19.01.2021

What type of roof is right for your log home? What nuances should be taken into account when erecting a roof? What materials are best to use for roofing structures? These and other questions are often asked by future owners of country houses made of timber, because erecting a roof is an important stage of the construction process, on which the comfort, safety and appearance of the house depends. The roof of a house made of timber is a complex structure and requires the participation of professional designers and builders. However, it will be useful for every customer to know the specifics of roof construction.

Pros and cons of a timber roof

Roofs with a timber rafter system are used for wooden and frame houses, as well as for structures made of slabs and piece building materials. This type of coating is considered universal and has many advantages:

- environmental friendliness and safety;

- warm house, wood retains heat well;

- good sound insulation (largely depends on the type of roof);

- natural ventilation of the attic floor or attic;

- low cost and ease of installation.

The disadvantages of timber roofs include low fire resistance and high requirements for timber for the installation of rafters. The fire resistance of timber can be increased by treating the wood with fire retardants.

Choosing timber for rafters

For rafters, it is preferable to use coniferous timber. The timber must be aged and have a humidity of 18-22%. If the humidity is above 22%, the wood will shrink unevenly, which will lead to misalignment of the rafter system and disrupt the geometry of the roof. For country houses and residential cottages, timber with a section size of 50*150, 50*200, 100*200 mm is most often chosen for making rafters. It is not advisable to use a larger beam, because at the same time, the load on the walls of the building will increase significantly.

The timber must be treated before installing the rafters. For processing we use:

- flame retardants - increasing fire resistance and reducing flammability;

- antiseptics - protection against rotting and fungus;

- insecticides - protection against insects and rodents.

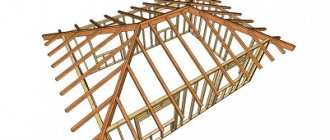

Types of timber rafter systems

A rafter system made of timber can be one of two types:

Layered rafters. This is the most popular option in private construction. With this method of installation, the rafter legs rest on a beam, which is located around the perimeter. The central part is reinforced with a ridge girder. In large buildings, additional beams are used to increase strength.

Hanging rafters. The structure is mounted on external walls. Crossbars, struts, headstocks, etc. are used as additional elements. The bars are held together by tightening. The use of hanging rafters requires detailed calculations.

When choosing a rafter system, designers take into account the angle of inclination of the future roof: for steep slopes, the optimal solution is layered rafters, for flat ones - hanging rafters. In some cases, the rafter system is combined: layered rafters alternate with hanging ones.

Load distribution

The special design of the roof of a house made of timber assumes the presence of not only vertical, but also lateral loads. To minimize the negative impact of vertical loads, the roof structure involves the installation of additional supports, thanks to which the weight of the roof is evenly distributed over all supporting structures. But most of all you should be wary of the impact of lateral load, due to which the walls of the log house can change their geometry. To avoid this, the upper frame is reinforced with ties made of 100x150 timber, which is cut into the opposite “extendable” wall beams using a dovetail joint. If the house is large and the design of the rafter system involves the use of racks, then the base under the roof is reinforced with beams - 150x150 beams, which are cut into the top frame of the log house perpendicular to the floor beams. The racks will subsequently rest on the beds; they most often determine the location of the internal walls of the attic.

Calculation of timber for rafters

The purpose of calculating the rafter system is to determine the required cross-section of the beam. To do this, you need to know: the length of the rafter legs, the installation pitch of the elements and the parameters of future loads. The dependence of the cross-section of the beam on the installation pitch of the rafters is shown in the table:

| Length of rafter legs, cm | Rafter spacing, cm | Section of rafter beam, cm |

| up to 300 | 120 | 8 x 10 |

| up to 300 | 180 | 9 x 10 |

| up to 400 | 100 | 8 x 16 |

| up to 400 | 140 | 8 x 18 |

| up to 400 | 180 | 9 x 18 |

| up to 600 | 100 | 8 x 20 |

| up to 600 | 140 | 10 x 20 |

Example: to make rafters from timber 3.5 m long, you can use two options: 1) timber 8x16 cm in increments of 1 m; 2) timber 8x18 cm with a pitch of 1.4 m. Knowing the length of the house wall and the pitch, you can easily calculate the required number of rafters and beams.

For other roof elements, dimensions should be taken based on SNiP 3.03.01-87 (updated SP 70.13330.2012):

- Mauerlat - 10x10 or 15x15;

- purlins, crossbars and struts - 10x10, 15x15 or 10x20;

- puffs - 5x15;

- hemming boards - 2.5x10 or 3x10.

The length of the rafters should not exceed 6 m! A structure greater than 6 m will not provide sufficient deflection strength.

When designing a timber roof, design engineers must calculate the current loads on the rafter system. The calculation takes into account the weight of the final roofing covering, thermal and waterproofing, sheathing, drainage and snow retention elements, as well as temporary loads. The calculation is made using special programs. It is impossible to make such a calculation on your own due to the large number of variable variables.

Installation of timber rafters

To install prepared and processed timber into a rafter system, you need a set of professional tools: a construction level (preferably laser), an angle grinder, a gas or electric saw, a drill with a set of drills. It is also necessary to prepare fasteners in advance: screws, corners, clamps, etc.

There are two options for assembling rafters:

- Assembly is carried out on the ground, and the finished rafters are lifted up and installed. This option is not suitable for massive rafter systems, because A construction crane is needed to lift the structure.

- Assembly is carried out on the roof. In this case, only timber, boards and tools rise to the top.

Installation of a gable roof made of timber includes the following steps

Mauerlat installation

The strapping is laid on the long walls of the house and attached to them using anchor bolts. In this case, the Mauerlat should be leveled along the inside of the wall. Waterproofing must be lined under the harness: geotextile, TechnoNIKOL, waterproofing or regular roofing felt. For timber houses, the role of the mauerlat can be performed by the very top crown. However, if the roof needs to be raised higher, then the Mauerlat is indispensable here. In the same way, 1-2 planks are laid on the internal load-bearing walls of the house.

Installation of supports and skates

The timber supports are mounted on a bench with a selected pitch. The supports are leveled and secured with jibs - boards 2.5x10 cm. The racks are rigidly attached to the bed with nails or metal corners (reinforced version). The ridge beam (purlin) is laid on the posts and secured with nails and metal corners.

When installing hanging rafters, the racks are installed temporarily, and the Mauerlat is attached to the wall using additional metal ties, because with this type of rafter system, an increased load will be applied to it.

Mauerlat for hanging rafters. Rafter legs are secured with brackets

Installation of rafter legs. The method of installing rafter legs depends on the type of rafters chosen. The legs of the layered structure are installed on the Mauerlat and secured using brackets, screws or staples. Reinforcement with brackets gives the rafters additional rigidity. If the length of the timber does not allow for overhangs, then fillets are mounted, which are made from the same timber as the rafters. The fillies are fastened with nails. The rafters are connected at the ridge of the roof, forming a triangle.

The hanging rafters are laid on the mauerlat, a cut is made, into which the rafter leg is then inserted and fastened with nails. Thanks to the sawing, the beam fits tightly to the Mauerlat and does not need to be fastened with brackets and brackets. Tightenings are applied to the installed rafters.

Roofing pie in a timber house

In addition to the ridge, sheathing and rafter system, a classic gable roof consists of the following elements: mauerlat, crossbars, tie rods, struts, vertical posts, gutters. Roof sheathing h3 Installation of the sheathing is preceded by laying a layer of waterproofing to prevent the accumulation of moisture inside the structure. Boards with a cross section of 20X100 mm are nailed onto the rafters as lathing. The distance between the sheathing boards is calculated depending on the type of roofing material chosen and varies from 5 to 30 cm. The overhangs and corners of the roof are hemmed with clapboard. Waterproofing material is placed on top of the sheathing. Roof ridge height h3 The roof ridge is the intersection of the slopes in the upper position. The ridge is installed at the last stage of roof construction, leaving a small gap for ventilation. To determine the height of the ridge, you need to know the angle of the rafters. In this case, for calculation, a value equal to half the width of the house is multiplied by a coefficient corresponding to the angle of inclination of the slopes.

Roof

The basis of the structure is always a rafter system, which is laid out with profiled or glued beams. A rafter system with a certain set of parts of the roofing pie is selected depending on the type of roof, the number of slopes and the angle of inclination. The standard set consists of rafter beams, sheathing, installation of hydro- and vapor barriers, insulation and roofing material. The rafter system is assembled on the ground and then raised above the walls of the house, where the roof beams are tightly fastened together.

Installation of sheathing

Once the roof timber rafter system is ready, you can begin installing the sheathing. For the lathing, 50x50 timber and dry boards 3 cm thick and 20-35 cm long are selected. Before lathing, the rafters are covered with waterproofing. The material is laid with overlaps of at least 10 cm and secured with construction tape.

The pitch of the sheathing depends on what roofing material was chosen for the covering and the slope of the roof. The pitch of the sheathing for corrugated sheeting and ondulin can be determined from the table:

| Corrugated sheet | Roof inclination angle, gr | Sheet thickness, mm | Lathing step |

| S-8 | at least 15 | 0,5 | Continuous sheathing |

| S-10 | up to 15 | 0,5 | Continuous sheathing |

| S-10 | more than 15 | 0,5 | up to 300 mm |

| S-20 | up to 15 | 0,5 — 0,7 | Continuous sheathing |

| S-20 | more than 15 | 0,5 — 0,7 | up to 500 mm |

| S-21 | up to 15 | 0,5 — 0,7 | up to 300 mm |

| S-21 | more than 15 | 0,5 — 0,7 | up to 650 mm |

| NS-35 | up to 15 | 0,5 — 0,7 | up to 500 mm |

| NS-35 | more than 15 | 0,5 — 0,7 | up to 1000 mm |

| N-60 | at least 8 | 0,7 0,8 0,9 | up to 3000 mm |

| N-75 | at least 8 | 0,7 0,8 0,9 | up to 4000 mm |

For metal tiles and seam roofing, continuous sheathing is performed (for roofs with a slope of more than 20 degrees) or discharged (for a slope of less than 20 degrees). Continuous sheathing is carried out with minimal gaps - no more than 5 cm. The best option: perform the sheathing in accordance with the recommendations of the manufacturer of the selected roofing product.

Regardless of the type of roofing covering and the calculated pitch, the sheathing is continuously mounted around roof windows, in places where complex roofs are broken and in those places where heavy elements of the drainage and snow retention system will be installed.

Under a soft roof, the sheathing is made of panel materials: plywood or OSB. The sheets are attached end-to-end to the rafters using self-tapping screws, forming a flat surface on which bitumen shingles are then installed.

Lathing and roofing materials

Part of the sheathing, as we have already said, can be mounted during installation of the rafters to hold them in a given position. But in general, the sheathing serves to secure the roof of the roof. The material for the sheathing, boards or timber, is selected based on the roofing material. For fastening metal tiles, slate, etc. You can use 50x50 timber with a suitable fastening pitch. For soft roofing, the sheathing is often made continuous or at intervals of one board, using inch boards. Subject to subsequent insulation of the roof, a layer of wind protection (super diffusion membrane) is laid between the sheathing and rafters. Roofing materials are fastened from bottom to top from one of the gables. To cover the roof of a house made of timber, you can use metal tiles, composite tiles, soft bitumen or copper tiles, seam roofing, ceramic tiles - there are plenty to choose from!

Choosing a roofing covering

A timber roof is universal, allowing you to choose any type of roofing covering. The following roofing options are popular in private housing construction:

- Seam roofing.

- Metal tiles.

- Ondulin.

- Profiled sheeting.

All these types of roofing materials are characterized by high strength and durability. The most affordable is ondulin, made from cellulose and polymers. Metal tiles are more expensive, but have a presentable appearance and require minimal maintenance. The disadvantages of roofing made from these materials include the need for sound insulation, because... every blow, precipitation and gusts of wind will be heard in the house. Also, such a roof necessarily requires insulation.

Separately, it is worth mentioning soft tiles - this is a relatively new roofing material based on synthetic bitumen. The material has a beautiful design, is silent, and is not subject to corrosion or rotting. A significant disadvantage of flexible tiles is their relatively high cost.

Types of roof

Before you build a roof, you need to make the final choice of roof design, it makes sense to get acquainted with the types of roofs that are often used in suburban construction.

Types of roof

Any roof can be classified according to the following criteria:

- Slope.

- Design form.

- Materials used for its construction.

Timber roof insulation

Despite the fact that a timber roof is quite warm, it needs insulation. Thermal insulation is carried out after the installation of the roof covering. Inside, the timber roof consists of rafters with sheathing and waterproofing. The following can be used as insulation:

- polystyrene foam or extruded polystyrene foam;

- mineral wool;

- sprayed polyurethane foam.

Each type of thermal insulation has its own advantages and disadvantages. For example, polystyrene foam is fire hazardous, flammable and does not allow the roof to “breathe”, but it has excellent heat-retaining properties and is low cost. Insulation based on mineral wool is suitable for large buildings, because... The weight of the mineral wool is quite large. The material is used in slabs or rolls. Thermal insulation is attached to the sheathing. The thickness of mineral wool slabs depends on the region and averages 15-20 cm. Mineral wool is environmentally friendly, breathable and durable.

Polyurethane foam spraying is the best way to insulate a roof. The material is sprayed with a special installation and creates a sealed coating without seams or joints. The disadvantage of polyurethane foam is its high cost.

In order for a timber roof to last a long time and not require expensive repairs, it is necessary to install an effective drainage system that will prevent water from entering the roof. The calculation of gutters is carried out taking into account the slope of the roof, roofing material and the amount of precipitation.

You can ask your question to our author:

Features of the construction of under-roof structures

In addition to the roof covering, the roof includes a whole range of additional elements and materials: vapor barrier, insulation, ventilation. Each of the elements performs its function and ensures the proper operation of the entire roofing structure. The absence or incorrect use of any element has a detrimental effect on the entire roof.

Roofing pie from bottom to top:

- Vapor barrier film - to protect against moisture penetration into the insulation;

- Insulation – for thermal insulation of interior spaces;

- Wind protection - to protect against wind, condensation, and reduce the thickness of the insulation.

The under-roof structure for different materials is approximately the same, the differences are in the size of the ventilation gap. Materials cannot be laid closely; penetrating moisture must be removed, otherwise the insulation will become oversaturated with moisture.

Methods for laying roofing pie:

- Houses with an attic. Only waterproofing is installed under the roofing. Vapor barrier and insulation are laid on the ceiling from the interior or attic. This scheme provides better insulation and good ventilation.

- Houses without an attic or with an attic. All layers - vapor barrier, insulation, waterproofing - are placed directly under the roofing. A ventilation gap is left between the roofing covering and the roofing pie, otherwise the insulation will become oversaturated with moisture.

- Houses with a flat usable roof. Such buildings have an inversion roof, in which the order of the layers is changed. The insulation is laid over the waterproofing, with a hard wear-resistant coating or soil with green spaces on top.

Roof waterproofing

The task of the vapor barrier layer is to cut off the penetration of moisture into the insulation from inside the house. The insulation is protected from cold wind blowing and external wetting, and excess moisture is removed outside.

The roof is traditionally waterproofed with bitumen-based roll materials, but now there is a better option on sale - a wind- and moisture-proof membrane. Compared to bitumen materials, the membrane is more flexible and environmentally friendly. The main advantage of the membrane is vapor permeability. As a vapor barrier, a cheap high-density polyethylene film or a more expensive vapor barrier membrane is used. The membrane differs from the film in that it retains moisture but allows air to pass through. The room breathes, there is no greenhouse effect.

Roof insulation

The comfort of staying in the house depends on the correct choice of insulation and insulation scheme. If insulation is incorrect, in addition to discomfort, condensation accumulates in the insulation, which is harmful for wooden and metal rafters, because the service life of supporting structures is reduced.

The main necessary qualities of insulation for a wooden house are fire resistance and moisture resistance. In this regard, one of the best insulation materials is basalt wool. Its additional positive quality is high elasticity; this property allows you to compensate for possible gaps after shrinkage.

When choosing insulation, the coefficient of thermal conductivity, hygroscopicity, and ease of installation are evaluated. Cotton slabs or rolls, ecowool or polyurethane foam are suitable for installation on ceilings and in the space between the rafters. A flat roof in use is insulated with rigid polystyrene foam boards.

If the attic is not residential, then insulating the roof in a wooden house is not necessary; it is enough to insulate the ceiling from the inside or from the attic side. Bulk materials such as expanded clay, perlite, vermiculite, and sawdust are well suited for insulating attic floors.