Soundproofing walls in a frame house. Many people choose a private residence due to the most common factors: the absence of upstairs neighbors and excellent sound insulation. At a summer cottage or in a household, frame partitions and insulation are thought out already at the planning stage.

The presence of extraneous noise in the house from the street or neighboring rooms penetrates through invisible cracks and openings. Poorly fitted windows and doors, window sills. Gaps for electrical cables in the ceiling and recesses hidden under baseboards on the floor. It is through these seemingly little things that the discomfort of being in an isolated room arises.

Soundproofing options

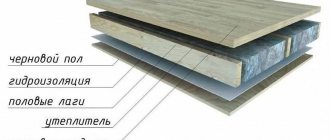

To begin with, you should understand that the house has load-bearing walls, which are most often built of brick. These structures are based on a raw ceiling and foundation. This is due to comprehensive planning. Load-bearing walls give the foundation not only its own weight, but also the weight of the roof or second floor. The remaining partitions and partitions are erected in the finished frame of the building and only divide the space.

Soundproofing frame partitions is important in any case. Its functionality depends on the materials used and build quality. When it comes to soundproofing, you should understand that no wall can protect residents from external noise. For example, if there is a railway line or a house built near the airport.

Air noise, shocks, and the general structural background are removed by high-quality partitions. The most commonly considered methods of protection from external influences are:

- ecological wool,

- mineral wool,

- polyurethane foam.

For private houses in rural areas, mineral wool and glass wool are suitable - in mineral wool with fragments of glass wool, we will never allow rodents inside the premises.

Those who have partitions made of sandwich panels instead of traditional frame walls can cover the walls with roofing felt. Some are moving on to plastering. When choosing a material, remember that the internal void between the edges of the partition should be “breathable”. Do not stick polystyrene foam or sobraizol. These materials are quite dense and flammable. Latex is sometimes used.

Cork sound insulators

Cork sound insulators

Cork panels are often used in interior decoration. They serve both a decorative function and protect against noise penetration. If you lay cork slabs in all the walls, you can ensure excellent sound insulation of interior partitions - noise from outside will practically not penetrate into the room.

The advantages of cork include:

- high decorative properties;

- good sound insulation;

- ease of installation;

- durability.

The only drawback of the material is its high cost.

Do-it-yourself frameless sound insulation (sound insulation) of walls with panels

Frame soundproofing (soundproofing) of walls with your own hands is quite doable for a simple person who knows how to hold a hammer and know how to work with a punch. Here we will look at how to make a thin soundproofing board such as Sonoplat, EcoZvukoizol, SoundGuard, that is, boards made of multilayer corrugated cardboard filled with quartz sand. The cheapest of them is Sonoplat, it costs about 600 rubles for 1 panel, its area is 0.72 m².

The thickness of the slab is 12 mm, which in combination with plasterboard and soundproofing underlay gives approximately 3-4 cm.

Do-it-yourself installation of soundproofing panels.

4. Installation of drywall on sound-absorbing panels.

5. Further finishing.

Sound-absorbing panel made of corrugated cardboard with quartz sand.

Preparing the base (wall) for frameless sound insulation

Let's start by preparing the base (wall). It needs to be leveled, that is, plastered. This is necessary, because without leveling the quality of the wall, it will not be possible to install soundproofing panels well, it will be crooked, it won’t even fit, and you can ruin the expensive material.

Therefore, if you do not have plastering skills and your wall is uneven, entrust this work to a specialist. If you are not going to do this, then there is no reason for an ordinary person to learn how to plaster.

The wall is plaster, aligned “in a row”.

We have leveled the wall, and deviations from the wall's plumb line will not be taken into account. Because installing frameless sound insulation with your own hands is not the main thing, it is important that there are minimal deviations in the plane, a maximum of 2-3 mm, no more than 2-meter bars under 2-meter bars. Check them, be sure to bring a smooth lath (construction rule) to the plane of the wall at various points. Slight deviations may be

Installation of the first layer of frameless sound insulation

If you checked the wall and did not find any deviations above, the finish from the wall, if (the finish) is smooth, then there is no need to remove, for example, wallpaper or paint.

This layer is not necessary, but it will improve the sound insulation of the wall. You can use a self-adhesive membrane.

Self-adhesive membrane for sound insulation

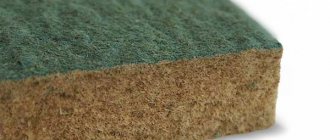

You can also use thin (3-4 mm) non-woven fabric (felt).

Felt soundproofing base

The first layer is either glued to the wall or fixed with plastic dowels or ordinary screws, if the wall is not concrete or brick, in which case the fastening can be done with a stapler. The membrane is laid in joints with each other, without overlaps or gaps, on a flat horizontal surface. This is necessary to ensure that there are no overlaps. There should be a slight overlap of the ceiling, floor and perpendicular walls across the width of the sound-absorbing slab.

Cost per 1 m2

Soundproofing materials are expensive, so they must be selected in the price-quality ratio based on operating conditions.

Cost of the most popular noise insulators for residential buildings:

- Shumanet-BM, Russia, basalt slab, 310 rub.

- StopZvuk BP, Russia, basalt slab, 450 rub.

- Shumostop-K2, Russia, basalt fiber 300 rub.

- ROCKWOOL Floor Butts, basalt material, 200 RUR.

- Rockwool Acoustic Butts, Russia, basalt slabs, 150 rub.

- StopZvuk BP S, Russia, basalt slab 280 rub.

- TECHNONICOL, Russia, Technoacoustic brand, basalt slab 260 rub.

- GREENGUARD ACOUSTIC - sound-absorbing stone wool 150 rub.

- Akulite, Russia, KNAUF brand, basalt mini-slab, 200 rub.

- Self-adhesive soundproofing membrane Tecsound SY 70, Spain, Tecsound brand, RUB 1,900.

- Sonoplat Combi Russia Sonoplat brand, soundproofing panels, 1600 rub.

- SoundGuard EcoZvukoIzol, Russia, SoundGuard brand, 1050 rub.

- TermoZvukoIzol soundproof multilayer fiberglass mat, Russia, TermoZvukoIzol brand, 400 rub.

- ZIPS-III-Ultra, Russia, ZIPS brand, sandwich panel with tongue-and-groove connecting system with fasteners, 2500 rub.

- Soundproofing membrane Tecsound 70 in rolls, Spain, Tecsound brand, RUB 1,700.

- ZIPS-Vector, Russia, ZIPS brand, sandwich panel with fasteners, 1,700 rub.

- ABEX-M soundproofing self-adhesive membrane, Russia, ABEX brand, 783 rub.

- EcoQuartz Standard soundproof seven-layer panel made of cardboard and sand, Russia, Ecoquartz brand, 750 rub.

- Topsilent Bitex in rolls, Italy, INDEX brand, 1050 rub.

Do-it-yourself installation of soundproofing panels

The panel adjacent to the wall should be level. It is better to lay the panel horizontally so that when drilling with a hammer drill there is less chance of the sand panel falling out. Point outwards (label side). Having bent over and exposing the panel, we drill a hole for fastening with a drill with a diameter of 6 mm and a hammer drill. length 160 mm. The standard size of a soundproofing polymer dowel is 6 * 70mm.

Having drilled a hole, we hammer in a plastic dowel so that it fits 2-3 mm into the board so that the flat part does not stick out. One panel is fixed with 12 pins.

Attaching the sound-absorbing panel

Apply soundproofing sealant to the edges of the panel for a perfect seal with the rest of the panels. Then install the second panel and so on.

An electric jigsaw is the best way to cut boards. Cut the board as straight as possible. You will get the sand out of the panel and you can refill the sand after you make the cut.

Cutting acoustic boards with a jigsaw

The cut is sealed with special adhesive tape (self-adhesive paper tape), but you can usually use regular masking tape.

The cut of the soundproofing board must be sealed with special tape.

It is not necessary to install the panels so that they are spaced apart and this can be avoided to make the task easier. Once all panels are installed, the joints should be sealed with soundproofing caulk, which should not extend beyond the edge of the panel and should be flush with it. Gaps formed between the edges of the boards and the walls should also be sealed with a sealing compound.

Installation of soundproofing panels (preferably horizontally)

After sealing the joints with sound-absorbing sealant, it is recommended to seal the joints with special tape. This is not such a mandatory procedure, you can even use ordinary masking tape, you don’t want to put them on the display.

Important. The panels should be installed level, without protruding parts or corners on the plane. This will facilitate and improve the quality of assembly of subsequent layers. If for some reason there are eaves (eg sand fell off the slab and it is not sticking tightly to the wall), try gently hitting the slab with a hammer, otherwise carefully cut a small notch on the inside of the GPB using a stationary tool. The uneven part of the plate entered into it, and the sheet was pressed tightly against the plate.

Once you have completed assembling the panels, proceed to cover them with GFB. GFBs can also be used, but they are heavier, more difficult to work with, and easy for a beginner to break. Although they have better sound insulation than drywall. We will continue to look at GFB.

How else can you soundproof a frame?

For protection, they resort to non-standard, innovative materials that absorb sound. The following insulators can be used in a frame building:

- Mineral wool acoustic slabs. They have a fibrous structure that repeatedly reflects sound waves, which leads to their attenuation.

- To increase the level of sound absorption by thin partitions, vibration-damping coatings that are highly elastic are used. They contain bitumen, silicone, mineral fillers, polymer and plasticizing additives. Noise muffling can be achieved by installing an insulation layer two to three times thicker than the base.

- Elastomeric vibration damping plates. Widely used in frame construction for sound absorption of floors and ceilings. Completely muffles the noise of engineering equipment and household appliances.

Installation of gypsum board sheets on soundproofing panels

This is where things get interesting because there is a lot of debate online about how to properly install GPB sheets on acoustic panels. Let's see what happens.

Manufacturers recommend attaching drywall directly to the boards using self-tapping screws with a diameter of 19-25 mm. However, the screw should not reach the wall and should not be a bridge for sound transmission (metal conducts sound well). But it will be there in any case, up to the wall or not.

This is the first.

The second question is the reliability of such fastening. After all, the self-tapping screw is screwed into the sandboard panel a few millimeters.

When the panels are laid horizontally, this fastening is acceptable, but when the panels are not perfectly level, it is quite difficult to attach the sheets to the panel.

Further finishing

The second fastening method is more reliable and durable. Sheets of drywall are attached directly to the wall in several places using the same dowels. Additionally, the GPB sheet is lubricated with silicone sealant, the sheet is glued to the slab with sealant, and then holes are drilled for fastening to the wall. This method is definitely more reliable, and the sealant additionally dampens acoustic vibrations. After drilling the hole, you can also fill it with silicone sealant and then hammer in the expansion plug.

When attaching drywall to a board with self-tapping screws, it is best to use drywall screws and secure them at a 45-degree angle for a more secure fit.

GPB sheets should be leveled, mounted intermittently, shifting the top layer by half a sheet, this will ensure more reliable fixation.

ZIPS

Sandwich panels or ZIPS modules are a modern material for sound insulation; they are a slab with basalt fiber inside and a solid sheet of plasterboard on the outside. Their advantages:

- light weight, which allows them to be attached to the ceiling;

- wide range of applications in any type of premises;

- ease of installation;

- corrosion resistance;

- can be used in damp areas.

The use of ZIP panels makes it possible to reduce energy costs by 30%.

Soundproofing a frame house: how to do it

Further finishing - sealing the joints of drywall with gypsum or special compounds for drywall joints with the obligatory gluing of paper tape to the joints of drywall or corrugated tape (seams, glued corrugated tape can crack, and paper tape can swell, become saturated with moisture for further finishing - there is no ideal material, but paper tape is still better). Before sealing, non-factory seams should be widened with a utility knife, cutting their corner at an angle of 45 degrees.

Soundproofing mechanism

Frame buildings have a number of advantages over traditional monolithic stone or wooden buildings. At the same time, frame houses have disadvantages, sometimes quite significant. They have low sound insulation both inside and outside. The fact is that the walls, partitions and ceilings of a frame house conduct sound much better than similar monolithic structures. Therefore, you cannot do without high-quality and reliable sound insulation.

Many people familiar with the construction of frame houses are surprised by the question: “Why do you need sound insulation?” After all, the walls of such a house are filled with insulation, and this protects against extraneous sounds. Let's say right away: insulation and soundproofing are two different things. Materials with low thermal conductivity do not necessarily conduct sound so poorly. And vice versa.

Noise and sound are acoustic waves propagating from their source, with characteristic frequencies, amplitudes and propagation speeds. out. Moreover, the sound, one way or another, spreads through all obstacles and is also reflected from them.

To reduce the intensity of external noise, reduce the energy of the sound wave reflected from the floor or wall. The phenomenon in which acoustic energy is dissipated and converted into heat is called sound absorption.

Ways to improve sound insulation

That is, so that the inhabitants of a frame house do not get headaches from the sound of the refrigerator, the internal surfaces (floor, ceiling, walls) must have a high absorption coefficient.

Sound insulation is a passive reduction in the sound pressure level of a sound wave passing through an obstacle. A high level of sound insulation allows you to protect the interior of a frame house from external noise, as well as reduce interfloor and interfloor audibility.

The values of sound insulation and sound absorption strongly depend on the length of the acoustic wave, in other words, on the height of external sounds. Therefore, for good sound insulation of premises, it is necessary to know not only the integral, i.e., generalized acoustic characteristics of the materials used, but also the spectral ones, i.e., those associated with the vibration frequency of the noise source. It is also extremely useful to know the spectral characteristics of noise sources near and inside the home.

Contrary to popular belief, conventional materials used for thermal insulation of a frame house do not have a significant effect on its sound insulation. Therefore, the standard wall frame of a frame house should be supplemented with a layer of specialized material, for example, acoustic mineral wool.

Types of noise

When soundproofing rooms, different types and sources of noise are identified. Internal discomfort does not create; external ones are divided into several types. An insulator is selected and work is planned taking into account the type of sound waves.

Taking into account the type of impact transmission, they are divided into impact, structural and air. The transmission of the latter occurs through the air; they have no connections with the fences; a simple sound insulator will suffice. Percussion occurs when surfaces come into direct contact with objects. Structural ones appear after the object of influence enters the very structure of the ceiling. The structural type is capable of covering significant distances in one building.

Frequency spectra that are taken into account when soundproofing:

- low – well audible for older people, bad for small children, representing the background of industrial installations, telephone vibration, train whistles;

- medium - audible to almost all people, this includes the hum of a TV, washing machine;

- high - clearly distinguishable by children and poorly by older people, this can be sharpening knives, violin music, squeaks of electronic devices.

Acoustic

Sounds travel through the air and take the form of acoustic waves. Sources: people talking, operating equipment, animal voices, noise from cars. The degree of severity depends on the location of the house, the passability of neighboring roads, and the thickness of the walls from neighbors, if any.

Drums

Sound loads created by solid bodies using vibration or impact actions. This includes the noise of a hammer, a perforator, as well as the loud stomping of people, the impacts of falling objects, and moving trains. Noise insulation from impact sounds is needed by residents of busy streets and railways.

Combined

A mixture of percussion and acoustic influences. For example, a hammer drill produces several types of noise at once: acoustic from the operation of the motor, plus private shock as a result of the impact of the nozzles on the working surfaces.

For high-quality sound insulation of walls in a wooden house, a combination of modern materials is used. The choice is made taking into account the type and volume of sounds.

Soundproofing in a frame house

The thickness of the soundproofing layer must be at least 50 mm. This also applies to the horizontal cladding of the house - floor and ceiling.

However, for the best effect, an acoustic insulator should not be used alone, but in combination with other methods, such as increasing the weight of the walls, soundproofing them from each other and from the ceiling, using special soundproofing fittings, etc.

Noise insulation materials

Sound insulation in a frame house is carried out at the stage of its construction. Thermal insulation is often used to create them, and some of them have noise-absorbing properties. Various materials can be used as sound absorbers. Insulators are installed in the walls of a frame house. They are one of the layers of this cake.

Features of choosing sound insulation

Why do you need to pay special attention to sound insulation in a frame house? Wood is a good conductor of noise. Therefore, we must make sure that staying in a house built for permanent residence is comfortable.

- The outer wall of the frame house has a three-layer structure, so sounds from the street do not penetrate inside the house. Its cavity is filled with a thick layer of thermal insulation, which will be the main material that protects against sound penetration into the house. Mineral wool, ecowool, isover, and foam pads are used as sound insulation.

- Various types of insulation are available. These are plates, rolls, mats. The thickness of the materials is from 2 to 20 cm. The choice of acoustic insulation for your home according to its parameters will determine the ease of its installation and the level of sound insulation.

- The thickness of the sound insulation of the internal walls must be at least 5 cm. Otherwise, sounds will easily penetrate into neighboring rooms. Mats and slabs should be used for installation in walls; they are easy to install. If we choose roll materials, we will need to ensure that they are securely fastened, which will take time.

The thickness of sound insulation in the floors between floors cannot be less than 15 cm. If it is thinner, those living below will hear footsteps on the floor of those living above. It is possible to place sound absorbers in interfloor voids from any material. It is laid horizontally and therefore even roll insulation will be easy to install.

Correct layout

When choosing insulation material for sound absorption, there are several points to consider:

The material must be fireproof. Elements of a wooden house must be fire resistant. They must withstand high temperatures and at the same time be non-toxic;

There are three types of noise in a frame house: airborne, structural and impact. Select materials for installation in walls and ceilings that can be sound absorbent. To withstand such conditions, insulation with good elasticity is required.

Which is better to use?

In order to conclude which insulator will work better under certain conditions, it is important to know what sound level needs to be dampened.

This is done with a sound level meter and if, for example, it is necessary to suppress Rw = 20 dB.

You should not buy expensive material with protection Rw= 50 dB.

When choosing a scheme, it is better to choose external wall protection, it is more effective with an NRC absorption rate of 0.8 to 0.95.

With an external noise level of 50 dB, with an NRC of the material equal to 0.95, the protection will dampen 50x0.95 = 47.5 dB, the remaining 2.5 dB will be damped by a wooden wall with Rw = 35-45 dB, that is, there is no extraneous noise entering the house will pass.

If we analyze the effectiveness of the material by cost per 1 m2 and the achieved NRC level, we can obtain the following rating.

List of TOP materials for external noise protection :

| № | Name | Price, rub. for 1 m2 | NRC | Rw,db | RUR/NRC | rub./Rw |

| 1 | GREENGUARD ACOUSTIC | 121 | 0,95 | 127 | ||

| 2 | Rockwool Acoustic Butts | 141 | 0,85 | 166 | ||

| 3 | Akulite | 200 | 0,9 | 222 | ||

| 4 | AKUSTIKNAUF | 120 | 57 | 2 | ||

| 5 | Shumostop-K | 298 | 32 | 9 | ||

| 6 | ROCKWOOL Floor Butt | 197 | 0,8 | 246 | ||

| 7 | StopSound BP S | 275 | 0,9 | 306 | ||

| 8 | TECHNONICOL | 260 | 0,85 | 306 | ||

| 9 | Schumanet-BM | 309 | 0,85 | 364 | ||

| 10 | StopSound | 447 | 0,95 | 471 |

Materials for internal sound protection have a higher price, with lower efficiency; their rating is based on the level of cost and the ability to absorb Rw, dB.

List of TOP materials for internal noise protection :

| № | Name | Price, rub. for 1 m2 | NRC | Rw,db | RUR/NRC | rub./Rw |

| 1 | ThermoSoundIsol | 396 | 30 | 13 | ||

| 2 | ABEX-M soundproofing self-adhesive membrane | 783 | 50 | 16 | ||

| 3 | SoundGuard EcoZvukoIzol | 1020 | 60 | 17 | ||

| 4 | EcoQuartz | 720 | 36 | 20 | ||

| 5 | Topsilent Bitex | 1025 | 27 | 38 | ||

| 6 | Soundproofing membrane Tecsound 70 | 1670 | 28 | 60 | ||

| 7 | Self-adhesive membrane Tecsound SY 70 | 1894 | 28 | 68 | ||

| 8 | Sonoplat Combi | 1600 | 13 | 123 | ||

| 9 | ZIPS-Vector | 1712 | 11 | 156 | ||

| 10 | ZIPS-III-Ultra | 2488 | 11 | 226 |

Floor

The “floating floor” technology is used, which makes it possible to reduce the impact of impacts and steps when soundproofing between floors. To increase the level of sound insulation of the floor you need:

- increase the thickness of the screed and the thickness of the insulation layer;

- limit the screed with spacers on the sides.

It is recommended to use mineral wool as an insulator.

If we are dealing with a floor on joists, then we need to increase the surface mass of the wooden covering and the height of the joists. For installation, use elastic fasteners, and fill the space between the joists with insulator.

Substrates

This is an affordable means of soundproofing a wooden house with your own hands. There are wallpaper backings that are used to cover walls at the preparatory stage. In addition to sound insulation, such wallpaper performs the following functions:

- home insulation;

- level the walls;

- protect against dampness and fungus.

To protect against floor noise, laminate underlays are used, which can also smooth out minor surface irregularities.

Fiberglass

The principle of making fiberglass is as follows: recycled glass is melted at high temperatures and pulled into very thin fibers. Due to the fiber length (150 m or more), a high degree of sound absorption is ensured.

It comes in the form of slabs and mats, and is characterized by ease of installation and a minimum number of joints. Fiberglass will be an ideal solution for soundproofing attics, attics, and walls.

Foamed polystyrene

Expanded polystyrene is an environmentally friendly, heat-resistant, safe, soundproof material. Its quality characteristics have been known for a long time and are in great demand.

When using penoplex and expanded polystyrene to insulate wooden houses, a number of positive aspects can be highlighted:

- ease and ease of processing;

- possibility of use without additional precautions;

- non-susceptibility to deformation.

However, it should be remembered that polystyrene foam is afraid of exposure to chemicals.

Correct layout

Proper distribution of space and planning of premises will help reduce noise levels. Tall windows with panoramic views should not overlook a noisy street or other busy place.

Even at the level of designing a house, think carefully about how the residential and utility rooms will be located. Noisy rooms should not border on rest rooms. You should not create such a neighborhood as, for example, a bedroom and a boiler room.

If the layout of the premises is done correctly, the level of penetration of extraneous noise will be significantly lower.

Required Tools

Soundproofing a wooden house is not an easy task, and without using the necessary tools it is almost impossible. Depending on the choice of insulation, the appropriate tools are selected. Considering the fact that for a wooden structure the best option would be mineral or basalt wool, for the work you will need: a knife, a screwdriver, a screwdriver and a hammer. As consumables you need to take: waterproofing, insulation, slats. You also cannot do without measuring instruments: a tape measure or a long ruler.

@instrument

Drywall

Drywall is often used to insulate walls from noise and cold, but this material itself is useless. For effectiveness, it is recommended to combine it with some kind of filler, for example, mineral wool. A modern development is plasterboard acoustic sheets in which there are a large number of holes, and a non-woven fabric is glued to the surface. Thanks to these details, maximum damping of sound waves occurs.

It is worth considering that the use of drywall “steals” square meters of the room.