When finishing walls, corners for tiles in the bathroom solve the problem of masking the uneven edge of cut tiles. In a standard separate bathroom there are 4 internal corners of the walls, one junction of the side of the bath, joints between the vertical enclosing structures, the ceiling and the floor.

External corners appear on gypsum board frames, doorway slopes, and homemade architectural elements. Metal, PVC, ceramic profiles allow you to hide the untreated end of the tile and improve the quality of the interior.

There are options for decorating corners on walls with tiles without a special profile. For example, professional tilers do not work with corners, preferring to “bevel” - trimming or grinding the ends at outer corners at 45°.

Ceramic borders

It was quite difficult and diligent work: I had to cut small squares from the tiles, which were then used to form the slope from the wall to the bathtub. If the work was done conscientiously, the effect was absolutely decent. Now there is no such need.

In many construction stores, when you buy tiles for a toilet, they can immediately recommend favorable ceramic borders. But often they still have to be purchased separately. When choosing such a frame, you need to work hard so that the border matches the color of the tile itself.

In exceptional cases, you should choose a white border, then merging with the plumbing fixtures, it will not stand out from the uniform design.

In fact, all ceramic products are considered quite strong and hard. And therefore, of all the options that have been considered, ceramic borders will especially last a long time; they are virtually not subject to deformation and can be used without replacement for many years.

But you need to remember about the disadvantages of this option: it has poor resistance to mechanical damage, i.e. with a strong blow, such an object may prick.

In most cases, this kind of trouble occurs when installing ceramics, and already installed borders add to their own hardness the mechanical strength of the wall and bathtub and are virtually invulnerable.

Working with ceramic components requires specific skills, and therefore the best option is to entrust this process to specialists. If, for example, you personally agreed to take on this task, then it will be useful for you to read how to make a border in the bathroom from ceramic profiles (or baseboards).

Features of installation work

To work, you need to purchase the required number of blanks. Buy borders with a reserve (in case of damage), and also calculate how many corner-type elements you will need. You will also need specialized tile adhesive (it must be moisture resistant), sealant and grout. All work consists of several stages:

- Surface preparation. They must be very thoroughly cleaned and dried.

- Sealing the gap. If it is small, you can get by with silicone sealant. If, for example, the gap is large, it is sealed with foam for installation.

- Preparation of glue (according to the rules).

- Laying the border itself. How to glue a ceramic skirting board to a bathtub? Using a spatula, glue is applied to the back side of the parts, and they themselves lie close to each other so that there is no gap. Special corner components are placed in the corners. You need to give it a day to dry.

- Grout. The finished grout removes small gaps between the parts, and also between the wall and the baseboard.

Any of these types of borders has both its own advantages and disadvantages. When choosing an option for yourself, consider the entire interior of your bath. In any case, decorating your bathtub with a border will give it a complete and beautiful look.

Preparatory activities

Before tiling a corner, you should think about carefully preparing the walls and floor themselves.

- They are pre-aligned so that the material does not peel off over a short period of time.

- Another possible defect in laying ceramic tiles on an uneven base is a poorly executed external or internal corner.

- In addition, the surface at the time of work must be not only dry, but also clean.

- It is important to check the horizontality of the floor and the verticality of the walls. This is done after the old coating has been removed.

- If we are talking about walls, then a plumb line is used in the form of a selected type of load attached to a thread.

A large number of tools can be used to measure angles:

- For horizontality, a building or water level is used. Everything will depend on the preferences of the performer.

- There is also a laser level, but its cost is very high for use in one-time work.

If these works are not completed before laying the tiles, subsequently gaps will form in the corners, spoiling the whole picture.

A layer of waterproofing in the form of a coating mastic is first applied to the cleaned surface, followed by a primer. If there are even minor defects, they should initially be repaired with putty. To create a flat surface, pour the following onto the base of the floor:

- cement-sand screed;

- self-leveling mixture.

We must also not forget about waterproofing and a primer layer.

Differences between external and internal corners

When carrying out work, remember the difference between internal and external elements. The first option is the space where the surfaces of two walls meet along the perimeter of a standard room. The second is a protruding area.

Examples of designing corners using trims

Also keep in mind that it is easier to glue the internal trim tiles, because in case of deviation from the norms, the situation is corrected with the help of glue and grout. In general, the fugue looks more organic on the inner corners of the walls. In the bathroom this is of particular importance, because external projections, for example, when installing a box, are more susceptible to destruction. Over time, the fugue simply crumbles and is washed out from there. That is why it is better to lay an additional plastic corner on the tile, which will not only protect, but also decorate the surface.

The solution to all problems: corner tiles

When dealing with the question of how to lay tile corners, it is worth paying attention to the tile lines that the manufacturer produces taking into account the presence of corner tiles. Then the problem is completely removed, since such ceramic corners can not only be easily laid, but will also even out uneven corners.

Many manufacturers offer a wide selection of corner tiles for both external and internal orientation. Such corners are laid out first, and the rest of the tiles are joined to them. Creating solidity and external integrity of the finish, the choice of such a design looks very harmonious, although such a finish will cost a little more, but not so significant as to refuse it.

Other corner design options

Installing a profile is an optional condition for upgrading the ribs between enclosing structures lined with tiles or mosaics. You can perform the same operations correctly in several ways:

- grind the edges of the cladding at 45 degrees;

- lean the tiles overlapping each other;

- Leave space between the tiles for grouting.

The most difficult is the corner on a short box, a podium, formed by three planes at once - two vertical walls, one horizontal plane.

Overlapping method

The perpendicular joining method is used for right external/internal corners. The end of one tile is located at a 90 degree angle to the other, flush.

The same seam is left between the tiles as in the adjacent rows. The joint is positioned in such a way that the solid tile masks it when viewing the room from the doorway, as in the photo below.

Burying method

The method is used only for external corners, called the “Kremlin corner”, bevelling, trimming, sharpening, cutting at 45 degrees. The ends of the tiles are cut at 45°, the decorative elements are joined closely to each other without seams or grouting.

You can grind off unglazed ceramics from the back of the cladding manually with a file or a whetstone. However, it is more convenient to use an angle grinder with a flexible diamond disk “Turtle” with a grain size of 50 units.

The outer corner in a combined bathroom often ends up on the edge of the inspection hatch under the tiles. In this case, instead of regular grout, use silicone sealant of a suitable color.

This material has increased plasticity, even after hardening, it does not fly off the edge of the tile.

Forming an angle at the junction of three planes

An additional element - a capsule plug for an external/internal corner - is available exclusively in collections of metal corners from domestic and foreign manufacturers.

The tiled profile itself is ideal for cladding the ribs formed by connecting walls.

Plug capsule for metal trims.

The plug is designed to fit into a vertex formed by the intersection of two or three edges. One side of the capsule is inserted inside the profile, the other two are adjacent to the remaining layout on the adjacent walls.

Wall-floor joint

To decorate the internal corner formed by porcelain stoneware flooring and tiles on the bathroom wall, the following methods are used:

- embedded profile made of polymer material, metal, ceramics;

- patch corner PVC, aluminum, brass;

- baseboard for tiles;

- ceramic or porcelain stoneware border.

- without a plinth - this is the most aesthetic and correct option; the joint is grouted with tile grout.

A regular PVC skirting board does not fit well with ceramic cladding, however, this is the only option with cable channels inside for electrical wiring, ensuring high maintainability of the wire.

Connecting the wall to the ceiling

The choice of layout for designing the angle of contact between the wall tiles and the ceiling depends on the method of finishing the floor slab:

- whitewashing, painting - overlay polystyrene foam fillet, glued to both surfaces;

- PVC panel - profile made of the same material;

- suspended ceiling - special insert.

Bathtub connection unit

The main problem with the junction of the bathtub bowl and the walls around it is to ensure tightness. The classic option is to tile the walls entirely along the entire height. There are several methods for designing the junction of the bathtub to the wall:

- sealant is a budget option, but short-lived;

- border tape - heated with a hairdryer, has an adhesive layer for fixing one edge to the wall, the other to the bathtub bowl;

- polymer plinth – F-shaped profile with a long bottom shelf, side plugs included;

- ceramic border - low manufacturability of installation due to the short length of the elements and their large number;

The downside of all of the above options is the lack of tightness of the upper joint, plus the easy dismantling of the bath without destroying the lining. But at the same time, the most reliable technology is wall cladding from the side of the bathtub, when its bowl is partially embedded in the wall.

Laying tiles from the side of the bathtub.

The bottom row is usually trimmed to even out the lack of horizontal lines and to hide other defects. After which, you have to mask the defects of tile cutting. For this, a PVC layout is used, which has elastic properties to compensate for the linear expansion of the bath when heated.

Tile profile classification

There is a profile division for finishing rooms with tiles according to several criteria:

- material of execution – plastic, metal (aluminum, brass), ceramic;

- purpose – external, internal, ceiling fillet, floor plinth, bath border;

- profile section – one-sided, two-sided, flat, L-shaped, volumetric;

- decorative properties - white, colored, chrome-plated, gold-plated, silver, gloss, matte;

- functionality – compensatory, connecting, decorative and protective;

- fastening method - sealing, gluing, overlay.

Overhead corners for porcelain stoneware and tiles are almost never used.

Vinyl external/internal white corner is used to design corners between walls finished with MDF and PVC panels; it is not used for tiles. There are several names/designations for the profile in the documentation, in the slang of finishers:

- “corner” – according to purpose;

- “layout” - elements allow you to increase the decorative value of the layout of tiles on the walls;

- “trim” - comes from the transcription of the word trim - finishing.

Tiled compensation profile.

The expansion profile is mounted along the expansion joints separating large screed blocks in large rooms. It is never used in the bathroom. The connecting profile is mounted at the joints of different claddings in the same plane.

According to the requirements of SP 29.13330, the floor covering of the bathroom must be lower than the level of the finished floor in the adjacent room, or separated from it by a floor. But in practice this is inconvenient, so a connecting profile is usually used between the bathroom and the adjacent room.

Let's consider the classification according to the material of manufacture.

PVC profile

Among other structural materials for tile profiles, polyvinyl chloride polymer has the lowest production cost. PVC is easily painted in bulk, does not collapse, and does not fade from solar ultraviolet radiation or detergents. A vinyl corner can be used to cover tile cutting defects on external and internal corners.

Interior

Manufacturers produce two types of inner corner:

- one-sided - the tile is inserted into the groove on one side of the profile, the second side is pressed against the cladding on the adjacent wall;

One-sided PVC profile internal. - two-part - the fittings are embedded in tile adhesive along the inner corner, and later a strip with a flexible element in the middle is snapped into it. Two-component PVC profile internal.

Important: A one-sided corner is always on sale and costs much less than a two-part profile. However, it is only suitable for acute and right angles; at obtuse angles, one of its edges protrudes above the cladding surface.

A two-piece trim is more expensive, but it makes joining ceramic cladding on surfaces at obtuse angles greater than 90 degrees easier.

Outer

The industry produces external PVC corners of several types:

- L-profile - one edge is put on the tile, the second is pressed against the first row of tiles on the adjacent wall; Single-sided external corner PVC profile.

- C-profile - both edges of the tile are tucked under the outer semicircular surface; Double-sided PVC corner profile for external tiles.

In the first trim, the decorative surface has a semicircular sector of 90°, in the second, 180°. However, most often only the L-profile is on sale, which allows you to hide defects in the cut edge of only one tile.

The “layout” is held at the corner due to the fact that one internal strip is wide and perforated. It is recessed into the tile adhesive during installation; after the solution has dried, dismantling without damaging the cladding becomes impossible.

Metallic profile

The main differences between metal trims and PVC trims are:

- in addition to the semicircular shape of the front side, there are box-type profiles with two flat edges;

Rectangular corner for tiles. - the presence of additional elements for the junction of three planes (outer, inner corner);

External corner for three planes. - an assortment of two-piece profiles with a snap-on anti-slip strip, used for steps. Metal profile for two-piece tiles

Metal profiles are made from steel (stainless steel), brass, and aluminum alloys. Manufacturers use decorative coatings matt/gloss silver, brush effect (worn denim), gilding, bronze, champagne, ground, polished brass, chrome, pewter.

Aluminum is a corrosion-resistant material with fairly high decorative properties. We use our own metal texture, plating with copper, gold, silver, and film lamination to obtain the texture of wood.

To separate areas of different colors, three types of metal profiles are used:

- C-shaped border - has stiffening ribs on the reverse side, mounted on walls; Decorative aluminum border.

- U-shaped – for installation on the floor; U-shaped decorative profile.

- T-shaped - with a wide top bar. Separating T profile for the joint between rooms.

In the bathroom, steps, podiums, and blind screens are sometimes made. The upper edge of these tiled structures is refined with a special F-shaped profile.

F-shaped profile for steps.

Unlike the outside corner corner, there is a shelf that additionally protects the riser at its top. It is in this area that tiles usually break off from concrete or masonry. Its middle strip is embedded in tile adhesive, and the upper tread tile is inserted inside the profile.

The Y-shaped outer profile looks very nice and neat. To install it, you will need to pre-cut the edges at 45 degrees.

The brass and stainless steel profiles have similar cross-sectional configurations. Options for finishing the front surface, its shape is similar to the aluminum corner.

Ceramic profile for steps

For cladding steps, clinker is considered the most durable material. In addition to clinker tiles for treads and risers, manufacturers have developed additional elements - a corner for the outer edges of the steps.

Clinker tiles with corner for steps.

The same steps. For some collections of tiles, they are also made from porcelain stoneware.

Less commonly used is a ceramic corner, which has shades of red and brown. There are protrusions at the bottom to increase adhesion with tile adhesive.

Ceramic stepped profile

The best offers for tile profiles in your city:

External corners

The most popular type. Used when facing external corners. The sizes on sale are mainly 7, 9, 11 mm (with a length of 2.5 m). One side is a groove for tiles, the other serves as decoration and protects the slabs from impacts and chips. The hidden part is perforated for better adhesion of the tile layout and ceramics. Decorative elements are produced from:

- plastic;

- aluminum;

- brass and other materials;

Decorating the end of the tiling near the window in the kitchen using a plastic layout.

Installation of corners

Tile profiles are installed when one of the two walls forming the outer corner is ready. Sometimes trims (layouts for tiles) are left until the end of the work. This happens under unforeseen circumstances: there are problems with delivery, there is a defect, etc. However, such a situation requires the tiler to have advanced qualifications and more serious calculations. The slightest inaccuracy can lead to refinishing or resignation to flaws.

When moving on to the next wall, a tile layout groove is placed on the back side of the finished wall. The product must match the size of the tile. The tiles will not fit into a corner of a smaller format, and a larger trim will force you to use more glue and will dangle.

To start laying the next wall, and the corner for the tiles does not slide, it is attached with tape or tile adhesive is used. The perforated side should be parallel to the tile to allow the perpendicular ceramic to lie tightly and evenly. Be sure to fill the joints with glue - voids deprive the structure of its functional meaning. Without a trained eye, it is better to spend time squeezing out excess mixture than to accept the hollowness. The video shows the installation of the layout using the example of a difficult place - slopes with a double outer corner: https://www.youtube.com/watch?v=b-9JPxPx2ks

Trimming corners

If the ceiling is suspended and rests on tiles, cut the layouts to match the tiles; do not leave yourself or others the need for further trimming. The installation of trims in the area of door and window openings (or in similar situations) deserves a separate discussion. To position the elements perpendicularly, you need to cut their edges at an angle of 45 degrees. Do this very carefully, otherwise there will be gaps or profiles for the tiles and will not lie without bends or burrs.

Trim at 45 degrees at the junction of 3 corners.

Corner repair

It happens that you no longer like the layout for the tiles, or maybe the profile for the ceramic tiles was damaged. In such cases, repairs are needed, but how to remove the trim, much less install a new one? This is a tedious task, but doable:

- Carefully, so as not to damage the tiles, cut off the old outer corner for the tiles;

- prepare a new one;

- trim the back of the trim;

- if necessary, level the area under the profile without touching the space under the tile;

- use liquid nails or silicone to glue the layout;

Design nuances

Considering the subtleties of interior design with tiles, you can avoid annoying mistakes:

- If the choice fell on wall ceramics with a vertical pattern for a small bathroom, the room with such decoration may seem narrow and high, like a well;

- Not worth it for a room with an area of less than 10 square meters. m. buy tiles with a large and bright pattern;

- Likewise, a panel on the entire wall does not look good in a small bathroom;

- A glossy surface tends to reflect light and create glare. Such illumination has a tiring effect on vision;

- The established design of the top of the wall with light tiles and the bottom with dark tiles evokes boredom. Separate dark, horizontal or vertical stripes on a light background will help to move away from the classical tradition.

Selecting ceramic tiles according to the rules will allow you to find a bathroom that will be distinguished by its excellent design and convenient operation of all elements.

Rules for laying corners with tiles

If you decide to use tiles for wall cladding, you need to take into account all the details of construction work at the planning stage

In this case, special attention should be paid to how to lay out the corners with tiles so that the room looks beautiful. Naturally, before starting work you need to prepare the necessary materials and tools

It is better to think about laying tiles in the corners in advance

To do this you will need to purchase:

- ceramic tiles;

- special glue;

- crosses for joints between slabs;

- notched spatula;

- finishing profiles;

- tile cutter and building level.

You will need to count the number of whole tiles that will fit in the area from the first inner corner of the room to the other. It is necessary to take into account: the size of the tile joints (which ranges from 3 to 5 mm); the distance from the joints of adjacent walls, which is approximately 5 mm; choose the so-called “red” place in the room, which, as a rule, should be in plain sight (for example, opposite the entrance).

It is recommended to start cladding from the most visible place

Therefore, it is recommended to start facing work with it. The opposite place on the wall should be less noticeable

When laying tiles in a “dark” place, you need to pay attention to the fact that it is advisable to lay out material larger than half the size on it. If too thin strips are glued, the cladding will have a makeshift appearance.

Therefore, you need to perform all the calculations quite accurately in order to comply with the rules for laying the material on the surface and obtain the visual effect of the integrity of the facing wall. All this must be taken into account at the planning stage.

It must be borne in mind that before tiling begins, the walls must be as level as possible. The quality of the cladding and the appearance of the surface depend on this.

Laying tiles in corners correctly

Before laying tiles in the corners, we decide on the so-called “red” place of the room - usually it is immediately noticeable. You need to start working with corners from this place. When tiling corners, the material must be glued on two adjacent sides - strictly symmetrically, so this must be taken into account and the same tile trims must be used. For cutting, you need to use a special tile cutter, which is equipped with a template that takes into account the required cut size with a seam allowance for grouting.

Making an internal corner

First, glue (mastic) is applied to a wall with an area of about one square meter; you need to start from the floor. The glue is spread with a special spatula over the entire surface to obtain an even layer with equal grooves. The solution is then applied in the same way. Glue the first tile. Then glue the second one.

Constantly check that the cladding is correct

To ensure an even seam, we install special crosses at the joints of the surface. Having glued the first row of tiles, we check the levelness of the cladding with a building level. Next, we continue to lay out the surface in the same way. Having reached the next wall, mark the distance to it, cut off the tile if necessary and glue it.

When starting to lay the material of the adjacent wall, we glue the remaining trimmed part. If the material is made with a pattern or design, then we combine its parts. In this case, we glue the edge of one tile overlapping onto the surface of the other, leaving a gap of about 2 mm. The material laid out in this way creates a feeling of integrity of the tiled surface, as if it were curved. Next, we continue to glue the tiles to the required height level.

Covering the outer corner

Only solid material is used for cladding external corners. When laying, the position of adjacent tiles on both the right and left must be strictly symmetrical, and the laying is carried out overlapping the surface of the tile. In this case, the cladding will look beautiful if the ribs have a rounded or glazed appearance. If the surface has unattractive edges, you can use a special profile for finishing, applying it with cement mortar. Such surfaces will look great. That's the whole secret of laying tiles. Further laying of the coating is carried out according to the rules described above.

When facing external corners, do not forget to maintain symmetry

Summing up the laying of corners with tiles, we can highlight the following important points that are necessary to complete the work:

- calculation of the quantity of ceramic tiles;

- choosing the right “red” place;

- the order of laying facing tiles on the internal and external surfaces of the corner.

Video on how to decorate the outer corner of ceramic tiles:

All that remains is to purchase the necessary materials and tools and begin work.

repaireasily.ru

How to lay tiles in corners: basic rules

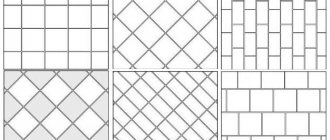

There are several options for connecting tiles:

- Perpendicular connection. The simplest way to solve the problem is a direct connection. In this case, the tiles are laid at 90 degrees, that is, one cut remains open, and the second is disguised under the top element. This way you can close any corner with minimal effort. If tile trimming is required, it is best to install the cut from below. The disadvantage of this method is the seam when connecting. Subsequently, it is masked with grout, but it is still visible on the surface.

- Trims. The most popular option is probably the installation of special elements - trims. This is a plastic profile that forms the necessary direction. For external corners, an L-shaped installation is used. The internal corner has the shape of an arc. Sometimes narrow convex trims are used.

- Pruning. This method is based on trimming the edge of the slab. It is performed in such a way that the fragments can be connected to each other at 45 degrees.

Perpendicular arrangement

The simplest solution to the issue is direct docking. In this case, the elements are laid perpendicular to each other, that is, so that one cut remains visible, and the other is hidden under the upper fragment.

In this case, a corner in any part of the walls is closed with minimal effort. If adjustment of the tile is necessary, it is advisable to place the cut edge under the bottom. The disadvantage of this method is the presence of a seam at the junction. Later it is sealed with grout, but this still affects the appearance of the surface.

Options for laying tiles at internal joints

There is another way to join tiles perpendicularly in the corners. This method is suitable, for example, for finishing curbs or bathroom frames. The main condition is that the cladding should not be visible from below.

The essence of the method is as follows: it is necessary to glue the tile so that the horizontally located (top) tile hangs over the edge. The corner will turn out neat if the width of the canopy is within 3-5 mm. The only condition is that the edge must be solid.

Edge Trimming

For more accurate work you will need special equipment. The method is based on cutting the edge of the tile at 45 degrees. The task is performed in the following ways:

- grind the edge with a grinder;

- a tile cutter is used;

- sandpaper is used.

The best option is to process tiles with an electric tile cutter with an inclined bed.

How to lay such wall tiles? For this purpose, the tiles are cut and glued with mortar into the corner so that their edges coincide and form a solid covering.

One way to lay tiles in internal and external corners is to trim the chamfer at 45 degrees.

For beginners, laying tiles in the bathroom using this method is not easy. If possible, practice on unnecessary material. Please ensure that the surface of the walls is as smooth as possible, otherwise you will need to lay a layer of glue of different thicknesses on it, which will disrupt the position of adjacent elements.

Using Trims

These are special inserts. The method using them is the most popular. They are a plastic profile that forms the angle of the desired direction. An L-shaped pad is used for external projections. And the inner surface has the appearance of a concave arc. Narrow convex models are also used.

One more important issue needs to be resolved - how to glue the plastic corner to the tile. Several options are possible:

- sealant;

- glue;

- liquid Nails.

Often, such trims have a special design that allows them to be laid on the solution. A special plate is driven under the tile and fixed with tile adhesive. This installation is extremely simple, the surface acquires a neat appearance, and the joints are protected from moisture and bacteria.

Some options for cladding inserts

The external plastic corner and trims at the junctions with the plumbing (curbs) are fixed differently, for example, using silicone or acrylic sealant. How exactly to glue the plastic to the tiles in the bathroom does not make much of a difference. This type of finishing of walls or corners of the box is suitable for almost any type of material.

Varieties and sizes

The corner can be installed on internal and external corners.

They completely follow the shape and help level the surface in the bathroom.

At the same time, the tiles look more rich and stylish.

The outer corner must be placed at the junction between two walls. Such protrusions are always connected to each other at right angles. The product has a slightly rounded shape, which prevents injuries from the sharp corners of the ceramic. Thanks to installation, it is also possible to significantly extend the service life of the surface.

Rounded outer profile

When purchasing this item, you will need to pay attention to its main characteristics:

- Width - from 7 to 11 mm.

- Universal length - 2.5 m.

There are special grooves on one side that provide strong adhesion to the tiles. The corner performs not only a decorative function, it also protects the structure from the negative effects of the environment. Today, plastic, aluminum and other types of materials are used to make corners. Most often they are painted white or another neutral color.

Internal elements are necessary to decorate the corners and are mounted in a similar way. Their width is standard and is 1 cm. However, it is possible to adjust this indicator depending on individual needs.

Mounting internal corners to tile material

This allows you to protect the surface from the harmful effects of liquid, fungus or mold. The material is universal, so there is no need to use special cleaning products to clean it.

Profiles for tile coverings fully cope with protection

Additionally, if used, it is possible to significantly speed up the installation process. Manufacturers offer their customers corners that are made in the following forms:

- P. Necessary at the stage of completion of finishing work.

- T. Dividing insert.

- D. Corner option, which can only be fixed at the joints. They can be mounted in a vertical or horizontal position.

- H. Separating insert between floor, ceiling or wall.

When installing the surface, you can do without this element. The choice directly depends on the designer’s idea, which is currently being implemented by the builder. The corner can be wall-mounted or overhead. The last option performs only a decorative function. Moisture may accumulate on its surface during operation. The element cannot fully protect the surface from external destructive influences. However, the overlay element is used when it is necessary to prevent the wet floor from slipping.

External corner for tiles (square) made of stainless steel

L-profile for tilesT-profile

Peculiarities

Decorative corners are used during the final stage of renovation.

The main purposes of the corners:

- give the finishing touch to the decorative design;

- neat and stylish design of the joints between tiles and plumbing fixtures, especially when it comes to difficult areas of the room;

- Use during refinishing or upon completion of renovations.

Depending on the shape, experts distinguish two types of corners.

- External. Use to design a convex corner. The main purpose is wall decoration. Thanks to them, sharp parts can be covered simply and practically.

- Internal. They are chosen when you need to design a concave (internal) corner. If you need to level the surface between the tiles and the bathtub or create a corner, choose corners of this type.

From a design point of view, corners can be divided into two groups:

- Decorative. During the manufacturing process of these elements, special attention is paid to the appearance of the product. They can have different colors and shapes depending on the style. The material most often used for manufacturing is ceramics or PVC.

- Functional. This is the main group of corners presented on the modern market. They are characterized by increased reliability, stability and practicality.

Existing types and sizes

The width of the corner is 7-12 mm, the length is 2.5 m. External and internal corners, according to their aesthetic characteristics, perform the following tasks:

- decorative, they decorate the cladding of premises and are distinguished by an abundance of color schemes;

- functional, they allow you to design surfaces with complex geometry, mask unevenness and roughness of edges, provide waterproofing of joints, and reduce the risk of injury.

What materials are they made from?

Materials for making corners for tiles:

- aluminum;

- metal alloys;

- polyvinyl chloride;

- ceramics.

For ease of installation, layouts should be 1-3 mm wider than the thickness of the tiles.

External and internal layout

Building materials stores offer a large selection of trims (another name for corners for ceramic tiles) of different shapes, sizes, thicknesses and all kinds of colors. External corner is a material for edging and decorating edges, ends and external corners in rooms decorated with tiles, ceramic tiles, porcelain stoneware. The materials from which the tile layout is made are durable, have good anti-corrosion properties, and allow the accuracy of the angular geometry to be maintained.

Advantages of external aluminum layouts:

- structural rigidity;

- resistance to corrosion and mechanical damage;

- beautiful appearance of the products.

Corners made of metal alloys are available in nickel or chrome plated, often painted gold or silver. This type of trim is considered universal, because they match any interior color scheme. External PVC panels are lightweight, have good waterproof properties, and offer a wide choice of colors. The ceramic profile maintains the aesthetic integrity of the cladding design.

The internal corner, used to design internal corners when joining adjacent surfaces, aligns the joints and hides trimming problems. The internal layout is highly water resistant. This type of trim does not carry a large functional load, so it is often used as a decorative element when decorating a bathroom.

Materials

Manufacturing companies use various materials to produce corners. Each of them has its own performance characteristics.

Metal

Designers call aluminum products the optimal choice for most stylistic trends. Lightweight and durable metal harmonizes perfectly with sanitary ware, bathroom furniture and a wide color palette. Elements of this type are ideal for working with outdoor tiles.

In terms of strength and hardness, the leading positions are occupied by corners made of stainless material. Due to its special properties, it is ideal for use in rooms with high humidity. As a rule, they are made in gold or silver. Often there are options plated with brass, chrome and nickel.

Chrome elements are an ideal choice for high-tech style.

PVC (plastic)

The products are lightweight and particularly flexible. Manufactured in a variety of colors. Can be used at any stage of gluing. In terms of price, this is the most profitable option, and therefore widespread.

Ceramics

Ceramic models attract attention with their expressive appearance. They stand out from the rest with their decorativeness, patterns and expressiveness. If tiles were used to decorate the bathroom, ceramic corners are ideal.

Installation technology

Aluminum, plastic and metal trims are attached to the wall surface using tile adhesive. The profiles have a perforated inner surface, which allows them to be slightly pressed into the adhesive layer for better fixation.

Layouts are divided into 3 groups: hard, semi-rigid, soft. To design corners and joints of complex geometry, the best option in choosing profiles would be plastic layouts, since they are easy to cut. Straight and clear joints cover metal products well.

Installation of corners for external joints:

- Make markings on the wall. To do this, cut off the required length of the profile and apply it to the finished joint. Rectangular tiles or products of a different configuration are inserted into the trim groove on both sides. Measurements are taken and the necessary marks are marked on the wall.

- The corner is covered with glue and the elements are laid. The correct installation is controlled by the marks made at the beginning.

- The edges of the tiles are inserted into the grooves and the trim is pressed against the surface of the cladding to remove voids.

- Remains of glue are removed with a rag, and the surface of the cladding is wiped dry.

To prevent the tile from “floating”, it is additionally fixed with masking tape, which is removed after the glue has dried.

The decorative corner for internal joints consists of several parts:

- groove for tiles;

- perforated protrusion;

- concave fragment.

Installation begins after the facing material has been completely laid on the wall. The profile is chosen 2-3 mm larger than the thickness of the tile. Apply glue to the cladding. The elements are applied to the edge of the wall covered with adhesive material, pressing tightly. Place the tile into the groove. The same procedure is done on the other side of the corner. Press firmly to remove voids between the tiles and the trim. After drying, grout the joints.

Particular attention should be paid to the processing of joints. When installing the layout between the edge of the bathtub and the adjacent wall, you need to treat all the cracks with sealant so that there are no large gaps left

This very important procedure is performed using an aquarium protective coating. Laying of trims begins after the glue has completely dried. The use of a PVC profile to seal the joint between the bathtub and the wall is most justified. It cuts well, does not allow moisture to pass through, and quickly sticks to “liquid nails” or tile adhesive. When gluing, the corner is pressed tightly against the wall and the edge of the bathtub.

Pruning

When cutting layouts, it is necessary to take into account the characteristics of the material. Cutting is done with a hacksaw or grinder. When using a hacksaw, you can use a miter box. This carpentry tool is essential for cutting corners correctly.

Application of trims

The outer or inner corner of the tile can be made with high quality using a decorative profile called trim. It is selected taking into account the color scheme of the tile. Can be made of plastic or metal (metal corners for tiles).

- If you are making an external corner, you should purchase L-shaped trims

- Internal – trims with a concave arc.

The last option is also most often used when moving from the wall to the floor (plinth). Their scope of application is very wide. The main thing is to choose the right option for execution.

In addition to its main function, trims can protect against external mechanical influence. Consequently, the service life of the laid tiles will increase slightly. The work is carried out very simply, without special knowledge and the use of special equipment.

Silicone or acrylic based sealant can be used to glue the profile. Any glue for this type of work, as well as liquid nails, is also perfect.

It is worth noting that for the bathroom there are features of the external corner. It is best to make it in one piece, rather than choosing from the remaining fragments.

Elimination of defects

Regardless of which method you choose, it may simply not be possible to do all the work perfectly. Especially if you are a beginner, non-standard situations can and will arise during your work.

Moreover, due to lack of experience, some nuances may simply get out of control. And if you need to lay boar tiles, then questions may arise about how to properly lay out the joint in the corner.

For example, one of the difficulties you may encounter is that it is difficult to achieve a perfect 45° cut. So, you can sand off the excess with sandpaper until you get the desired result.

If you overdid it and your cut was too large, then do not rush to break the tile. Leave it until the next joint. Perhaps there will need to be tiles already.

But what if during the work chips form on the surface of the tile. It is clear that this is not a completely rosy situation. However, you can get rid of them using regular grout. If it is difficult to disguise them in the corner, then you can cut out a plastic corner and glue it to liquid nails or silicone. Everything will go very quickly and easily.

Conclusion So, now we have considered the question of how to lay tiles in the corners. This work is important, because very often a person’s gaze is directed precisely to the corners. Therefore, you should not rush when laying them, but try to do everything according to the level.

If there is no level, then you can use a rule to make everything visually smooth. Considering that all the technological aspects cannot be described here, we invite you to additionally watch a video that clearly shows the methods for finishing corners.

Source

Docking methods

There are several methods for finishing wall corners. In this article, we suggest you consider the following options:

- Direct docking.

- Edge trimming.

- Using trims.

- Corner tiles.

Each of these methods has its own differences. We are confident that one of the listed methods will help you lay tiles.

Direct docking

You can lay tiles at right angles. This is the easiest way without any hassles. That is, it is assumed that the tiles are joined to each other without any trimming. As a result, one slice will be hidden, and the second in plain sight.

This method allows you to level a corner in any part of the wall, even the most inaccessible, with the least effort. If the tiles converge into a corner and one of the edges is cut off, then think about it so that it is not visible. It is better to have a factory cut on the outside.

Another method that involves perpendicular joining can also be included in this category of joining tiles. This method is only relevant if a special border is used to cover the protrusions.

The principle of joining tiles is as follows: the tile is glued to the surface so that the top tile, located horizontally, hangs over the edge. In this case, the joint of the tiles in the corner will be neat (provided that the canopy reaches no more than 5 mm). In this case, it is important that the overhanging edge has a factory cut.

Laying tiles in an internal corner - video

Edge Trimming

We can safely say that this is the most difficult way to decorate the corners of ceramic tiles. It is mainly used by those who have special equipment for cutting tiles or by experienced tilers.

The idea is that the sides of two tiles are cut at 45°. The result is a perfect 90° angle. Mostly the tiles are placed so that there is a small gap near the walls. A tile at least half the width of the whole is placed in it.

And laying it is not difficult, because it has a rectangular shape. To form such a clear angle, you need to understand that the walls must be perfectly aligned. If the angle of the wall, both internal and external, does not have 90°, then cutting 45° corners on the tiles does not make sense.

As for the cut, it is best done with an electric tile cutter. The cutting element should be a diamond-coated circle. Due to high speeds, a perfectly even and smooth cut is obtained.

The only thing is that the guide on the bed must first be set at 45°. After such a cut, you will not need to further process this side of the tile.

Some craftsmen have adapted to using a budget option, making the cut with a regular tile cutter and adjusting the edge with a grinding machine. However, this method has its drawbacks. It is extremely difficult to make a perfect cut, as is the case with an electric tile cutter.

If you already have a tile cutter, and it has the ability to change the cutting angle, then you can beautifully design the internal and external corners of the walls.

A visual example of tiling a corner with cutting tiles at 45 degrees

Using Trims

This decoration of wall corners is in great demand. Joining tiles using trims greatly simplifies the tiling process. They exist both internal and external.

One of the main advantages is that it is possible to choose trim of a wide variety of colors, which will be most suitable for decorating a corner. They can be plastic or metal. Accordingly, they differ in cost, the first ones are much cheaper. Among workers, trims are also called corners.

So, to finish the outer corner, an L-shaped corner is used. It has a slight bulge. Corners for internal corners have a concave shape. They are often used as a transition from tiles to a bathtub.

The advantages of such corners:

- Excellent aesthetic properties.

- Excellent protection of corners from possible mechanical damage. If you accidentally catch a corner with a heavy object, you will have to replace not the tile, but just the corner. And if the corner is metal, then no damage will be visible at all, except perhaps a small scratch.

- Trims are convenient for finishing wall corners. There should be no difficulties during laying the tiles.

- When forming a tile corner, there is no need to use expensive equipment, such as a tile cutter. It is enough to have a level at hand.

- The trim is glued using liquid nails or silicone. Special adhesives can also be used. Some specialists can lay such corners on the same mortar that is used to lay the tiles.

Options for correct installation of tiles on external and internal corners - video

Corner tiles

Ordinary corner tiles are often used to decorate wall corners. But not all manufacturers produce tiles of this shape. By far, this is the easiest way to trim corners. In appearance, they are presented as two tiles connected at 90°.

However, they are used primarily for external corners. When laying tiles of this shape, glue is used, onto which the remaining tiles are laid in a straight line.

The result is beautiful. Using special corners made of metal or plastic cannot even compare with this method.

Tips for choosing

- In order to get an even, beautiful, smooth surface after laying the tiles, you need to be very careful in choosing the necessary materials, including corners.

- When purchasing corners, it is better to take them with a small margin relative to the estimated quantity. The stock is needed for pruning.

- The size of the corner must exactly match the height of the tile.

- When choosing a molding from a specific supplier, it would be useful to read in advance the reviews of customers who have already evaluated these products from different points of view (how the corner behaves during installation, operation, its physical and mechanical characteristics, etc.).

- When purchasing components, you should definitely check the documents confirming the high quality of the products.

This is interesting: How to properly lay a ceramic border for a bathroom? Laying methods

For more information on installing the corner, see the following video.