In this article we will look at a diagram for installing water supply pipes in any private house with our own hands. It is quite difficult for a person without special training to understand the intricacies of arrangement, but we recommend that every home owner understand the basics. This will be useful for monitoring the work of installers, as well as for choosing the optimal supply option. Laying a pipeline is no less significant a task than organizing a network of pumping equipment. We will provide all the necessary information to make it easier to understand the specifics of the device and the rules, in addition, everything is based on regulatory requirements.

Types of water supply wiring in a private residential building according to the drawing

There are 2 main types of water supply, which is carried out in households:

- autonomous - everything comes from a personal well or a drilled well;

- centrally - supply from a special line that takes resources from a tower or a station designated for this.

Both methods have their positive and negative sides; you should decide on the subspecies before starting installation, because each of them has its own characteristics. The final cost of the entire process also depends on the choice. Although there are situations when only one of the methods is possible (for example, in the absence of a centralized water supply system) and then there is no choice.

Scheme of input and connection of water supply (water) of a residential private house from the central water supply

When choosing a system, you should think about several criteria:

- is there a water main in the area? It’s funny, but people sometimes forget to take this into account;

- what quality of moisture is supplied - it happens that it is only technical, it is not recommended to drink;

- how reliably and uninterruptedly does the supply function? In some regions there is pressure only by the hour or on days of the week;

- does it depend on external factors - some lines stop working in winter;

- how expensive it is - sometimes it is much cheaper to drill your own well than to crash into a working highway.

How to distribute water around the house if there is an autonomous water supply

When an owner wants to equip his personal well, he should prepare for large labor and financial costs even at the construction stage. First you will have to dig a well or drill it, draw up the correct technical plan, select and buy equipment. Only then will you need to mount and connect.

If you do not focus on the price of this choice, then it has many advantages:

- you don’t have to depend on any external factors;

- can be carried out everywhere, it is especially convenient where there is no common highway;

- no need to pay monthly;

- The quality of moisture is usually much higher, in addition, you can install any filters if necessary.

If it turns out that the source is not clean enough and drinking from it is not recommended, then special treatment facilities can be installed. This will greatly clean and improve the condition of the liquid, making it suitable for cooking and drinking. Choose such a device on our website, and if you have any questions, the managers will be happy to answer them.

PVC

Polyvinyl chloride is known primarily as a material for the production of sewer pipes. However, PVC pressure pipes are also used in the installation of water pipelines.

The photo shows water pipes for adhesive joints. Material - polyvinyl chloride

Characteristics

- Operating temperature: up to 40 degrees with the possibility of a short-term increase to 60 ° C;

- Working pressure: up to 16 kgf/cm2;

- Service life: from 50 years.

Fitting

PVC pipes and fittings for water supply are mounted on adhesive socket joints.

How it's done:

- The pipe cut to size is cleaned of burrs;

- The surfaces of the pipe and socket for gluing are degreased with gasoline or white spirit;

- Glue is applied to both parts with a brush;

- The pipe is inserted into the fitting socket and rotated 90 degrees. Turning is necessary in order to evenly distribute the glue;

- The connection is fixed for 30-60 seconds depending on the diameter of the water pipe.

Assembling an adhesive joint on a PVC water pipe

Photo of the installation diagram for a water supply system, which is usually used in a private country house

There are 2 ways in which the connection can be made - in series, one after the other, and in parallel, when everyone is turned on at the same time. What to do at home depends on how many people live, whether they are there permanently or periodically, and how intensively the water supply is used.

In some cases, a mixed type is used, when all mixers are connected through a manifold-combiner, and all other elements must be connected in series.

If the connection is serial

It looks like alternately supplying pipes that lead from the riser or water heating device to the plumbing and taps. First, general ones are diverted, and then branches go from them through tees to the places where moisture will be consumed.

This is a more economical method; it is often used in apartments and small houses. The essence of saving is in a small amount of materials, and the installation itself is simplified. The system will be compact, it will be easier to hide it under the decoration.

A serious drawback is that if several people use hot liquid at the same time, then at the most distant point the pressure will be significantly lower than at others.

Another disadvantage is that if you need to repair or connect any of the plumbing fixtures, you will need to disconnect the entire housing from the supply.

This is why we recommend using a different scheme in private homes with high consumption to avoid problems with operation.

If the connection occurs in parallel

This option is based on the fact that the pipes themselves go from the main collector to the points where water intake will occur. Separate nodes are placed for each line.

It will be necessary to lay a lot more pipe lines, which means that it will be difficult to camouflage them. And any part with a tap or appliance will have a stable, unchanging pressure, even if several plumbing fixtures and taps are used at the same time. Changes in pressure will be minimal, the pressure will be even.

A collector is a device that has one input and two or more outputs. Their number will depend on how many nodes and equipment the source uses.

1.5 m3/h For process water

1.5 m3/h For process water

MBFT-75 Membrane for 75GPD

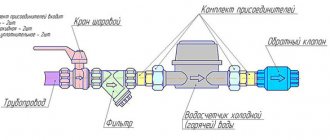

For cold water supply this is done before entering the premises, and for hot water supply - immediately after the water heating product. A cleaning filter and a reducer are installed in front of the collector, which will control the pressure.

How to create a project yourself?

In order to properly plan the plumbing system, you must first draw up a house plan, placing in it all the plumbing fixtures and equipment that will be connected to the water supply.

All dimensions are indicated on the same scale, according to actual measurements of the premises. The more accurately the plan is drawn up, the more accurately it will be possible to determine the required amount of materials and components.

The water supply diagram should reflect as accurately as possible all water intake points, the length and location of pipes for transporting water, and even sewerage, since these communications are often located nearby. The number of filters, boiler volume, and pumping equipment parameters are also taken into account.

The wiring diagram must be simplified as much as possible, trying to avoid crossing pipes. Water pipes are located closer to sewer pipes in order to hide them with a common duct. When placing pipes under the floor, the outlet of the tees is positioned straight up

The project must take into account the requirements of building regulations, as well as the rules of water supply and sanitation approved and in force in the country.

If the water supply is external, where is the housing supplied from?

There are several schemes for distributing water in every private house without do-it-yourselfers, let's look at them in more detail.

Central water supply

The most budget-friendly way to organize water indoors. To cut in, you need to get permission from the settlement administration, then install meters, install equipment, and lay a pipeline to your home. Another condition is the installation of a septic tank or other wastewater treatment facility.

Well

One of the most common mining methods in suburban areas and in the country. Typically used where the liquid is shallow. The main advantage is that even if there is no light or pump, you can still fill a bucket, even with a lot of effort.

Well

The purest liquid of all the options proposed above. There is more of it, you can simultaneously provide several areas at once. But creation requires significant investment, and a license for use will also be required.

Copper

The advantages of copper are durability, corrosion resistance and bactericidal qualities that help disinfect tap water. The disadvantage is the high cost (from 300 rubles per linear meter).

The appearance of copper pipes allows them to be laid openly: the water supply does not spoil the design of the room at all

Characteristics

- Temperature - up to 150 degrees;

Note: in this case too, the temperature is limited by the heat resistance of the connections. Copper itself can withstand heating up to 400 degrees or more without loss of strength; it melts only at 1085°C.

- Recommended operating pressure - up to 25 kgf/cm2 at a breaking pressure of 200 - 240 atmospheres;

- Service life is estimated. In practice, the oldest copper water pipes have been functioning properly for more than a century without repairs or leaks.

Fitting

| Image | Description |

| Solder fittings are equipped with sockets that form a gap with the pipe of 0.1-0.5 mm. After stripping and fluxing, the pipe and fitting are heated in the flame of a gas burner or in a stream of hot air from a hair dryer, after which a solder rod is inserted into the gap between the socket and the pipe. Capillary action causes the molten solder to fill the entire cavity. After cooling, we have a maintenance-free connection with an unlimited service life. |

| Compression fittings are very similar to those used for installing metal-plastic. However, they use a conical copper ring as a seal. The plasticity of copper allows it, when tightening the union nut, to fill all the unevenness of the connection and ensure the tightness of the connection. |

| Press fittings are sealed with a rubber ring. The fitting is crimped onto the pipe using mechanical or electrical pliers. |

Types of wells

There are only 2 main subspecies. In the first case, you can drill an artesian, which has a depth of up to 150 meters, or a regular one, “into the sand.” The second one does not go deeper than 15-50 meters.

They also differ in the time they can be used. The former last up to 50 years, and the latter usually no more than 20 years.

Polyethylene PE-RT

Thermally modified polyethylene PE-RT, due to the introduction of octylene into it, which forms additional molecular chains, acquires increased resistance to high temperatures. It can be used, like PE-X, in hot water supply and heating systems.

Modification of polyethylene with increased heat resistance

Characteristics

- Operating temperature - up to 95 degrees with the possibility of a short-term increase to 110°C;

- Working pressure - up to 10 atmospheres;

- Service life is at least 50 years.

Fitting

Water pipes made from PE-RT are fully compatible with press fittings and can be installed using them; however, much more often cheaper welding fittings are used to connect to collectors, plumbing and heating fixtures.

Low-temperature socket welding uses the effect of molecular diffusion in molten plastic: the pipe and the inner surface of the fitting sleeve are melted upon contact with the soldering iron tip and aligned with each other, forming a strong, maintenance-free connection.

Pipes and fittings made from PE-RT polyethylene for hot water supply and heating are connected by sleeve welding

Which pump to choose

In order for water to flow from the tap, you need to install pumping equipment that will cope with the task.

The main thing is to take into account several parameters:

- how much liquid will be consumed;

- where is the highest point of consumption;

- what performance is needed;

- how deep is the well;

- average pressure (will be written in the passport).

We recommend using a voltage stabilizer when connecting such equipment.

What is this - patina

People who collect coins and antiques are constantly faced with the fact that antique objects made of wood, precious metals, bronze and brass, which were stored in good conditions, have a visually visible patina of antiquity. In professional language, such a coating is called patina. There is patina on furniture, ancient coins and household items.

Among specialists, objects with an intact layer of patina are valued several times higher than products that have been cleared of it, even if they shine like new. In fact, patina in this case acts as a kind of standard confirming that the item has a solid history.

Owning antique furniture, which can be immediately identified by its characteristic layer of microcracks and darkening, gives a special status to the owners. It is proudly shown to guests, with pleasure telling the history of the set. Therefore, such furniture arouses such interest among buyers. However, not everyone has the opportunity to make such expensive purchases.

Taking this into account, designers have developed special technologies. Artificial aging of wood is no longer a problem. Patination of furniture, performed by professional craftsmen, allows you to create real masterpieces from inexpensive materials.

The comfort of wood and antiquity creates a pleasant atmosphere in the kitchen

You can make a patina either on solid wood or make patinated MDF facades. The quality of workmanship is so high that few will be able to distinguish a fake. Looking at a kitchen set, a person is sure that it is old wood until he opens the door. Only then does he discover that only the facades have a patina, and the rest of the structure is quite modern.

Today, designers can artificially age wood so much that they can create living rooms and kitchens in the Provence style with high reliability. The white patina and light abrasions applied to kitchen fronts allow people to create a small corner of the French countryside in their home.

Application of patina

Patination, as an artificial aging process for a product, is used in various fields.

- Modern gift shops are trying to reach people with different purchasing power, so they actively sell antique items that are made in modern times and have a patina effect made by skilled craftsmen.

- Numismatists who collect ancient coins turn to professionals. Do-it-yourself patina on the coin’s metal increases the self-esteem of such “collectors.” Manufacturers of copies of ancient coins do the same.

- It is common for furniture manufacturers to apply patina to wood. It covers the texture and places of milling of wooden elements, and also creates a patina on MDF facades for the kitchen.

- Artificial patina is also used to cover fittings used to make “antique” furniture.

The use of the artificial aging method is the breath of a new style

Types and methods of applying patina can vary greatly from each other.

- The style of patination can vary - thin layer patina, fill and aged.

- Obsolescence is done with rubbing into the texture, while the other two styles are done without rubbing.

- Aging implies a clear and rich highlighting of the milling, the patina and filling on the milling is applied smoothly.

At the same time, furniture manufacturers have catalogs of the textures of various trees, which describe patination methods.

In furniture production, there are two technologies for applying patina to wooden parts.

- Membrane vacuum pressing.

- Manual application of varnishes and paints to facades and other parts.

The types of patina differ depending on the paints and materials used, as well as the surface on which they are applied. They also depend on the method of applying paint to the facade.

Simple patination

Simple artificial aging of facades can be done with your own hands

This is the easiest way to do patination yourself. A basic paint composition is applied to the front side of the façade blank made of laminated MDF or solid wood. It should level the surface and form a base layer. After the applied composition has dried, it is carefully sanded using sandpaper. In this case, the patina for wood will play the role of a covering composition for the paint. The level of abrasiveness and force must be adjusted depending on the required pattern. Finally, the surface must be coated with a special colorless matte varnish.

Method using bronze, gold and silver

This is how a kitchen patina is processed which has no gloss. The surfaces to be treated must have a textured surface. Since gold, silver or bronze is applied as an additional layer, the main background must be prepared in advance and have a matte finish. Additional paints are applied to protruding parts. After drying, these surfaces are also lightly sanded. Antiquity does not imply bright shine.

Patination and craquelure

Behind these words lies a more complex process of artificial aging. It is necessary to achieve the appearance of cracks and the formation of a “patina” of antiquity. Bevel varnish is applied in layers. In this case, the next layer is applied to the previous one that has not yet completely dried. This creates a basis for the formation of cracks. For their appearance, a fairly large number of layers are required, so this is a labor-intensive process. Do-it-yourself patina with the desired shade is applied to the surface with cracks that have appeared. And only after the prepared facade has completely dried, it must be sanded.

Texture coating technique

When making kitchen facades, patina film is the most common surface. Because PVC film covered with a simple patina is a cheaper way to make such furniture. As a result, it falls into the top category of cheap furniture.

Scheme for introducing a water supply system into any private house, where to start drawing up a water supply project

All installation activities should begin with the project. Already at this moment it is worth thinking about what type will be built, how often it will be used and approximately how many drainage points will be required. This is important because the parameters will determine what system and equipment needs to be supplied.

Options:

- submersible pump with automation;

- pumping station;

- hydraulic accumulators.

What to consider when designing a connection diagram and introducing cold water in a private house (with photo)

Equally important are the ways in which the liquid will be filtered. The easiest way is to find out the quality and install the appropriate filter or the whole system.

You should also think in advance about how the hot pressure will be supplied and at what depth the products should be laid - each region has its own options.

Pumping stations for water supply. When should it be placed?

The question of choosing a pumping station faces those who do not have the opportunity to connect a water supply from a central water supply system. In this case, water will be supplied directly from a well or borehole. The pumping station is capable of raising water to a level of 9 meters. This option is convenient for collecting water from wells and wells.

Pumping units have the advantages of having a special protection mechanism against burnout, as well as a hydraulic accumulator.

The nuances with which DHW is supplied

Typically, electric or gas boilers, water heaters or boilers are purchased for this purpose. The equipment can operate on solid, liquid fuel or gas. Each option has its own advantages and disadvantages; it is worth focusing on what is most often chosen in the region.

Key Features

This is due to the fact that during the construction of the system you will not have to worry about measures to prevent water from freezing.

The pipes will not need to be buried in deep trenches, and the areas that are on the surface will not need to be wrapped with a heating cable and insulated.

Thus, summer water supply is very affordable and will be affordable even for a financially limited gardener.

Typically, when designing seasonal water supply, two options are considered.

Open (collapsible) water supply

The simplest method of installation is in which pipes are placed on the surface of the earth. Requires a minimum of labor costs, but has a number of disadvantages:

- At the end of the season, the system will have to be disassembled and stored for storage, and reassembled in the spring.

- In the absence of owners on the site, the water supply may be stolen.

- The pipes laid on top make it difficult to walk.

If plastic pipes and parts are used, they can easily be damaged by sharp tools.

Hidden (permanent)

According to the list of advantages and disadvantages, it is the complete opposite of the option described above.

It does not interfere, does not require annual installation/disassembly, it is difficult to steal, but you will have to tinker a little more with the device.

Pipes must be laid with a slope that will allow water to drain before the onset of cold weather.

Different fluid supply principles

You can install cold and hot water supply using one of 2 methods, which we will discuss below.

SF-mix Clack up to 0.8 m3/h

SF-mix Runxin up to 0.8 m3/h

SF-mix manual up to 0.8 m3/h

"Blind" wiring

A dead end is installed at the last water intake mark - the liquid does not flow further. This is economical in terms of finances and space. At the extreme node, water will appear with a delay, and will flow into the tap only after it touches the plug.

Circulating closed system

The moisture here moves in circles all the time at the same temperature. The user will receive it immediately. This is best used for hot water supply to avoid serious temperature changes. Combined techniques can be used.

Products on the market

The catalogs of accessories for collector water supply systems provide a wide variety of not only combs, but also their components.

- Dividers without taps are much cheaper. They allow you to assemble a device that will best suit the object. This option is preferable, as it allows you to easily replace only the failed faucet. While the one-piece design will require complete replacement.

- Devices with shut-off valves greatly simplify the installation of a water supply collector. They simplify the assembly of the unit - there is no need to install taps.

- Accessories allow you to adapt the system according to your wishes: valves, pump groups, plugs, valves, brackets, couplings, ends, servos, fittings.

- Manifold cabinets are sold separately, which are mounted into the wall and provide an aesthetic appearance, as well as access to the engineering unit.

What kind of pipes can be used to lead through the premises?

Another popular question is what material the line is made of. It all depends on several factors:

- what type of wiring is used;

- will DHW be required?

- budget;

- type of installation - hidden or open.

Polypropylene

Usually used with a tee system. Cross section – 20-25 mm. A larger diameter is preferable if there are 3 or more nodes. 25 mm can pass up to 30 liters per minute.

Peculiarities:

- are not afraid of corrosion;

- inexpensive;

- cut with any tool;

- lungs;

- tolerate defrosting up to 4 times;

- do not bend;

- It is necessary to have the skill of soldering sections.

Metal-plastic

Another very popular option. Usually used if the wiring is collector. Section – 16 mm. When choosing, pay attention to the thickness of the aluminum layer; it should be in the range from 0.3 to 0.55 mm.

AMETHYST - 02 M up to 2 cubic meters/day.

Aeration unit AS-1054 VO-90

Main table dispenser AquaPro 919H/RO (hot and cold water)

Nuances:

- durable;

- are not afraid of corrosion;

- used up to 100 years;

- can bend;

- more expensive than polypropylene;

- uneven;

- if installed incorrectly, there will be leaks;

- do not tolerate defrosting.

Cross-linked polyethylene

Usually they are placed on a warm floor, but sometimes this acts as an alternative to metal-plastic.

Peculiarities:

- flexible;

- lungs;

- do not react to corrosion;

- wear-resistant;

- withstand changes in pressure and temperature;

- easy to install;

- expensive;

- not suitable for open types of wiring.

Metal or steel

Previously they were made from them, then they switched to PP or metal-plastic. They should not be used for plumbing because:

- suffer from corrosion;

- difficult to transport and install;

- more expensive than plastic;

- connection requires a welder and equipment;

- growths gradually appear inside;

- high thermal conductivity.

Copper

Usually they are not installed in houses. It is not afraid of corrosion, but it is very expensive and difficult to install; special equipment will be required for welding. High thermal conductivity - hot things cool down quickly, and cold things heat up.

Stainless steel corrugation

This is also not a cheap option. For example, you can pay three times less for PP. But it is used because the quality is high and the service life is quite long.

Nuances:

- keeps its shape;

- bends;

- not afraid of corrosion;

- no welding machine required.

Ready-made systems for plumbing

Some manufacturers offer pipe kits that can then be used for manifold wiring.

The advantages of this choice:

- quality and reliability;

- energy efficiency;

- simplicity and speed of installation.

Laying methods - hidden and open system

Pipes in the water supply system can be laid in closed or open ways. The choice of one of the methods does not affect the quality of the connections or the functionality of the entire system and depends only on personal preferences.

It would seem that it is not difficult to decide and the closed method is preferable as it is more aesthetic and allows saving up to 10 cm of usable space. Why is an open pipeline still used when installing a water supply system? Let's try to give an answer.

Image gallery

Photo from

Water supply made of metal-plastic pipes

Polypropylene water supply system

Water supply system using VGP pipes

Water pipes made of copper and stainless steel

Hidden wiring allows you to hide pipes and not spoil the aesthetic perception of the interior of a house or apartment. The hidden method is used when assembling a water supply system from PP pipes. They hide the contour behind a decorative wall, for example, made of plasterboard, or they groove the walls and insert pipes into the resulting niches, sealing them with facing material or plaster over a mesh.

The pipeline should not be tightly adjacent to the surfaces - always leave a small gap for possible repairs. When installing a pipeline into a monolith, it is recommended to place them in a casing, inserting the pipe into the pipe.

The disadvantage of the method appears when there is a need to repair or replace hidden elements of the system - the plaster or tiling has to be opened and then re-decorated.

In addition, in the event of damage and leaks, the problem may not be detected immediately and lead first to a loss of operational technical characteristics of the structures, then to flooding of the premises.

It is better to start installing a water supply system with a pre-drawn diagram - otherwise errors in calculations or assembly will lead to the need to cut new grooves and re-install the pipes

To avoid such difficulties, when installing the wiring, only whole sections of the pipe are hidden, placing connecting fittings in open areas. Inconspicuous doors are made in places where shut-off valves are installed. This gives access during maintenance to pipe connections, which are the weakest links in the system.

It should also be noted that pipes made of not all materials can be hidden under a layer of plaster - only products made of polypropylene, metal-plastic or copper are suitable for this.

Open pipe laying is carried out after finishing is completed. The method involves the uncovered laying of pipes and water supply elements. It looks ugly and reduces the usable area of the room, but at the same time this method is very convenient for maintenance, repair and dismantling of elements.

Redevelopment and rearrangement of plumbing in the house with such a plumbing arrangement will also not cause difficulties.

Open wiring makes it possible to quickly detect the location of a leak and eliminate the cause of breakdown or damage to system elements

What are fog lights for?

In order to remove them, you need to unscrew the screws on the inside of the bumper.

During operation, it is important to prevent clouding or fogging of the optics glass. Fuse and relay panel

And so, the fog lights have been purchased, just the ones you need for your model of car, motorcycle, etc.

To prevent this, you should regularly treat their surface with special polishes at least once a month. Connect the button and the th output of the relay. There is nothing complicated about connecting fog lights, and anyone can handle this task!

During installation, you should insulate the wire connections and terminals using heat-shrinkable tubing or electrical tape. If installed correctly, you only need to adjust the luminous flux, which will be discussed below. Measure the distance from the ground to the middle of the headlight. Taking into account the fact that according to this scheme, power is supplied to the fog lamps only when the ignition is on, the decision to connect the fog lights according to this scheme allows you to automatically turn off the PTF after removing the key from the lock.

Post navigation

It is worth mentioning the cross-section of the wires, which depends on the load, that is, on the current strength. The installation order may be as follows - more precisely, to the battery terminals, two wires are installed under them, as we have already said, black and red, which go first to the left headlight on the driver's side, and then to the right.

It will serve as a guide for the light spot of the center of the second headlight. Let's list them: fuse;. Then two fog lights can be connected to each other in series. 2 WAYS TO CONNECT A CHINESE SWITCH WITH LIGHT 3 CONTACTS, 220 VOLT.

https://youtube.com/watch?v=AZjEhAsykAw