An unpleasant surprise for homeowners is the appearance of unpleasant odors in the kitchen, bathroom, toilet, and then throughout the apartment. Almost immediately, cause-and-effect relationships are established: due to the occurrence of reverse draft, air flows from the ventilation vent connected to the ventilation duct - an element of natural ventilation of the apartment or house.

Many residents solve the problem simply: they seal the ventilation windows or install mechanical plugs that open as needed: cooking starts in the kitchen - the device opens, ends - it closes. The method works by removing emerging odors. But in this case, apartment dwellers are in for an even bigger surprise: stale, waterlogged air appears in all rooms. As a result, family members develop problems with the respiratory system, and mold and mildew begin to grow rapidly on the walls in different places.

The solution to the problem is completely different: you need to block the path of air flow from the hood, maintaining a free exit of air from all rooms of the living space. The problem is solved by installing a check valve for ventilation. The method does not require changes to the existing air exchange scheme or significant financial expenditure.

To get a positive result, you need to know how a ventilation check valve works, its design features, pros and cons, and installation features.

The editors of the StroyGuru portal have prepared material with photos and videos explaining the principles of operation of the back draft valve for ventilation and how to install it with step-by-step instructions. In addition, it is discussed in detail how to make a check valve for ventilation yourself.

Before we take a closer look at the simple device, let’s find out the principle of organizing air exchange in apartments, which will allow us to understand the reasons for the occurrence of reverse draft and ways to combat it.

Reasons for the formation of backdraft

Any home must have an air exchange system. If this is not done, air with a lower oxygen content (homeowners use it to support life), high humidity and dust accumulates in the premises. Waterlogging, dust and gas pollution, increased concentration of carbon dioxide (exhaled) lead to the development of various diseases.

In wooden houses, the exchange function is performed by walls, windows and doors, where air is removed from the house through wood (it “breathes”) and micro-cracks. In apartment buildings, ventilation shafts are installed for these purposes, to which apartments are connected using ducts. Air intake is taken from “dirty” or damp rooms: bathroom, bathroom, kitchen. The system has two tasks:

- remove excess moisture and odors to the street;

- create a reduced pressure in the apartment to bring in fresh air from outside.

This air exchange system is provided by supply and exhaust ventilation. The “golden rule” of its operation is based on the principle: at any given time, the volume of air removed from the apartment must be equal to the amount of air supplied.

If this balance is disturbed and the total air flow from the housing is higher, backdraft from the ventilation occurs. Experts name several reasons for this effect, grouping them by characteristics into external and internal. External reasons include:

- narrowing of the ventilation shaft. This effect is observed due to the settling of volatile fats (formed during cooking) on the walls of the channel, to which, in turn, dust adheres. As a result, draft overturning occurs on the upper floors of high-rise buildings: exhaust air enters the apartments;

- reducing the flow of clean air. Replacing wooden windows with metal-plastic ones disrupts the flow of air from the street - it becomes less. Under these conditions, the hood weakens. And, as soon as the temperature in any room with ventilation vents increases even slightly, for example, in a bathroom with a bathtub filled with hot water, the draft in it increases, and with it the volume of air removed increases. Compensation occurs due to the reverse flow of air from the ventilation duct in the kitchen or bathroom.

Internal factors include the installation of forced ventilation in the kitchen without taking into account the changing balance of inflow and outflow of the gas-air mixture, which leads to reverse draft (stray flow) in other rooms without ventilation.

You can give a dozen more reasons leading to the overturning of traction. But the examples given are enough to understand the essence of the difficulties that arise.

Advice from the experts

Wall-mounted models are recommended for installation during the construction of walls, but they can also be installed in finished premises. It is not recommended to install window valves yourself - it is easy to break the tightness of the window frames and lose the manufacturer's warranty service. However, the most important thing is to choose the right type of additional ventilation you need. Poorly selected models can clog the natural ventilation system of rooms, overturn it, or create uncomfortable conditions due to the additional noise of the operating fan.

Why do you need a check valve for ventilation?

The problem of backdraft from ventilation can be solved in two ways:

- install forced supply ventilation, which, by creating excess pressure in the apartment, blocks return flows from the hood;

- use a check valve for ventilation in the apartment.

In the first case, financial investments are needed, which consist of the cost of the fan and the work required to install it, as well as constant spending of the family budget on electricity bills.

In the second case, you can buy an inexpensive, simple check ventilation valve, install it yourself and forget about the problem for many years. The device properly and easily passes air flows in one direction, outward. As soon as the flow weakens or changes direction, the shutter instantly blocks the ventilation duct. This is why a check valve is needed in ventilation.

Advantages and disadvantages

The supply valve has a number of positive qualities:

- there is no need to constantly open/close the window (the service life of the fittings is extended);

- low noise level;

- air flow can be adjusted;

- installation next to a heating radiator or at the top of the wall eliminates temperature fluctuations in winter;

- the device is almost invisible indoors;

- relatively affordable price.

But there are also some disadvantages:

- you need to make a hole in the wall;

- In regions with severe frosts in winter, a regular valve cannot be used; the room will be cold. The problem can be solved by installing a valve with a recuperator;

- errors in installation can result in freezing of the wall or freezing of a certain part of the air duct;

- Low performance of devices without a fan.

Principle of operation

The non-return ventilation valve is not a complex device. His work is based on the idea of building a shutter into the air duct, which can only allow flow in one direction. During standard air movement it is open, but when it stops or when counter flows occur, it closes. The device operates automatically, without human intervention.

Operating principle of a diaphragm valve.

This principle of blocking reverse thrust is embodied in several types of devices, each of which has varieties (modifications).

TOP 3 models for production sites

TEKHNOTSENTR LLC general industrial valve 150x150

A reliable device that is designed to remove large volumes of contaminated air. Adjustment is carried out manually using a special handle. Thanks to this solution, the product can be installed in one position, which contributes to good ventilation of the room.

The average price is 16,300 rubles.

TEKHNOTSENTR LLC general industrial valve 150x150

Advantages:

- Simple controls;

- High throughput;

- Durable housing;

- Reliability.

Flaws:

- High price.

Production valve KOP from TD "COMTECH"

An excellent option that is suitable for installation in large rooms. The body is made of durable material that is not subject to corrosion. Adjustment is carried out using a special lever.

Average price – 1,200 rubles

valve Production valve KOP from TD "COMTECH"

Advantages:

- Durability;

- High-quality execution;

- Removes air quickly;

- Optimal cost;

- Convenient controls.

Flaws:

- Not found.

TCOG-05-250x500 from Vympel LLC

An excellent valve that will help organize proper ventilation of the room and eliminate toxic and unpleasant odors in a few minutes. The body is made of a thick layer of metal, which increases durability and increases the reliability of the device.

Sold at a price of 8,800 rubles.

valve ТКОГ-05-250х500 from Vympel LLC

Advantages:

- Efficiency;

- Quickly removes contaminated air;

- Lasting;

- Easy adjustment.

Flaws:

- Not found.

Types of check valves

In scientific and popular science literature, a check air valve for ventilation is classified according to many parameters:

- operating principle;

- device form;

- material of manufacture;

- installation method;

- control method;

- type of construction.

We especially emphasize that specialists do not always have a common point of view on the distinctive features of individual valve models that allow them to be classified into any classification group. Let's try to sort out the confusion.

According to the principle of action. In the classic version, all locking devices according to their operating principle are divided into gravitational and mechanical. The separation is based on the method of blocking the air channel. In gravitational devices, the shutter closes the channel under its own gravity. This ability appears in two cases:

- the sash fastening axis is fixed above the middle of the channel. As a result, when the air flow weakens, the heavier bottom falls, blocking the air duct;

- A small weight is attached to the bottom of the petal, acting as a counterweight. In this case, the location of the axle attachment does not play a significant role.

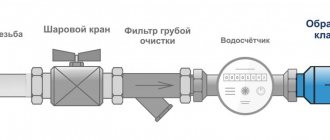

Reed check valve design. 1 - body with a flange connection (there is also a bell-type connection, when it is simply inserted inside) 2 - flap on an eccentric axis 3 - rim, to which the damper is pressed in the “closed” position 4 - damper mounting axis 5 - adjustment lever 6 - counterweight

With mechanical devices, the reverse thrust is blocked under the influence of springs on the sash.

But this classification does not include membrane devices that allow flow in one direction under the pressure of an air stream. There are two ways out of this situation.

- Add a third characteristic of the parameter: add a membrane principle to the gravitational and mechanical principles of operation.

- Replace the mechanical method of blocking the channel with a forced one, which will have two subtypes: mechanical and membrane.

According to the form. A forced or gravity check valve for ventilation can be round, rectangular or square.

Rectangular valve.

In residential construction, mainly round devices with a diameter of 100-125 mm are used. Rectangular and square systems are designed for public buildings and industrial production.

According to the material. The materials for the manufacture of locking devices can be plastic, galvanized steel and aluminum. Plastic models have become most popular among the population. They have many advantages:

- affordable price;

- light weight;

- silent operation.

Plastic valve.

The disadvantages include a shorter service life compared to metal counterparts and poor resistance to aggressive environments.

Industrial versions of the valve are made from metal. They are heavier and more reliable. But there are disadvantages: in the removed air there are various chemically active substances in a dusty state, which corrode the zinc, after which the process of oxidation of the steel starts (it rusts). And condensation settles on aluminum dampers.

Metal valves.

According to the installation method. The valve can be mounted horizontally or vertically. The need for such an installation is dictated by the design of the air duct and the type of ventilation: supply or exhaust. At the same time, only devices with a forced operating principle operate in a vertical position.

Control method. The shutter control can be:

- automatic - the position of the damper is determined by the strength of the air flow;

- manual - adjusted by the homeowner using a valve, valve or lever. Used in natural ventilation of both types (supply and exhaust);

Locking device with manual adjustment.

- electric - the volume of air passing through the duct is controlled using touch sensors operating in the same system as the fan.

Type of construction. Structurally, the check valve can be: membrane; petal; butterfly; lattice.

In the membrane version, a very thin flap (membrane) is attached to the valve outlet, which opens the outlet from the device channel at the slightest breath. When the flow direction changes, it is pressed tightly against the grid, which fixes its stable position.

Diaphragm valve.

You can make such a locking device yourself. To do this, on the back side of the ventilation grille, to its top, you need to glue a thin lavsan or food grade polyethylene film, cut to the shape of the channel, but slightly larger. During exhaust, such a damper perfectly allows air flow to pass through, and when reverse draft occurs, it sticks to the grille, blocking the exhaust hole.

In a reed valve, a rigid flap is mounted on an axis on which it rotates freely through 90o, but only in one direction. In gravitational types of devices, the center line passes above the center. Thanks to this, the channel opens under the pressure of the flow. When changing the direction of movement, it closes - the lower part of the damper lowers under the influence of gravity. This valve model can only be installed in a horizontal position.

Reed valve.

In mechanical locking systems, an electric motor or magnets open and close the damper. A standard technique: a loss of power supply lowers the damper, blocking reverse flows. In case of a power outage, manual adjustment of the damper position is provided. Can be installed in any position: horizontally, at an angle, vertically.

In mechanical valves there is an option, although not very popular, when instead of one petal two are used. This is the so-called butterfly. Sometimes they say "cracker". The principle of operation is the same as that of a device with one plate: under air pressure, the petals fold like the wings of butterflies, opening the way for the flow. When the pressure is released, the plates return to the “closed” position under the influence of counterweights or springs. Such systems only work in a horizontal position. Minus - they do not open with low air flow.

Butterfly valve with springs.

An inertial ventilation grille with a check valve (also called “blinds”) is a gravitational type of device. It is installed either at the outlet of the ventilation duct, i.e. on the roof - prevents the draft from being overturned by the wind, or in a ventilation duct with forced air supply. In the apartment, the force of the air flow is not enough to open several plates mounted on hinges parallel to each other.

Inertial ventilation grille.

Rating of the best models of the “Butterfly” type

ERA 12SKTs 120mm

A classic product that is suitable for installation in public places or at home. The flaps operate at low pressure, which facilitates rapid removal of air. For greater efficiency, the blades are equipped with special springs. Fastening is carried out using clamps. A damper seal ring is located inside the structure.

The average cost is 275 rubles.

valve ERA 12SKTs 120mm

Advantages:

- Long service life;

- Reliability;

- Spring-loaded blades;

- Sealing ring;

- Easy installation.

Flaws:

- Not detected.

Shuft RSK 100

A universal device that can be placed anywhere, including outdoors. Withstands temperatures down to -40 degrees and is not subject to corrosion. The body is made of high quality steel, which is covered with a protective layer. To prevent the blades from knocking while moving, there is a rubber seal that absorbs all noise.

Sold at a price of 290 rubles.

valve Shuft RSK 100

Advantages:

- Durability;

- High-quality case;

- Does not make noise;

- Optimal price.

Flaws:

- Not found.

Polar Bear RSK 355 "butterfly"

A good valve that operates automatically and does not make much noise. The body is made of galvanized steel. Behind the blades there is a damper ring that absorbs excess noise and does not distract a person from work. The valve can be installed in any position, which is a big advantage.

Sold at a price of 1,280 rubles.

Polar Bear RSK 355 butterfly valve

Advantages:

- High service life;

- Reliability;

- Automatic adjustment;

- Tight fit;

- The blades are made of aluminum.

Flaws:

- High price.

Recommendations for selection

There are so many types, types and varieties of valves on sale that you can be stumped: what to buy? Knowing the selection criteria will help you decide:

- the shape and size of the device must fit freely into the existing ventilation hole (duct). Therefore, before going to a retail outlet, it is necessary to take appropriate measurements of the hood: determine the diameter if the duct is round, and the width and height if it is rectangular or square;

- the material from which the devices are made. For household needs, the best option is plastic. Metal is purchased only in two cases: there is a membrane or damper with an electric drive or manual control;

- for natural exhaust ventilation, dampers are needed that open under weak air pressure: membrane or gravity with one blade;

- with weak draft, effective air exchange is possible only with forced ventilation. The fan can be installed both on the supply side - excess pressure in a private house or apartment will be vented into the exhaust duct - and on the exhaust hood. But with the second option, it is necessary, firstly, to install shut-off valves on other exhaust windows, and secondly, to check with the management company about the capabilities of the mine, so as not to create an excess volume of air flow - it will end up in the apartments located above. For example, if you install a check valve with an electric drive for ventilation in the kitchen, then the likelihood of reverse flow entering the toilet and bathroom not only from the ventilation shaft, but also from the exhaust kitchen air of your own apartment increases;

- The valve capacity (denoted by Kvs, measured in m3/hour) should be:

- for the kitchen - 60-90 m3/hour;

- bathroom - 25 m3/hour;

- toilet - 25 m3/hour;

- combined bathroom - 50 m3/hour. Data on the volume of air passed through during natural draft are indicated in the passport.

- installation location - many devices do not work in conditions of negative temperatures, for example, “butterflies”.

Rating of quality models with grilles

Grille with valve from Revizzona LLC

A classic device designed for installation in residential and office premises. The operation is completely silent. The main feature of the design is its tight fit to the walls, which makes it unnecessary to use sealant.

Sold at a price of 500 rubles.

Grille with valve from Revizzona LLC

Advantages:

- Beautiful appearance;

- Good ventilation;

- Tight fit;

- Bandwidth;

- Easy installation.

Flaws:

- Not found.

AURAMAX S 5S S

A beautiful, modern product designed for installation in residential areas. The design includes a fan and a check valve, which increases efficiency significantly and eliminates even minor odors. The product is made of plastic. Provides a tight fit to the wall.

The average price is 1,600 rubles.

valve AURAMAX C 5S C

Advantages:

- Fan and check valve;

- Efficiency;

- Durability;

- Tight fit to the wall.

Flaws:

- High price.

Ventilation grille made of ABS from Revizzona

An excellent product that will purify the air and decorate the room. The grille is equipped with a check valve that is activated at the slightest air fluctuation. Installation does not take much time and can be carried out by an ordinary person.

Sold at a price of 450 rubles.

Ventilation grille made of ABS from Revizzona

Advantages:

- High service life;

- Works quickly;

- Removes excess odors;

- Doesn't make noise.

Flaws:

- Not detected.

Choosing an installation location

Choosing the correct location for installing the check valve is possible only if a number of requirements are met:

- when taking exhaust air in one place, regardless of whether it is connected to the shaft or goes outside, it is enough to install one valve at the inlet;

- with a branched exhaust ventilation system - there are several independent hoods or windows of one channel - they do this: a check valve is installed at each intake point. This technical solution prevents redirection of air flows, especially if there is an active hood in the kitchen. To be on the safe side, in private houses and cottages they install an additional check valve at the outlet - it prevents the draft from tipping over in strong winds;

Louver valve for installation at the ventilation outlet.

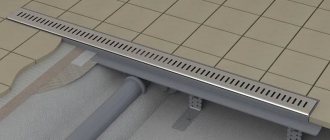

- In apartments, the check valve is installed on the wall; in cottages, installation on the ceiling is allowed. Such requirements are explained by the need for regular maintenance of the device - the damper must open/close easily, but grease and dust interfere;

- It is better to install a check valve on the supply and exhaust ventilation in the apartment, eliminating the slightest possibility of the damper freezing.

The presence of different ventilation schemes does not allow this article to consider in more detail the issues of placing a check valve in the kitchen, bathroom, and toilet. This requires separate material.

How to choose the right equipment?

In order for the check valve to last as long as possible, you need to know some features of the choice. The first thing that is taken into account is the maximum air flow speed that is present inside the channel. It should be remembered that the blades must open even under slight pressure. Because this is the only way to ensure effective elimination. Some models are equipped with a return fan, which increases the valve operation. Power is selected only based on the area of the room.

Also important is the ambient temperature. Single-leaf devices are not able to cope with negative temperatures, so they will not be effective. To vent air outside, it is necessary to install a “blind” type check valve. It withstands low temperatures and does not break down over time.

The installation features are also taken into account. Because there are models that need to be placed only at a certain angle. There are also universal versions that can be installed in any way.

The cost of the structure usually comes in last place, since it has little effect on anything. It is better to look at the main parameters: type of section, dimensions, what material was used in production, etc.

Installation instructions

To install a check valve for ventilation with your own hands, you will need:

- the valve itself;

- dowels with self-tapping screws;

- electric drill;

- perforator;

- silicone sealant.

Correct order of work:

- the equipment is checked (the list is given on the insert), although this is best done during the purchase process;

- the fan, if standing, is dismantled;

- the new fan is installed in place;

- marks are made on the wall for fasteners;

- Using a hammer drill, a groove is cut out in the wall for electrical wiring. The channel can be replaced with a plastic box or retro wiring, which, on the one hand, looks impressive, on the other hand, is expensive, and the wiring can be done directly along the wall;

- use an electric drill or hammer drill to drill holes for dowels;

- the fan is inserted into the air duct and fixed with self-tapping screws;

- wiring is connected;

- the connection between the fan and the wall is sealed with silicone sealant (some sets provide a rubber seal for this purpose);

- the operation of the fan is checked;

- At the fan inlet, a mesh is first installed, and then a check valve is installed for ventilation. If it is gravitational, check the horizon of the damper axis - if it is deflected, the petal may not close;

- the operation of the system as a whole is tested;

- a decorative cover is installed.

No instructions are needed to install valves at natural draft collection points. Everything is extremely simple there. The work progress is described in the instructions printed on the insert.

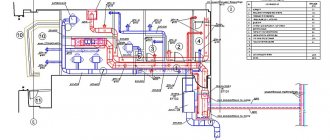

Valve installation diagram for natural (petal) and forced (butterfly) draft.

Epilogue

Let someone say that installing a check valve on ventilation is nonsense and is not worth wasting time and money on. But still, many of those who have done such work say that the air exchange in the room has improved significantly after their work. Humidity has decreased, unwanted odors have disappeared, etc. Based on the reviews, it's safe to say that the vent check valve is worth the cost of installation. After all, our health depends on what we breathe, so any improvements aimed at cleaning the air will be beneficial.

Non-return valve for forced ventilation in the section

In any case, there is nothing worse than installing such valves, which means it’s worth trying, first, to at least install a valve made by yourself, because it won’t cost anything. Well, having understood the advantages of such equipment, you will probably want to purchase a more advanced factory product.

Is it possible to make a check valve with your own hands?

Why buy a check valve when you can make it yourself. Of course, not electronic, but working effectively. How to make a check valve for ventilation with your own hands has already been discussed above (primitive membrane).

The second valve option is a modernized “butterfly”. You will need:

- decorative ventilation grille;

- a sheet of thin, soft plastic, like film from a fluorographic apparatus;

- knife or scissors;

- hot glue gun.

The film is cut so that its shape can completely cover the inlet hole in the grille. In this case, IMPORTANT, small ears are left in the middle on both sides, for which the future shutter will be glued to the grille body. After this, the plate is bent exactly in the middle by 45° and glued. You can’t bend it completely, otherwise it won’t close. The grate is put in place. The valve is ready.

One of the options for a homemade valve.

This same idea can be framed differently. Cut a rectangular sheet of paper in the middle. Glue the edges to the grill. The principle is clearly visible in the photo below.

Homemade check valve.

Similar systems were installed in Rus' in the chimneys of Russian stoves to prevent frost from creeping into the house in winter.

Troubles that may arise

Using this device has its disadvantages:

- The flow of natural ventilation is disrupted, which can lead to unpredictable consequences.

- There is noise during operation that may cause discomfort. In such cases it gets worse. When the direction of air movement changes and frequent switching occurs.

Experts do not give a clear answer to the question whether these dampers should be used correctly or not. To provide reliable ventilation, it must be designed and constructed in such a way that it can operate properly without additional devices. However, this method is expensive and not available to everyone. Using a check valve in this case is a more convenient way to solve the problem.

Fireplace hood Krona SELIYA 600 white S

Photo: market.yandex.ru

The Krona SELIYA 600 white S hood has an ergonomic inclined design with a thin glass finish and LED lighting. Convenient mechanical push-button control and 3 performance levels. The performance of the model is designed for a kitchen area of up to 10 sq.m.

Fireplace hood Krona SELIYA 600 white S

Peculiarities:

- Sloping design

- Case material: metal, glass

- Operating modes: circulation, exhaust

- Maximum productivity 500 m³/h

- Motor power 65 W

- Button control type

- Number of engines 1

- Number of speeds 3

- Grease filter

- Lighting type LED lamp

- Number of lighting lamps 2

- Power of each lamp 1.5 W

- Noise level 34 dB

Built-in hood Krona Kamilla Slim 2M 600 black/inox

Photo: market.yandex.ru

The wall-mounted fireplace hood Krona Kamilla Slim 2M 600 black/inox is equipped with two motors (each with a power of 90 W) and has a maximum productivity of 550 m3/h. The installation width is 60 cm. This model is made of stainless steel and operates quite quietly - 46 dB. The device is equipped with backlighting and has push-button control. This is an indispensable acquisition for every kitchen. The device perfectly absorbs smoke and fumes and does not allow droplets of fat to settle on walls and other surfaces.

Built-in hood Krona Kamilla Slim 2M 600 black/inox

Peculiarities:

- Installation built into a cabinet

- Type of installation in a cabinet: pull-out

- Dimensions (WxD) 60x30.60 cm

- Minimum height 17.2 cm

- Installation width 60 cm

- Air duct pipe diameter 120 mm

- Case material: metal

- Power consumption 236 W

- Motor power 90 W

- Number of engines 2

- Operating modes: drain/circulation

- Maximum capacity 550 cu.m. m/h

- Number of speeds 3

- Mechanical control, push-button

- Lighting halogen lamp, 28 W x 2

- Grease filter

- Maximum noise level 46 dB

- Weight 6.2 kg

Content:

- Built-in hood Krona Kamilla 1M 600 black

- Built-in hood Krona Kamilla Slim 2M 600 black/inox

- Built-in hood Krona Kamilla 2M 600 white

- Built-in hood ELIKOR Flat 72P-650-K3D White

- Fireplace hood MAUNFELD Tower C 50 white

- Fireplace hood ELIKOR Aquamarine 60 black

- Fireplace hood TEKA MIRABEL 90 HP VANILLA

- Fireplace hood Krona SELIYA 600 white S

- Fireplace hood MAUNFELD Tower C 50 black

- Kuppersberg DUDL 4 LX hood

Double leaf spring

The valve, which is called a “butterfly”, has several curtains. They open if there is significant pressure from a certain side. If it is not there, the springs cause it to slam shut.

These moments do not depend on gravity, but unlike the previous version, this design can be fixed at any angle. Typically, the normal operation of this model is guaranteed when using a hood with forced ventilation.

It is necessary to check exactly those flows that are characteristic of the air duct. There are modifications that can be modified so that they take the desired parameter - in accordance with the force of the springs.