In order to effectively solve problems such as pumping from great depths and supplying water to an autonomous water supply system, it is necessary to understand the design of a submersible pump for a well. The use of such pumps makes it possible to pump water from wells whose depth reaches 80 meters. In this article we will look at how a submersible pump works, what categories it is divided into and how to choose the right device.

The pump for the well is selected taking into account certain features of its future operation

Types of pumps and their classification

The main function of a deep-well pump is to extract water mass from the bowels of the earth and transport it to the consumer in residential premises or outbuildings (kitchen, shower, toilet). It is also used to water a plot or greenhouse and fill reserve tanks.

Modern deep-well pumps are quite compact and easy to use.

Deep well pumps have a small cylindrical body. They take up virtually no space on the site. There are 2 types of such pumps:

- Industrial. Used by enterprises. Due to their high power, they can lift water from a depth of up to 100 meters. They have impressive dimensions.

- Household. They are used in private homes or summer cottages, can be installed independently, are compact and have relatively high power.

Advice. Before installation, consult with specialists. The power of the selected pump will depend on the depth of the water.

Pumps also differ in the way they are installed.

- Submersible pump. The device is completely immersed in water, a pressure hose is removed from it, through which the connection to the water supply is made.

- Surface pump. The device is located outside the water surface, 2 hoses are removed from it: pressure (supplies water to the water supply system) and suction (ensures liquid is sucked into the pumping unit).

In addition to differences in the scope of application and installation scheme of pumps, there is also a classification according to the type of design and principle of operation:

Diagram: centrifugal pump device

Centrifugal pumps. Can be used at any time of the year. A hydraulic mechanism is used. Water is supplied by rotating wheels located near the engine. The working part (wheels) is made of dense plastic or stainless steel, which ensures low weight of the structure. Resistant to abrasives (sand and clay). The installation of this equipment requires the presence of a coarse water filter to remove sand and stone particles. It is cooled by water passing through the body, which is why it is installed according to the recess principle. Such pumps are equipped with a temperature sensor that automatically turns off the device if it overheats. The only drawback of the equipment is the high cost compared to vortex.

Advice. If you plan to live year-round in a country house, then it is better to choose a centrifugal pump.

Scheme: vortex pump for a well

Vortex or vibration pumps. Such equipment is not designed to supply large quantities of water. They are used only in shallow wells. Designed for seasonal water consumption. The operation of the mechanism is carried out due to high-frequency vibrations that drive a mechanical piston, which ensures the suction of water into the device. The advantages of this type of equipment are low cost, compact size, and minimal energy consumption. Disadvantages - it destroys the walls of the well due to prolonged vibration, low power and low productivity.

Advice. To prevent the vortex pump from destroying the walls of the well, rubber rings are put on the housing when installing it.

Distinctive features and parameters of screw electric pumps

A typical screw pump for wells used in individual water supply has the following technical parameters:

- Power supply voltage: AC 220V ± 10%, frequency 50 Hz.

- Temperature range of the pumped liquid: from 0 to 35 °C.

- pH of pumped water: 6.5 - 8.5.

- Operating ambient temperature range: from 0 to +40 °C.

- Minimum depth of immersion under the water surface: 0.5 m.

- Permissible volume of mechanical particles in pumped water: - no more than 500 g/m3, the content of fibrous materials in the liquid is not allowed.

- Permissible diameter of mechanical fractions: - 1 mm.

- Maximum pressure: 3 m3/h, for most models it does not exceed the threshold of 1.5 m3/h.

- Maximum pressure: up to 200 m, this indicator is a rare exception; most modifications create a pressure pressure of no more than 100 m.

Rice.

8 Main characteristics of Chinese Oasis Main advantages of screw electric pumps:

- Low cost, the price of the cheapest models is about 80 USD, in general all models are cheaper than centrifugal types.

- Simplicity of design. The working part consists of a screw and a rubber cage; they are easy to maintain and, if necessary, simply replaced, which makes repairing screw units very simple.

- Due to its operating principle, a screw pump for a well can transport liquid with large fractions of sand and clay deposits - this is its main advantage. A submersible screw pump is preferable to use for water intake from well sources on sand, which often have a high content of suspended particles of clay and sand. Although their parts are subject to mechanical stress from solid particles, the service life of a screw pump in turbid sources will be longer than that of centrifugal models.

The disadvantages of screw units include the mediocre quality of many products (chrome-plated screw, quickly abraded holder) and not very high technical characteristics, noticeably inferior to centrifugal types, as well as low efficiency, not exceeding 45%.

Design of a deep-type pumping unit

In order to correctly install pumping equipment, you need to know which pump consists of what, how it is assembled and how it works.

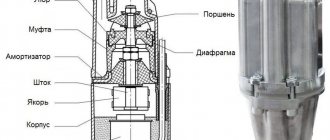

Diagram: deep well pump device

The main parts of the device are the engine and the pump part. The engine is located in the lower part of the housing; during installation, special attention is paid to its waterproofing. The pump part is a multi-stage mechanism that includes impellers, blade outlets and a working shaft that drives them.

The product is cooled using pumped water. External cooling occurs due to the passage of water masses between the pump housing and the walls of the well. Internal - when water passes directly through the unit.

Important! If installing a pumping unit on the bottom or walls of a drilled well is not possible, then the well is equipped with asbestos pipes.

Operating principle of a submersible pump

Which pump to choose: tips

Among all water pumping devices, deep-well pumps are the most popular. They have a number of advantages over other units:

- quiet operation;

- there are no interruptions in the supply of water mass;

- easy and quick installation;

- water intake at great depths;

- narrow cylindrical body shape;

- protection against engine overheating;

- made of anti-corrosion materials.

Advice. In order to choose any pump, it is necessary to take into account the shape and depth of the well. Subsequently, you will not waste time, effort and money on installing additional equipment.

Connection diagram for a submersible pump

In order to choose the right submersible pump, the following data must be taken into account:

- water consumption at each water intake point and across the entire site in total;

- diameter and depth of the drilled well;

- geological data of the land (soil type, depth of groundwater, etc.);

- Availability of electricity sources on site.

The choice of pump directly depends on the depth of the well and the occurrence of groundwater. If the aquifer is located at a depth of 10 m or more, then it is worth choosing a deep pump. When purchasing a pump, choose a device with a power slightly higher than required: later you will be able to improve the water supply without having to replace the water pumping device.

Optional equipment

Automation for downhole devices allows you to forget about the operation of the pump. Let's look at some types of equipment and connect it according to the diagram.

Automation

Divided into 3 generations:

- 1st generation: pressure switch, dry run blocker, float switch;

- 2nd generation: an electronic device that has several sensors installed in the pipeline, on the pump and other places. Thanks to it, the following work is performed: water level recording, dry running blocking, emergency shutdown, engine temperature control;

- 3rd generation: has advanced functions, with precise control of operation.

How does the pumping device depend on the depth of the well?

To select a pump, you need to look at the well’s passport data; all its parameters are indicated there. If you do not know the depth of the well, then you need to take measurements. Attach a weight to a dry (!!!) rope and lower it into the hole, remove the rope and use the wet mark to determine the distance from the surface of the earth to the water level in the well. By lowering the rope deeper, you can determine the depth of the well.

Well depth measurement

When purchasing a pump, be sure to read the instructions and product data sheet. These documents indicate the pump power depending on the depth of the well.

- 30-60 meters. In such conditions, pumps are installed directly into the well. During installation, 2-3 additional check valves are installed so that the raised water does not flow back. Centrifugal pumps equipped with thermal protection are installed in such wells. The device is inserted into the well using special equipment and secured with a cable to the surface of the earth.

- 10-20 meters. When water occurs at medium and shallow depths, you can use a surface rather than a deep pump. Such a device is installed far from the source, and water is drawn from it using a hose.

Connecting a submersible pump

Conditions for the build-up

To successfully complete the buildup process and obtain the desired result, certain conditions must be met:

- the process will not bring results if the installation of equipment is not carried out at the proper level and the well has serious holes, as well as if the conditions for high-quality pumping are not met;

- organize the removal of dirty water away from the well. Discharged water near the well will penetrate back, and the water purification process will be useless;

- if the pump is hung very high, it will not be able to pump out small particles from the bottom of the well. This will lead to rapid silting and repeated pumping will be required;

- if you hang it too low: firstly, it will become clogged with dirt and stop working, and secondly, it can “go” into the mud and it will be very difficult to get it out;

- It is better to perform pumping with an inexpensive pump, since due to the heavy load there is a risk of equipment failure;

- periodically remove the pump and clean it;

- To immerse the pump in water, it is better to use a thin, strong cable rather than the cord included in the kit. If the pump gets stuck in a muddy bottom, the cord may fail.

Installation of a deep-well apparatus using the example of a submersible pump from GRUNDFOS (Grundfos)

Grandfos deep-well pumps are equipped with submersible motors. Quiet operation of the engine is ensured by installed plain bearings lubricated with a special liquid anti-corrosion lubricant. The electrical part of the pump is filled with liquid, the maximum freezing temperature of which is -20°C and below. In order for the engine to work properly, it is necessary to constantly monitor the level of the filled fluid in it. It is recommended to add liquid type SML-2 only from Grunfos. To fill the electric motor, use the following algorithm:

Grandfos deep well pump

- Make sure that the engine is installed in a vertical position with a deviation of 10-12°.

- Unscrew the plug using a screwdriver.

- Using a syringe, pour fluid into the engine.

- Distribute the liquid evenly over the surface of the engine capsule by rocking the device, the collected air will come to the surface.

- Tighten the screw plug as tightly as possible to prevent spillage.

- Install the motor into the pump housing.

Next, it is possible to install a submersible pump. The device can be mounted in a vertical or horizontal plane.

Grandfos pump installation diagram

In order for the pump motor to cool freely, it is necessary to control the temperature of the liquid being poured and the minimum value of the water flow rate. To ensure free convection, the width of the well pipe is made 4-6 cm larger than the diameter of the pump housing.

Important! Free convection of the motor is not allowed under conditions of deposit formation on the pump housing.

Before installing the pump, you must make sure that it is disconnected from the network after a possible check and that it cannot be turned on accidentally. All technical data of the product are described in the passport in the form of a table; power, electricity consumption, supply voltage, “cosine phi” value, etc. are included there.

Grudfos pumps are equipped with an internal thermal relay, which is activated when the installation overheats, turning off the power to the pump. No additional protection is needed.

Installation of the Grundfos deep pump (grundfos) is carried out as follows:

- A check valve is installed on the pump pipe. The water will not drain after the power is turned off. A cup-shaped coarse filter is mounted on the suction pipe. It will protect the working pump chamber from silting.

- After installing the check valve, install a discharge pipe through which water will be supplied upward.

- The waterproofed power cable is passed through the discharge hose and secured with clips.

- Polymer twine is inserted into the brackets provided on the upper part of the stainless steel body, which will subsequently hold the pump in the well.

- The device, ready for launch, is lowered into the well shaft. Only the twine serves as support; the cable bundle with the hose does not bear any load.

- The rope is fixed on a bracket, which is located on the outside of the casing.

Pump and parts for its assembly

Please note that a person who does this professionally will help you choose the correct installation algorithm. If you want to do the installation yourself, consult a technician to avoid mistakes.

What to do?

Depending on the reasons why the pump got stuck in the penetration, further tactics are chosen. We will tell you what to do in different situations.

How to remove a unit from a well onto sand?

If your pump is stuck in the shaft of a hydraulic structure due to a blockage, you can try to remove it yourself. To do this, you need to swing the device in the tunnel by pulling the cable towards you and releasing it. Such back-and-forth movements should be repeated several times. This will allow the device to break out of the clogged plug at least a little, and it will be much easier to do this in the future, since water will be able to flow into the resulting gap and will begin to erode the dirt even more. To prevent this from happening in the future, the well must be cleared of blockages at least once a year.

What to do if the device gets stuck in a well on limestone?

Although this type of hydraulic structure is not subject to siltation, like sand wells, the pump can still get stuck here. Other reasons may lead to this. For example, if the unit goes very deep, sediment may form around the device due to the high content of calcium and iron salts in artesian water. These substances, when interacting with oxygen, form a coating on the body of the device and the walls of the penetration, making it difficult to remove pumping equipment from the well.

The thing is that these are very dense deposits. Accumulating in the gap between the unit and the walls of the tunnel, they block the pumping equipment in the shaft. This happens if the hydraulic structure is cleaned very rarely or not at all. In such a situation, you can do the following:

- try to swing the unit in the penetration, as described above (you can do it yourself);

- use a chemical or mechanical method (this method can only be used by specialists).

The essence of the chemical method is that the hardened sediment is treated with special compounds to dissolve it. The mechanical method is the impact on mineral deposits with a stream of compressed air blown under impressive pressure. This will either completely remove the sediment or reduce its density.

What to do if the casing string is deformed?

If the pump gets stuck while being lifted upward due to bends and breaks in the casing pipes, then a characteristic blow and sound is heard during the lifting. In this case, there may be several reasons for deformation of casing pipes:

- a dent has formed due to soil pressure;

- the pipe was deformed under the weight of the entire column;

- the junction of adjacent pipes has separated.

This is the most serious problem, as a result of which sometimes it is simply impossible to get the pump out of the well. Depending on the degree of deformation, even the smallest unit, like the Baby, cannot be removed from the deformed casing. In this case, the only way out will be to completely dismantle the column.

In simple cases, you can try to cope on your own. To do this you need to do the following:

Try to rotate the cable carefully at first. As a result, the rotational movement will be transferred to the unit, and it will be able to successfully turn and pass the problem area. If this does not help, lower the unit by loosening the cable and try to lift the device again. Perhaps the device was simply skewed in the penetration.

If the unit gets stuck during lifting and the previous methods do not help, you can try the following:

If the unit gets stuck during lifting and the previous methods do not help, you can try the following:

- Take a piece of pipe 1 m long. This piece should weigh more than the pumping equipment. The diameter of the pipe should be much smaller than the cross-section of the hydraulic structure trunk.

At the end of this element you need to make a hole or you can weld a special eyelet. A cable is passed through the prepared loop or hole and tied to the pipe. To prevent the prepared product from falling into the shaft, the second end of the cable is tied on the surface near the wellhead. Now the element must be carefully lowered into the penetration, trying to push the pump back to the bottom of the structure. If you succeeded in lowering the unit in this way, you can now try to raise it to the surface again.

Replacement and repair of deep-well pump

Even the most reliable system wears out and can malfunction. To ensure further operation of the device, it must be dismantled and replaced or repaired. This procedure is carried out as follows:

- Disconnect the electrical and water supply systems from the pump unit.

- Remove the pump from the well. To do this, you need to use the help of your comrades, since this procedure involves a lot of physical labor.

- Disconnect the check valve and the coarse filter located at the pump inlet.

- Perform product diagnostics.

- Replace or repair failed parts.

- Carefully inspect all pipes, hoses and cables for damage.

- Clean the filter or replace it.

- Assemble the pumping device and install it at the workplace.

Repair of a deep-well pump

When replacing the device, new polymer couplers and filters should be used.

As you can see, installation and dismantling of a deep-well pumping unit can be done independently. The main thing is to choose the right device and select the pump power for the appropriate well depth.

Owner reviews

Andrey. My whole house is equipped with different Vortex pumps - there is a circulation pump for heating, it drives water well through the pipes. When the bathhouse and outdoor pool were built, we had to buy a regular deep-water unit to fill it. I read somewhere that you can’t install a hydraulic tank for a pool, that it will kill the pump, so mine works directly. About 7 years ago I bought a fecal one for the septic tank, but I haven’t repaired it yet, since we turn it on once every 3 months. In general, I am satisfied with the goods, there is no need for repairs. There is an idea to replace the jet pumping station, but this is in the future. I recommend it, but don't choose the cheapest ones.

Faith. They recommended a very low-power Whirlwind for the dacha. More than enough, even a lot. I fill the shower and water it. There is no heating in the dacha, but I think that a device could cope with it. For two years of work, not a single repair.

Vasya the summer resident. I wanted to save money and bought a Chinese one for the well. He worked, or rather, suffered for 1.5 months and smoked. I take it out, and black smoke comes out of it and smells like rubber. I’m wondering what level of protection such unfortunate producers have. As a result, I decided not to play with electricity and took our Whirlwind. It turned out to be reliable.

Svetlana. When my back problems started, I had to think about buying a pump. Now I remember the daily buckets of water like a bad dream. I water immediately from a long hose and at the same time fill the barrel for myself. I don’t install a tank, they said that it can turn on and off many times, and since I live alone, I rarely do anything with water.

Arseny. The heating system and plumbing were redone. The store advised not to overpay and buy a domestic Vikhr station. It turned out that it was no worse than the Italian one, which burned out due to a power surge. Now we bought a stabilizer, maybe it will work longer. So far there are no complaints about the work - everything is working properly.