A country estate, as a rule, does not have a central water supply. In this case, the source of water is a well or well, from where the liquid is pumped into the home water supply system using a pump.

Water consumption is not a constant value. Sometimes you need to draw a glass of water from the tap, and other times you need to fill the bathtub. In both cases, when the tap is opened, the water pressure in the system will drop and the pump will turn on, but if the pump runs for 10 minutes for a bathroom, then 5 seconds will be enough for a glass of water. And if you need to draw several glasses of water at intervals of half a minute, the pump will turn on for each of them - this mode of operation is unacceptable for an electric motor and it quickly breaks down. To prevent this from happening, a hydraulic accumulator for water supply systems is built into the pipeline. A hydraulic accumulator in a private home will help avoid problems with water supply Source novosibirsk.tiu.ru

Why do you need a hydraulic accumulator for water supply systems?

November 15, 2013

A hydraulic accumulator for water supply systems is a device whose main function is to store a certain volume of water and maintain the pressure set by the settings in the operating system. Very often, this device is used to work in conjunction with a pump, a check valve on a five-way fitting and a pressure switch. A hydraulic accumulator for water supply systems is indispensable when organizing an independent scheme for automated receipt and distribution of water, which is especially in demand by residents of many cottages and rural houses.

Depending on the installation method, the hydraulic accumulator for water supply systems can be vertical or horizontal. Based on ergonomic considerations, the former are designed for a larger volume, since usually free space is limited in the horizontal axis, and increasing the dimensions upward is quite acceptable. The accumulator body itself is made of powder-coated black sheet or stainless steel.

Construction and operation

There is a misconception that hydraulic accumulators for water supply systems are designed in such a way that the inner walls are constantly in contact with water. This is wrong. The internal space consists of two chambers - water and air, separated by a butyl partition membrane. There is always a certain volume of air inside the housing (periodic checking with a pressure gauge is required). Water is pumped into a special pear-shaped compartment (one of the options), which, expanding, compresses the air located between the compartment and the walls of the housing. The latter, in turn, begins to exert pressure on the flexible butyl: just open the tap and water will rush out of the container under pressure. Now it is very easy to buy a hydraulic accumulator for water supply systems. The instructions must be included - this is where the type of membrane is indicated, since not all materials from which it can be made are allowed to be used for contact with drinking water.

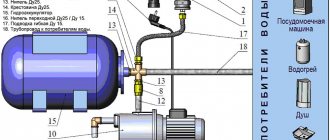

As mentioned above, the hydraulic accumulator (HA) itself is part of the system

In addition to a properly selected pump, special attention must be paid to the pressure switch - a mechanical device connected to the hydraulic pump, the task of which is to control the water pressure in the water compartment. By rotating special screws in it, you can set the desired upper (off) and lower (on) limits

It must be remembered that they strongly depend on the current value of air pressure in the tank. As a rule, relays are supplied already configured to standard values. Using a system without a hydraulic accumulator would lead to the fact that when the pump is turned on, the pressure increases sharply, which causes the relay to operate and turn off the electric motor. However, this is followed by an instantaneous drop in pressure and the pump restarts. Obviously, such a system is only operational in constant operation mode, for example, watering a garden.

When purchasing a hydraulic accumulator for water supply systems, the price of which is too low, you need to request all accompanying documents. Roughly, we can assume that the lower limit of the cost corresponds to $30 (model for 25 liters for drinking water), and the upper limit, as is usually the case, is not limited by anything. In addition to the membrane material already mentioned, you may encounter other non-obvious features. A metal flange is screwed to the housing where the pipeline is connected. It can be made of galvanized or stainless metal. The cost of a high-quality and cheap flange differs by 2-3 times, which makes it possible to reduce the overall price. There have been cases when, upon dismantling, an externally intact product turns out to be covered with defects on the inside, which causes rapid rusting of the metal and the appearance of fistulas in the flange. In addition, the HA tank itself may be coated with low-quality paint, which significantly reduces its service life, especially in rooms with high humidity.

Charlie Gard Died A Week Before His First Birthday Charlie Gard, the terminally ill baby the world is talking about, died on July 28, a week before his first birthday.

What does your nose shape say about your personality? Many experts believe that you can tell a lot about a person's personality by looking at their nose.

Therefore, when you first meet, pay attention to the stranger’s nose

How to look younger: the best haircuts for those over 30, 40, 50, 60 Girls in their 20s don’t worry about the shape and length of their hair. It seems that youth is created for experiments with appearance and daring curls. However, already last.

9 Famous Women Who Have Fallen in Love with Women Showing interest in people other than the opposite sex is not unusual. You are unlikely to be able to surprise or shock anyone if you admit it.

20 photos of cats taken at the right moment Cats are amazing creatures, and perhaps everyone knows this. They are also incredibly photogenic and always know how to be in the right place at the right time.

Top 10 Broke Stars It turns out that sometimes even the biggest fame ends in failure, as is the case with these celebrities.

Installation rules

When installing a hydraulic accumulator, you must strictly adhere to certain rules.

The first thing to do is to select a site in the heating network where the device will be installed.

Experts strongly advise mounting the expansion tank in the return pipe through which cooled water circulates.

Important! The unit must be installed in front of the pumping equipment. In order to ensure maximum protection of the network from sudden changes in pressure of the working fluid, a safety valve must be installed at the outlet of the heating device

In order to ensure maximum protection of the network from sudden changes in pressure of the working fluid, a safety valve must be installed at the outlet of the heating device.

The valve has the same purpose as a hydraulic accumulator, but it is able to withstand higher pressure drops.

The expansion tank normalizes the operation of the heating system during minor surges in water pressure.

Before proceeding with installation, you need to select a location for installing the device. Do not forget that the device must be freely accessible; nothing should prevent you from getting to the air compartment control valve.

Shut-off and control valves cannot be installed between the expansion tank and the pump; they can significantly change the hydraulic resistance.

In the room where the hydraulic accumulator will be located, the air temperature must be at least 0 degrees. The surface of the device must not be exposed to mechanical loads.

The activation of the gearbox to remove air from the heating system of a private house must be carried out in accordance with the parameters of the heating system.

If you follow all the above recommendations, you will be able to install the expansion tank on your own, without outside help.

During the work process, you should strictly adhere to the connection rules, accurately calculate the optimal tank volume and use products that are made of high quality materials.

Why you need a hydraulic accumulator in heating systems, how to install and configure it - we suggest you watch it in the video.

How to choose

The main working body of the hydraulic tank is the membrane. Its service life depends on the quality of the material. The best membranes today are made from food-grade rubber (vulcanized rubber plates). The housing material matters only in membrane-type tanks. In those in which a “pear” is installed, water comes into contact only with rubber and the material of the body does not matter.

The flange should be made of thick galvanized steel, but better - stainless steel

What's really important about bulb tanks is the flange. It is usually made of galvanized metal. In this case, the thickness of the metal is important

If it is only 1 mm, after about a year and a half of operation, a hole will appear in the metal of the flange, the tank will lose its tightness and the system will stop working. Moreover, the warranty is only one year, although the stated service life is 10-15 years. The flange usually rots after the warranty period expires. There is no way to weld it - the metal is very thin. You have to look for a new flange at service centers or buy a new tank

In this case, the thickness of the metal is important. If it is only 1 mm, after about a year and a half of operation, a hole will appear in the metal of the flange, the tank will lose its tightness and the system will stop working. Moreover, the warranty is only one year, although the stated service life is 10-15 years. The flange usually rots after the warranty period expires. There is no way to weld it - the metal is very thin. You have to look for a new flange at service centers or buy a new tank.

So, if you want the accumulator to last a long time, look for a flange made of thick galvanized or thin, but made of stainless steel.

Vertical or horizontal?

From the point of view of the physical processes occurring in the accumulator, its vertical or horizontal orientation does not matter. Choose a vertical or horizontal form factor based on the convenience of placing the equipment in a house or caisson. According to statistics, horizontal hydraulic accumulators are more often chosen for pumping stations due to ease of mounting. For borehole pumps - vertical, as they take up less space when installed in a caisson.

hydraulic accumulator horizontal and vertical

Choosing the right device

When choosing a model with the necessary functions and volume, take into account the fact that the frequency of pump operation depends on the total volume of the tank.

The leading characteristic for any tank is not its functionality, but its volume.

At the same time, for each water supply system there are criteria that cannot be neglected, namely:

- Number of regular water users. (Daily use).

- Number of points for water intake. (Appliances, taps and other plumbing fixtures).

- Approximate frequency of using water intake points at the same time.

- The “on-off” cycle. You need to know exactly the limit of this cycle per hour for your pump.

Approximate calculation:

When calculating for three regular consumers, install a tank with a total volume of 20-24 liters. However, the pumping equipment should produce approximately 2 cubic meters per hour.

When calculating for four regular users with a reserve, it is better to install equipment of 50 liters or more. The pump productivity in this case is approximately 3.5-3.7 cubic meters per hour.

If there are more than 10 consumers, then a tank of at least 100 liters is required, and pumping equipment with an indicator of more than 5 cubic meters per hour.

To avoid breakdowns and expensive repairs, you need to carefully familiarize yourself with the manufacturer.

In this choice, there is no need to chase a cheaper and dubious brand. Improper savings can lead to breakdowns in the future.

Models with a low retail price inside are made, as a rule, without defects. But consumable parts are always made from the cheapest materials.

How to choose tank volume

You can choose the tank volume arbitrarily. There are no requirements or restrictions. The larger the volume of the tank, the greater the supply of water you will have in case of a shutdown and the less often the pump will turn on.

When choosing a volume, it is worth remembering that the volume that appears in the passport is the size of the entire container. There will be almost half as much water in it. The second thing to keep in mind is the overall dimensions of the container. A 100 liter tank is a decent-sized barrel - about 850 mm high and 450 mm in diameter. You will need to find a place somewhere for it and the harness. Somewhere - this is in the room where the pipe from the pump comes. This is where all the equipment is usually installed.

The volume is selected based on the average flow rate

If you need at least some guidelines to select the volume of a hydraulic accumulator, calculate the average flow rate from each water intake point (there are special tables or you can look at the data sheet for household appliances). Sum up all this data. Get the possible consumption if all consumers work simultaneously. Then figure out how many and which devices can work at the same time, calculate how much water will be consumed in a minute in this case. Most likely by this time you will have already come to some decision.

Reliable manufacturers

Before choosing the volume of a hydraulic accumulator, you should familiarize yourself with reliable companies whose products will definitely not let you down. Among the companies that have gained trust: 1. Gilex. Engaged in the production of equipment adapted for operating conditions in Russia. The line includes tanks of almost any volume. There are models with a galvanized or stainless steel body. There are also models with a galvanized or plastic flange. If necessary, spare membranes can be purchased for the tanks. 2. Wester. A very well-known manufacturer of membrane tanks for heating and hydraulic accumulators for water supply. The membrane itself is made of butyl rubber, which is not subject to rotting. If the membrane is damaged, it is easily replaced.

If you want to choose a hydraulic accumulator, we will be happy to help you. Call us now!

Tank volume is the main selection criterion

The most important question is how to choose the volume of a hydraulic accumulator for water supply systems. To answer it, you need to bring together a lot of data. This includes the performance of the pump, the equipment of the house with water-consuming equipment, the number of people permanently living in the house, and much more.

But first of all, you need to decide whether you need this reservoir only to stabilize the operation of the system as a whole, or whether there is a need for a supply of water in case of a power outage.

Internal cylinders of different volumes

If the house is small and equipped only with a washbasin, toilet, shower and watering tap, and you do not live in it all the time, you don’t have to make complex calculations. It is enough to buy a tank with a volume of 24-50 liters, it will be enough for the system to work normally and be protected from water hammer.

In the case of a country house for permanent family residence, equipped with everything necessary for a comfortable life, it is advisable to approach the issue more responsibly. Here are a few ways you can decide on the size of your accumulator.

According to pump characteristics

The parameters that influence the choice of tank volume are the performance and power of the pump, as well as the recommended number of on/off cycles.

- The higher the power of the unit, the larger the volume of the hydraulic tank should be.

- The powerful pump pumps water quickly and turns off quickly if the tank volume is small.

- A sufficient volume will reduce the number of intermittent starts, thereby extending the service life of the electric motor.

To calculate, you will need to determine the approximate water consumption per hour. To do this, a table is compiled that lists all devices that consume water, their quantity and consumption rates. For example:

Table for determining the maximum water flow

Since it is almost impossible to use all devices at the same time, a correction factor of 0.5 is used to determine the actual flow rate. As a result, we get that you spend an average of 75 liters of water per minute.

How to calculate the volume of a hydraulic accumulator for water supply, knowing this figure, the performance of the pump and taking into account that it should turn on no more than 30 times per hour?

- Let's say the productivity is 80 l/min or 4800 l/h.

- And during peak hours you need 4500 l/h.

- When the pump operates non-stop, its power is quite sufficient, but it is unlikely to work for a long time in such extreme conditions. And if it turns on more than 20-30 times per hour, then its resource will run out even faster.

- That’s why we need a hydraulic tank, the volume of which will allow us to turn off the equipment and give it a break. At the indicated cycle frequency, the water supply should be at least 70-80 liters. This will allow the pump to remain idle for one minute out of every two, pre-filling the reservoir.

According to the formula of the minimum recommended volume

To use this formula, you need to know the settings of the pressure switch, which turns the pump on and off. The following picture will help you understand:

Changes in pressure in the accumulator when turning the pump on and off

- 1 – initial pressure Pair (with the pump turned off);

- 2 – water flow into the tank when the pump is turned on;

- 3 – reaching the maximum pressure Pmax and turning off the pump;

- 4 – water flow with the pump turned off. When the pressure reaches the minimum Pmin, the pump turns on.

The formula looks like this:

- V = K x A x ((Pmax+1) x (Pmin +1)) / (Pmax - Pmin) x (Pair + 1), where

- A is the estimated water flow (l/min);

- K – correction factor from the table, determined depending on the pump power.

Table for determining the correction factor

You must set the values of the minimum (starting) and maximum (switching off) pressure on the relay yourself, depending on what pressure you need in the system. It is determined by the farthest and highest water collection point from the accumulator.

Approximate ratios of pressure switch settings

To adjust the pressure switch, you need to know how to inflate a hydraulic accumulator for water supply systems with air, or bleed off excess air. To do this, you will need a car pump, which is connected to the tank through a spool.

Now you can calculate the volume. For example, let's take:

- A = 75 l/min;

- Pump power 1.5 kW, respectively K = 0.25;

- Pmax = 4.0 bar;

- Pmin = 2.5 bar;

- Pair. = 2.3 bar.

We get V = 66.3 liters. The nearest standard hydraulic accumulators in terms of volume have a volume of 60 and 80 liters. We choose the one that is larger.

FAQ

Can a hydraulic accumulator produce a pressure greater than the pressure produced by the pump? No. The hydraulic accumulator does not create pressure, but only accumulates it. If you set the pressure on the hydraulic tank higher than the pump can produce, then the only thing this will lead to is pump failure.

Why does the hydraulic accumulator hit the wall very hard when the pump is turned on? It’s a matter of water hammer. Most likely, the accumulator is poorly secured. Is it possible to combine two membrane tanks (hydraulic accumulators) into one system? Yes. You can combine any number of hydraulic accumulators - they will work as one large volume.

Connection diagram for hydraulic accumulator

Depending on the assigned functions, the connection diagram of the hydraulic accumulator to the water supply system may be different. The most popular connection diagrams for hydraulic accumulators are given below.

Booster pumping station wiring diagram

Such pumping stations are installed where there is high water consumption. As a rule, one of the pumps at such stations operates constantly.

At the booster pumping station, the hydraulic accumulator serves to reduce pressure surges when additional pumps are turned on and to compensate for small water withdrawals.

This scheme is also widely used when the water supply system frequently interrupts the supply of electricity to booster pumps, and the presence of water is vital. Then the water supply in the hydraulic accumulator saves the situation, playing the role of a backup source for this period.

The larger and more powerful the pumping station, and the greater the pressure it must maintain, the larger the volume of the hydraulic accumulator, which acts as a damper, must be. The buffer capacity of the hydraulic tank also depends on the volume of the required water supply, and on the difference in pressure when the pump is turned on and off.

Scheme for a submersible pump

For long-term and uninterrupted operation, the submersible pump must make from 5 to 20 starts per hour, which is indicated in its technical characteristics.

When the pressure in the water supply system drops to a minimum value, the pressure switch is automatically turned on, and when the maximum value is turned off, it is turned off. Even the most minimal water flow, especially in small water supply systems, can reduce the pressure to a minimum, which will instantly give a command to turn on the pump, because the water leakage is compensated by the pump instantly, and after a few seconds, when the water supply is replenished, the relay will turn off the pump. Thus, with minimal water consumption, the pump will run almost idle. This mode of operation adversely affects the operation of the pump and can quickly damage it. The situation can be corrected by a hydraulic accumulator, which always has the required supply of water and successfully compensates for its insignificant consumption, and also protects the pump from frequent activation.

In addition, a hydraulic accumulator connected to the circuit smoothes out a sharp increase in pressure in the system when the submersible pump is turned on.

The volume of the hydraulic tank is selected depending on the frequency of activation and power of the pump, water flow per hour and the height of its installation.

Connecting a hydraulic accumulator to a water heater

For a storage water heater in the connection diagram, the hydraulic accumulator plays the role of an expansion tank. When heated, water expands, increasing the volume in the water supply system, and since it does not have the ability to compress, the slightest increase in volume in a confined space increases the pressure and can lead to destruction of the water heater elements. The hydraulic tank will also come to the rescue here. Its volume will directly depend and increase from an increase in the volume of water in the water heater, an increase in the temperature of the heated water and an increase in the maximum permissible pressure in the water supply system.

Connecting the hydraulic accumulator to the pumping station

The hydraulic accumulator is connected in front of the booster pump along the water flow. It is needed to protect against a sharp decrease in pressure in the water supply network when the pump is turned on.

The capacity of the hydraulic accumulator for the pumping station will be greater, the more water is used in the water supply system and the smaller the difference between the upper and lower pressure scale in the water supply in front of the pump.

Vertical or horizontal installation

Products are classified depending on the type of installation. There are devices that are installed horizontally. They are most often used to install a surface pump. For this purpose, a special platform is made on the surface of the tank.

Horizontal hydraulic accumulators are also convenient to mount to the wall. They are inconvenient to use with borehole pumps. Vertical models are suitable for well pumps. Installed vertically. Models of small volumes can be attached to the wall using special fasteners. All hydraulic tanks with a volume of over 35 liters have support legs on which the tank stands stably on the floor.

The mounting holes in the legs allow the tank to be securely fixed to the floor.

Types of hydraulic accumulators

- freight

- spring

- hydropneumatic

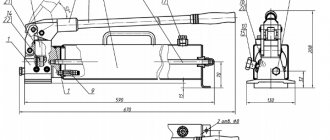

Construction of a cargo hydraulic accumulator

In cargo hydraulic accumulators, the liquid is subject to a load caused by gravity. When charging such a battery, liquid enters under piston 1 on which weight 2 is installed; when liquid enters, the piston rises along with the weight. When discharging, the load presses on the piston, which transfers energy to liquid 3 under pressure flowing from the accumulator.

Calculation of pressure in a cargo accumulator

In a cargo accumulator, the fluid pressure is directly proportional to the mass of the pressing load and inversely proportional to the area of the piston.

The pressure will be constant regardless of the volume of remaining liquid, since it is determined only by the mass of the load and the area of the piston.

Spring accumulator device

When charging a spring accumulator, instead of lifting the load, piston 1 compresses spring 2. When discharging, the spring, expanding, transfers the accumulated energy by acting on the piston, which in turn presses on liquid 3.

Calculation of pressure in a spring accumulator

In a spring accumulator, the fluid pressure depends on the stiffness and amount of movement of the spring.

The pressure in the accumulator will decrease as the volume of fluid in the accumulator decreases, since the spring force depends on the amount of compression.

Hydropneumatic accumulators

The most widely used in technology are hydropneumatic accumulators, in which the mechanical spring is replaced by a locked gas volume.

There are hydropneumatic accumulators with and without a separator.

Hydropneumatic accumulators without a separator are rarely used, because... at high pressures, the accumulating gas will saturate the working fluid, which is undesirable in hydraulics. Pistons, cylinders and membranes are used as separating elements. Let's get acquainted with the design of the most common pneumohydraulic accumulators.

Balloon pneumatic hydraulic accumulator

In batteries of this type, gas is located in cylinder 1, which is located in housing 2. Charging valve 3 is used to fill the hydropneumatic accumulator with gas. Valve 4 limits the expansion of the cylinder in the absence of liquid under pressure in the cavity. The supply of working fluid is carried out through channel 5.

It is recommended to install cylinder batteries vertically, although in some cases a horizontal arrangement is acceptable.

Hydraulic accumulator functions

The hydraulic accumulator, also called a membrane tank or hydraulic tank, performs a number of functions:

— Maintains pressure in the water supply system at a stable level.

— Protects the water supply from sudden changes in water pressure. In case of changes, strong temperature fluctuations in the water occur if several taps are turned on at the same time, for example, in the kitchen and bathroom. The hydraulic accumulator can cope with such issues.

— Saves the pump from rapid wear due to frequent use. There is a certain volume of water in the hydraulic tank, so the pump does not start working every time the tap is opened, but only when the water is completely used up. Each pump has a standard indicator for the number of starts per hour. Using a hydraulic tank allows you to increase the number of unclaimed pump connections, and this affects its service, increasing the operating period.

— Protects the water supply system from potential water hammer that occurs when the pump is connected, which can significantly damage the pipeline.

— Allows you to create a certain supply of water in the system. Thanks to this, you will always have water, even during periods of power outages, which is a common occurrence in our world. This function will be especially useful for owners of country houses.

Why is it needed?

By and large, a water tower is the simplest type of hydraulic accumulator that provides a pressure level depending on the height of the liquid.

It performs three important functions, without which the operation of the water supply system is impossible.

- Maintains constant pressure in the system.

- It is a water storage facility.

- Protects the system from water hammer, acting as a buffer between the lines and the lift pump.

There is a fourth function, in the performance of which the supplier is more interested than the consumer. This reduces the operating time of the pump and the number of its starts, which not only increases the time of its trouble-free operation, but also saves energy.

For a private owner who owns his own source of water, it is no less important than the first three.

For all its apparent simplicity, a water tower is a very complex and material-intensive structure that takes up part of the usable area of a suburban area. Therefore, compact membrane devices are more often used in individual water supply systems.

Purpose

Before choosing the volume of a hydraulic accumulator for water supply, you should determine the main differences between different models.

Mainly, a correctly selected hydraulic accumulator allows you to:

- ensures optimal pressure in the system (working in tandem with a pressure switch);

- reduces the number of starts/stops of the well pump (maximum wear of the pump occurs at the time of its start-up);

- allows you to avoid troubles associated with water hammer in the system;

- provides low water flow without turning on the pump;

- creates a reserve supply of water in case of interruptions in its supply.

You also need to consider the following features:

- membrane manufacturing material;

- membrane or balloon design of a hydraulic accumulator;

- vertical or horizontal installation is provided for by the design.

Operating rules

After installation of the device is completed, it must be serviced taking into account why the hydraulic accumulator is needed in the household water supply system. At least once a month you need to check the status of the pressure switch settings and, if necessary, adjust them.

The integrity of the membrane, the condition of the tank body and the tightness of the joints also need to be checked. Most often, membranes in pressure tanks fail - they rupture. Constantly repeating cycles consisting of compression and stretching cause damage to this element.

The fact that the membrane is torn is indicated by sharp changes in readings on the pressure gauge, as a result of which water begins to flow into the air section of the accumulator. To be sure that there is a breakdown, the air is completely bled from the tank. If water begins to flow out behind it, this indicates the need to replace this element.

Carrying out such repairs is not difficult, for which they proceed as follows:

- the hydraulic accumulator tank is disconnected from the power supply and water supply;

- unscrew the bolts holding the neck of the container;

- remove the old membrane;

- install a new product;

- assemble the tank in the reverse order;

- the device is installed in place and connected.

After completing the repair, you need to check and adjust the pressure settings in the tank and pressure switch. The connecting bolts are tightened evenly to prevent distortion of the installed membrane and to prevent its edge from sliding into the body of the device.

In this case, they do this: place the bolts in the sockets and alternately make a couple of turns of the first one and move on to the next one. As a result, the membrane is equally pressed to the body along the entire circumference.

Having figured out why hydraulic accumulators are used for water supply, and what types there are, you can go shopping

This device is an important part of a modern autonomous water supply system.. https://www.youtube.com/embed/SRDp5VRHYYU

How to choose the right hydraulic accumulator?

Selecting a hydraulic accumulator

When choosing a pressure tank, you must first consider the volume of water that will flow through the system. In general, such devices can be of two types:

1. Vertical, which are characterized by the fact that they take up little space.

2. Horizontal, which are equipped with special fasteners in order to install an external pump.

Finally, pay attention to the volume of the accumulator itself. The smaller it is, the more often the pump will turn on, and the pressure will “jump” in the system with a higher frequency

On the contrary, large tanks will allow you to store a large amount of water in them.

Principle of operation

The storage tank begins to accumulate excess heat in the upper part of the tank after the room is completely heated. As the accumulator cools, it gradually releases heat into the heating system.

The capacity of the hydraulic accumulator determines how many times during the day the solid fuel boiler will be loaded.

The operation of the storage tank is based on the use of high heat capacity of water, which, when cooled by 1 °C, releases several times more heat to heat 1 m2 of room.

To calculate the volume of the storage tank, use the ratio - 25 - 30 liters of tank per 1 kW of solid fuel boiler power.

For example, for a 20 kW boiler, the tank volume will be from 500 to 600 liters.

Important Details

Once you have completed all the steps above, you need to check the system for leaks. It is recommended to pay the most attention to the joints, since this is where water most often leaks. Do not forget that the pressure regulating relay has special marks. Under the cover you will find the “pump” and “network” contacts; look carefully and do not mix up the wires.

Once again, it is worth noting the importance of sealing connections. Leaks are often found where there are threads.

Even if you find a gap in the system, you can use industrial sealant or technical flax for a tighter fit. After this, check everything again; the presence of water plugs is unacceptable. If necessary, drain the water and do everything again. As you can see, the hydraulic accumulator, the connection diagram of which was just discussed, is installed quite simply. Let's move on.