The foundation is the basis of any building; the service life of the structure depends on its strength. Reinforcing the foundation slab with metal reinforcement rods is the simplest and most effective way to increase the durability of the foundation. This technology is especially popular when constructing monolithic foundation structures that are subject to high bending loads, the force of which can easily destroy an ordinary concrete slab not protected by a metal frame. This article will discuss the main stages of constructing a metal frame and the principles for calculating its key parameters.

How to correctly calculate the amount of reinforcement

The number of rods used directly depends on the size of the slab, primarily on its thickness (if it is more than 25 cm, two-layer reinforcement will be required). We use as an example a house whose base measures 8x4 meters. The minimum grid pitch, according to SNiP, should be 20 centimeters. Accordingly, the number of rods in length will be equal to:

Let's multiply the resulting quantity by 5% to ensure a reserve. The linear footage of the reinforcement will be:

As we mentioned earlier, the diameter of the rod should be selected in accordance with the loads on the slab. The minimum degree of reinforcement for concrete M-200 and M-300, respectively, is 0.1 and 0.15%, which should also be included in the calculation of material consumption. Knowing these parameters, you can accurately calculate the material consumption for a foundation slab with reinforcement.

For example, let’s take a slab measuring 6x6 m and 20 cm thick and calculate the parameters of the reinforcement belt located directly in the interface zone with an area of 1.2 m2. The optimal value of the reinforcement area is 0.3% of the slab area, respectively:

For one layer of reinforcing belt, in which the elements are located in increments of 10 cm, the area of the reinforcement used must be no less than:

Several types of reinforcing bars are suitable for reinforcing the foundation slab. All available options indicating the length and cross-sectional area are available for review in GOST 5781-82. From the results of our example, it follows that the most suitable rod is 14 mm in diameter (a total of 12 rods will be used for each interface zone). With a slab side of 600 cm, the optimal pitch of the frame grid will be 30 cm (for the horizontal direction), the same step will be used for the vertical direction, but 8 mm rods will be used.

To present the calculations in a more visual form, it is necessary to create a drawing of a metal frame. It will help in calculating the total number of rods that will be used during the installation process. For our example, the total consumption of reinforcement will be 515.2 linear meters of 12 mm reinforcing bars and 56 meters of 8 mm bars.

Design calculation

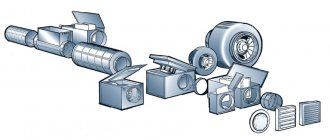

Main types

Monolithic reinforced concrete floors can be partially or fully supported along the contour, pinched on supports or freely supported. In the practice of monolithic construction, quite often there are slabs that are pinched along one edge (cantilever) or supported at corners (points), for example, a beamless floor. The load calculation is contained in this material.

Layout of reinforcement meshes.

According to the design scheme, they are divided into beams (single-span-split, continuous-multi-span, cantilever), operating in several directions, which exist single-span (with non-hinged or hinged support along the edges) or multi-span continuous.

Slabs are considered beam slabs if the forces acting in one direction are very small compared to the forces acting in the other direction. Beams include flat rectangular ones, uniformly loaded, which are supported on two opposite sides, in addition, slabs that are supported along the contour or clamped on 4 or 3 sides at a ratio of spans. In regulatory documents, the boundary span ratio is limited to 3 or 2.

Reinforcement scheme

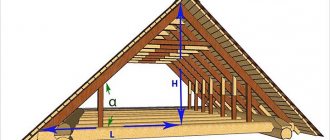

For spans of 6-8 m, monolithic floors must be made flat, and for larger values - flat with intercolumn beams or walls, hollow or ribbed. For halls with a span of 12-15 m, it is necessary to use caisson, hollow-core and ribbed floors supported on beams or walls on 4 sides.

For spans of more than 7 m, ligation should be carried out using additional prestressed reinforcement from high-strength ropes of class K7 without adhesion to concrete.

A calculation must be carried out.

The thickness of the reinforced concrete coffered frequently ribbed floor should be at least 25-30 mm.

Monolithic reinforced concrete must be reinforced with a standard welding mesh or knitted structure.

Scheme of reinforcement of a concrete slab.

The diameter of the working rods of a welded structure must be used at least 3 mm, and for a knitted structure - at least 5.5 mm. The distances between the working rods should be no more than 400 mm.

In private and multi-storey construction it will not be possible to do without floor slabs, of which there are several types: monolithic, beam and precast reinforced concrete. In low-rise and private construction, the procedure of self-reinforcement of floors is most often used, which, thanks to the combination of concrete and reinforcement, can have increased strength. In addition, stair steps, arched and reinforced lintels can be made into the house in the same way.

Tying the reinforcement cage

If, before construction work, calculations were made of the maximum load created by the building structure on the foundation, the connection method is included directly in the working drawing. But in practice, the bonding or welding method is used to combine the elements of a metal frame. At the same time, builders are gradually abandoning welding, since heating the metal causes its deformation and changes in structure. The bonding method avoids these disadvantages, providing the lattice with additional flexibility.

Steel wire with a diameter of 4 mm is best suited for tying rods. Possessing the necessary strength, it remains flexible and is quite easy to work with using ordinary pliers.

A few tips for proper tying of reinforcement:

- When connecting rods along their length, an overlap of about 250 mm or more is left;

- Using rods of different diameters, the thinner ones should be placed on top;

- Knitting is preferable to welding; only in exceptional situations should one switch to the welding method;

- In areas of increased deflection, the structure is reinforced with additional rods.

An example of a diagram (drawing) of reinforcement for a slab foundation.

The procedure for constructing a frame for reinforcing foundation slabs:

- Creation of formwork along the outer perimeter, installation of rolled waterproofing material;

- Installation of a horizontal reinforcement belt at a height of 50 mm from the underlying sand and gravel cushion. It is necessary to ensure that the rods do not touch the walls of the formwork and the cushion;

- Installation of vertical rods in increments of 20-40 cm. They are connected to the elements of the horizontal belt in the lower base. In the corners, vertical rods can be installed in smaller increments, strengthening them with longitudinal rods to increase the strength of the structure;

- For horizontal belt elements, it is better to choose an interval of 15 cm or less (depending on the thickness of the slab);

- The top edge of the vertical chord must be above the slab in order to combine the reinforcing layer of the foundation slab with the wall structure.

Next, the entire structure will be filled with concrete.

Materials

Reinforcement is the strengthening of a concrete block from the inside using various materials. Rods or fibers can be used that, when the block is stretched, do not allow it to crack.

In practice, reinforcement materials can be divided into 3 groups:

- metal rods,

- composite reinforcement,

- fiber.

Steel bars

The standard length of a steel bar for reinforcing concrete structures is 11.75 m. The reinforcement can have different diameters and grades. Depending on the marking, the rods are joined into a reinforcing frame by welding or knitted with wire.

In the mass of concrete, the connection between the steel rods and the mortar is quite strong due to the corrugation on the rod. The steel frame inside the monolith redistributes the loads and keeps the concrete from cracking, since the metal has greater tensile strength. At the same time, concrete, in turn, protects the metal from corrosion.

Steel reinforcing frameComposite material

Such fittings have a fairly wide range of source materials, increasing almost every year. To date, fiberglass and basalt plastic rods with spiral wrapping, simulating the periodicity of the steel reinforcement profile, are more or less used.

In addition, the construction market offers polyethylene rephthalate and hydrocarbon fittings, which have not yet received widespread popularity. The undeniable advantage of the composite is its low weight. But when constructing foundations or retaining walls, this advantage is of little importance, but the strength characteristics are very important.

Composite reinforcement is usually used in horizontal building elements supported on the ground

Fiber fiber

Fine material (fiber) is added to the solution at the mixing stage. Moreover, the fiber itself can have different diameters and lengths.

Fiber is made from fiber based on:

- become,

- glass,

- polypropylene compounds,

- basalt.

Fiber fiber to enhance the tensile strength of concrete

Description of reinforcement schemes

Reinforcement along the width of the slab

Most often, reinforcement of a slab foundation is carried out along the main width of the slab using a mesh with the same cell size. When calculating the grid spacing, the size of the foundation and the amount of load it will take upon itself after the building is erected are taken into account. It is possible to use rods of different diameters, with thicker rods placed under the bottom of the structure. It is recommended to use reinforcement along the main width for the lower part of the slab to distribute the load over the entire area.

U-shaped rods are placed in the end parts, connecting the lower and upper reinforcing balls into a single whole. These elements further strengthen the structure, compensating for the destructive effects of torques.

Creating a floor using corrugated sheets

An interesting technology that allows you to create floors with high load-bearing capacity. Profiled sheets N-60/N-75 are suitable for work. The sheets are mounted in such a way that after pouring, ribs are formed at the bottom. The reinforcing mesh is installed on top of the sheet at a distance of 150 mm. A rod with a diameter of 12-14 mm is installed in the ribs; plastic clamps should be used to mount the rods.

Solid slab

This technology is used if it is necessary to create a slab foundation or span with a thickness of no more than 200 mm. The frame consists of two grids located in parallel planes. For installation of meshes, rods with a diameter of 10 mm are suitable. In the middle of the structure, additional reinforcing elements with a length of 40 cm or more are installed in the lower grid. The frequency of installation of reinforcing elements should be equal to the pitch of the main grid.

The support points of the slab must be equipped with additional reinforcement, installing it in the upper part of the structure. The ends of the mesh are also fastened with U-shaped elements combining the segments.

Minimum reinforcement according to SP 63.13330 (SNiP 52-01-2003)

The percentage of reinforcement with longitudinal tensile (compressed, if required by calculation) reinforcement in sections of reinforced concrete elements is determined by the formula:

b—section width in m ;

As is the cross-sectional area of the reinforcement in m2 ;

h - working height of the section in m , calculated by the formula

A

— the distance from the resultant forces in the reinforcement to the nearest edge of the section (with one row of reinforcing bars from the center of gravity of the reinforcement to the edge of the section) in m.

μ s should be taken at least:

0.1% - in bending, eccentrically stretched elements and eccentrically compressed elements with flexibility l/i ≤ 17 (for rectangular sections l/h ≤ 5);

0.25% - in eccentrically compressed elements with flexibility l/i ≥ 87 (for rectangular sections l/h ≥ 25);

for intermediate values of element flexibility, the value is determined by interpolation.

Note!

In elements with longitudinal reinforcement located evenly along the section contour, as well as in centrally tensioned elements, the minimum cross-sectional area of all longitudinal reinforcement should be taken twice as large as the above values and referred to the total cross-sectional area of the concrete.

Source

Installation sequence of a monolithic slab

To ensure the safety of a reinforced concrete slab for a long time, it must be placed on a bed of sand-crushed stone mixture and protected with insulation and a waterproofing layer. The general progress of work can be divided into the following stages:

- preliminary cleaning of the construction site from vegetation and foreign objects;

- digging a pit, the parameters of which are calculated according to SNiP, taking into account the mass of the building and the characteristics of the soil;

- the bottom of the pit is equipped with ditches for drainage, the surface of the ditches is covered with geotextile material;

- A 30 cm thick sand layer is poured over the entire area of the pit, and a 20 cm layer of crushed stone is placed on top of it;

- an additional layer of roofing felt is placed on top of the resulting cushion;

- installation of formwork, consisting of boards 2 cm thick, fastened together with nails behind fixed external supports;

- erection of a reinforcing frame, the distance between metal rods and wooden formwork should not be less than 5 cm;

- After pouring the concrete, processing and hardening, the formwork is dismantled and the main construction work begins.

Excavation

The soil is marked according to design standards, increasing its perimeter by 50 cm on each side for the installation of a drainage system

- The soil is marked according to design standards, increasing its perimeter by 50 cm on each side for the installation of a drainage system. It is worth remembering that the slab itself should protrude beyond the walls of the future house by 10 cm on each side.

- Pegs are driven into the ground and a marking cord is pulled. The axes of the future slab should also be drawn.

- The soil is removed from the pit to a depth of 60 cm. At the same time, you should carefully monitor the quality of the soil being removed. If early digging of soil is observed on a building site, then the loosened soil must be removed layer by layer until you reach layers untouched by a shovel. Here, according to the instructions, you will have to remove layers of soil around the entire perimeter of the pit in order to completely level it. After this, the bottom of the pit is compacted and filled with sand to the design level of the pit. If this is not done and the foundation is mounted on soft soil, then the force of the house’s pressure on the slab will simply break it over time precisely in the place of loose soil.

- A drainage system is laid around the design base area in the form of special perforated pipes with their slope towards the storage well or central storm drain.

- Then you should lay a layer of crushed stone 20 cm thick and carefully compact it according to the principle of laying a sand cushion.

- Now we install the formwork from high-quality wooden panels. Their height should be at least 40 cm. It is advisable to clean the inner walls of the formwork. The formwork is fastened with bolts, screws or self-tapping screws. From the outside, the wooden frame can be supported with wedges for greater stability.

Do-it-yourself pouring and grounding of the slab

After completing the installation of the reinforced frame of the monolithic slab, it is necessary to carry out grounding. This procedure involves installing an outer ring made of galvanized strip. This ring will protrude from the outside of the slab, being its integral part. The grounding is equipped with connecting busbars, to which the rain drain elements and lightning rod will be attached. The busbars can also be taken out at the point where the electrical network is connected to the house to provide grounding for the internal electrical wiring.

The foundation is poured after completion of all work related to the installation of the reinforcing frame. During the process of mixing the solution, fiber can be added to the concrete if the requirements of SNiP require additional reinforcement of the concrete base. The filling process is carried out continuously until the entire volume is filled. Upon completion, the mixture must be freed from air bubbles by vibration compaction. The slab will gain the necessary strength after 4 weeks.

What to consider when purchasing

The regulated requirements for the material are given in paragraph 6.2 of the SP “Concrete and reinforced concrete structures. Basic provisions". For ease of purchasing, it is recommended to calculate in advance the amount of material of each diameter, taking into account the reserve for unforeseen expenses (3-5%). The calculation results can be summarized in a statement, which will indicate the diameter, total length and mass of the rods.

When purchasing, you should pay attention to the following points:

- Compliance of the material with the required class. Rods of class A400 have a periodic profile with a crescent-shaped pattern (“herringbone”), which makes them easy to distinguish from rods A240 and A300.

a - ring profile (not suitable), b - crescent profile (suitable), c - combined profile (suitable, but rare).

A little fresh rust on the surface of the reinforcement is acceptable; moreover, it increases the adhesion force to concrete, but there should be no flaking old rust.

To summarize, we can say that it is necessary to pay attention to the following points when purchasing in order to prevent problems during operation of the foundation:

- class and diameter of rods;

- steel grade;

- availability of a passport and necessary certificates for the material;

- no external damage to the rods.

Advice! If you need builders to build a foundation, there is a very convenient service for selecting specialists from PROFI.RU. Just fill out the order details, the experts will respond and you can choose who to collaborate with. Each specialist in the system has a rating, reviews and examples of work, which will help with the choice. Looks like a mini tender. Placing an application is FREE and does not oblige you to anything. Works in almost all cities of Russia.

If you are a master, follow this link, register in the system and be able to accept orders.

Frequent mistakes made during the reinforcement process

In order to provide the slab with the necessary properties and protect it from premature destruction, the technological process of reinforcing a monolithic foundation slab should be strictly followed. Below is a small list of mistakes made by inexperienced builders:

- Do not install plastic film over the poured concrete mixture. Its absence provokes the leakage of cement laitance through the cracks in the formwork. As a result, the frozen solution will become covered with surface cracks.

- After filling the sand-crushed stone cushion, it is not compacted or covered with film. During operation, the foundation will begin to deform and deep cracks will appear.

- When installing the formwork, the cracks through which fresh mortar will begin to flow out are not sealed. This error will lead to the formation of unevenness in the slab.

- The absence of a waterproofing layer between the slab and the ground surface leads to rapid destruction of the foundation, which can only be stopped through expensive work.

- Using stones as foundation spacers.

- During the installation of the reinforcing mesh, the reinforcement bars are fixed in the ground, as a result of which the metal will begin to deteriorate quite quickly under the influence of corrosion.

- When arranging the foundation, a sand-crushed stone cushion is not poured, which reduces the strength characteristics of the slab. Another common mistake is to use only crushed stone for the cushion, while the minimum sand content in the mixture should be 40%.

- The mesh spacing when reinforcing a slab foundation exceeds the maximum limit of 40 cm, or it does not correspond to the calculations for the load on the foundation.

- There is no protective concrete layer at the ends of the reinforcement, which is why it becomes corroded.

- There are no vertical rods under load-bearing walls and columns, as a result the load from the weight of the building is distributed incorrectly.

We have listed only the most serious mistakes that will certainly affect the performance characteristics of the foundation. There are also more unobvious nuances that only experienced builders know about. That is why we recommend entrusting such important work as reinforcing a slab foundation only to craftsmen with a good reputation.

Advantages and disadvantages of continuous reinforced floors

The reinforced concrete floor is made in the same way as ready-made slabs from 2 materials:

- iron rods;

- cement mortar.

Concrete has high hardness, but it is brittle and cannot withstand deformation and is destroyed by impacts. The metal is softer and tolerates bending and torsion well. When these two materials are combined, durable structures are obtained that can withstand any load.

Advantages:

- absence of seams and joints;

- smooth, continuous surface;

- the ability to make floors for any shape and size of premises;

- installation and assembly of fittings is carried out directly on site;

- a reinforced concrete monolith strengthens the structure and binds the walls together;

- there is no need to seal joints and align transitions after installation;

- the local large load on the floor is evenly distributed over the foundation;

- It is easy to make various openings between floors for stairs and communication wells.

The disadvantages of reinforcement include high labor costs for assembling the reinforcing mesh and the long process of drying and hardening of concrete.