An unpleasant surprise for homeowners is the appearance of unpleasant odors in the kitchen, bathroom, toilet, and then throughout the apartment. Almost immediately, cause-and-effect relationships are established: due to the occurrence of reverse draft, air flows from the ventilation vent connected to the ventilation duct - an element of natural ventilation of the apartment or house.

Many residents solve the problem simply: they seal the ventilation windows or install mechanical plugs that open as needed: cooking starts in the kitchen - the device opens, ends - it closes. The method works by removing emerging odors. But in this case, apartment dwellers are in for an even bigger surprise: stale, waterlogged air appears in all rooms. As a result, family members develop problems with the respiratory system, and mold and mildew begin to grow rapidly on the walls in different places.

The solution to the problem is completely different: you need to block the path of air flow from the hood, maintaining a free exit of air from all rooms of the living space. The problem is solved by installing a check valve for ventilation. The method does not require changes to the existing air exchange scheme or significant financial expenditure.

To get a positive result, you need to know how a ventilation check valve works, its design features, pros and cons, and installation features.

The editors of the StroyGuru portal have prepared material with photos and videos explaining the principles of operation of the back draft valve for ventilation and how to install it with step-by-step instructions. In addition, it is discussed in detail how to make a check valve for ventilation yourself.

Before we take a closer look at the simple device, let’s find out the principle of organizing air exchange in apartments, which will allow us to understand the reasons for the occurrence of reverse draft and ways to combat it.

Design and advantages of a grille with a valve

The model includes three main parts: fixed, movable, and a flange for connecting the air duct.

The stationary part is the grille itself. It acts both as a decorative element and as a barrier that protects and closes the valve from accidental damage.

Since the grille closes the ventilation hole, smell and all kinds of small particles do not penetrate from the street. When the outside temperature drops, the grille prevents heat loss

It has a rectangular geometry and is made of plastic. The structure should cover not only the ventilation shaft, but also cover a little of the wall.

The mobile part visually looks like a petal, round or rectangular, although sometimes you can find an unusual shape - a “butterfly”. It only opens in one direction.

The valve for gratings is made of plastic, since it has to be used in conditions of aggressive moisture.

The flange in cross-section looks like a circle. Its diameter is from 11 to 15 cm. The valve is integrated into the air duct using a flange

This ventilation grill has a number of advantages:

- It will protect from both cold and too warm street air.

- No insects or dust will enter the room.

- The room will be protected from foreign odors.

- The presence of a noise-absorbing effect will prevent the penetration of extraneous sounds.

- Easy installation and maintenance.

- Aesthetic appearance of the decorative grille.

The main disadvantage is that if the temperature is below zero, the blinds or petals may freeze. To solve this problem, a heater is built into the system.

Recommendations for selection

There are so many types, types and varieties of valves on sale that you can be stumped: what to buy? Knowing the selection criteria will help you decide:

- the shape and size of the device must fit freely into the existing ventilation hole (duct). Therefore, before going to a retail outlet, it is necessary to take appropriate measurements of the hood: determine the diameter if the duct is round, and the width and height if it is rectangular or square;

- the material from which the devices are made. For household needs, the best option is plastic. Metal is purchased only in two cases: there is a membrane or damper with an electric drive or manual control;

- for natural exhaust ventilation, dampers are needed that open under weak air pressure: membrane or gravity with one blade;

- with weak draft, effective air exchange is possible only with forced ventilation. The fan can be installed both on the supply side - excess pressure in a private house or apartment will be vented into the exhaust duct - and on the exhaust hood. But with the second option, it is necessary, firstly, to install shut-off valves on other exhaust windows, and secondly, to check with the management company about the capabilities of the mine, so as not to create an excess volume of air flow - it will end up in the apartments located above. For example, if you install a check valve with an electric drive for ventilation in the kitchen, then the likelihood of reverse flow entering the toilet and bathroom not only from the ventilation shaft, but also from the exhaust kitchen air of your own apartment increases;

- The valve capacity (denoted by Kvs, measured in m3/hour) should be:

- for the kitchen - 60-90 m3/hour;

- bathroom - 25 m3/hour;

- toilet - 25 m3/hour;

- combined bathroom - 50 m3/hour. Data on the volume of air passed through during natural draft are indicated in the passport.

- installation location - many devices do not work in conditions of negative temperatures, for example, “butterflies”.

When is a grille with a check valve needed?

The advisability of installing a grille with a check valve is due to the presence of reverse draft in the ventilation system.

Therefore, if this phenomenon is absent, there is no urgent need for it, but for prevention it is still worth installing a grille.

A high-quality valve shutter should be so sensitive that it can quickly respond even to weak air movement

The following factors can cause backdraft:

- Lack of air flow into the room or reduction in its volume.

- Debris getting into the hole.

- Failure of elements that control air flow.

- Operation of high power hoods.

- The wind that was not taken into account when designing the house was constantly blowing.

- The presence of several pieces of equipment in the ventilation system, the air outflow operating simultaneously.

All these circumstances create conditions for the appearance of reverse thrust. In this case, pure oxygen does not enter the room. There is no guarantee that at least one of the listed factors will not appear. It is better to protect your ventilation system by installing a grille with a check valve.

Ventilation valve: where and how to install it

If the ventilation system is made without the use of fans and hoods with motors, it is called natural. In order for everything to work, valves are installed immediately at the outlet of the channels to block the backdraft. To maintain normal circulation, it is advisable not to use grilles that block the valve. Yes, this option looks better, but ventilation suffers. Most likely, it simply will not work with little traction.

If you still want to install a decorative ventilation grille in front of the valve, you will have to put up with worse ventilation, slower odor removal and excess moisture. Only installing a grille/valve with a larger diameter than calculated can help. In this case, air exchange will not be affected.

Natural ventilation works due to temperature differences and pressure differences

In the case of forced ventilation, the check valve can be placed either before or after the fan. This choice depends on the type of system and fan. Since ducted fan models are rarely used in private systems, it usually turns out that the damper is located after the fan in the pipe. How far is not important. The main criterion for choosing an installation location is ease of maintenance, since the damper will have to be periodically cleaned and checked.

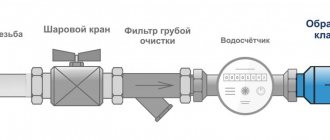

Installation in the kitchen with a hood

When installing a forced-air hood in the kitchen, many people want to maintain natural ventilation. To do this, you will need to install a tee at the entrance to the ventilation duct. Connect a hood with a check valve to one of its inputs, and install only a check valve in the second. As you can see, the system is not too complicated, but it works.

How to connect a hood so that natural ventilation remains

Why should there also be a check valve on the hood? Because if it is not there, the reverse flow of air may pass through the hood. Yes, this will not happen every time, but with a strong flow it will.

When installing this unit, try to ensure that the check valve for ventilation is located as high as possible under the ceiling. As a result, the warmest and most humid part of the air will be removed, which is very important for the kitchen.

For bathroom and toilet

The ventilation of the bathroom can have its own exhaust duct - then everything is easy, simple and clear. Before entering the ventilation duct, we install a check valve to block the flow of air that will move into the room. But not all apartments can boast of individual shafts for the bathroom and toilet. In some old-style houses, the exhaust duct is only in the toilet. Ventilation of the bathroom is done by running a duct through the wall. In this case, we install a check valve for ventilation not only at the outlet to the ventilation duct, but also in the duct between the bathroom and the toilet. This will prevent unpleasant odors from entering the bathroom.

How to install a check valve for ventilation in a separate bathroom with one ventilation duct

There is an even sadder situation: when there is only one exhaust duct and it is located in the kitchen. Actually, the installation logic does not change - the devices must be installed so that odors from one room do not enter another.

One check valve for ventilation is placed on the outlet to the dome hood (or on the channel that removes air from the kitchen), the second - on the pipe that comes from the bathroom. As you can see, if you understand the logic of operation, you can determine the most successful installation location yourself.

Design features

Any ventilation grille of this type consists of three components:

- Stationary part. A decorative grille that simultaneously acts as a full-fledged design element and a barrier that protects internal structural elements from damage. Most often, the lid has a rectangular shape, not only completely covering the body, but also partially protruding onto the wall surface for fastening.

- Movable part. It looks like a rectangular or round plate that can open only in one direction. The valve is often operated in conditions of high humidity, so the most suitable material for its manufacture is plastic.

- Flange for connecting the air duct.

Grate design with check valve

The standard diameter of the device can be from 110 to 150 mm. As a rule, such dimensions are sufficient to implement the vast majority of domestic ventilation system projects.

Features of operation

In frosty weather, a crust of ice may form on louvered grilles, causing the following problems:

- The flaps no longer completely block the outlet of the air duct, and the return flow of air into the apartment begins, although insignificant, but in cold weather it is very noticeable.

- The cross-section of the hole decreases due to frozen ice, the overall performance of the hood decreases, and the fans are overloaded.

Ice is removed mechanically, but the main thing here is not to overdo it and not remove the grate along with the ice. It makes sense to install a metal structure on the street instead of a plastic one.

In conclusion, we can conclude that by investing a relatively small amount in installing a grille with a check valve, breathing will become much easier, and in the literal sense of the word. A person can go without food for a month, without water for three days, and without air for one and a half to two minutes. Do not neglect the most necessary things, as necessary as air.

How does a ventilation grille with a check valve work?

The essence of the device’s operation can be described as follows. Contaminated exhaust air from the living room, kitchen or bathroom is removed from the premises. We are talking only about forced circulation systems, since the force of the natural air flow will not be enough to open the valve (with the exception of membrane-type devices).

The air flow from the fan, on the contrary, easily overcomes the damper resistance. The passage opens and air masses are removed from the room. As soon as the fan stops operating, the air flow stops and the damper returns to its original state.

The design of the valve is such that it easily opens only in one direction. If unwanted air flow from the street or from a ventilation shaft tends to enter the room, it will be reliably blocked by a damper tightly pressed to the body of the device.

Reasons for the formation of backdraft

Any home must have an air exchange system. If this is not done, air with a lower oxygen content (homeowners use it to support life), high humidity and dust accumulates in the premises. Waterlogging, dust and gas pollution, increased concentration of carbon dioxide (exhaled) lead to the development of various diseases.

In wooden houses, the exchange function is performed by walls, windows and doors, where air is removed from the house through wood (it “breathes”) and micro-cracks. In apartment buildings, ventilation shafts are installed for these purposes, to which apartments are connected using ducts. Air intake is taken from “dirty” or damp rooms: bathroom, bathroom, kitchen. The system has two tasks:

- remove excess moisture and odors to the street;

- create a reduced pressure in the apartment to bring in fresh air from outside.

This air exchange system is provided by supply and exhaust ventilation. The “golden rule” of its operation is based on the principle: at any given time, the volume of air removed from the apartment must be equal to the amount of air supplied.

If this balance is disturbed and the total air flow from the housing is higher, backdraft from the ventilation occurs. Experts name several reasons for this effect, grouping them by characteristics into external and internal. External reasons include:

- narrowing of the ventilation shaft. This effect is observed due to the settling of volatile fats (formed during cooking) on the walls of the channel, to which, in turn, dust adheres. As a result, draft overturning occurs on the upper floors of high-rise buildings: exhaust air enters the apartments;

- reducing the flow of clean air. Replacing wooden windows with metal-plastic ones disrupts the flow of air from the street - it becomes less. Under these conditions, the hood weakens. And, as soon as the temperature in any room with ventilation vents increases even slightly, for example, in a bathroom with a bathtub filled with hot water, the draft in it increases, and with it the volume of air removed increases. Compensation occurs due to the reverse flow of air from the ventilation duct in the kitchen or bathroom.

Internal factors include the installation of forced ventilation in the kitchen without taking into account the changing balance of inflow and outflow of the gas-air mixture, which leads to reverse draft (stray flow) in other rooms without ventilation.

You can give a dozen more reasons leading to the overturning of traction. But the examples given are enough to understand the essence of the difficulties that arise.

Device and principle of operation

A ventilation grille with a check valve consists of a protective housing, a mounting flange, a front decorative panel and a damper. The valve flap is able to open due to the forced circulation of air masses moving under a certain pressure. The grille is connected to the air duct using a flange, which is available in different sizes and is fully compatible with all types of air ducts. For the manufacture of grilles with a check valve, plastic is mainly used, which is due to the operation of the device in conditions of high humidity, where the use of metal components is impractical.

The principle of operation of the check valve is as follows: exhaust air masses leave the room through the decorative trim and, under a certain pressure, pass through the valve, lifting the damper. When the air flow pressure drops, the valve valve closes and acts as a reliable barrier to street dust, insects and unpleasant odors. Models are often installed in kitchens and bathrooms adjacent to similar rooms in neighboring apartments.

The check valve prevents the penetration of air masses and noise from adjacent rooms, which compares favorably with a conventional ventilation grille that is not equipped with additional protection. Installation of gratings can be done both from the side of the room and on the external wall of the building. The devices are connected to the end of the air duct, and the joints are additionally sealed.

Operation and care

The grille is used strictly in accordance with its functional purpose.

During operation, the following rules must be observed:

- do not clutter the hood with furniture or household items;

- monitor and clean the air duct annually;

- wash the decorative panel when dirty;

- check the mechanical condition of the valves or the integrity of the membrane.

If ice appears on the locking mechanism, it must be cleaned mechanically. If the device is plastic, you can melt the icing with warm air.

It is necessary to monitor the condition of the panel and air duct.

Advantages and disadvantages

Stable consumer demand and high popularity of grilles with a check valve are due to a number of undeniable advantages of these devices .

- The valve prevents the draft from tipping over and prevents the penetration of air masses from adjacent rooms or from the street.

- The high noise-absorbing effect reliably protects the room from extraneous sounds coming from neighboring rooms and street noise.

- The modern aesthetic appearance of decorative grilles allows devices to be placed in rooms for any purpose without the risk of cluttering the interior.

- Simple installation and low maintenance requirements make grilles one of the most practical devices for this purpose.

- The devices are available in a wide range with a wide variety of sizes, colors and designs. This greatly simplifies the selection of the desired model and allows you to purchase a grille to suit any interior.

- The low cost of products makes them even more accessible and popular.

The disadvantages of the devices include the risk of the dampers freezing in winter and the not very high performance of most models. However, the problem of freezing of the device is easily solved by installing a built-in heater.

Advantages of the device

The grid with a check valve is a simple and easy-to-use device characterized by a number of advantages:

- Prevents the penetration of cold or hot air from outside.

- Serves as a reliable barrier against dust and insects.

- Protects the room from the penetration of extraneous noise and unwanted odors.

- It is easy to install and maintain.

- Has an attractive design. A large assortment of such devices will allow you to easily select the grille that best suits the interior of the room.

Note! The check valve, although it acts as a reliable barrier to noise, dust and odors, does not provide complete tightness.

At sub-zero temperatures, the valve can freeze, which is easily solved by adding a heater to the system.

Main types of ventilation grilles

According to the type of locking device, a ventilation grille with a valve can be:

- single-leaf gravity;

- petal;

- membrane;

- butterfly

The principle of operation assumes that a correctly directed air flow lifts the locking device and passes freely into the air duct. The reverse flow presses the locking part against the supporting surface of the grille body and locks it.

A single-leaf gravity structure is a round or rectangular locking element eccentrically mounted on an axis.

The lightweight flexible membrane opens and closes with a low-intensity air flow. Typically, ventilation grilles with a check valve for natural ventilation are equipped with membranes made of lightweight synthetic materials.

The compact petal design is similar to gravity blinds.

Butterfly valves have locking flaps that fold when opened by air flow and are closed by a spring. Thanks to the spring they can be installed in any position.

Troubles that may arise

Everything seems clear and logical: foreign odors in the apartment are very unpleasant. Rollover in a private home is no less unpleasant, but also dangerous. In principle, with a correctly designed system, such phenomena should not occur and the causes of their occurrence must be dealt with. But not everyone has the opportunities and resources. It is easier to install a check valve for ventilation. This is true, but there are nuances that are worth knowing.

- A valve installed in the vent interferes with natural ventilation. If you want natural exhaust to work, you need to think through the connection so that the valves do not interfere.

- Even “quiet” plastic valves slam when closed, sometimes making quite loud sounds. These pops are stronger, the stronger the thrust. In variable winds they are very annoying. So you will have to come up with something to make the valve “quieter”.

This is the quietest valve - an elastic membrane, but not very reliable- Some fans or kitchen hoods have a built-in check valve. If the regular one doesn’t suit you for some reason, you need to delete it. Then you can install a separate one. Two valves on the same channel may not get along. Or rather, the exhaust duct is unlikely to work.

- For normal operation, the check valve must be regularly maintained - cleaned, checked, lubricated axles. Considering that it is not always easy to get to him, this is at least inconvenient. So provide access for cleaning and inspection.

As you can see, installing a check valve on the ventilation does not mean solving the problem once and for all. You will have to monitor the state of the system and put up with the shortcomings of this solution.

Materials and shapes of ventilation grilles with check valves

Depending on the materials, the ventilation grille with a check valve can be:

- plastic;

- metal made of galvanized steel.

The main material is lightweight, corrosion-resistant, inexpensive, easy-to-install plastic. However, it does not tolerate high temperatures and such products are more often used for indoor installation. For outdoor installation, metal models are usually used. To prevent winter freezing, heated structures are used.

In accordance with the shape, the ventilation grille with a check valve is available in the following cross-section types:

- round;

- square;

- rectangular section.

When choosing a specific grille, you should focus on operating conditions, the shape and size of the entrance to the ventilation duct.

The nuances of self-production

Self-production is advisable if the box has a non-standard geometric shape or dimensions. The simplest design is a membrane or single-leaf device. During manufacturing, it is necessary to monitor the tight fit of the sash, eliminating the knocking of the plate due to a change in the direction of the air stream.

Selection of materials

The most popular material for the production of ventilation systems is plastic. It is lightweight, does not corrode, and is cheap. However, it is better not to use it on the external parts of the channels.

Products made of galvanized steel can be used in conditions of frequent temperature changes: they are strong and durable.

However, this material is susceptible to corrosion and is heavy compared to plastic.

Choice of product shape

It all depends on the size of the duct. For small pipe sizes, you can use a round one. In other cases, a square or rectangular device is suitable.

Existing varieties of such gratings

There is a classification of ventilation grilles equipped with a valve.

Depending on the type of locking device, they are:

- gravity single-leaf;

- petal;

- membrane;

- butterfly

Ventilation grilles are made of plastic and galvanized metal.

Nowadays, ventilation grilles with a check valve are very popular. With their help, air flows are controlled. Such products are often used in bathrooms and toilets.

The former cannot tolerate sub-zero temperatures, so they are mainly used for indoor installation. They have light weight, high corrosion resistance, long service life, and low price.

Metal grilles are usually installed outside. To prevent them from freezing in winter, heating is used. The shape of the gratings can be rectangular or round.

They are characterized by high heat resistance, so they are used for installation in hot shops, large kitchens, and outside buildings. The big disadvantage of these products is their susceptibility to corrosion and heavy weight.

Type #1 - single-leaf gravity grille

This model has an extremely simple design. The locking element here has the shape of a circle or rectangle. It is a structure with a locking mechanism eccentrically fixed to the axis.

The work is based on the fact that the air flow, having the correct direction, moves the damper and then moves freely along the air duct. An air avalanche of reverse direction pulls the valve to the frame of the grille and closes it.

The working leaf of the gravity single-leaf grille opens under the influence of the pressure of air masses coming from the room. The advantage of the design is that it works automatically

There are two versions of such models - with a displaced damper mounting axis relative to the axis of the air duct pipe and with a counterweight located outside or inside the device.

The device is installed strictly vertically or horizontally. Otherwise, the damper will not close completely and will not provide adequate protection of the room from the outside atmosphere.

Type #2 - membrane type of device

This type of grating is the most common. Here, a light and flexible membrane acts as a sash. Since it has little resistance, it closes under the influence of gravity.

Due to its simplicity and reliability, the model is used in ventilation systems where air flow circulates naturally.

There are no mechanical elements or complex mechanisms in the design of the membrane grid, therefore, they are reliable and durable. The membrane itself is made of weightless synthetic material

To prevent membrane deformation as a result of increasing pressure of air jets in the system, these models are reinforced with stiffeners. The membrane partition rests on them if excess draft occurs.

Type #3 - petal grille models

The petal design is similar to the gravity model. Here the valve is shaped like a louvers. Its work is based on gravity.

In a basement or garage, it is better to install a galvanized petal grille. The valve regulates the air supply by turning it clockwise

The device functions more efficiently if it has several doors. The valve on such a grill can be installed only on the hole or over its entire area.

Type #4 - model with a butterfly-shaped locking device

The butterfly valve has two curtains. It closes under the influence of built-in springs. This model can be installed in any position.

Spring devices operate exclusively in ventilation systems with forced ventilation. They cannot work in networks with natural draft

Having chosen such a grille, you need to check how the springs work under the influence of air pressure. In the latest models, the spring force can be adjusted.

Kinds

The ventilation check valve can be made of metal or plastic. The metal is most often galvanized, less often stainless steel. There is also a small group with a plastic body and a metal damper - most often called a “combined check valve for ventilation.”

The check valve for ventilation is made of plastic and metal

How to choose on this basis? Just. Choose the material from which your air duct is made. There may be round or square models. Here again we choose the same shape as the existing/planned air ducts. Fortunately, the dimensions correspond to standard pipes used for air ducts.

Opening method

Check valves can open in different ways:

- Manual . The dampers are opened or closed manually; for this they have a special lever. This is not very convenient; in addition, due to their design features, they are not airtight, so they cannot completely block the penetration of foreign odors.

- Electrically driven . They are forced to open simultaneously with the fan or hood being turned on. Suitable only for ventilation systems with forced air removal (without natural circulation).

- Mechanical . The most common type. They open and close according to air movements. They can be used in combination with a fan or hood, or for natural ventilation.

In addition to mechanical ones, there are manual opening and electromechanical ones.

A manual check valve can be placed on an exhaust pipe with forced air removal that goes outside. This is what they sometimes do - they take them out not into the ventilation duct, but through the wall into the street. In this case, it is better to have a damper that will open only while the hood is operating. You can, of course, install a normally closed valve, but in cold weather it will freeze and stop performing its functions. Therefore, manual opening is more reliable in this case.

If the hood is vented outside through the wall

The most common are mechanical check valves. They are installed in approximately 90% of cases. Structurally, they can be of different types. Let's talk about them in more detail.

Mechanical valve shapes

Various dampers can be installed in the check valve. The force at which it will move back largely depends on the shape of the damper. If the valve will work with a fan or hood, it is important that the weakest fan operating mode can open the damper. They say that the fan must push through the valve. If you want to maintain natural ventilation, it is necessary that the damper can “work” even from slight air movement.

The designs and shapes of mechanical check valves for ventilation ducts can be as follows:

- With a solid rotary valve on the axis (clacker). This option is most common. This is a disk or rectangular piece that is movably mounted on an axis. Sometimes the axis runs through the center, sometimes it is shifted. This is a fairly popular model, as it does not have springs and can be installed in a system with natural air circulation. But there is a problem: when the damper is closed, a bang is heard. The stronger the pull, the louder the bang. This is annoying during the day, and at night it generally interferes with sleep. Because of this feature, this model is often called a “cracker”. Moreover, gaskets made of rubber and foam rubber do not help much. When installed for natural ventilation, the axis is oriented vertically. This is important, since in this position the opening force is minimal.

Types of dampers on check valves for ventilation - With a two-piece flap (butterfly). This option is only found in round valves. There is also an axle. There are two half-disks attached to it, which are held in the closed position by springs. The springs are weak; even a not too strong flow can open them. But with a weak breeze, natural ventilation may not work.

- Membrane. Flexible plastic is used as a damper. This option seems to be the most preferable - the membrane should open more easily. In fact, diaphragm valves perform worse than others. At first they can actually respond to even slight air movement. As dust and soot accumulate, they become heavier and, after a while, stick.

The diaphragm valve looks so movable

Choosing a valve for ventilation is indeed not easy. If you are guided by what the majority uses, you will have to settle on a firecracker. Despite all its shortcomings, it works more reliably and opens even with natural ventilation. The most effective way to make the clapper quieter is to take silicone sealant and apply it to the thrust ring on the body (do not apply it to the disk, as it will become heavier, which means it will be more difficult to turn). Lubricate the valve disc with soapy water and press it against the sealant ring until polymerization begins. Then we move the valve away, we get an o-ring that dampens the pops. The result is an almost silent closing, and almost airtight.

How to choose a grille with a valve

Before choosing a specific grille model with a check valve, you should focus on some important points:

- Carefully inspect the ventilation shaft opening, assess its condition and measure geometric parameters.

- Pay attention to the manufacturer. Slightly more expensive models under a well-known brand are a guarantee of quality and durability. Of course, you can find high-quality and reliable products from less famous brands.

- When purchasing a ventilation grill, it would be a good idea to ask the seller for a quality certificate. This document will not only provide comprehensive information about the product, but will also serve as an additional guarantee of quality.

Note! It is important that the device is made from environmentally friendly materials and fully complies with all standards and requirements.

Progress

The easiest mechanism to manufacture is a membrane (petal) valve. The manufacturing sequence is as follows:

- A metal plate or piece of plastic is suitable for decorating a curtain.

- Thick paper is used instead of a membrane. The main thing is that it should be larger in size than the ventilation hole.

- The curtain is attached as tightly as possible to the edges of the body.

- A grill is installed on the device. This is necessary to prevent membrane deformation.

A self-made part can be used for its intended purpose.

Installation Tips

Due to the simple design and low weight of the gratings, their installation can be carried out independently. The exhaust grille should be installed on the surface of the wall, however, some models can be mounted in a ventilation shaft. The first stage of installation should be connecting the device to the air duct, which is done using a connecting flange. It is recommended to foam the space between the air duct and the wall. Next, you should wait until the polyurethane foam hardens, and then remove its excess using a stationery or construction knife.

The next step will be fixing the grille to the load-bearing surface, which is done using self-tapping screws or dowels . The choice of fastening element depends on the weight of the model and the material used to make the walls of the building and the body of the device. Once the grille is in place, you can begin a test run of the device. Ventilation grilles with a check valve are an important part of exhaust ventilation. The devices reliably protect the space from external flows and help create a favorable indoor microclimate.

Rules for the placement and installation of a ventilation grille with a valve

The basic rule is that the system should be installed in such a way that there is no reverse draft when fans and hoods are turned on or off.

If the system has only one air intake point, from which it is directed to the street through an air duct, then installing one valve will be sufficient. In the case of a more complex ventilation topology, the following rules are followed:

- A valve is installed at each air intake point to avoid backdraft at this location.

- At the point where the air duct exits to the street, another valve is installed, for prevention - there will be no reverse draft without it only if the air duct is completely sealed.

Check valves are installed so that they are easy to reach and care for – remove dirt and grease so that they do not stick.

Before installing the valve, you should make sure that the manufacturer has not installed its own device in the air duct; if it is already there, there is no need to install it.

In addition to foreign odors from neighboring apartments, the ventilation shafts of apartment buildings are inhabited by birds, rats, and insects. Their waste products are not particularly sanitary, so in such systems the use of forced ventilation is mandatory. The access of air from the air duct back into the room should be prevented. You should not count on management companies to be conscientious in carrying out cleanup work.

Installation of ventilation grille

Before installation, a ventilation grille with a backdraft valve is checked to ensure that the valve is properly oriented so that the correct air flow will open the locking element. You should also carefully study the product passport and fully comply with all the requirements given therein.

If the kit does not include fasteners, you must purchase the required products. The surface is being prepared for installation of the grille flange. Places for fasteners are marked, holes are made for dowels, and dowels are installed. The product is installed with self-tapping screws. After installing the grille with an effective non-return valve for ventilation, leaks in the joints are sealed.

Installation instructions

To install a check valve for ventilation with your own hands, you will need:

- the valve itself;

- dowels with self-tapping screws;

- electric drill;

- perforator;

- silicone sealant.

Correct order of work:

- the equipment is checked (the list is given on the insert), although this is best done during the purchase process;

- the fan, if standing, is dismantled;

- the new fan is installed in place;

- marks are made on the wall for fasteners;

- Using a hammer drill, a groove is cut out in the wall for electrical wiring. The channel can be replaced with a plastic box or retro wiring, which, on the one hand, looks impressive, on the other hand, is expensive, and the wiring can be done directly along the wall;

- use an electric drill or hammer drill to drill holes for dowels;

- the fan is inserted into the air duct and fixed with self-tapping screws;

- wiring is connected;

- the connection between the fan and the wall is sealed with silicone sealant (some sets provide a rubber seal for this purpose);

- the operation of the fan is checked;

- At the fan inlet, a mesh is first installed, and then a check valve is installed for ventilation. If it is gravitational, check the horizon of the damper axis - if it is deflected, the petal may not close;

- the operation of the system as a whole is tested;

- a decorative cover is installed.

No instructions are needed to install valves at natural draft collection points. Everything is extremely simple there. The work progress is described in the instructions printed on the insert.

Valve installation diagram for natural (petal) and forced (butterfly) draft.

Selection rules

The choice of model depends on the design of the room and the design features of the ventilation.

The choice of grille element depends on the design features of a specific ventilation system; in some cases, the parameters are specified in advance. You can also select a part using special monograms designed for specific requirements. For large systems, the main selection criteria are air flow and air speed, so they require custom-made grilles and equipped with a special regulator. In addition to technical requirements, attention must be paid to aesthetics and design of elements.

In most cases, the choice of a specific model depends on the shade of the part, the need for adjustable blinds and a fine mesh. Additionally, noise and aerodynamic properties, characteristics and areas for installation, and installation location, for example, on the floor, ceiling, wall or door, are checked. An important parameter is the absence of problems during maintenance, the size of the air duct or opening, as well as the ability to consume air during operation. At the beginning, you should always take into account the dimensions of the ventilation duct and its geometry, as well as operating conditions.

The choice of gratings for industrial premises should be entrusted to professionals. If we are talking about parts for apartments or houses, you can select them yourself if you have a design or diagram of the ventilation system.

Possible problems

During operation of the device, the following troubles may occur:

- valve jamming (the reason is a violation of the position of the element during installation);

- icing of valves;

- deformation of the locking mechanism (this can happen in cheap models with high traction);

- the appearance of unpleasant pops when closing the sash.

It must be taken into account that the valve prevents the natural movement of air. If this is unacceptable, then it is better to remove the element.

Installation and operation

The hood grille is installed on the outside of the house

A ventilation grille with a check valve for natural flow ventilation is installed on the outer part of the wall; some parts are allowed to be fixed in ventilation shafts. At the first stage, the device is connected to the air duct using a connecting flange, filling the gap between it and the wall using sealant. After the foam has hardened, its excess is removed with a stationery or construction knife.

At the next stage, the grille must be fixed to the load-bearing surface using dowels or self-tapping screws. You need to select a fastening element taking into account the weight of the part and the material from which the walls of the building and the body of the grille are made. After completing the installation work, the device can be started in test mode. If the installation is carried out correctly and without errors, in compliance with all requirements and safety rules, the grille will operate as stably as possible.

A properly installed grille with check valve is an important part of the hood and ventilation system. With its help, you can reliably protect the air duct from external flows and create an ideal microclimate in the room.

How to make effective ventilation - general principles

With proper design, the exhaust vent when installing this type of climate control equipment should be on the ceiling or on top of the wall, at least 10 cm from it.

Because warm air is expelled through it. In its place comes fresh and cold. But in reality, in many rooms everything is different - the ventilation hole is made quite low. Warm light air cannot sink lower to escape through the grille. This creates a stagnation zone located above the hood.

Another mistake in ventilation design is that the pipes are installed at a lower height than they should be. The pressure difference is minimal and this prevents the hood from working efficiently.

Often in private homes, in order to save money, they make one ventilation shaft for two rooms next door. Because of this, air can move freely, and odors along with it. It turns out that the exhaust air masses are not removed, but “transfer” them into the room. This state of affairs is completely wrong, and in order to avoid such a situation, one should not skimp on developing proper ventilation.

A fireplace also often causes ineffective operation of the ventilation system. When the fuel burns, the amount of oxygen also decreases, and air is pumped out of the hood.

A ceiling grille with a built-in check valve helps to establish a healthy microclimate in the house, and does not require a lot of money or highly qualified installation specialists to equip it with it. Recently, this climate control technology has become a component of modern ventilation in every home and even office. When done well, it will give you fresh air and great well-being.

Front and rear view of grilles

Membrane

Diaphragm valves are used in non-forced ventilation systems because the diaphragm changes position when the flow is low. But this feature has a downside.

Due to strong pressure in the pipe, the membrane can become deformed and lose its properties. To prevent bending, additional stiffening ribs are installed.

These valves should not be installed for powerful exhaust or with strong reverse draft.

The most common valves are suitable for most hoods installed in kitchens of apartment buildings.

Blinds

Air valves in the form of blinds have become widespread. The principle of operation is gravitational - without air pressure in the pipeline, the petals hang in a vertical position, closing the channel from reverse draft.

The gratings are made in standard sizes. Unlike single-leaf options, smaller doors open more easily for the outgoing air flow and close easily with reverse draft.

Such petal models are used, as a rule, at the exit of ventilation systems to the street. The blind system is made of metal plates that are more resistant to temperature changes.

The disadvantages are the likelihood of corrosion over time when the coating wears off, and greater weight compared to plastic.

Do not use without exhaust devices!

Butterflies

Butterfly valves include two curtains and close under the influence of springs installed in them. These grilles can be placed in different positions; when choosing, check the operation of the springs under the influence of air pressure in advance. More innovative options allow you to change the spring force. It should be taken into account that butterfly devices only work in systems with forced ventilation and are not suitable for schemes with natural draft.

Petalaceae

Petal variants have a structure similar to their gravitational counterparts. They contain valves in the form of blinds, the operation of which is based on the principle of gravity. If there are several doors, such devices function much better. Valves can be placed on them only over the entire area or on one hole.

A ventilation grille with a petal valve is considered the most versatile and practical.

Gravity single leaf

Such models are a standard design with a locking element in the shape of a circle or rectangle. Their operating principle is to move the damper part with the help of a flow of air in the correct direction, which then continues to move freely along the air duct. Then the valve is pulled to the base of the ventilation grille and closes it. Gravity elements are presented in two types: with an offset axis where the damper is fixed, and with an internal or external counterweight. The device must be installed vertically or horizontally, otherwise the lid will not close completely and will not protect the room.

Single-leaf product based on gravitational action

Such a device operates on flows directed from the room with pressure exerted on the valve leaf. In the presence of reverse draft, there is no pressure, and the flap closes under the influence of gravity.

This device is used with natural ventilation. When installing, be sure to observe the placement of the valve based on its design features. This is done horizontally or vertically.

Photo 1. Scheme of installing the product horizontally and vertically.

Types of design solutions for check valves

There are four main options for preventing backdraft into the ventilation system. Each option has strengths and weaknesses; the choice of a particular option depends on specific conditions:

Single-leaf gravity valve

The principle of operation is based on the use of the law of gravity; the sash closes under the influence of gravity in the absence of draft from the room. It is carried out in two versions for horizontal and vertical installation - opening occurs either due to the displacement of the axis on which the leaf is mounted relative to the center of the air duct, or due to a counterweight located in the device (or outside the device).

Butterfly valve using springs

It is also called a “butterfly” due to the similarity of the damper petals to wings, folding when there is excess air pressure and expanding when there is no draft. Does not depend on gravity and is placed in the ventilation system at any angle. By tensioning and loosening the springs, the valve's sensitivity to pressure changes is adjusted. Most install butterfly valves in forced exhaust ventilation systems.

Blinds for ventilation grilles

The operating principle of the device is gravitational, it is placed outside the system and looks like a grille covering the air duct from the street. There are valve options for the entire grille and the size of the air duct opening being closed. Due to the small size and mass of the petals, it is suitable for natural ventilation.

Flexible membrane

The design is very sensitive to air flow, therefore it is used in both natural and forced ventilation. When air moves in one direction, the membrane bends, allowing air to circulate freely, and when the air direction changes, the membrane unbends and closes the air duct.

Double leaf version with springs

The valve, in the form of a butterfly, has two curtains in its structure. They fold under the influence of pressure forces from a certain side or slam shut when there is no pressure factor. The slamming mechanism is due to the action of built-in springs.

Such a device can be placed on the floor at any angle.

As practice shows, such a device works clearly in the presence of a hood. When purchasing such a device, be sure to test the springs for air pressure. Modern devices require adjusting the force of the springs.

Types of valves

The valve is designed in such a way that it directs air masses only towards the shaft, but not back. It is made in the shape of a “butterfly”, square or round (according to the cross-sectional shape). It has petals attached to its axis; they close the entrance to the reverse thrust. The butterfly can be installed in any position.

When the valve is made in the form of a square or circle, the principle of their operation is the same as that of “butterflies”.

The inertial grille can also serve as a valve; it is mounted outside. Blinds open only in one direction. When the grille is turned off, they are closed.

If there is no check valve, condensation will occur on the product and in the exhaust shaft itself, and drafts will also become possible.

Depending on the heating method, the valves are distinguished:

- with electric heating - do not fail in winter;

- without electrical heating - used indoors.

In hoods where large drafts occur, an explosion-proof check valve is used.

Blinds on the ventilation grille

The valve installed on the outdoor grille may be in the form of a louvers. The operating principle is similar to a single-leaf product and is based on gravity. When using several sashes, the operation of the device is more efficient. Dimensions are based on possible hole patterns. The valve can be installed over the entire grille area or exclusively on the hole.

Photo 2. An example of ventilation grilles with blinds.

Advantages and operating principle

Conventional ventilation grilles allow air to flow in both directions. This can be a big disadvantage when it is either very cold or hot outside. It is also possible that various unpleasant odors will sometimes be heard from the mine. And add flies, mosquitoes, dust to this and it doesn’t turn out good at all.

Advantages of a ventilation grille with a built-in valve:

- has protection against insects, dust, debris;

- reduces the noise level, as it is equipped with a special noise absorber;

- blocks access to cold air in winter and hot air in summer;

- prevents odors from entering the room where it is used from the mine or nearby apartments.

The disadvantage of the device is that the petals sometimes freeze in winter when it is frosty outside. Then the ventilation does not perform its function. This disadvantage can be neutralized by installing this structure in the hood area.

Use of flexible membranes

The use of a membrane version of the valve is due to the action of the air flow, which will change the position of the plate.

One direction of flow serves to open the membrane, the other vector of pressure closes it. A strong backdraft process can deform the plate. To avoid such a situation, you need to purchase a product with stiffeners. If you try to save money and buy a device without ribs, then there is a possibility of deformation of the product. The result will be the passage of air in an unwanted vector.

Sources

- https://sovet-ingenera.com/vent/montazh/ventilyacionnaya-reshetka-s-obratnym-klapanom.html

- https://TopVentilyaciya.ru/ventilyaciya/elementy/reshetka-s-klapanom.html

- https://stroy-podskazka.ru/ventilyaciya/reshetki-s-obratnym-klapanom/

- https://ventilaciya.info/ventilyatsiya/ventilyatsionnaya-reshetka-s-obratnym-klapanom.html

- https://StrojDvor.ru/ventilyaciya/ustrojstvo-ventilyacionnoj-reshetki-s-klapanom-obratnoj-tyagi/

- https://oventilyacii.ru/ventilyaciya/ventilyatsionnaya-reshetka-s-obratnym-klapanom.html

[collapse]

Is it possible to make a check valve with your own hands?

Why buy a check valve when you can make it yourself. Of course, not electronic, but working effectively. How to make a check valve for ventilation with your own hands has already been discussed above (primitive membrane).

The second valve option is a modernized “butterfly”. You will need:

- decorative ventilation grille;

- a sheet of thin, soft plastic, like film from a fluorographic apparatus;

- knife or scissors;

- hot glue gun.

The film is cut so that its shape can completely cover the inlet hole in the grille. In this case, IMPORTANT, small ears are left in the middle on both sides, for which the future shutter will be glued to the grille body. After this, the plate is bent exactly in the middle by 45° and glued. You can’t bend it completely, otherwise it won’t close. The grate is put in place. The valve is ready.

One of the options for a homemade valve.

This same idea can be framed differently. Cut a rectangular sheet of paper in the middle. Glue the edges to the grill. The principle is clearly visible in the photo below.

Homemade check valve.

Similar systems were installed in Rus' in the chimneys of Russian stoves to prevent frost from creeping into the house in winter.

Purpose of a check valve in ventilation

A check valve for ventilation is needed to prevent the draft from tipping over. Why this might happen:

- There is not enough supply air (there is no supply ventilation, or it is clogged and does not function).

- Incorrect location of the exhaust pipe on the roof (in the wind shadow area).

- If the apartment has several exhaust openings, and in one of them, for some reason, the draft increases (for example, the time when one fan turned off coincided with the intense operation of another).

- A similar situation occurs in houses with stove heating. In the chimney, during combustion, the draft increases, and in the channel with natural ventilation a reverse current is obtained.

- The role of a powerful hood can also be played by a staircase in a two-story cottage.

- In multi-storey buildings, intensive forced exhaust in one apartment can disrupt the flow of flows in other apartments.

- Reverse draft can lead not only to the penetration of foreign odors, but also to gas poisoning and frost entering the house during periods when the ventilation is turned off.

Check for proper draft using a candle flame or a sheet of paper. You need to open the window and bring the leaf to the ventilation hole. If the flow is “correct”, the paper will not fall, but will remain hanging on the wall.