In the absence of a centralized water main, residential building owners have to solve the water supply problem themselves by digging wells or drilling wells. Often, owners are faced with the problem of a small flow rate (volume of incoming water) of a source, for the exit from which a storage tank for water supply is used.

In order to effectively provide a home with water using a storage tank, the owner will have to solve a number of difficult problems in choosing a tank, its installation location, additional pumping equipment and automation devices, and connection diagrams. In order to avoid making critical mistakes, you should carefully study all the information on the use of storage tanks in autonomous water supply systems.

Rice. 1. Plastic storage tanks

Why do you need a storage tank?

The need to install a storage tank arises in the following situations:

- Low flow rate of a well or borehole. In this case, the submersible or surface pump, due to its low power and intensive water consumption, does not have time to fill the water supply system and the hydraulic accumulator, which is a mandatory element of automation devices, with water. It is worth noting that the use of a more powerful pump or pumping station in low-flow sources will lead to rapid suction of water, a drop in the dynamic level and, as a result, further operation of water suction devices in idle mode.

- Interruptions in water supply. In some country villages or dachas there is a centralized water supply. However, due to the insufficient power of the autonomous system, water is supplied hourly with long breaks. Or during the day, when everyone uses water resources for watering their gardens and household needs, the pressure in the system drops to almost zero. In this case, the only option for permanent water supply is a water supply system for a private house with a storage tank.

- In city apartments, when the water pressure in the main is low, a booster pump is used. However, its operation while sucking water from a common riser can lead to a lack of water supply in other apartments located above. To get out of this situation, use a storage container that is suspended from the ceiling.

- If there is no source of water intake or, for example, it dries out during a drought, an autonomous water supply for a private house can be provided with imported water from cars. In this case, the use of a reserve storage tank is effective for storing water resources.

Rice. 2 Metal water tanks

Optimal operating mode of an electric boiler

Setting the temperature to the minimum permissible is highly not recommended for the following reasons:

- Reduced efficiency of water heating equipment;

- Liquid temperature 30-40⁰ C is an ideal environment for the formation and proliferation of bacteria and mold, which inevitably end up in the water;

- The rate of scale formation increases.

These devices are often equipped with an economy mode option, designated by the letter E. This operating mode means heating the liquid inside the capacitive tank to a temperature of +55⁰ C, which allows you to extend the period of use before maintenance. That is, at a given temperature regime, scale forms the slowest, and accordingly it is necessary to clean the heating element less often. This does not apply to energy savings.

Materials for the manufacture of storage tanks

Storage tanks of any volume are made from plastics - food-grade environmentally friendly low-density polyethylene (HDPE) or polypropylene (PP). Also for their production, linear high-density polyethylene LLDPE (LLDPE) is used. The material is superior in its characteristics to conventional high-density polyethylene LDPE, having higher tensile strength, resistance to impacts and punctures.

Thanks to the materials made from synthetic polymers, the tanks are light in weight, not subject to corrosion, are chemically resistant, and can be used for a period of at least 50 years, regulated by GOST.

An important advantage of plastics, in addition to their low cost, is their low thermal conductivity, which makes it possible to install tanks in the attics of houses and outside on the street.

Perhaps the only drawback of polymer tanks is their poor resistance to ultraviolet radiation. If the tank is installed outdoors, measures must be taken to protect it from direct sunlight. Usually the tank is coated with paint or a canopy is made over it.

In addition to plastics, tanks for accumulating water volumes are made of stainless steel. It is worth noting that metal products have no advantages over polymers, with the exception of ultraviolet resistance, but there are a lot of disadvantages.

This is heavy weight, significant price, high thermal conductivity, requiring mandatory insulation of the container when in contact with cold air, lower chemical and corrosion resistance than neutral plastics. Therefore, stainless steel storage tanks are not widely used and are considered rather as an exclusive option.

It is worth noting that a high-capacity hydraulic accumulator used in individual water supply systems can also serve as a storage tank. The unit is a steel tank, inside of which there is a pear-shaped rubber membrane. The capacity of such tanks also varies over a wide range and can reach up to 1000 liters.

Rice. 3 Design and principle of operation of the hydraulic accumulator

Related article:

How to find water on a site for a well - folk and scientific methods . Perhaps, while reading what a storage tank for water supply is, it will be interesting to read an extended article about options for independently and with the involvement of specialists for searching for water on the site for drilling a well or digging a well.

Where else can plastic barrels be used?

They can be used for storing any liquid, granular media - neutral or aggressive, but:

- if the internal pressure in the tank (the product of the density of the stored material by the height of the column and the acceleration of gravity) does not exceed the calculated (declared by the manufacturer) tensile strength values;

- the material is inert to the substance loaded for storage.

Technical information: Thermoplastics of the polyester group, including polyethylene and polypropylene, are completely inert to ammonia, gasoline, acetone, butanol, acetic acid (CH3COOH only), ethyl chlorides, chlorine gas, hydrogen sulfide, mineral oils, propane, etc.

Design of polymer storage tanks

Plastic tanks for storing water resources come in various volumes (up to 10,000 liters) and shapes. They can be square, cylindrical, vertical and horizontal, flat, angular.

Tanks are produced in two designs. The first is ordinary containers with smooth walls and a sealed lid equipped with a breathing valve. Any storage tank requires access to air, otherwise it will be flattened by atmospheric pressure when emptied. Conventional tanks are designed for storing water resources, extracting them with an electric pump or using a self-installed tap.

The second option is special tanks for use in individual water supply systems. They have four holes in the body on one side - two at the top and two at the bottom. One top and one bottom hole are equipped with a 1-inch male thread. These bends are used to connect the inlet and outlet pipelines of the water main to them.

There is also a hole with a diameter of 28 mm at the top. It is usually used to organize emergency drainage by connecting a pipeline directed to the street or to the sewer.

It is worth noting that any installer can use the top threaded pipe and hole at his discretion. For example, in a 28 mm cutout you can install a float valve that turns off the water supply when the tank is filled, and a 1-inch threaded pipe can be used for emergency draining.

The 3/4 inch pipe at the bottom is used to empty the tank. The need for this arises when dirt accumulates at the bottom of the container in the form of sand and clay deposits, products of decomposition of metal oxides.

There is a different design for storage tanks for underground installation than the traditional one. Since the soil pressure on the tank walls is quite high, they are equipped with stiffeners. In addition, they have a high neck, which allows them to be immersed underground to a depth below the freezing point.

Rice. 4 Storage tank for water supply - examples of use in the home

Indirect heating boiler - what is it?

To heat water, indirect heating boilers use heat from the home's heating system.

A little higher we looked at the design of an electric water heater. Now we will talk about indirect heating boilers. What are they and how do they differ from electric models? Indirect heating boilers operate from heating systems, taking some of the heat from them. Inside them there are coils, characterized by a large area - they provide rapid heating of water. There are also thermostats and thermometers.

Indirect heating boilers are highly efficient and productive, since the area of the heating elements (coils) is quite large, and heating is carried out throughout the entire volume. How to get hot water in the warm season, when heating systems no longer work? To do this, you need to purchase or make an indirect heating boiler with a built-in heating element - it will provide water heating when the heat from the heating system is not enough.

Some indirect heating water heaters do not have complete heating elements, but are equipped with flanges for their installation. The heating elements themselves are purchased separately.

Household indirect heating boilers are highly economical, since in the winter they do not consume electricity, but are powered by heating systems. At the same time, connecting them to heating does not lead to noticeable gas consumption, which is a big plus.

Accommodation options

Storage tanks are installed in the house or outside on the street, and the following options for their placement are used:

In the house downstairs. Autonomous water supply for a private house with a storage tank in the basement or ground floor of a residential building is the most popular option with a set of the following advantages:

- Since the tank is located next to the outlet of the external water main, wiring when connecting it will require minimal consumption of pipe materials.

- To supply water from a tank to a house, surface pumps, pumping stations or submersible electric pumps are usually used. When placed lower, it is easier to connect them to the internal water supply and ensure the supply of electricity to the units.

- The upper pipeline for emergency drainage and the lower one for cleaning the tank are easier to put into the sewer due to their short length.

- The container in a heated house does not have to be insulated.

- The large weight of a water tank will not place a high load on the attic or ceiling structural elements of the house, leading to their deformation.

- The disadvantages of placing a storage tank at the bottom include the mandatory presence of an electric pump that increases the pressure at the outlet of the tank to supply water to the internal water supply and maintain high pressure in it.

Rice. 5 Storage tank for water supply in attics and indoors

How is it used?

The problem of organizing watering at a dacha or a site of a country house is solved in different ways. The main difficulty is finding a suitable container. When choosing a Eurocube for irrigation, you can refuse to use barrels that are not very strong and install a drip irrigation system at minimal cost. This type of technical containers refers to medium-tonnage containers, complemented by a metal grid and a pallet made of plastic, metal, or wood. The cube itself is a polyethylene tank with a tap, thick walls of 1.5-2 mm, and a neck at the top.

This type of container is widely used in industry. For the irrigation system, used Eurocubes, empty of contents and chemically treated, are most often used. Thanks to the presence of an adjustable tap, you can organize a gravity flow of water for a greenhouse or green spaces in the open ground.

Under normal conditions, containers, also known as IBC containers, are used for transporting technical liquids - alkalis, acids, oils. Eurocubes are also used as storage for food products.

The principle of operation and piping of a storage tank in a domestic water supply system

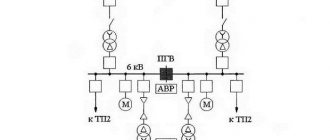

The water supply system with a storage tank located at the bottom of the house operates according to the following algorithm.

When turned on, a submersible or surface electric pump or pumping station pumps water into the storage tank.

Usually it is fed through a filter system into the upper threaded pipe. After filling the tank, the electric suction pump must be switched off. This is achieved in the following ways:

- A float valve installed at the top point is used inside the chamber. As soon as the water level reaches a predetermined threshold, the float floats up and the mechanism blocks the water flow. The electric pump or pumping station begins to operate when the tap is closed, the pressure in the water supply increases, and when a certain threshold is reached (usually 3 bar), the pressure switch turns off the suction unit.

- A float switch is used. With this option, a float is placed inside the tank, connected to the power circuit of the electric pump suctioning water. As soon as the water reaches a certain level, the floating float opens the contacts and the power supply to the electric pump stops - the flow of water into the tank stops.

There is also a hole at the top of the tank, or a hole is made, which is used to connect the overflow pipeline. In the event of an emergency, in the event of a failure or failure of the float, it directs the water flow behind the house or into the sewer.

It is worth noting that one or two sand filters must be installed along the water supply pipeline. Usually this is a self-cleaning filter with a pressure gauge and a second cartridge type in the flask.

Rice. 9 An example of a tank piping diagram fed from a submersible well pump and a water main

Also, during wiring, two lines are installed - supplying water directly from the suction electric pump to the internal water supply and to the storage tank. In this case, it is possible to disconnect one or the other branch using shut-off ball valves.

Water from the reservoir is usually directed to the internal water main of the house using a pumping station. In addition to a centrifugal pump, it includes a pressure switch, a pressure gauge and a hydraulic accumulator.

If the pressure in the area from the storage tank to the taps and plumbing fixtures is below a certain threshold (usually 1.5 bar), the pressure switch closes the power contacts of the pump, and it begins to pump water into the pipeline. When the pressure level reaches 3 bar, the pumping station is switched off. The station’s hydraulic accumulator serves to compensate for water hammer, ensure correct operation of the pressure switch, and creates additional water reserves in the main line.

Also, at the bottom of the storage tank, at the very bottom or very close to its surface, a drainage valve is installed. It serves to drain contaminated water after cleaning the container or as a result of its contamination with bacteria or loss of its taste due to long-term storage.

If the storage tank is powered from a centralized water main with guaranteed high water quality, filters are not installed along the water flow path and the pipeline is directly connected to the tank.

Norms for the distance of treatment facilities on the site

According to SNiP, treatment facilities and pits must be located at a considerable distance from the house, water well and other engineering facilities.

- From a residential building - at least 5 m to a septic tank, VOC, cesspool to avoid unpleasant odors entering the room. And also prevent in advance the possible disastrous consequences of the influence of a humid environment on the foundation of the house.

- It is 30-50 m to a water well. Of course, it is very difficult to follow this rule, since the size of the plots is very limited. It is still necessary to remove the septic tank from the water supply system as much as possible, to the extent technically possible.

- To the borders of the neighboring plot - at least 2 m.

- From the collector to plants and trees - the location is 2-4 m if the tree roots are large.

Storage tank for water supply - installation diagrams

There are several ways to provide water to homes using storage tanks. It is also worth noting that the above option of working with a pumping station for filling the internal water supply with a certain pressure after the storage tank is not the only one.

Rice. 10 Pumping station design

With hydraulic accumulator

The hydraulic tank is an integral part of any water-suction submersible and surface pumping equipment, with the exception of units with frequency control. It sets the time intervals for turning on and off the electric pump when the automation is operating, prevents water hammer, and provides a certain water supply. Typically, the capacity of such a tank is small and does not exceed 20 liters in pumping stations.

But if you take a large-volume hydraulic accumulator, then it can also be used to accumulate water resources. Hydraulic tanks are produced in large volumes, but when using them, one should take into account the fact that they are not completely filled. Since water enters the stretchable internal rubber membrane and its expansion is limited by the air pumped into the tank, approximately 30% of the hydraulic tank capacity remains free.

The use of this method is limited by the high cost of large-sized hydraulic accumulators, for example, a hydraulic tank with a volume of 300 liters, which is approximately equal to a regular plastic one of 200 liters (its average price is 3,300 rubles) costs from 9,000 to 20,000 rubles.

However, the advantages of using a hydraulic accumulator compared to a conventional tank are obvious. Installation is greatly simplified; there is no need for a second electric pump or pumping station to fill the internal water supply, additional shut-off valves, floats, and energy is saved. In addition, one hydraulic accumulator is much more reliable in operation than a plastic tank with a large number of connections in the piping and additional pumping equipment. And finally, the decisive argument in favor of a large-sized hydraulic accumulator is that it replaces its smaller-volume counterpart, that is, the cost of a small one can be subtracted from its price.

In principle, immediately or in the long term, a large-sized hydraulic accumulator tank can turn out to be much more profitable and practical than a plastic container.

Rice. 11 Water supply diagram for a house with a hydraulic tank

Expansion tank with pumping station

The use of a pumping station after the tank is the main water supply scheme for a private house with a storage tank. Its advantages are the relatively low cost of the station and the presence of an electric pump, pressure gauge and hydraulic tank in one module, which greatly simplifies installation. Also, the built-in hydraulic accumulator prevents damage to pipelines and equipment from water hammer.

A significant drawback of pumping stations, namely noise during operation, can be eliminated by using high-tech equipment from Grundfos with a water-cooled electric motor. Also, some pumps and pumping stations from the world's leading manufacturers are made using innovative technology with frequency control of the speed of rotation of the electric motor shaft. That is, the unit monitors and strives to maintain constant pressure in the system, smoothly changing the speed of rotation of the impeller. As a result, there is no need to use a large hydraulic accumulator tank.

It is clear that the cost of high-tech pumping equipment is several times higher than traditional water intake units.

Rice. 12 Water supply diagram with storage tank and pumping station

With submersible electric pump

In addition to surface electric pumps or pumping stations, deep well electric pumps can be used to supply water from the tank to the internal pipeline.

However, this option is used quite rarely due to the fact that submersible units have high cost and productivity, which is absolutely not required for water intake from a tank.

In addition, when connecting submersible electric pumps, you will have to additionally look for a place in the room to place a hydraulic accumulator, pressure gauge, pressure switch and dry running.

In principle, instead of a downhole electric pump, you can use a budget vibration pump, which has much lower productivity. However, due to vibrations during its operation, the likelihood of depressurization of connections in the tank increases sharply.

Rice. 13 Storage tank for water supply and submersible pump inside

With booster pump

A special electric pump that increases the pressure in the main line can be effectively used when placing the storage tank at the top of the attic of the house. The unit includes a flow switch and the vortex pump itself. The electric pump is connected to a pipeline rupture in any vertical or horizontal position; it operates according to the following principle.

When the faucet is turned on, the flowing water flow raises the flag (flap) of the flow switch, which in turn closes the internal contacts of the built-in reed switch. Voltage is applied to the electric pump and it begins to push water, thus increasing the pressure in the system. The booster electric pump can operate in automatic mode using a flow switch, which is forced when turned on manually; it is also possible to turn off the unit. These modes are set on the pump control unit.

In principle, you can use a booster pump in a system with a bottom-mounted storage tank, if you do not pay attention to water hammer or additionally install a hydraulic accumulator. However, in this case, when using water, it will have to be turned on manually. The second option is to place the booster pump on a vertical section of the pipeline in front of water-consuming equipment or taps in such a way that the water flow through the relay can start the unit.

However, this option of using and connecting a booster pump is rarely or practically no one uses.

Rice. 14 Water supply diagram with a booster pump and an upper storage tank

Without electric pump

With some ingenuity and technical preparation, it is possible to implement an autonomous water supply for a private house with a storage tank and one pumping station (Fig. 15). The wiring in this option is done with a number of check valves that cut off unwanted water flows, and the water supply occurs as follows.

During operation, the pumping station fills the water supply and storage tank through check valves located on the bypass (1), in the electric pump line (2) and at the upper inlet of the tank (3). After the line and tank are filled with water, the float inside the tank floats up and shuts off the water supply to the chamber. The pressure in a closed circuit from the tank, internal water supply to the well increases, and the pumping station is turned off via a relay.

When water consumption occurs, the pump turns on when the pressure drops and begins to simultaneously suck water from the well and from below the storage tank through the opened check valve 4.

Rice. 15 Wiring diagram with one pumping station

Rules for choosing the volume and location of septic tanks

The daily water consumption rate is 200 liters per person, and the septic tank must be able to accommodate wastewater. Collected within 72 hours or 3 days. Thus, subject to permanent residence, a three-chamber septic tank made of 250-liter barrels is suitable only for one person. Therefore, septic tanks of this type are used only for temporary residence or for treating wastewater from one point (for example, from a bathhouse). In most cases, they try to somehow increase the capacity of septic tanks, which is why among treatment facilities made from barrels there are practically no two-chamber options (they have too small a volume).

It is important to comply with sanitary requirements regarding permissible distances from the septic tank to certain objects. For example, the distance from the source of drinking water should be at least 50 meters. Garden plants and fruit trees must be located at least 3 meters from the treatment plant

Distance to the road – at least 5 meters

Garden plants and fruit trees must be located at least 3 meters from the treatment plant. The distance to the road is at least 5 meters.

Conditions of a homemade pump for overflowing water...

To get started, I suggest you watch a video about this homemade product:

Probably many people have ever had the problem of pouring water from one vessel to another... Of course, you can simply lift and turn one vessel over another, but... this method is not always good, since the vessel can be large, that is, you will have a lot of weight containers and you simply cannot physically lift the container...

The second way is to pour, for example, in mugs... But this method is also not always good, since, for example, the shape of the vessel may not allow you to scoop up water in mugs or some other circumstances... And then the old proven method of pouring liquid comes to mind - take a flexible hose, lower one end of the hose into a container of water, and take the other end of the hose into the oral cavity and sharply blow air into yourself... Pressure will be created and then water will pour out of one container into another by inertia until you pull out the hose... Simple physics , but... this method is not very hygienic, and if the circumstances are bad, you can even choke on water... Therefore, this method is quite dangerous...

So, let's begin…

In order to make a pump we will need: - a bottle cap; - a drill and an 8 mm drill bit; - scissors or a knife; - a threaded bottle “neck”; - a flexible hose; - a small piece of pipe...

To begin, remove the gasket from under the lid and cut off its edges as shown in the photo, leaving a small “tail”...

Now we carefully place the cut gasket inside the lid and tighten it as shown in the photo... Our cut gasket will serve us as a valve...

We cut off the “neck” from another bottle and do something like a turbo water intake...

Now we put on a flexible hose from the other end of the pipe...

That's all!!! Our water overflow pump is ready...

Now we lower the side of the pipe where the valve is located into a container with water, and with sharp up and down movements we build up pressure... Water flows through the valve into the pipe and then into the hose, and from there it pours out...

About other important devices

If water is taken from its own source, then the tank must be equipped with a float mechanism that will turn off the liquid supply when the required volume is reached. In the event of a failure of the float valve, it is important to install an overflow pipe that will insure the system against overflow.

We recommend filling the tank through a diffuser. This precaution is necessary to prevent sediment from rising from the bottom of the container if for some reason the filters do not cope with their work and impurities enter the reservoir. And also don’t forget about installing other components.

Any system is equipped with a pressure gauge and a safety valve.

Where to begin?

The arrangement of water supply in an automatic or semi-automatic mode begins with planning and project development and ends with periodic maintenance. At the first stage, it is important to analyze:

To ensure uninterrupted operation, it is important to use storage tanks that are needed to store water. A reserve supply is important in emergency situations, such as when the power goes out temporarily. This is the second advantage of installing storage tanks.

Reasons for the formation of condensation on the tank

So, why does condensation form on the tank in the first place? Everyone knows that the appearance of condensation is typical not only for toilet tanks, but also for glass on windows, drinks in the refrigerator in glass containers, etc. And the reason for this in many cases is the same - warm and/or moist air in contact with a cold surface.

As a result, the air, cooling, loses its ability to hold the water vapor it contains. As a result, steam falls onto the cold surface in the form of moisture and is condensate.

Poor ventilation in the bathroom is one of the main reasons for the accumulation of moist air and the formation of condensation. When normal air circulation is restored, the problem will disappear by itself.

Below is a table showing a clear dependence of the appearance of the dew point (the moment when condensation forms) on the parameters of air temperature and humidity, as well as the temperature of the surface on which moisture collects.

Table of dependence of the appearance of condensation on humidity and temperature in the room

For example, if the air humidity in the bathroom is 75% and its temperature is 25 degrees, condensation will appear on the tank, whose temperature is 20 degrees or lower.

Price

The price level for storage tanks for water supply depends on their volume and material of manufacture.

A model with a volume of 200 liters, made of food-grade plastic, costs around 4,000 rubles.

A larger tank, for example, 700 liters, will cost the consumer approximately 8,000 rubles.

Containers made of stainless steel are much more expensive:

- volume 180 liters – 13,700 rubles;

- 635 liters – 30,500 rubles.

However, despite this difference in price, the majority of consumers prefer steel storage tanks.

Submersible pump

This type of system works directly in water. There is a centrifugal and vibration unit. The first option is considered more preferable. However, you must buy a filter for it. The unit is installed directly on the water intake hole.

To pump out clean water without small particles, it is better to use a vibration pump. In terms of price, it will be significantly cheaper. Submersible installation can be installed using any method. The main thing is that the water that is pumped helps cool the engine. If the installation is carried out correctly, then even during prolonged operation the engine will not overheat.

Many models have a float switch. It is designed to minimize the risk of breakage. When the liquid level drops below the set level, the pump automatically turns off.

Main advantages:

- there is practically no noise during operation;

- no overheating;

- the unit functions perfectly with partial immersion;

- is compact;

- ease of installation.

Minuses:

- you need good insulation of the electrical cable;

- for repairs, the installation must be removed from the barrel;

- high price compared to surface devices.

Why does strong condensation form?

Condensation on the toilet flush tank appears as a result of condensation of water vapor that is present in the air. It condenses on surfaces that have a temperature lower than the dew point temperature. This happens because the air, when cooled, can no longer hold the same amount of water vapor in a gaseous state and condensation occurs. In addition to temperature, the relative humidity of the air has a direct influence on the condensation process. As humidity increases, the risk of condensation increases. Unfortunately, determining the humidity value is difficult to predict at the design stage of a bathroom ventilation system.

During construction and renovation, we widely use insulation to reduce energy losses caused by changes in the temperature of the transported medium, when the ambient temperature differs from the temperature inside the system. In the case of devices with average temperatures below ambient, such as a toilet flush cistern, insulation has another very important function - it prevents condensation from forming on the surface of the device.

Types

The storage tank can be a container with sufficient internal volume, made of a material that is resistant to corrosion and safe for storing drinking water. The following materials are used:

- polyvinyl chloride;

- cross-linked high or low pressure polyethylene;

- polypropylene;

- stainless steel;

- steel coated with waterproof varnishes and ceramic coatings.

Plastic Tanks

Although galvanized steel is corrosion-resistant and waterproof, over time the protective layer of zinc can wear thin, especially at joints and welds.

By design there are:

- open containers that have a neck with or without a lid, but with sealed walls and bottom;

- closed, completely sealed membrane-type containers.

In the first case, everything is simple: the entire internal volume is filled with water and, if necessary, drained through a pipe fixed at the lowest point.

In the case of membrane storage tanks, the useful volume is at least a third less than the volume of the entire structure. Part of the volume is allocated under the air chamber, separated from the water using a durable elastic membrane. As the container fills with water, the membrane presses on the air chamber, creating excess pressure. When it is necessary to get water back, the valve opens and it enters the water supply system under the influence of accumulated pressure.

Which form is better?

The shape of the container for storing water at the dacha determines the ease of its installation and the tank’s ability to withstand certain loads.

It is advisable to install rectangular containers and tanks indoors, since they will fit exactly into any free corner, which cannot be achieved when using a round tank or barrel.

Round water containers in the country differ from rectangular tanks in that with the same wall thickness, due to a more uniform load distribution, they can withstand pressure better. It is better to place round barrels for collecting and storing rain and process water in an open space.

Containers of the Eurocube type have proven themselves well. Such containers are available in different capacities and can be installed both outdoors, for watering plants, and in the house, for storing drinking supplies. Thanks to the tap at the bottom of the container, you can make an autonomous watering system from the Eurocube, the water from which will flow into the ground under slight pressure. Another advantage that cubes have is their collapsible design. Collapsible rectangular cubes with a tap and lid are easy to move from place to place, and the pallet allows you to conveniently install them on the ground anywhere in the garden.