We drill all types of water wells: Abyssinian well , sand well , Artesian well in Moscow and the Moscow region.

Drilling is carried out by all types of equipment, from small-sized machines to drilling machines based on the ZIL-131 vehicle. Our capabilities allow us to drill a well both for irrigation of a personal plot and for supplying water to an entire enterprise.

We also carry out well construction, design and installation of water filters.

With us you can be confident in the performance of your water well. We provide warranty and post-warranty maintenance of drilled wells and installed equipment.

| Drilling an Abyssinian well from 16,900 rubles. | Drilling wells for sand from 2000 rubles. per meter | Drilling artesian wells for limestone and deep sand from RUB 1,600. per meter |

| Construction of an Abyssinian well from 5,000 rubles. | Construction of wells from 50,000 rubles. | Installation of water treatment systems from RUB 30,000. |

Advantages of small-sized drilling

Small-sized drilling of water wells - creating an autonomous source in a small area. The drilling rig allows you to prepare a well with augers to a depth of up to 30 meters, the drilling diameter reaches 180 mm. Using a crown, you can prepare a source up to 100 m deep - the artesian well can be used all year round. It will lift water from deep limestone aquifers; thanks to natural filtration, it contains a minimum of impurities and does not require complex purification.

Drilling wells with a small-sized installation has several important advantages:

- The ability to use mobile equipment in hard-to-reach places, including on slopes and in small areas.

- The ability to carry out drilling operations without causing damage to paths, flower beds, and garden plantings.

- Rapid deployment of equipment and completion of work in the shortest possible time. The well can be prepared in 1 day, it will be ready for use very soon.

- The ability to use various drilling methods, including equipping artesian wells with flushing and with purging.

Our company’s specialists first conduct geological surveys on the site to determine the most suitable location for constructing a well. Small-sized drilling will allow you to quickly and inexpensively solve the problem of creating an autonomous source of water supply.

In demand

Abyssinian well made of black pipe ⌀ 32 mmFrom 16900 rub.View all prices | Abyssinian well made of galvanized pipe ⌀ 32 mmFrom 18900 rub.View all prices | Abyssinian well made of stainless steel pipe ⌀ 32 mmFrom 23900 rub.View all prices |

Artesian well made of PVC pipe ⌀ 125 mmGOST R51613-2000, ISO 9001:2008 10-year warranty Bestseller! From 2100 rub/mView all prices | Artesian well made of steel pipe ⌀ 133 mmManufactured according to GOST 10705-80 1 year warranty From 1800 rub/mView all prices | Artesian well made of steel and internal HDPE pipesSteel pipe ⌀ 133 + internal HDPE pipe ⌀ 117TU: 2248-007-23208482-2010 3 year warranty From 2000 rub/mView all prices |

Drilling rig characteristics

Drilling with a small-sized MOZBT M4 rig can be carried out in already developed areas with a completely landscaped territory. The drilling rig on a crawler chassis is delivered to the place of use on a trailer; it can be used in small areas and in dense urban areas.

The MOZBT M4 installation has the following main characteristics:

- Suitable for auger and rotary drilling using direct or reverse circulation or purge.

- Can be used with drill pipes with a diameter of 63.5 mm.

- The operating pressure of the installation reaches 63 bar.

- The presence of a remote control for movement - it allows you to accurately control movement.

A mobile small-sized drilling rig allows you to cope with the task in the most difficult conditions in order to provide the area with clean water in sufficient quantities. At the same time, it causes minimal damage to the site, does not break the soil, and can be passed through even small gates without any problems. This is the simplest and most convenient solution for creating your own autonomous water source in the country. Drilling wells with a small-sized drilling rig is inexpensive, this is an opportunity to reduce costs when developing an autonomous source.

Description of the well design

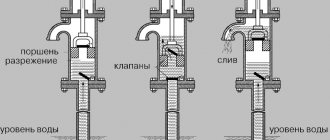

You can understand what an Abyssinian well is if you consider its design features.

Often there is an aquifer underground at a relatively shallow depth (less than 15 m). To create a “needle”, a pipe with a diameter of 2-4 cm and with a filter at the lower end is vertically deepened into the ground. The upper end is located above the ground. Using a column or pump, water is pumped up from the aquifer.

Thus, in particular, it is possible to provide water to a private home. If there is not enough water, then you can make another well.

The Abyssinian well consists of the following parts:

- The lowest part is the cone-shaped tip. It can also be shaped like a pyramid.

- The filter is a piece of pipe whose diameter is smaller than the tip at its widest point. It usually has small holes drilled in a staggered pattern.

Pipe tip Source rmnt.ru

- A coupling is attached to the filter, which connects it to the next section of pipe.

- Further to the surface there are pipe sections 1.5-2 m long, connected by couplings. The topmost pipe goes to the surface of the earth.

- In the upper part there is a pump for the Abyssinian well, which ensures the rise of water from the aquifer to the top. A column can also be used for this purpose.

Usually the upper part is decorated additionally.

We carry out water drilling with a small-sized drilling rig throughout the Moscow region and in several surrounding regions. New equipment in excellent condition is used for work: a compact modular installation will allow you to equip a well in the shortest possible time. A full range of work is being carried out: includes the installation of a head, a submersible pump, a hydraulic accumulator, and possibly the installation of a caisson for year-round use of the well.

All types of work to create a well are inexpensive: affordable prices are offered for the use of a small-sized drilling rig. To clarify the conditions of work and their cost, call the numbers provided and discuss all issues with a specialist.

Technological features of the work

A drilling rig is used to develop a well. Before starting work, dig a pit measuring 1.5 x 1.5 m and 2 m deep. It is needed to ensure that the water supply system is below the soil freezing level.

Drilling equipment is installed in the center of the pit. The drilling process is carried out in different ways, the choice of which depends on the type of soil and the depth of water, but always consists of three stages:

- targeted targeted destruction of soil;

- excavation of excess soil to the surface;

- cleaning and strengthening the trunk.

To avoid the collapse of soil from the walls, the well is reinforced with casing pipes. The gap between the outer part of the pipe and the earthen layer is filled with cement mortar to give strength to the structure.

A deep pump is installed inside the well, with the help of which water is supplied to the top.

Prices for drilling with a small-sized drilling rig

| Ø 133 metres. | Ø 133 metres. + Ø 117 HDPE | Ø 159 metres. + Ø 125 HDPE | Ø 125 uPVC | Ø 125 uPVC + 90 uPVC |

| from 2200₽ | from 2700₽ | from 3000₽ | from 2200₽ | from 2400₽ |

Where to install

Before drilling an Abyssinian well, it is necessary to find a suitable place for it. It is important to find a location so that the aquifer is not very deep.

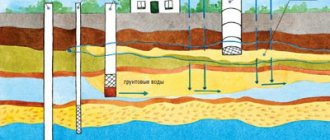

Typically, soil consists of several layers located at different depths. It is important to find where the aquifer will be located closer to the surface. When installing a pipe, it may happen that there will be quicksand on the way - a layer of solid earth that cannot be broken through. In this case, you will need to look for another place.

Soil structure and aquifer Source greendom74.ru

Soils can be divided into the following categories:

- Bulk . They differ in that they do not hold their shape. If enough moisture accumulates in them, they can float.

- Plastic . Can be easily passed using the Abyssinian well tip.

- Hard rocks . These are limestones, sandstones, marls, dolomites and the like. They cannot be drilled without the use of special tools.

An Abyssinian well can only be built where from the surface to the aquifer there are only soils of the first or second type.

It must be taken into account that it is not possible to equip a well everywhere. The following places should be avoided:

- ravines;

- cliffs;

- steep hillsides.

In these cases, there is a higher risk of contamination of underground natural water reservoirs.

It is important to remember that you should not approach potential sources of pollution closer than 15 m. This applies to places where animals are kept (such as a barn or poultry house), compost pits, and sources of industrial pollution.

It is necessary to maintain distances between the well and other buildings Source ad-cd.net

See also: Companies specializing in the installation of heating, water supply, sewerage.

How to determine the depth of water

It is important to understand at what depth the groundwater is located. The simplest way is to obtain information about the depth of water in a neighbor's well. It should be borne in mind that in this way only an approximate estimate can be obtained. The aquifer is not necessarily located at the same level in different places.

When looking for the right layer, you need to take into account that the one that is located next to the surface of the earth is not recommended for drinking. It is usually fed by melted snow, rain, and household waste. Due to the shallow depth, the water is poorly filtered. The level in this surface layer will vary depending on atmospheric conditions. It is recommended to find a deeper groundwater level.

When water is taken from a sandy layer at a depth of 12-15 m, it is well filtered and represents a stable source that can be used throughout the year. In this case, you will need to make a pumping station for the Abyssinian well.

What an aquifer looks like Source ochistkavodi.ru

When searching for a suitable location, you can rely on the following features:

- In the early morning or evening during the warm season, fog can be observed. If you look closely, you will notice that it has unequal density. Where it is thicker, groundwater is closer to the surface.

- Animals, thanks to their natural instincts, know well the places where water is located. They are not able to tell, but if you understand their habits and observe their behavior, you can get the necessary clue. Dogs in the heat tend to find a cool place to escape overheating. If a horse is thirsty, it will put its hoof where it feels the most moisture. Similar features are inherent in other species of animals and birds.

Plants help determine the depth of the aquifer Source stroim-dom.net

- The depth of the aquifer can be judged based on observations of plants. Each species grows best where the conditions are most suitable for it. For example, blackberries, lingonberries and bird cherry grow well where groundwater is closest to the surface.

- You can use the help of neighbors and friends.

If your neighbors use an Abyssinian well, you can ask what its depth is. Source obustroeno.com

To find a suitable location for a well, you can use the following methods:

- You can use several jars of the same size. If you immerse them in the ground with the neck down so that the bottom is clearly visible, then within a day you will be able to see the place where the humidity is highest. To do this, you need to compare the amount of condensation that has formed inside the glassware.

- Salt, crushed red brick and silica gel absorb moisture well. It is necessary to prepare several flower pots, the surface of which is not covered with glaze. An equal amount of the selected material is poured into them and placed for a day in different places on the site. After the appointed period has passed, they must be weighed. The heaviest will be the one that has absorbed more moisture.

Using flower pots to find water Source fermer.blog

- You can determine the presence of underground water using a garden auger. It is important to consider that if the depth of the Abyssinian well is less than 6 meters, then it will not be clean enough for drinking. Therefore, it is necessary to check the presence of the required layer at a greater depth.

Is it necessary to maintain an Abyssinian well?

In order to maintain it in working condition, it is recommended to use water regularly. At the same time, reserves will not decrease over time.

If the use is seasonal, then it will be necessary to prepare for the time when it will be idle. If negative temperatures are expected, then you need to drain the water so that it does not freeze and burst the pipe. The pump must be covered with waterproof material so that it is not damaged by bad weather.

When the well begins to be used again, it is necessary to pump water in the same way as was done at the beginning of operation. This must be done until clean water comes out.

How to choose the right pipe format

The diameter is selected based on a number of factors.

Among them:

- planned well depth;

- flow rate - the volume of water planned for supply;

- pump and submersible equipment options;

The following requirements are attached to the column for its effective operation;

- reliable fit of the column to the drilled hole;

- ensuring the supply of the required volume of water;

- resistance to deformation under pressure.

Video description

This video shows the entire process from drilling an Abyssinian well to obtaining water, including installation of a pumping station:

Well in the yard Source burenie-m.ru

It must be taken into account that sometimes site owners use a pump not only for lifting, but also for horizontal movement of water.

In this case, the movement of water by 10 m horizontally reduces the maximum suction depth by 1 m. If the water is at a depth of 12-15 m, then a hand pump or airlift can be used for lifting. The operating principle of the last pump is based on the fact that air is pumped under pressure into the lower part of the well, which pushes water upward.

If the water is deep, you can build a pit. In this case, make a wide hole several meters deep and reinforce the edges with concrete rings. The pump is installed at the bottom of the pit. Thus, water has to be pumped from a slightly shallower depth.

Thermal insulation methods

First, let's consider whether it is necessary to insulate sewer pipes in a private house. Freezing of drains in the circuit is one of the possible malfunctions, which eliminates the possibility of using plumbing equipment. The reasons for this phenomenon may be:

- untimely cleaning of pipes and removal of blockages;

- design of a system with a large number of turns and insufficient slope towards the waste collection point;

- non-compliance with the level of penetration of the sewer circuit into the ground.

Another reason can be considered the erroneous belief that the canal is periodically heated by warm wastewater. However, such an assumption may be relevant only for regions with a warm and mild climate. In northern latitudes, thermal insulation of external circuits is a necessary measure. Let's look at the main ways to insulate a sewer pipe.

Deepening the line

Here the main parameter is the depth of soil freezing. Pipes with a diameter of 100-110 mm must be laid 30 cm below this level. To do this, a trench is formed, the bottom of which is compacted at a slope from the house within 10-12 degrees.

Laying a sewer channel in a trench Source makler.md

This solution is simple, but has its drawbacks:

- it may be necessary to deepen more than 1.5 meters (labor-intensive);

- excavation work takes a lot of time and effort from the worker (affects wages);

- it is difficult to maintain the required slope, especially for a long pipeline (a 10-meter channel needs to be lowered by about 1.5 meters at the septic tank);

- above the level of soil freezing there are many elements of the system that are still subject to insulation (wells, collectors, the area where the circuit exits the house);

- Isolated sections of the sewer system are more difficult to check for serviceability and repair.

However, despite the disadvantages, deepening below the freezing soil is an effective solution. This way the pipes are protected from natural phenomena and human factors, which reduces the likelihood of emergency situations on the way to the septic tank. This approach also allows you to localize and reduce the area that needs insulation. This is a cost-effective solution.

Providing heating

An electrical cable is used here, which emits a certain amount of heat when connected to the network.

Insulation of a pipe with a heating cable Source yandex.net

See also: Catalog of companies that specialize in water supply, sewerage and related work

Installation involves wrapping the pipe with wire or pulling it inside the main line. The number of threads and the pitch between turns depends on the heater power; higher heat transfer means shorter distance and, accordingly, cable length. The elements are fixed with aluminum tape (the plastic is completely wrapped in foil before attaching the wire). The entire structure is covered with insulation.

Experts say that this solution is relevant for regions with frosts below -15 degrees Celsius. It also allows you to limit the deepening of the sewer system to 0.5 m. You can turn on the heating of the pipes as needed, that is, it is not necessary to constantly maintain one or another temperature. This is especially true for a property where residence is periodic.

There are two cable options. Conventional or resistive heats the line along its entire length with the same heat transfer. Self-regulating is more expensive, but quickly pays for itself due to work in areas with lower temperatures. The economic benefit here is lower energy consumption.

Self-regulating heating cable Source kanaliza.ru

Thermal insulation

This assumes the choice of insulation for outdoor use. The main thing is compliance with installation technologies. This is justified by the fact that the thermal insulation material may also need protection.

It is worth noting that the effect of insulating compounds is not aimed at warming the circuit, but at reducing the level of heat loss. Both above-ground elements of the pipe structure and those laid in the ground need this. In this case, heating the circuits with waste water works. Therefore, the event is held for sewerage, which is used constantly.

Ground channels that need to be insulated Source moikolodets.ru

Materials for making pipes

Plastic pipes for wells are made mainly from the following materials:

- Polyvinyl chloride (PVC)/unplasticized polyvinyl chloride (uPVC). The material has a low coefficient of linear expansion when heated, perfectly retaining its shape.

- Low-density polyethylene (HDPE). This is a popular material for outdoor use, as it retains its qualities even at a temperature of -20 degrees.

Large diameter plastic pipes for wells

How to decide on the material

There are a large variety of pipes on the market today, both steel and plastic. Let's consider their comparative characteristics.

Advantages and disadvantages of steel

For the production of steel pipes, ordinary steel is usually used, less often - stainless steel coated with zinc or enamel.

The advantages of such a pipe:

- mechanical strength - the pipe, which has walls 6 mm thick, is resistant to any ground displacements, so you can safely clean the well without fear of damaging anything;

- tightness - welding of individual pipes together is very reliable, so water from the upper layers cannot penetrate into the pipe;

- such a pipe must be repaired; if the pipe outlet is well sealed with the head, then it will be resistant to rust;

- durability - such a pipe will last about 50 years, and this has been confirmed by practice.

Stainless steel products have one big drawback - they are expensive. Chips may form on the enamel surface during installation, which can lead to rust in the near future. Galvanized pipes have a lower price, but interaction with water leads to the formation of zinc oxide, which, according to some assumptions, poses a health hazard.

The disadvantages of iron pipes include their instability to chemical reactions and corrosion, short service life, heavy weight and poor hygiene, unlike PVC.

Advantages and disadvantages of plastic

The advantages of PVC pipes include:

- chemical resistance;

- long service life (this is still tentative, since PVC pipes began to be used relatively recently);

- lightness and low cost when compared with iron ones (although in reality the price of a well with such a pipe will practically not differ from the cost of a well with an iron analogue).

The following disadvantages were found in PVC pipes:

- low mechanical stability (movement of soil layers can lead to breaking or collapse of the pipe). Therefore, these pipes are not used to equip wells deeper than 80 m;

- poor tightness at threaded joints, especially when there is “saving” on sealing agents, and in these places water from the upper layers can enter the well. When forming a casing, PVC pipes are screwed into each other, and sometimes soldered together with a coupling where they are inserted;

- These pipes are practically unsuitable for repair, since it is not possible to repair the plastic structure;

- they are negatively affected by low temperatures. If the well is installed incorrectly and the water is located close to the surface, freezing of water in winter can lead to rupture of the plastic;

- the insufficiently studied (and it is possible that negative) effects of PVC on human health when water from a well equipped with such pipes is used for drinking and cooking. At the same time, the manufacturer is assured that these pipes are absolutely safe and comply with GOST standards.

If you have any questions or doubts before purchasing casing pipes for a well, our managers will be happy to help you choose pipes and send the necessary samples free of charge by the transport company.

When purchasing casing pipe from TZPT LLC (Tula), you can always be sure of the quality guarantee, as well as the best price from the manufacturer!

Repairing an old well using plastic pipes

Using plastic inserts into the well, it is deepened.

In addition to the construction of new wells, polymer pipes make it possible to repair old wells into which water has stopped flowing, or their concrete rings have shifted and began to let water through. A plastic sleeve is inserted inside the old well, and the bottom of the well is deepened. Filter material is poured between the plastic pipe and the concrete walls. It can be coarse sand, sand concrete, small crushed stone. This material will serve as an additional filter, and water will flow into the plastic sleeve only through the bottom.

Using plastic pipes, you can improve the efficiency of an existing well, as well as make a new well or well.

Advantages of hydraulic drilling over driving an Abyssinian well

There are clear advantages of hydraulic drilling technology over driving a needle into a well.

Firstly, the process is simpler - no gigantic physical effort is required to hammer steel pipes with a headstock.

Secondly, the soil is constantly washed out to the surface, that is, the driller clearly understands whether he is passing through clay or sand.

Thirdly, it is clearly determined that the pipe has reached the aquifer - this layer absorbs water, which is supplied to the pipe to flush the well, and the driller sees that the water has stopped coming to the surface.

The only disadvantages of hydrodrilling include the need to have a reserve of several hundred liters of water, and the difficulty of working in cold weather - the water in the hoses freezes.

The video describes the process of hydraulic drilling, but we are looking at a simplified process - a well in sand.

How to make a regular well

You can make a well from a plastic pipe with your own hands. To do this, you need to decide on the location of the future well and purchase a pipe of the required length. The diameter of the pipe can be from 40 cm or more.

Sequence of work:

- A shaft of a certain depth is dug manually or using a wide drill. It must reach the aquifer.

- A plastic pipe for the well is being prepared. From below, at a distance of 50 cm, drill many holes using a drill with a diameter of 7-8 mm. Drill holes in the depressions of the outer shell.

- Wrap two layers of geotextile (you can use a special polymer filter mesh) around the perforated bottom of the pipe, securing the material with wire. This is necessary to filter the water.

- Lower the pipe into the shaft until it reaches the bottom.

- Fill the gap between the walls of the shaft and the pipe with sand.

- Insulate the top of the pipe, rising above the soil surface, with polystyrene foam.

- Place a submersible pump into the well and begin pumping the well. This action is performed until clean water appears at the outlet.

- Place a lid on the well.

The photo shows an example of a finished well made of plastic pipes

Installation features

Installation of casing parts is carried out by drilling the soil with a drill. The diameter of the drill must be less than the diameter of the casing. Then it is taken out of the ground and the contaminants are removed. The casing is lowered when the well depth reaches 2 meters. Further drilling should be carried out together with casing until the aquifer is reached.

The classic version of the casing looks like this:

- The filter for coarse purification of well water is a wire or stainless mesh.

- A bottom filter made from gravel. Protects water from contaminants that can penetrate into the source from greater depths.

- A sealed head that prevents contamination from entering the well shaft from the outside. Its fastening is accompanied by the formation of negative pressure, which leads to an increased influx of water. To increase the negative pressure, the head is cemented.

When choosing a suitable casing for a well, they are guided by a simple but proven combination of quality and price. These parameters determine how long the structure will operate.

It is recommended to design deep wells with metal products equipped with external and internal threads. If the depth of the well shaft is less than 50 meters, preference is given to a budget alternative - plastic pipes. Asbestos-cement products are installed at a well depth of no more than 15 meters, otherwise the material may not withstand the pressure exerted by the soil layers.