algorithm. Subsequently, the damaged area is repaired using two-component epoxy resin.

Bonding technology

The procedure for gluing earthenware and porcelain cutlery depends on the size of the defect. The algorithm within which this procedure is carried out is the same for all formulations used.

Universal waterproof adhesive

Adhesive compositions of this type are recommended to be used to eliminate defects in places that are not constantly in contact with water:

- the junction of the tank and the bowl;

- toilet rim;

- the outer side of the tank and others.

The gluing of the tank is carried out in three stages. First, debris and other foreign particles are removed. Then the material is cleaned of fat. And after that, glue is applied and the broken fragment is pressed. The period during which the material must be held is indicated in the instructions for the glue.

This method is suitable for restoring those parts of the toilet cistern that are not subject to increased stress.

Epoxy resin

Epoxy resin is used to seal one-sided cracks. This product removes defects better than all-purpose glue. To restore a damaged tank, you need to mix the two components of this product (hardener and resin) and apply it to the problem area. After this, you need to press the gluing area. In this case, any means will do, including tape. After the resin has hardened, it is recommended to clean the gluing area using fine sandpaper and felt.

Silicone sealant or liquid welding

Both products are suitable for repairing small cracks and gluing broken fragments. Surface preparation for this case is carried out according to a similar algorithm. If a sealant is used, then you first need to saturate the surfaces with silicone, removing the excess with a spatula, and then walk with a soapy hand, thereby smoothing the composition. This restoration option is convenient in that the tank can be used 20 minutes after completion of the manipulations.

Liquid welding gives the same result as sealant. This product must first be rolled out in your hands and then applied to problem areas, compacting it into the cracks. After the four hours required for the paste to harden, you need to sand the surface with sandpaper.

Final finishing

It is recommended to treat the surface with fine-grained sandpaper in each of the above cases. If the crack was large, then after sealing the gluing area should be painted over in the appropriate color. Otherwise, the area where the defect was located will stand out against the background of the rest of the tank.

It is recommended to seal the internal seam with tiled grout.

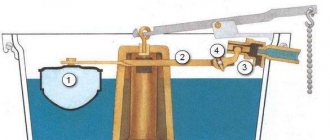

Pear malfunctions

The bulb is, at first glance, a simple, but rather problematic element of the cistern: if it fails, leaks cannot be avoided. There may be several reasons for this negative phenomenon, but in practice there are two most common:

- Loss of elasticity. A pear is primarily a rubber device, and as you know, over time, rubber that is constantly in contact with water loses its performance properties: it becomes less elastic and even hard. As a result, the contact of the pear with its saddle is disrupted, and cracks are formed through which water flows out. There are two ways to correct the situation: if the deformations are insignificant, try additionally weighting the pear with a pair of stainless nuts - they will allow the element to come into closer contact with the saddle, but if the pear has been serving for quite a long time, there is only one way out - replacing the product.

- Plaque on the saddle. The bulb may have poor contact with the saddle not only as a result of loss of its elasticity, but also due to corrosion of the saddle itself. The cause of poor fit in this case is deposits of rust and hard water salts. The fix is easy: just clean the seat.

Advice. The best way to remove dirt from the pear saddle is to use sandpaper.

Glue selection

The product that will be used to solve the problem with the toilet must have good adhesive strength. Therefore, preference should be given only to special mixtures, avoiding simple universal options that will quickly lose the stability of the compound when exposed to water. Perfect for this:

- glue (waterproof, silicate);

- cold welding;

- sealant (waterproof);

- epoxy resin with hardener;

- liquid Nails.

The products have similar properties, and some of them even have slightly similar composition. The last option differs most in terms of effectiveness - liquid nails will only help glue the toilet tank lid. They do not give the desired effect when gluing frequently used elements under high pressure.

It is recommended to purchase gluing products from trusted manufacturers who have managed to prove their reliability by producing high-quality products. It is recommended to buy one of the following brands:

- "Rapid";

- "Mars";

- "Moment Epoxylin";

- "Unicum";

- MC-1;

- BF-2;

- EDP;

- UHU Porzellan;

- EpoxyMax;

- Bliz Steel;

- "Poxipol";

- "Almaz-press".

If it is not possible to purchase glue for a broken toilet, you can prepare a special mixture for gluing yourself. This requires a few specific ingredients. However, the final result will not be worse. There are 3 main options for homemade solution:

- Mix borax, water and casein in a ratio of 1:2:10, add a couple of drops of formalin or aluminum alum, mix thoroughly. The mixture sets within two hours.

- Pour turpentine and light shellac into one container in a ratio of 1:2, put on fire. After melting, you need to mix everything well. When hardened, the mixture can be reheated before gluing.

- Mix chalk, quicklime and liquid glass in a ratio of 10:1:2.5. The mixture must be prepared immediately before installation, as it hardens quickly.

There are other folk recipes, one of which even uses crushed glass.

Getting rid of unpleasant odor after draining

If you want to prevent the occurrence of an unpleasant odor after draining the water from the water seal, you can do this by inserting a ball chamber into the pipeline element, which will be filled with gas.

It must be lowered until a sealed air plug is formed. A more modern and at the same time complex option for eliminating odor is to install a check valve with a damper. Some gardeners make the mistake of pre-filling the water seal with an aromatic liquid or detergent. This contributes to the destruction of the autonomous sewer system or the evaporation of added substances throughout the year right in the toilet house.

How to repair a crack in a toilet?

The plumbing fixtures seem to be very reliable and nothing can damage them. But in fact, its strength is quite comparable to the fragility of porcelain cups. And any “disrespectful” attitude towards the toilet can lead to the appearance of unpleasant chips and cracks on its surface. Depending on the extent of the damage, the owner either repairs the toilet cracks or replaces the equipment with new ones. If everything is very clear with the second option, then the first can seriously puzzle the owner of the house, because not everyone knows how to repair a crack in the toilet.

Photo 1. Crack in the toilet base.

Design features of the device

The microlift is sold together with the toilet lid, but it can also be purchased separately. Covers equipped with closers are made of plastic or its modern version - duroplast. Although this polymer looks like plastic in appearance, its quality characteristics are closer to ceramics.

Fix the device to the toilet in a rigid way. The main structural elements of the microlift:

- A rod that securely holds the rigid plastic installation.

- Spring to balance the weight of the structure.

- Hinged micro-lift mechanism that allows changing the position of the lid.

In more expensive functional systems, the basis of the mechanism is not springs and rods, but pistons and cylinders. Structures of this type are classified as non-removable.

Functional systems, in which seats and covers are supplemented with a built-in microlift, are produced by many manufacturers of sanitary equipment. If desired, you can purchase and install a universal system, which includes, in addition to the microlift, other devices.

They are capable of providing several functions at once:

- adjusting the temperature of incoming water;

- possibility of seat heating;

- high-quality washing, enema and massage;

- extraction of unpleasant odors followed by deodorization.

Many models are often equipped with a convenient self-cleaning function, thereby minimizing the participation of household members in the process of using the plumbing fixture. The presence of a microlift is just one way to make your living conditions more comfortable.

What is needed for repair

The selection of adhesive for the toilet is a crucial moment on which the strength of the seam and the further use of plumbing depend.

How to choose glue

It is possible to glue the surface so that the seam is invisible. Silicate glue is often used, as it is resistant to water, temperature changes, has a long service life, and prevents the spread of fire.

To secure the seam, you can resort to using liquid nails. Ready-made adhesive mixtures are also purchased:

- BF-2 is a viscous reddish liquid containing an alcohol solution of polyvinyl acetate with a resin complex. Waterproof, does not form fungus or mold on the surface. The composition is flammable, for this reason it is necessary to operate away from direct flames and heat devices, in a thoroughly ventilated area. Bonds ceramics, glass, plastic, etc.

- Unicum is a one-component adhesive containing rubber and reinforcing additives. Scope of application: gluing ceramics, glass, leather, rubber, etc. viscous mass of beige color. The seam can withstand temperature changes from –40 to 70 degrees. Method of application: the surface of the toilet bowl is cleaned, the glue is applied in a thin layer, after 10 minutes a second layer is applied, after 10 minutes press the surfaces to be glued. The product is put into operation within half a day. The operating temperature should not be less than 10 degrees. The mixture is flammable, for this reason it is necessary to operate away from direct flames, heat devices, and in a thoroughly ventilated area.

- Rapid is an adhesive in the form of a solution of nitrocellulose with resins and organic diluents. Used for gluing leather, wood, porcelain. During operation, the planes are degreased, dried, a layer of glue is applied and dries for up to 20 minutes, after which a second layer is applied, the planes are pressed firmly and secured. Complete drying is achieved after two days.

Homemade adhesive composition

For the purpose of gluing a toilet bowl or toilet cistern, an adhesive mass is made independently. To do this you need to follow these recipes:

- Durable, but not easy to use, proportions: one part of crushed glass, two parts of sand (pre-sifted), six parts of sodium silicate.

- Durable, but hardens quickly, for this reason it is prepared directly before use, applied to cleaned surfaces: one part lime, ten parts chalk, two and a half parts sodium silicate.

- Glue mixture: one part turpentine, two parts shellac. Mix well, melt over low heat, cool. The mass is divided into parts. Melts before use. Apply a thin layer to the prepared surfaces, press tightly and fix. If excess mixture appears through a seam, it must be wiped off immediately.

- Gypsum composition: gypsum is soaked in alum for 24 hours. Afterwards it is dried, calcined, and crushed. To prepare the glue, the dry mixture is diluted with clean water until a creamy mass is formed.

Recipes for homemade adhesives

For gluing porcelain and earthenware, you can prepare your own compositions from the following components (optional):

- 1 part glass to 2 parts sifted sand. Then add 6 parts sodium silicate.

- 1 part lime to 2 parts chalk and 2.5 sodium silicate. After mixing, the composition must be applied immediately.

- 1 part turpentine to 2 parts shellac. After mixing, the composition must be heated and then cooled. Before each use, the mixture should be melted over a fire.

- The gypsum is kept in alum for 24 hours. Then the composition is dried, calcined and divided into several parts. Next, each piece is diluted in water until a creamy mixture is obtained.

It is recommended to apply the above compositions to problem surfaces immediately after preparation.

Bonding plumbing fixtures

Repair work involving gluing plumbing fixtures is simple. In this case, you must do everything carefully. It is not difficult to notice a crack on a toilet bowl. Damage appears on the tank due to mechanical stress. Some of the most dangerous damage is at the base of the toilet. Damage of this nature can increase, making it difficult to repair. The crack must be repaired immediately to extend the service life of the plumbing fixtures. If you follow all the rules of the experts, you can achieve success.

Subtleties of preparing the surface of the toilet

The first step is to start cleaning. The chip must be cleaned thoroughly and carefully. The work is carried out using sanding paper. After this, the surface must be thoroughly wiped to get rid of small particles. Degreasing allows the glue to adhere well to the material. In this regard, gasoline and acetone are suitable. You also need to evaporate moisture from the surface of the plumbing and warm it with a hairdryer. Preparation is the best option if the cracks are simple in shape.

In the case where the damage has a complex fault topography, a different procedure must be followed. In this regard, repair work requires the need to strongly trim the bulges

Plumbers warn that fractures of this shape must be handled with caution. Small debris should be blown out with a hairdryer

After this, the surface must be degreased and dried.

Seam gluing procedure

You can understand the procedure by studying the user manual that comes with the glue. If you follow the recommendations written in it, you can do everything correctly. Basically, the procedure is identical, it involves applying glue to the surface of the toilet and after it dries. Having completed everything, you need to firmly press the elements together. The result is affected by the compression force. This must be done as strongly as possible to achieve maximum seam strength. The use of an elastic tight tourniquet or clamp will help in this matter.

Final finishing procedure

Plumbers have determined an algorithm for performing work regarding the seam located inside the plumbing. In this regard, strengthening is a prerequisite. The dried seam must be cleaned using sandpaper. You need to degrease well and dry with a hairdryer. After completing this work, it is necessary to coat the seam with glue. The reinforcement is a padded strip of soft metal or thin plastic. After this, you need to thoroughly dry the area that was to be glued.

If the damage was outside, it should be treated with grout. Builders advise using grout designed for tile joints. If this is not available, then you can alternatively use a solution that contains epoxy resin. The compositions are available for sale in different shades, so you need to choose the most appropriate tone in relation to the product.

Precautionary measures

Plumbers note that the work associated with gluing is temporary. Repeated repair may cause further damage. The device must be handled with care, following certain rules.

It is better not to place shelves with objects above the toilet. This will prevent them from falling and being damaged. Construction tools must not be used near ceramics. In cases where this is necessary, precautions must be taken that involve covering the product with soft cloth in several layers. After installation work is completed, no additional fastening can be carried out. When assembling the product, be sure to loosely tighten the bolts. You also need to be careful to avoid possible distortions.

It is forbidden to pour boiling water into the toilet. This precaution will prevent the appearance of cracks inside the plumbing. You also need to make sure that the toilet lid is closed, which will prevent foreign objects from getting in. Following these rules will avoid possible damage to the toilet and extend its service life. If damage is detected, you can repair it yourself. Repair work must be carried out competently to prevent repeated damage. If you do everything following the recommendations, you can get the desired result.

Currently reading

- Features of installation of corrugations on the toilet and under the hood

- Is it possible to paint a bathtub with acrylic paint?

- How you can and cannot clean porcelain stoneware sinks

- Is it possible to clean the pipes in the bathroom yourself at home?

Which glue to choose?

It is known from practice that to securely fasten ceramic fragments, you can use so-called liquid nails.

If you need to restore the drain tank, then the gluing technology is exactly the same. Sanitaryware and porcelain adhere well to ready-made compounds, which are freely sold in the retail chain.

Among them, we must mention the BF-2 glue, which has proven itself for a long time and has proven itself. The abbreviation BF stands for “butyralphenol”.

The numerical value indicates the percentage of polyvinyl buteral. The higher the number, the higher the elasticity of the adhesive joint. Therefore, BF-6 is not suitable for gluing a toilet bowl.

In order to glue a toilet bowl or cistern, you can use epoxy resin. It glues reliably, but handling it is not very convenient.

It is preferable to use Rapid or Unicum glue. Any of these compounds can also be used to glue the toilet seat together.

In the process of choosing an adhesive composition, each master has to rely on his own experience and advice from those closest to him.

Often you have to prepare such a composition yourself from individual components.

Using liquid nails, you can prepare a high-quality adhesive mixture by adding chalk and a little quicklime. At the same time, you need to know that this composition “sets” very quickly.

It is prepared immediately before gluing. During the gluing process, excess composition must be immediately removed using a rag or soft cloth.

As practice shows, cracks or chips on the toilet often occur. No one living in the apartment is insured against such a nuisance.

Video:

If the seat is cracked, it is easier to replace it than to glue it. The glued toilet will, of course, still serve for some time.

At the same time, we must remember that the restored plumbing fixture (including the tank) no longer has its original strength.

And after some time it will have to be replaced with a new one.

Review of ready-made formulations

Various means are used to eliminate defects in drain tanks. In addition to those described, liquid nails, which are applied according to the specified algorithm, help restore earthenware and porcelain products. Specialized products, such as Unicum, BF-2 or Rapid, can also cope with such defects.

BF-2

BF-2 is a universal adhesive that is used to restore various materials, including sanitary ware. When purchasing this product, you must pay attention to the labeling. A number of varieties of BF-2 are not suitable for gluing toilets.

Unique

One-component epoxy resin based on rubber and other additives. Unicum is characterized by increased resistance to temperature changes, but does not tolerate exposure to open fire.

Rapid

Another type of epoxy resin used to restore plumbing fixtures. Rapid, unlike Unicum, is suitable for eliminating defects on porcelain. This product dries completely within two days.

See also

Hidden and visible fastenings for shelves, how to hang them on the wall correctly

how to glue a toilet

Forum / Smoking room / how to glue a toilet bowl

Ask a question you are interested in on our forum without registration

and you will quickly receive an answer and advice from our specialists and forum visitors! Why are we so sure of this? Because we pay them for it!

Find out details

Velov

Rating: 19

September 10, 2016 at 11:15 pm I have experience gluing ceramics, in particular the broken base of a toilet in the area of the hole for its fastening, with ordinary construction mounting adhesive Moment. Sold in the same packaging as silicone sealant, for a mounting gun. The glue works effectively. I mounted the toilet on a glued ear and have been using the device for more than three years without any problems.vitas64

Rating: 85

September 11, 2016 at 7:21 am If a toilet bowl breaks, there are usually chips at the cracks, so in such cases I would advise using epoxy glue.

How to glue a toilet and a cistern

The choice of glue and gluing method depends on the location of the defect and its nature (one-sided or two-sided crack, complete chip).

If a fragment breaks off

When a fragment falls off the toilet, for example, a piece of the base, and its tightness is not affected, you can glue the element with universal mixtures. The fallen parts of the cistern (the fastening elements of the shelves or lid) are also attached. “Supermoment” made by Henkel or any other trustworthy company will do.

Gluing instructions:

- clean the chipped surface from dirt and dust crumbs;

- wait until the surface is completely dry;

- degrease it with gasoline or acetone;

- Apply a layer of glue and press the broken fragment. Fix in a stationary position for the time specified in the glue instructions.

If the crack is only on the outside

To seal a crack in a toilet that is only visible from the outside, or a broken cistern lid, use a two-part epoxy resin.

- Prepare both components of the product (resin, hardener) and a container for mixing them.

- Clean and thoroughly dry the surface you plan to seal.

- To seal the toilet tank, you must first turn off the water supply to it, install forced ventilation and remove all drops from the broken area.

- Degrease the surface.

- Mix the resin and hardener according to the instructions on the package.

- Apply the compound to the cracked surface.

- Fix the treated area using any available method. For example, tape or tape.

- After the resin has completely dried, the remaining seams can be carefully sanded, then the crack will become invisible. Use M20 or M40 sandpaper and then felt. Without sanding, dirt may collect in the bonding area.

If the crack is visible on both sides

With such damage, the tightness of the toilet bowl or cistern is compromised, so the adhesive seam must be waterproof and prevent the defect from spreading over a large area.

To repair a crack in a toilet cistern or a burst bowl, you will need:

- epoxy with hardener;

- drill with drill bit for ceramics;

- grinder with a disc for stone;

- sandpaper and felt for sanding seams.

The principle of gluing a double-sided crack will be as follows.

- At the ends of the cracks you need to drill two thin holes through. This will stop them spreading.

- Use a grinder to make a depression along the entire length of the crack, going halfway down the thickness of the earthenware. During operation, the material must not be allowed to overheat, otherwise the toilet may burst in another place. The side of the recess does not matter (inside or outside), because the crack will still remain noticeable.

- Carefully fill the prepared recess with the resin mixture. Remove excess resin immediately so that you have to sand the surface less later.

- Wait until the resin has completely hardened and sand the seams.

The process is well shown in the video.

If the toilet bursts at the base, then even a waterproof adhesive composition does not guarantee its tightness. It's better to replace it with a new one.

Regardless of the cause of the defects, the questions of what to do when the toilet tank is cracked, and what can be used to glue the damaged plumbing fixtures together, are resolved using a single algorithm

It is important to choose a product that can not only remove the defect, but also withstand constant contact with water. Both store-bought compositions and adhesive mixtures prepared at home are suitable for this purpose.

Straight Tile Cutting Tool

When carrying out tiling work, ceramics are cut in a straight line using the following special tool.

Glass cutter

The glass cutter is suitable for cutting wall tiles; it is quite difficult to cut hard porcelain floor tiles with it; work with a roller glass cutter is performed in the following sequence:

- Place the product on a flat, hard surface and draw a line along the ruler with slight pressure towards you.

- Break the tile against a sharp hard corner along the drawn line.

Manual tile cutter

A standard tile cutter is a bed with a rubberized surface, above which there are two guides - the cutting element mounted on the handle moves along them. The slab is placed inside the device towards the base, the cut is made by smoothly moving the cutting wheel along the surface with slight pressure. Upon completion of the pass, the handle lowers and a special lever presses on the slab, breaking it along the cutting line.

For convenience, each tile cutter is equipped with an angular ruler, which allows you to cut pieces of the same size; high-quality expensive tile cutters have a floating bed and one durable guide, which allows you to cut with high quality edges.

Rice. 10 Tool for cutting ceramics straight

Electric tile cutter

The main elements of the device are an electric motor, on the shaft of which a diamond-coated disk is installed, and a water pump, immersed in a cuvette with water and supplying liquid to the working surface of the disk during cutting.

An electric tile cutter is a rather expensive device; it is used for high-quality cutting of tiles at right and sharp angles without dust; it can be used to cut narrow strips less than 10 mm wide, which is difficult with a conventional mechanical tile cutter.

Work order

For preliminary surface preparation you will need materials: sandpaper, clean rags, degreaser.

First, the breakage site is cleaned with sandpaper. Then wipe with a clean cloth and degrease. The solvent used as a degreaser is acetone.

The surface is dried with a hairdryer. One of the split parts is coated with glue and immediately pressed against the second with maximum force (but you need to feel the pressing force so that further cracking does not occur). The interlocking parts are fixed.

These steps are used for gluing small chips and cracks. If a split occurs inside the toilet, it is better to use epoxy resin for gluing.

If the fragments occurred on the tank, then they can be sealed in the same sequence. Only the material of the tank is thinner and it undergoes gluing much faster.

When using resin for gluing, after sanding, the surface is wiped with felt material and dust is not allowed.

Signs of leakage

If the tank is leaking, you can observe the following:

- you can hear falling drops of water or a flowing stream;

- you can see rusty stains, lime deposits on the walls of the tank;

- a small wet trace is visible in the toilet bowl, which remains after flushing;

- the appearance of condensation on the outside or on the hoses;

- The water does not go away quickly after pressing the button.

If the water does not drain quickly or the level is incorrect, then the water pressure is not sufficient to pass the waste through the water seal. And some of it remains in the toilet bowl.

As soon as you detect one of the listed symptoms, you need to determine the cause and eliminate the problem.

If the toilet is cracked

Repairing a toilet, at first glance, may seem complicated, so many people simply call a specialist who will do everything, but will definitely charge you a certain amount of money. This may seem like the only way out, especially if you have never encountered such problems before. And many people simply don’t know how to seal a toilet. But you shouldn't make hasty conclusions. Try to fix the problem yourself, especially if the problem is that your toilet or tank is cracked. After all, the crack can be sealed. The main thing is not to panic and do the work carefully.

So, if you are faced with the fact that your toilet has cracked, then first you need to find out where exactly the breakdown occurred. And it’s not at all necessary to count how much money you have left in your wallet and remember where there is a plumbing store nearby, because you can fix this problem yourself using improvised means. Let's consider the moments when you have a crack in the toilet, flush cistern, or if a piece of ceramic breaks off from them. All this can be fixed if you approach this matter correctly.

Toilet drawing.

If your toilet has a crack, it needs to be sealed as soon as possible. Firstly, so that it does not become even larger, and secondly, so that water does not leak out. To seal a crack that has formed on the toilet, you need to have glue. It must be waterproof. You can also use cold welding or silicone sealant. Find some sandpaper and a putty knife. It's good if you also have a hair dryer.

When you have found everything you need for repairs, you can proceed directly to it. Take a hair dryer and heat the crack. This must be done not only outside, but also inside. Such actions are necessary to ensure that excess moisture evaporates. It is necessary to degrease the surface on both sides. To do this, use either acetone or solvents. Next, carefully coat the surface with epoxy resin. Then stick strips of plastic on both sides and wait for everything to dry. And at the very end it is necessary to apply waterproof glue to the crack.

But it happens that a piece of ceramic simply breaks off from the toilet. Then you will need glue, which should be waterproof. Apply a thin layer of glue to the broken piece, press it to the place from which it broke, and after about four hours it will stick. Next, treat the seam that you have formed with joint putty or epoxy resin with filler. After this, it is better to clean the area with sandpaper.

Deformation of the siphon membrane

Finally, another frequent failure, due to which water can flow continuously from the tank into the toilet bowl, is a violation of the siphon membrane. In this case, the problem will only be corrected by replacing the membrane with a new one, since the old one cannot be repaired. The procedure is performed according to the following scheme:

- Drain all the water from the tank so that during further actions it does not leak onto the floor.

- Attach the float arm to the cross bar to block the water supply. For example, you can remove the lid of the cistern, fasten a wooden stick in its place and tie a lever to the latter.

- Unscrew the nut that secures the drain pipe to the tank.

- Unscrew the nut that secures the siphon to the float lever - it is usually located at the base of the tank.

- Remove the siphon and replace the deformed membrane. Keep in mind that the new part must have exactly the same dimensions as the old one.

- Reassemble all the elements of the tank in exactly the reverse order.

As you can see, there is nothing overly complicated in diagnosing and correcting breakdowns of the drain tank - most of the problems can be quickly and inexpensively solved with your own hands. So we advise you to carefully study common problems and tips for eliminating them - perhaps your tank does not hold water for precisely one of the reasons mentioned?