Active consumption of water resources is a characteristic feature of most industrial enterprises, where water can act as a coolant, coolant, solvent or means of supplying minerals. When using a standard water supply scheme, enterprises consume huge amounts of water resources. In addition, an additional negative factor is the disposal of polluted wastewater into water bodies.

This situation is not only unfavorable for the environmental situation, but also economically unprofitable for business, so now many enterprises are gradually switching to recycled water supply, in which water that has gone through a full cycle is not sent to waste, but is reused. Various elements are used in such systems, but the most important tasks are invariably assigned to pumping equipment.

Purpose

The stability of the functioning of circulating systems and their reliability depend on many aspects, but the main fundamental factor is the correct selection of pumps , their level of quality and durability. This equipment is responsible for the following tasks:

- Sampling of liquid from a selected water supply source (well, reservoir, river, etc.).

- Lifting fluid if necessary.

- Supplying water to the water supply system.

- Creating proper conditions for water circulation through the network.

The creation of closed systems operating on the basis of pumping equipment is the most cost-effective option for minimizing water consumption. The elements of such systems are determined in accordance with the requirements for the quality of the reused liquid. If the water requires additional preparation before the repeated cycle, then the water recycling scheme may include water purification plants, cooling facilities, etc. Depending on the quality requirements, treatment complexes may include a different number of stages (from 1 to 6).

Basic prerequisites for the formation of a circulating system:

- The source used for water supply cannot cover the needs of the enterprise because it does not have sufficient resources.

- The source is located at a considerable distance from the object, which is located on a hill.

This type of water supply is especially common in regions with high costs for water resources or where water quality does not meet production requirements, as well as in situations with particularly toxic wastewater that pose a real threat to the environment.

Features of the operation of vortex-type structures

The device operates using a vortex wheel, which is a metal disk with blades that create centrifugal force. Due to the design features, the water twists into spirals that look like a vortex. The main advantage of vortex-type pumps is their powerful pressure. With the same dimensions, weight, wheel size and number of revolutions as a centrifugal pump, the vortex pump provides stronger pressure. Therefore, the dimensions of the body of a vortex model can be significantly smaller than those of a centrifugal model.

Due to the high pressure created by vortex pumps, they are successfully used for watering gardens and vegetable gardens. They are excellent for installation in water supply systems of cottages and private houses, if there is a need to increase pressure in the network. Unlike centrifugal models, vortex models normally tolerate large air bubbles entering the pipeline. Compact dimensions expand the scope of application of pumps of this type. The disadvantage is sensitivity to suspended particles in water. If there are a lot of them, the pump will work intermittently and will quickly become unusable.

Due to their compact size and high power, vortex pumps are well suited for installation in deep wells of small diameter

What types are they divided into?

Industrial pumps for water intakes are divided into three categories:

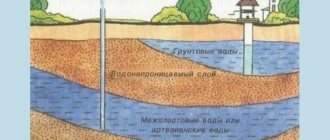

- Superficial . This group of pumps is intended for drawing water from ground reservoirs, freshwater rivers, from filtration wells, and water recycling units (recirculating water supply units). The equipment is also in demand when draining areas and pumping liquid from flooded rooms. To ensure liquid suction, the pump is placed in close proximity to the source, installed on the surface of the earth. Depending on the power of the model, the pump can pump water from a depth of 8-20 meters. The most common type of equipment for water intake from surface sources is type D double-entry centrifugal pumps.

- Semi-submersible . The equipment is a symbiosis of a surface and submersible pump. When installing it, one part of the equipment is immersed in water, and the second remains on the surface. Semi-submersible modifications are used if the water level in the system is low relative to the inlet of the double-suction pump.

- Submersible . Pumps of this type provide lifting of water from wells, reservoirs, wells and other sources. Well pumps have a multi-stage design and a submersible, completely sealed motor. Depending on the power, submersible pumping equipment is capable of lifting and supplying water from wells and other sources located at a depth of 100 meters or more. The main disadvantage of downhole models is the difficulty in installation and maintenance, but if reliable equipment is selected and properly operated, the pump will be characterized by stability and trouble-free operation for many years.

Various types of pumps are also responsible for ensuring the circulation of liquid through a system with a complex multi-stage device. Due to high reliability, productivity, low noise and vibration levels and a number of other advantages, preference is mostly given to multi-stage centrifugal pumps (vertical, horizontal) and single-stage monoblock pumps of the IN-LINE type.

It is worth noting that in industrial water supply pumps are rarely used independently, since complex pumping stations are most effective for the circulation system. Depending on production needs, they are equipped with pumps ranging from one to six. Such stations effectively increase the pressure in the system, provide stable pressure and allow you to adjust the flow to obtain optimal parameters.

Vibrating pumps for home and garden

For your home, cottage and garden, you can choose an electric vibration-type water pump. Its operating principle is based on the influence of an electromagnetic field created by a coil that draws in a metal core with a flexible diaphragm. By bending, the rubber diaphragm creates low pressure, due to which water is sucked into the hydraulic chamber. When the diaphragm returns to its place, the pressure increases and the valve closes the inlet, so the water is pushed out through the outlet. The constant movement of the diaphragm ensures uninterrupted pumping of water.

Vibrating pumps are used to organize watering and irrigation of plants. They are installed in autonomous water supply systems. A huge advantage of this design is the ability to pump contaminated water, which allows them to be used when pumping wells and boreholes for preventive cleaning. When working with dirty water, the performance of vibration pumps drops noticeably, but they are quite capable of cleaning the bottom of hydraulic structures. Another advantage of the design is its relatively low cost and reliability. The durability of the devices is ensured by a design in which there are no moving or rubbing parts.

If the diameter of the well is relatively large, then you can install a vibration pump, after putting rubber rings on it to “dampen” the vibration

Electric vibration pumps have as many disadvantages as advantages. Devices often malfunction due to power surges. If the home owner decides to install a vibration pump, he will additionally have to purchase a voltage stabilizer. Such pumps are successfully used for pumping water from wells, but it is not advisable to install them in wells, especially small ones, despite the ease of installation. Constant vibration negatively affects the casing structure, and sooner or later the pump will either break itself or destroy the production pipe.

It is not advisable to install the Rucheek pump in narrow casing pipes. This may result in unplanned pump repairs or even the drilling of a new well.

Operating principle and classification

Due to their high reliability, performance and energy efficiency, centrifugal pumps are most often used for industrial water supply. The operating principle of such installations is quite simple. The liquid medium entering the internal chamber of the pump is captured by the blades of the rotating impeller and moves with it. The resulting centrifugal force throws water towards the walls of the working chamber, which contributes to the appearance of excess pressure, under the influence of which the liquid enters the pressure pipe. As a result of a decrease in the liquid level inside the housing, the pressure indicators decrease, due to which water is drawn into the pump from a source or reservoir through the suction pipes.

Centrifugal pumps are classified according to a number of parameters:

- By shaft location: horizontal and vertical.

- According to the method of shaft sealing: dynamic, end and stuffing box.

- By type of pipe arrangement: IN-LINE , console.

- Method of connecting the electric motor and the hydraulic part: monoblock design, coupling.

- By number of stages: single- and multi-stage devices.

Irrigation pump rating

Before writing the TOP, consultations were held with sellers, and many reviews from buyers and gardeners were studied. The analysis took into account the following characteristics:

- Type – surface or submersible;

- Mechanism – centrifugal or vibration;

- Installation – horizontal or vertical;

- Manufacturing materials;

- Weight and dimensions;

- Suction depth;

- Power;

- Liquid temperature range;

- Water quality – clean or polluted;

- Mains voltage;

- Bandwidth;

- Maximum pressure;

- Operating pressure;

- Protection against splashes, drops and solid particles;

- Heat resistance;

- Noise level.

The selection also focused on safety, versatility, reliability, ease of use and value for money. After a detailed analysis and comparison of all parameters, 10 winners were selected from more than 30 nominees.

The best battery sprayers

Main characteristics

To select a pump in accordance with your tasks, you need to pay attention to the following parameters:

- Equipment power, productivity (pressure that the pump can provide).

- Quality of components.

- Dimensional parameters of the device.

- Installation method.

- Well depth (when selecting a water intake device).

- Nominal diameter of inlet/outlet pipes.

- The distance over which the selected pump model can transport liquid.

- Type of pumped medium, etc.

The best option is to purchase a pump from the manufacturer, since technical specialists from such companies will always be able to select equipment that optimally matches the parameters of your system and can ensure the smooth and efficient operation of the water supply network.

A short video tutorial on pump selection

When choosing an electric water pump for your home, cottage or garden, first of all consider its intended purpose. There is no ideal equipment for “everything”. Consider what main tasks the device will perform, whether it will only work to pump clean water or whether there is a possibility that it will have to lift water with sand and dirt.

When selecting a specific model, be sure to take into account the most important technical parameters: power, performance, efficiency, maximum pressure. If during the calculations you have doubts about their correctness, consult a specialist. As for brands of household water pumps, the brands Wilo, DAB, Gilex, and Belamos have proven themselves well. The market leader is the Grundfos brand.

- Author: irina-jakuschenko

Rate this article:

- 5

- 4

- 3

- 2

- 1

(6 votes, average: 3.8 out of 5)

Share with your friends!

Benefits of use

Centrifugal pumps are one of the most popular equipment options when creating autonomous water supply and sanitation systems, as well as completing booster and fire-fighting stations.

The main advantages of centrifugal industrial pumps for water intakes and circulating water supply:

- High performance with small body dimensions.

- Easy to install, start up and operate.

- Pronounced performance with moderate energy consumption.

- Absence of pronounced vibrations and noise during operation.

- Stable operation even with long periods of inactivity.

- Durability ensured by reliable assembly and high quality components.

Drainage pumps for irrigation

These models do an excellent job of pumping contaminated water from swimming pools, basements, ponds, cesspools and swamps. Their advantage is a filter or chopper installed on the rotor. Unlike a garden pump for watering from a barrel, this type allows you to supply water with branches, leaves, silt and other debris, which later becomes liquid organic fertilizer for the garden beds. Drainage units are economical to use and inexpensive. Initially, 10 applicants took part in the testing. After a detailed study and comparison of their characteristics, the 3 best models were selected.

Bison NPG-M1-400

The submersible drainage unit “Zubr NPG-M1-400” is equipped with 400 W electric motors powered by a 220 V network. With a small head of 5 m, it provides high productivity of 7.5 cubic meters. m/hour and an optimal immersion depth of 7 m. The device is suitable for draining flooded rooms, cleaning wells and filling containers from ponds. Thanks to the installed filter, you can pump both clean and dirty water with particle sizes up to 3.5 cm.

The model provides automatic switching on and off using a float that controls the water level. It is equipped with a thermal fuse to prevent overheating of the motor and has protection against dust, solid objects and moisture of class IP 68. The housing of the device is highly durable. For its manufacture, hygienic fiberglass reinforced plastic was used. The kit includes a universal fitting for connecting hoses.

Advantages:

- Light weight – 3 kg;

- Compact dimensions – 19 x 9 x 16 cm;

- Power cord length – 7 m;

- Warranty period – 5 years;

- Low price.

Flaws:

- There is no provision for connecting a ¾ hose.

Owners of the Zubr NPG-M1-400 drainage unit note the benefits of the built-in plastic handle. With its help, it is convenient to carry and immerse the device.

Gilex Drainer 110/8

This submersible pump pumps out groundwater, rainwater and waste contaminated water with temperatures ranging from 1 to 35°C. The size of the particles passed through should not exceed 5 mm. It is suitable for supplying clean liquid from ponds, wells and storage tanks. A centrifugal impeller is used here. With a power consumption of 210 W, the unit provides a capacity of 6.6 cubic meters. m/hour, as well as pressure and depth of 8 m.

The Gilex Drainage 110/8 model features dry-running protection and an automatic water level control system using a float. The single-phase electric motor of the device is not subject to external damage due to the hermetically sealed housing. Its stator has a working and starting winding with a thermal protector that turns off the engine if it overheats. The included universal outlet connector allows you to connect hoses with diameters of 1.0, 1.25 and 1.75 inches.

Advantages:

- Electrical protection class IP 68;

- Optimal weight – 4.8 kg;

- Optimal dimensions for installation – 17 x 37.7 x 22 cm;

- Versatility;

- Easy to maintain.

Flaws:

- Shelf life – 12 months.

Buyers note the convenient length of the power cord (5 m) of the device, its good performance and low noise during operation.

Karcher BP 1 Barrel Set

This watering pump should be purchased by those who want to pump water from tanks of almost any configuration. The Karcher BP 1 Barrel Set model is equipped with a 400 W electric motor. It provides a vertical water lift of 11 m (1.1 bar) from a maximum immersion depth of 7 m and a capacity of 3800 l/h. A pre-filter is installed here, which protects the system from dirt and small particles up to 1 mm. The design provides a flexible mount on the handle, adjustable in height.

The advantage of the device is its complete set. There is a 15-meter hose, adjustable in length, 2 universal connectors and a watering gun. The pump is equipped with a float switch to automatically adjust the water level. Its light weight (4.6 kg) and compact dimensions (17 x 52 x 13.5 cm) make it easy to transport. The maximum temperature of the pumped liquid is allowed up to 35°C.

Advantages:

- Built-in protection against switching on without liquid;

- The optimal cord length is 10 m;

- Convenient carrying handle;

- Economical energy consumption;

- Solid build quality.

Flaws:

- The bottom filter is not installed very securely.

Owners of the device praise it for its low power consumption and quiet noise during operation (44 dB).

The best vacuum pumps

terms of Use

To maximize the service life of centrifugal pumps, it is necessary to strictly follow the rules of their operation. First of all, you need to choose a model whose performance and technical characteristics fully meet the system parameters.

The second important condition is compliance with recommendations on the types of substances transported and temperature conditions. It is not allowed to transport substances that are incompatible with the material from which the pump flow part is made. All current conditions and recommendations for the operation of the selected model are indicated in the technical data sheet of the equipment.

For what purposes which pump should you choose?

In order to choose a pump, you need to decide on the purpose: what you need it for. After that we move on to class. For example, for watering garden beds when using a local reservoir with significant water pollution, it is better to use submersible drainage pumps. Such pumps will also successfully drain basements and cellars flooded with water. They will also do an excellent job of removing contaminated water from small ponds, wells, and sewer pits (see how to make a sewer here).

If you intend to pump clean water, then submersible pumps (well or borehole type) or surface pumps are suitable. Moreover, they are capable of supplying water both to the water supply and to the irrigation system for watering plants. Someone may need to pump a large amount of water through a plumbing or heating system - and here you can’t do without the help of circulation pumps.

Among other things, pumps can be divided into two more classes: household and professional. Agree, for a small country residence a device that distills 50-60 liters per minute will be sufficient, but for production needs large capacities will be needed - several thousand liters.

An important factor in choosing a pump is its energy source. If you have access to the power grid, that's one question. And if the installation is located far from a stationary source of electricity, then you should choose autonomous pumps running on gasoline or diesel fuel. Such units were adopted by firefighters, rescuers and utility workers.

Recommendations for installation and maintenance

If you have experience and skills, you can perform the tasks of installing the pump and its subsequent maintenance yourself, but it must be taken into account that any errors will lead to incorrect operation of the equipment, its accelerated wear and failure. If quality and reliability are your priority, then it is better to entrust the installation of pumping equipment and its subsequent maintenance to specialists.

offers customers a wide range of industrial centrifugal pumps of various types and provides a full range of services for equipment selection, installation, comprehensive diagnostics and maintenance. Our range includes equipment for domestic and industrial water supply, pumps for drainage, pumping stations for fire extinguishing and pressure boosting systems.

JETEX pumping equipment is characterized by standard quality, long service life, reliability, energy efficiency, and reasonable prices for its purchase, constant availability of spare parts and expert support make it an affordable alternative to imported equipment when installing water intake and recycling water supply systems.

Metering pump block for stabilization of circulating water

Metering pumps and complete installations based on them are used for dosing reagents that prevent scale formation, softening and stabilizing circulating water (coolant). In some cases, it is necessary to use installations for the preparation and dosing of solutions of flocculants, coagulants and other reagents (for example, water intake from a river).

Dosing pumps can be either individual or as complete complete dosing units.

Also for circulating water, systems for preparing sodium hypochlorite solutions by electrolysis followed by automatic dosing can be used. Dosing hypochlorite into the circulating water system prevents the formation of microorganisms and helps keep both pipes and cooling towers clean.

For consultations on pumps and equipment for recycling water supply systems, you can contact technical specialists by phone Telephone: 8 800 250 0154 Telephone/fax: E-mail

Is it necessary to heat water from a well before irrigation?

With drip irrigation, the water has time to warm up in the air.

Experts assure that heating is the only way to protect the garden, lawn, and vegetable garden from destruction. Special storage tanks are filled with well water. The liquid should settle in them for about a day or more. During this period of time the following will happen:

- The water will warm up to the optimal temperature. As a result, shock is avoided in plants when irrigated.

- It will be saturated with oxygen, become alive, suitable for moistening the soil and the root system of crops.

- It will settle, as a result of which all iron ions oxidized by oxygen will precipitate. This does not require an expensive cleaning system.

- Carbonate salts will linger on the walls of the storage tank.

- The density of water changes with height. Its upper layers will be less mineralized. Moisture from this part of the storage tank should be used.

This results in a natural purification of the liquid. It is advisable to have such a volume of storage tanks that you can gradually add new liquid to them, taking some of it earlier.

It is permissible to ignore the temperature regime if water is supplied using aerators. Liquid droplets warm up in the air before falling onto the ground.

To properly moisten the soil in the garden, vegetable garden, or lawn during the hot period, 500-1000 liters of water should be used per 1 hectare of land.

Is it dangerous to water a vegetable garden or garden with drainage from a cesspool or septic tank made of concrete rings?

Definitely dangerous. And it makes no difference whether it is a simple cesspool or a cesspool concreted with rings. Such a cesspool, which is mistakenly called a septic tank, does not clean the wastewater at all. It is leaky and allows both groundwater from the outside and gray runoff into the soil through cracks. It turns out that the main task of the septic tank, which is to process pollution by anaerobic bacteria, is completely disrupted.

Irrigation from a cesspool is dangerous

How to choose a pump?

When choosing a pump, you should take into account both its basic and additional characteristics.

By performance

To calculate the performance of submersible pumps, you need to know how much water your device will process. Our sanitary standards stipulate that 200 liters of water are needed per person per day. Now let's move on to the water pressure in the pumping units. To calculate it, you need to know the lift height and horizontal length of the pumped water path.

The pressure and amount of water pumped by a pumping unit per unit time directly depend on its power, which is measured in W.

Attention! The pump must not be allowed to run “dry” (when the water drops below a critical level), as this may cause the pump motor to overheat. To avoid such risks, you should use a float system that turns the device on and off automatically.

By power and pressure

When you have already decided on the class, type and energy source of the pumping unit, you should decide on its main characteristics: power, volume of water pumped and pressure.

When choosing a pump based on power, do not forget to take into account the following pattern - the greater the engine power, the (as a rule) the greater the noise level of the pump.

The maximum water pressure in the pumping unit should be calculated vertically: from the earth's surface on which the unit is located to the water intake point.

Attention! Oil-cooled pumps are of higher quality and more reliable.

When choosing a deep-well pump, the main attention should be paid to the height of water rise (pressure). This value is measured in meters. Another important parameter is the performance of the pump, that is, the amount of water pumped. It is measured in liters per hour.

By water consumption

The calculation should be made based on the number of people consuming water, the number of water intake points and the presence of additional places for water consumption: swimming pool, bathhouse, garden irrigation system.

The standard water consumption per person in a country house is from 120 to 180 liters. The calculation did not take into account the bathhouse, swimming pool, etc. Moreover, we should not forget that with the simultaneous use of taps in the bathroom, kitchen, and so on, the load on the pumping unit also increases. So a well pump should be purchased with a reserve of up to 300 liters per hour per person.

Important! To constantly maintain the required pressure in the device, a non-return valve should be installed.

When choosing a pump, you should pay attention to what material the pump body is made of. Cast iron installations, with an obvious disadvantage - weight, are less “noisy”. Units with a plastic or steel body are not so heavy, but they are noisier during operation.

For additional functionality

- The idle control function controls the shutdown of the pumping unit when the water supply is interrupted.

- Air pumping function to prevent air locks in the water supply system.

- The function of turning on the pump at low water level assumes absolute drainage of the surface. This is possible with air-cooled drainage pumps.

- The noise absorption function is especially important for pumps with powerful motors.

Since you are interested in pumps, it is quite possible that you do not have a centralized water supply. In this case, you may also be interested in the topic of how to choose a good and economical water heater for your home. And if you also like to plant various plants in your dacha, then I advise you to read an interesting article about hedges instead of a regular fence. And finally, having a dacha and not having a means of transportation to get to it is unrealistic. Therefore, a summer resident must have a car, and maybe also a bicycle to boot.

Tags: Tags dacha house purchases