We lay tiles around doors, windows and other obstacles. Practical advice.

When you are going to cover a large enough area of wall or floor, it seems that there will be no problems.

However, this is not so - in order to foresee possible problems in advance, you need to plan in advance (it is advisable to even make markings) how the tiles will be positioned. It is easy to imagine that there may be obstacles on the surface under cladding, which are extremely important to take into account. For the sake of economy and appearance, it is necessary to think about how to go around these obstacles, if possible, with whole tiles, so that you do not have to split them into an incredible number of halves. According to the standard scheme, markings should begin from the midline of the wall or floor. On a flat surface without obstacles this will not be difficult. But what to do if on the way there is a kitchen window, a door for the bathroom and toilet, a switch, an outlet, a ventilation vent, or a battery? Theoretically, all of the above-mentioned obstacles claim that the cladding begins precisely from them. It is much more difficult to correctly mark a wall when there are several similar obstacles on one surface. To solve this problem, you need to work through several options in order to then select the most suitable “central point”, acting from which you will not have to use a tile cutter often.

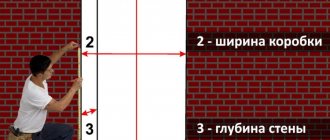

For marking, a special wooden ruler approximately 1.2 m long with the dimensions of the tiles and the gaps between them already marked is best suited. You can check how the tiles will be installed, for example, around a doorway, and whether the cut strips on both sides will be the same width. Follow the same procedure, marking the tiles in height, starting from the baseboard to the top of the doorway and beyond. For each door, it is necessary to take individual measurements - interior doors from the manufacturer for the bathroom may differ in the properties of the frames, trim, etc.

We lay tiles around the doors. Step by step.

- In the case where the door is located close to the corner of the room, you need to start with a full tile from the door frame. We install the bar plumb if the platband is not strictly vertical.

- Lay the tiles over the entire surface area; We cut the tiles to the corner of the room and to the ceiling, carefully measuring the distance.

- We install one plank above the door in line with the tile row, and the second one exactly above the level of the baseboard between the first and the opposite corner of the room.

- We lay solid tiles above the door. We lay cut tiles to the corner of the room and to the ceiling.

- We remove the strip above the doorway and fill the empty spaces with tiles.

- If the door is located in the middle of the wall, take the opening as the center, from where we lay out the tiles. We fix the planks and marking slats in an identical way.

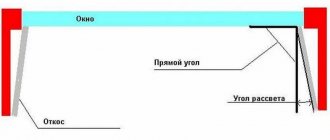

We lay tiles around the window. Step by step.

- First select the center. If there is one window in the wall, then the center of the installation will be a plumb line in the middle of the window opening.

- If there are two windows in the wall, then you will need to center from two lines at the same time, but you need to take into account that between these lines a whole number of tiles must fit.

- Alternatively, we take the line laid through the middle of the gap between the windows as the center of laying the tiles.

- We always lay tiles across the wall and upward, starting with whole tiles under the window sill, and then along the sides of the windows.

- We fix a strip over the window opening to fix the strip of uncut tiles.

- After removing the planks, we cut the tiles and lay them on the wall plane on each side of the opening.

It is laid out inside the slope in such a way that the edges of whole tiles coincide with the edges of the tiles outside the slope. After this, we lay out the remainder of the cut tiles up to the window frame.

Video description

You can get acquainted with the process of laying tiles from a ladder onto a pre-prepared screed with a slope in this following video:

However, professionals carry out the work of tiling a sloping floor with ceramic tiles as follows:

- first, cover the far triangular surface opposite the entrance door to the room with tiled material;

- then the tiles are laid on the left and right sides of the ladder;

- then the ceramics are placed on the last sloping section of the floor near the entrance;

- at the end of the process, the surface directly next to the drain is coated.

Thanks to this sequence of work, the master moves less on the facing material, the glue under which has not yet reached its maximum strength. At the same time, during the masonry process, experts pay increased attention to the watershed lines of the floor with expansion joints, as well as cuts and joints between the ladder and the tiles. After all, such places are most susceptible to damage of various types.

To increase the strength of the seams, they are reinforced using metal profile elements. In this case, the gaps themselves are first filled with bitumen, which is preheated. Such a mass, when cooled, can reduce the negative impact of loads.

Metal profile for protecting tile joints Source profil-mo.ru

Lining of cuts

Craftsmen perform this work after laying all the solid ceramics and drying the glue underneath. In the process, specialists use exclusively individually cut tiles for a specific location. At the same time, the tile material is distinguished by its decent thickness and high strength. Therefore, only experienced craftsmen can cut floor ceramics efficiently. Moreover, they use a special tool.

Decorating doorways with decorative stone - step-by-step instructions

There is an opinion that this method of designing openings is not suitable for residential premises. However, many experts recommend in some cases finishing the door jamb with decorative stone. A detailed examination of this technology leads to the idea: this type of framing allows you to realize original design ideas, and with your own hands.

The feasibility of using decorative stone is determined on site; it depends on many factors - the overall interior, the appearance of the door installed in the opening, its geometry and others. But in some cases this material is simply irreplaceable.

- For decorating openings in large, spacious rooms. As an option - small, but with a minimum of furniture.

- If the walls in the area of the door jamb have significant, difficult-to-remove defects, decorative stone perfectly masks them.

- In cases where this finishing material is an integral part of the decor. For example, if the room is stylized as antique.

There are two types of decorative stones on sale – natural and artificial. The former are not used so often in the interior of residential premises due to the high cost and complexity of the cladding; they are characterized by heavy weight. And this includes the load on the ceiling and certain difficulties in fixing the samples on the jamb. The tiles are an imitation of natural analogues; moreover, they do not contain “chemistry” (or its concentration is negligible and is not taken into account). The raw materials are crushed rocks; Dyes are added to the mixture prepared for molding to give the desired shade. To reduce the weight of samples and increase fracture strength, some manufacturers add granular polymers.

Other publications in the “Question – Master’s Answer” section

Cladding the facades of a building is an important question, the answer to which determines not only the future appearance of the house, but can also solve many practical problems. By separating the functions of cladding, insulation and load-bearing structures of the building facade, it is possible to achieve good protection of the house from destructive air.

The final step in installing the flooring is installing the baseboard. The plinth is not just an element of the interior; in addition, it is assigned both functional and aesthetic tasks. First of all, the main functional purpose of the plinth is to close the compensation gap, etc.

No matter how much chimney protection is installed, some small amount of moisture will still get into the pipe. It all depends on what cross-section the chimney has and what dimensions the “skirt” of the umbrella or deflector installed above it has. It should be noted that the use of a deflector is additional.

Source: blogstroiki.ru

Advantages of artificial stone

- A variety of shapes, shades, textures of decorative slab products.

- Easy to attach. The imitation of natural material is characterized by correct geometry, low weight and is easy to cut, which makes it easier to fit fragments when finishing door jambs.

- Increased sample strength and resistance to abrasion.

- Inertness to climatic factors and aggressive chemical compounds. Consequently, finishing doors with decorative stone can be done in any room, regardless of its specifics. Even in those where there are sharp changes in humidity/temperature and their high/low values.

- Convenience of choice. All artificial stones differ in standard sizes and thickness. In addition, they have smooth edges, and this makes it easier to calculate the required number of products for finishing a specific area.

- Consistency of color over time. The dye introduced at the stage of preparing the mixture is evenly distributed throughout the entire structure of the material.

- Decorative stone does not burn and does not block the base; it “breathes”, which has a beneficial effect on the microclimate of the room.

- Good maintainability of the jamb lining.

Features of choice

- The color must contain at least two shades. The uniformity of color neutralizes the naturalness of the decorative stone. It is immediately clear that this is just an imitation, and not the most successful one.

- Edges. The front surface is free of large fractions, dye clots, stains and stains. On the back side, the base should not be perfectly smooth - this will reduce the quality of adhesion of the decorative stone to the door jamb; or rough, or with notches (grooves).

- Sample edges. You need to decide on the type of seam between the stones. If it is chosen to be even along its entire length, then chips of up to 2 mm are allowed. Some owners prefer to lay masonry with a visible seam; in this case, edge defects can be more significant - up to 6 mm.

- Surface treatment level. First of all, this relates to the moisture resistance of decorative stone. If there is no protective layer, it is better not to purchase; independent application, and high-quality one, is a complex process that requires practical experience.

Basic rules for decorating jambs with stone

- Symmetry. Both sides of the opening, regardless of whether there is a door jamb in it or it is dismantled, are finished identically. Only this approach will ensure the completeness of the composition.

- Height proportions. Priority is given to the bottom of the door. This applies not only to the vertical, but also to the horizontal axis. That is, the base of the opening, with any method of its design, should visually look more massive. In accordance with this, a scheme for decorating the jamb is drawn up, taking into account the size of the purchased samples.

- A combination of texture and seams. The task of a master working with artificial stone is to achieve complete naturalness of the cladding. Experts recommend that before starting installation, lay out the “picture” on the floor and evaluate the effect it gives. How to position the products relative to each other, with what interval or offset - all such nuances are calculated in advance.

- Compliance with the jamb material. This must be taken into account even before purchasing decorative products. If the door frame and slopes are well polished and varnished, then stones with a smooth front surface are used to decorate the opening. And it is advisable to attach textured samples around a jamb that is untreated (made independently) or with a “rough” wood pattern.

Junction design options

Now we invite you to see how a hallway can look with tiles around the front door. Next, photos with design variations will be presented, and maybe one of them will appeal to you specifically and will be able to decorate your home:

The procedure for designing the opening

Decorating the slopes of the front door with decorative stone is done using the same technique as the interior door. The only difference is in the choice of material - not every imitation is suitable for these purposes.

Preparing the base

- The excess is removed - old paint, plaster, and in some cases the door is also dismantled if an arched opening is planned. The task is to achieve a flat and durable surface on which the tiles will adhere securely.

- Marking the wall according to the diagram for fastening the stones.

- Applying notches (grooves) to the base. This increases its adhesion to the cladding.

- Treat all segments to be finished with a primer. The goal is the same; Plus, this composition prevents the absorption of moisture by the wall material.

- After drying, it is advisable to apply concrete contact to the base. This product will further increase the level of adhesion, which means that the fixation of the stone will be as reliable as possible.

Door jamb trim

- The tiles are laid out on the floor according to the diagram. This will make further installation easier and will allow you to once again evaluate the correctness of the choice of location of the fragments.

- Removing the baseboard. The stone is laid to the floor, and therefore the lower molding will be a hindrance; Upon completion of the work, it is easy to return it to its place.

- Determination of the horizon line. Task: to ensure that all seams are located in this plane. Using a level and a long strip, a line is drawn on the wall that corresponds to the lower cut of the stones of the first row.

- Fastening the tiles. Cladding work always starts from the corner. To fix the samples, adhesives recommended by the manufacturer are used (tile, “liquid nails”).

The nuances of the work depend on the design intent. During the finishing process, stones will have to be cut, edges polished, and bevels made; but these are details that are not of fundamental importance. If platbands are installed later, then indentations are made for them.

- Finishing the joint

To make the stone more natural, it is advisable to spray the prepared composition over the entire area of the cladding, as well as adjacent areas of the wall: acrylic varnish + tinting paste. The mixture is diluted with water to the desired consistency and applied to the surface. It is not difficult to choose a recipe.

Decorating a jamb with decorative artificial stone does not require professional training. But if this option is unacceptable for some reason, you can use materials that successfully imitate such a finish. There is a large assortment of polymer texture panels on the market, special wallpaper of the appropriate texture; working with them is much easier, as well as updating (reinstalling) damaged samples. But still, they are not able to completely replace decorative tiles. This design solution can be considered the most preferable.

Mayakovy row

After all this has been done, you need to create a beacon line.

Why apply the initial tiles with a distance of five or seven millimeters from the wall, if tiles have not yet been laid on the walls, put a T-shirt signaling the end of the laying, then apply it to the far corner of the floor, also put a notch and connect the marks with a line.

The lighthouse first row will be laid along it, focusing on which all further layout will be carried out.

Source: freegameinfo.ru

How to lay tiles on the floor with your own hands

General construction work, which includes laying tiles on the floor, is the domain of professionals. However, if you know certain rules and the sequence of work, even such a complex task becomes accessible to everyone. How to lay tiles on the floor yourself is described in this article.

Any major renovation ends with the installation of the floor. A huge number of flooring options ensures uniqueness, both in terms of color and texture solutions, and in terms of operational characteristics, of renovated premises. The only obstacle in choosing may be a lack of imagination. However, there are rooms and areas in which you don’t need to invent anything or reinvent the wheel - the best option already exists. Such premises include the entire sanitary and utility block: hallway, bathroom, toilet and kitchen. Common requirements - increased wear and water resistance and ease of cleaning - determine the optimal type of flooring - tiles.

Anyone can choose a tile so that it fits perfectly into the interior, but putting it in place requires very specific skills. How to do this will be discussed in this article.

The need for a floor slope in the bathhouse

Before laying tiles on the floor in a bathhouse, it is important to correctly calculate the required slope of the surface, which will be obtained after finishing it with the finishing material. If it is insufficient, then all the water from the floor tiles will not flow into the drain system. If there is a large slope, it will be necessary to increase the estimate for construction and finishing work on installing the floor.

Therefore, to solve this problem, professional help is required, as well as to perform all other rather complex work. An error in their implementation will lead to a deterioration in comfortable conditions when using bathhouses and even to the destruction of the building structures of the structure.

If the floor is sloped, then the following problems can be solved:

how to glue a wooden plinth to a wall

The slope of the floor in the bathhouse can be created even at the stage of construction of the rough foundation. When performing such work, a large number of technological nuances are taken into account. Therefore, calculations are performed first. Designers do this at the stage of developing a bathhouse project or after the construction of the building and its owner contacts a specialized organization.

Required tools and materials

1. Levels: one meter and two meters.

2. Tape measure and pencil.

3. Notched spatula (tooth height 5 millimeters), regular spatula.

5. Mixer with a nozzle for mixing bulk mixtures.

6. Rags for cleaning tiles.

7. Brush or broom.

8. Angle grinder (grinder) with a cutting wheel for stone - necessary for cutting hard tiles, for example, porcelain stoneware.

9. Tile cutter - necessary for cutting regular ceramic floor tiles.

10. Rubber mallet.

Laying tiles

1. Prepare the floor for laying tiles. The ideal surface would be a concrete screed. We clear the screed of debris and cut off all the cones. Sweep the surface to be prepared with a broom soaked in water. Using a brush, prime the floor surface. Mix the tile mortar with a mixer and use a spatula to smooth out all the unevenness of the floor.

2. We place lighthouse tiles in the corners of the room and, using a two-meter level, measure the floor for horizontalness. This is done in order to find the highest point of the floor. Here the layer of glue will be minimal. We estimate the required thickness in other places using a level.

3. Using a square, measure the corners of the room to determine the direction of laying the tiles. The fact is that the tiles have right angles. If you move from a wall that forms an angle of less than 90° with another wall, you will either have to cut each tile to the width or move each row relative to the previous one, which will spoil the appearance of the finished floor. You should start from a right or slightly larger than 90° angle - a small gap can then be covered with a plinth. When choosing a starting angle, you should also consider how visible it will be. A row of solid, uncut tiles should be in the most visible place.

4. If there are obstacles on the floor, for example, a sewer pipe, then mark the tiles and cut a hole in it with a shape corresponding to the obstacle. This is best done using special crowns. If they are not there, then a hole can be made in soft ceramic tiles by biting off small pieces of the tile using pliers. The risk of splitting the tile is quite high, but when you put even the cracked tile back in place, the seams will be practically invisible. If you are laying porcelain stoneware, you need to understand that it is almost impossible to make a hole in it at home. In this case, just skip this place. Subsequently, it can be covered with something, or laid out as a mosaic from scraps. In any case, when cutting tiles, it is important to follow safety precautions and be very attentive and careful. Safety glasses and gloves should be worn.

5. Mix the solution. To do this, take two liters of water into a bucket and only then add glue to it, bringing the solution to the state of thick sour cream. Let the solution sit for five to ten minutes.

6. Using a comb spatula, apply a layer of mortar to the floor, the width and length corresponding to the expected number of tiles to be laid, optimally three to four tiles. To remove dust and ensure better adhesion to the floor, wipe the tiles with a rag soaked in water.

7. We begin to lay the tiles, taking into account the required layer of adhesive and controlling its position in the horizontal plane, using a meter level. We press down the tile with the same level, evenly distributing the load over the entire plane. If necessary, tap the protruding tiles with a mallet.

8. We insert spacer crosses between the tiles, and immediately use them to clean the seams. Periodically wipe the surface of the tile from excess glue. Once dry, this will be much more difficult to do.

9. Having finished laying the tiles, wait three days and grout the seams using a rubber spatula.

The article mentioned that the best base option for floor tiles is a concrete screed. However, even a wooden plank floor can also become the basis for tiles. To do this, it must be prepared. The simplest option would be to lay at least two layers of cement particle boards 10 mm thick with the obligatory spacing of the seams directly on top of the boards. The surfaces of the layers are coated with tile adhesive and fastened to each other and to the wooden base with self-tapping screws. This option will slightly raise the final floor level, but will allow you to lay tiles, even where there is no concrete screed. Naturally, when calculating the required number of layers of cement particle boards, it is necessary to take into account the rigidity of the base - for a wooden floor mounted on top of a concrete screed, two layers are enough, for floors in wooden houses - at least three.

Evgeny Dubinin, rmnt.ru (based on materials from the competition entry of user chugaiigor)

Marking

The first step is to mark a line passing through the center of the ladder and coinciding with the crease line on the screed, or just the center line if you plan to remove the slopes with tile adhesive. When laying with an envelope, it will be a diagonal line, a cross - parallel to the walls. For convenience, you can pull a thread instead of a line. It is worth noting that when facing with a “cross”, the markings can be shifted from the axis of the ladder to the edge, as in the first photo of this publication.

The next step is to mark and cut out four tiles that form planes around the drain - this is the base. The previously marked line should clearly follow one of the lines of the cross formed by the joints of the tiles. Sawed joints on porcelain tiles should be immediately leveled with an abrasive disc on the stone (sawed with a diamond, trimmed with an abrasive).

The sawn tiles should be tried on the ladder, how they will lie, taking into account the thickness of the glue. You need to make sure that the drain fits well, the sawn edges fit together well, without steps. If everything is in order, you can begin installation.

Outdoor threshold tiles: what is needed before installation?

It is important to properly prepare for such a responsible job as laying tiles on the porch. There is nothing wrong with the fact that after reading this article, you decide not to experiment with tiles and grout yourself, but invite a professional. External steps, terraces and porches present significant challenges when facing. Without the appropriate experience, freshly laid tiles can not only quickly fall off, but also cause injuries to residents of the house, relatives or guests.

The porch and its steps are constantly subject to mechanical stress - provided that the house is residential. Exposure to rain, frost, dust or heat is also mandatory and does not depend on the presence of residents. To ensure decent quality of cladding work outdoors, the following conditions must be met:

- The base of the porch and the steps themselves must be made of durable concrete or reinforced concrete, without cracks, signs of shrinkage or play;

- The entire porch structure should be protected from moisture - increase the roof overhangs, lay waterproofing on areas in contact with the ground, even if you only plan to lay tiles for the threshold on the street;

- It is necessary to carefully follow the cladding technology: the use of high-quality grouts, primers, solutions and adhesives - saving on such materials is inappropriate and financially unjustified.

Tile for outdoor porch: choosing material

A prerequisite is that the tiles for the porch on the street should not slip underfoot , even if the shoes are slippery (and in snow, rain or humidity, they will certainly be slippery). When choosing a material, its “anti-slip” qualities are a priority. The impact strength of facing ceramics and its resistance to frost can be judged from the accompanying documentation; these indicators should be maximum.

It is equally important to choose the right tile size. Decorating the porch with tiles looks attractive if the cladding is made of solid elements. If necessary, you can “move” the tiled edges beyond the porch area - but no more than a few centimeters. It is important not to make a mistake with the texture. Relief patterns look great on a stand in a store - when installing such tiles on the street, they will definitely become clogged with dirt and will require daily and labor-intensive cleaning. Color preferences when choosing tiles for outdoor work are taken into account last, although they are important for aesthetics and design.

To finish the steps, it is best to choose special ceramic elements with a rounded surface. They not only look beautiful, but are also designed to evenly distribute the load during operation. Regular tiles are less durable and will require careful filling of the entire internal space with mortar. For the riser, any tiles or mosaics are chosen - here you can focus on the aesthetic appearance of the future staircase.

Some tips

Craftsmen advise everyone who is involved in finishing and decorating slopes to adhere to several rules.

- On leveled slopes, it is necessary to lay out the parts in advance to determine the best location. It is better that narrow elements are not located at the junction of adjacent surfaces. The appearance is spoiled.

- When the size of the side surface does not allow laying a whole part, cladding must begin with a trimmed piece. In this case, the upper segment should be the same dimensions.

- If the width of the part exceeds the width of the slopes, the whole figure must be laid out along the outer edge. The free space formed between the parts and the door frame is closed with additional pieces cut to the required dimensions.

- From time to time the part does not stay on the top surface. Its mass cannot be held by glue. To solve the problem, you can use wood struts. They should hold it until the applied glue completely sets.

- Grouting of joints must be done the next day. During this period of time, the glue will dry one hundred percent.

Tiling the porch - step by step diagram

Step 1: Preparing the Porch

Even when building a house, you should consider the possibility of tiling the porch and its steps in the future - that is, giving the surfaces concrete strength and the necessary slope. If this has not been done, preparing the porch will require almost more effort than all subsequent facing work. You cannot apply a “slope screed” made of cement-sand mixtures to a finished concrete surface - it will peel off along with the laid tiles. It is necessary to attach a metal mesh to the concrete of our porch and perform the screed using “layered” technology (see below).

An ordinary chain-link made of wire 2.5-4 mm thick is suitable as a mesh. To fasten the mesh, dowels, mounting or U-shaped brackets, etc. are used. in increments of about 20 cm. Next, we set up the beacons, otherwise a uniform slope will not work. It is best to make beacons from ordinary sand, mixing it with tile adhesive - then the entire structure can be walled up directly into the screed. After that, layers of mortar and tile adhesive are alternately applied to the slope frame. Moving from the door to the first step, we fill the entire surface and wait for it to dry, usually at least a day.

Step 2: Laying tiles on the porch

We check the new concrete base for the presence of “humps” or cracks, rub and cover the defects. On the first day after pouring, the concrete is still soft and easy to grind. After grinding, carefully sweep and prime the concrete surface with an aqueous solution of PVA glue using a brush. The primer must dry completely; in air this happens in 15–20 minutes.

We lay out our ceramic beauty along the porch, starting from the door. Ideally, the entire surface should be occupied by solid tiles. Small cuts around the perimeter are acceptable, within 20-30% of the overall tile dimensions - otherwise the appearance of the porch will suffer, and small tiles will fly off quite quickly under heavy load.

We install the ceramics on a thin (up to 1 cm) layer of tile adhesive with a “hover” of 1.5–3 cm above the edges. We ensure that the mounting gaps are completely filled with the solution, especially as we approach the edges of the porch. Do not be afraid to remove the element if the filling with mortar seems unreliable or the tiles are uneven, and lay it again.

Step 3: Preparing the Riser

For the strength of the steps and porch, it is important to tightly fill the space under the overhanging tiled “overhang” with mortar. To do this, use a special stencil - a corner with a cutout to match the thickness of the ceramic tile. With its help, the end of the step is quickly and easily leveled.

If the riser depth is significant (from 3-3.5 cm), it must be reinforced with the remains of the mesh or scraps of reinforcement. The filling of such ends is combined, first - a layer of glue, after it hardens - cement mortar.

Step 4: Cladding steps and ends

While the first end is drying, the tiles are laid on the steps. First, the tiles are laid out without glue to evaluate the appearance and installation sequence. It must be remembered that the slope must be maintained to allow water to drain. Each step after cladding is subjected to an end-filling procedure.

As a result, on the second day of repair efforts, the porch itself was lined, and the steps received a ceramic vestment. All that remains is to decorate the ends of the surfaces underneath. For this, mosaics, various tiles, marble or granite are used. Unlike the porch and the steps themselves, facing the ends begins from the corners (yes, with trimmed tiles!), otherwise the symmetry of the appearance may be disrupted.

Step 5: Finishing Touches

All joints should be grouted the next day. It is performed using a solution with the addition of liquid glass or special fugues - frost-resistant compounds for external use. Sharp corners and turns can be lined with thin metal corners, using special glue and carefully removing its remnants from under the chrome surface.

The tiles for the porch steps can be laid in a few days; the work requires significant repair skills. It is wise to first try your hand at working with tiles indoors, on small and flat surfaces. If the result is positive, you can move on to independent cladding work on the porch and steps.

Sequence of work

It is necessary to begin laying tiles on the side surfaces. In this case, only whole tiles should be used. The work lasts until the horizontal row is higher than the upper end of the opening.

A flat strip is attached above the gap. The upper edge of the plank must correspond to the strip that connects the lower edges of the entire tiles located above the opening strip.

When the laying of solid tiles is completed, you can begin tiling around the slopes with additional pieces. Work must start from the bottom point. It is very important that the cut of the last tiles be made at an angle. You'll have to use a grinder.

After this, the facing of the side planes begins. During the work, the glue on top will set perfectly. You can remove the support bar. All that remains is to close the joint space remaining above the door.

Tiling door slopes in the bathroom