Crimping a wire cable is a very responsible task, especially if this connection is a power connection. In this article we will look at how to correctly terminate connections of low-current wires (up to 15–20 amperes).

Remember! The use of power cables and lugs made of the wrong material and cross-section can lead to serious consequences, such as fire of the wiring, for example.

Crimping technology

There are two methods by which crimping is carried out:

- local indentation;

- complete compression.

The wire for crimping is copper or aluminum. Therefore, the sleeve can be either copper or aluminum. There is also copper-aluminium. Since an aluminum cable is prone to the formation of an oxidizing film, the aluminum sleeve must be cleanable and treated with a special lubricant. To protect aluminum from oxides, quartz vaseline paste is used. Copper wire is also subject to lubricant treatment. With its help, the likelihood of damage to the core during crimping is reduced and friction is reduced.

If the cores are multi-wire, they are aligned and folded so that they easily fit into the sleeve; you can twist the wires a little. Then the cable is inserted into the cartridge until it stops. The connection can be made not end-to-end, but, for example, with a factory. Then the total cross-section of all wires should not exceed the cross-section of the bushing.

In any case, sleeves are used that are designed for the total cross-section of the cores being crimped. If a press with point (local) indentation is used, make 2-3 pressings evenly distributed along the length of the sleeve to ensure mechanical strength of the connection and good electrical contact. For continuous crimping using hexagonal or square dies, the recommendations are essentially the same

In both cases, it is important that the sleeve does not crack during crimping (if it is too small) and that there are no uncompressed areas or cavities (if it is too large)

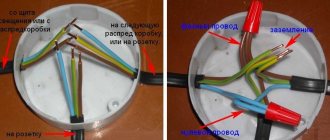

After the crimping has been carried out, it is necessary to create an outer insulating layer at the junction using electrical tape or elbow cloth. After insulation, you should carefully fold the wires and the cable itself in the junction box.

The video below clearly shows how to crimp wires with press pliers:

Types of sleeves

It is very important to choose the right sleeves for crimping wires

According to the material of execution

A copper cable or wire should be crimped with copper sleeves accordingly. They come in two types and have the following abbreviation:

- GM - copper sleeves. They are made purely of copper, do not have any coating or processing, and in appearance they look like ordinary pieces of copper pipes.

- GML – tinned copper sleeves. They undergo a tinning procedure, that is, their surface is treated with a special tin-bismuth layer. This is done in order to prevent oxidation and corrosion processes. It is also known from school physics lessons that copper, like any other metal, oxidizes. Tinning prevents this process; the crimped wires will not enter into a chemical reaction with the tinned sleeve.

I would like to give one useful piece of advice. Do not listen if suddenly one of the experienced electricians tries to prove to you that using GML sleeves it is possible to crimp aluminum wires, since the tin layer will not allow direct contact of aluminum with copper. This is incorrect, because during crimping the surface layer of the tube is deformed and the corrosion process is still inevitable.

To connect aluminum wires, they use products made of the same metal; they are designated GA (aluminum sleeve).

There are also combined sleeves, they are designated GAM (aluminum-copper sleeve), in everyday life many call them aluminum-copper. This option is used when you need to connect wires made of different metals end to end. The sleeve is a tube of two parts; at the junction of dissimilar metals, the connection is made by friction welding. Here everything is extremely simple and clear - you need to insert copper wires into the part of the tube made of copper, and an aluminum conductor into the aluminum part.

And the most modern version with the designation GSI (insulated connecting sleeves). They are based on ordinary tinned tubes, only they are covered with polyvinyl chloride insulation on top. They crimp copper wires. During crimping, the insulating layer is not removed, pliers are put on top of it, and compression is performed. Such sleeves greatly simplify the work of an electrician, since the crimped electrical assembly no longer requires any additional measures to insulate it.

By size

After the letter designations, a number is written on the sleeve. What does it mean? This is the cross-section of the conductor for which this product is designed. For example, tinned copper sleeves are produced for wires with a cross-section from 2.5 to 300 mm 2. Accordingly, with an increase in the cross-section of the conductor, the sleeve itself has larger dimensions (diameter and length). For combined products, two numbers are written through the fraction, one indicates the cross-section of the copper conductor, the second - the aluminum.

By design

The sleeves also differ in design. They can be hollow, that is, inside they are bare through tubes. And they come with a partition in the middle, which allows you to adjust the depth of the conductors, that is, the tips of both connected wires will enter the sleeve to the same length. Combined sleeves are produced with partitions, which are used when connecting conductors at the joint.

How to connect electrical wires with lugs

Another way is to use tips. The tip looks like a piece of tube, cut and turned flat on one side. A hole for a bolt is drilled in the flat part. The lugs allow you to connect cables of any diameter in any combination. If it is necessary to connect a copper cable to an aluminum cable, special lugs are used, in which one part is copper and the other is aluminum. It is also possible to place a washer, brass or tinned copper, between the tips.

The ferrule is pressed onto the cable using a crimper, similar to how wires are connected using crimping.

Crimper for pin bushings

The pin lug crimp consists of a series of indentations and tabs, each of a different size. Each hole is used to clamp bushings of a different size.

Each hole has a number that determines what cable section the hole is intended for. For example, this crimp can clamp wires with a cross section from 0.5 mm to 16 mm square.

How to brew twist

For good contact, the twist can be welded with a graphite electrode or a gas torch. Torch welding has not become widespread due to the complexity and the need to use gas and oxygen cylinders, so this article only talks about electric welding.

Electric welding is performed using a graphite or carbon electrode. Graphite electrode is preferable. It is cheaper and provides better welding quality. Instead of a purchased electrode, you can use a rod from a battery or a brush from an electric motor. It is better not to use copper electrodes. They often get stuck.

For welding, you first need to make a twist 100 mm long, so that the finished one turns out to be about 50. The protruding wires need to be trimmed. For welding, it is best to use an inverter welding machine with adjustable current. If this is not the case, then you can take a regular transformer with a power of at least 600 W and a voltage of 12–24 V.

Near the insulation, “ground” or “minus” is connected using a thick copper clamp. If you simply wrap a wire around a twist, the twist will overheat and melt the insulation.

Before starting welding, it is necessary to select the current. The required current varies depending on the number and thickness of the wire that makes up the twist. The welding duration should be no more than 2 seconds. If necessary, welding can be repeated. If everything was done correctly, then a neat ball will appear at the end of the twist, soldered to all the wires.

Tip sizes, design features

The minimum available sections for GML are 1.5 mm 2. Further sizes increase - 2, 4, 6, 10 mm 2 and higher. Based on these values, we can say that the cross-sections of the sleeves are equal to those of wires and cables. It is quite easy to decipher the tip designations. For example, GML-6 is a copper tip, tinned. The cross-section is 6 mm 2. In the case of combined sleeves, the marking indicates two sizes - for aluminum wire and for copper. For example, GAM 16/10 - 16 for aluminum, and 10 for copper.

By design, the sleeves can be end-to-end in the form of a hollow tube or with a partition. The latter are used when crimping wires with end-to-end lugs is performed. These partitions are located in the middle of the sleeve. With their help you can adjust the depth of the cable entry. If it is necessary to extend it, then both ends will go into the tip to the same length.

Ferrule crimping

To find out which tool is best to use for crimping various types of tips, watch this video:

As you can see, you don’t need any special intelligence or experience to use the tips; everything is done easily and quickly. The only thing you will need are special devices - a stripper and press pliers, but they are affordable and can be purchased. When connecting multi-core conductors, be sure to use lugs and make the power supply as reliable and safe as possible.

How to crimp a wire: instructions for single and double NShVI

The wire with the tip must be installed in press jaws in a matrix of a suitable size. During the crimping process, you need to ensure that the wire does not move inside the sleeve. The first crimp is done with an indentation of 1–2 mm from the edge, if necessary, the second at the same distance from the first.

The handle of the press pliers is compressed until it is in full contact with the surface of the part and the matrix is connected, then the sleeve is moved and a second crimping is done. If the shank is long, work continues until the colored skirt.

The crimping scheme for a double tip is practically the same. You only need to insert two wires into one hole in the shank at the same time.

Stages of wire crimping

Visual instructions for crimping a wire with an NShVI lug are presented in the video:

Crimping power cable lugs

When crimping power cables, tinned copper lugs are used, which are well protected from corrosion. If, when cutting the cable, its cores “fluff” significantly and become larger in diameter than the rest, then perform the work on a sharpener. When unrolling the cable, make sure that the circle removes excess knots along the cores and does not bend them.

Soldering is absolutely not suitable for crimping a power cable, since single tin contacts cannot be used on such wires.

Principle of wire crimping

You can perform crimping of wires using sleeves in several ways. It will not be possible to single out the best of them, since comparison is inappropriate here. The choice of crimping method directly depends on the conditions for electrical installation work, cross-sectional parameters and other important points. Let's consider the features of the main method of crimping using sleeves.

Work begins by introducing the previously stripped ends of the wires into the cavity of the sleeve. The next step is crimping - squeezing using a special tool. The metal surface of the cores and sleeve is compressed, resulting in a reliable adhesion of the parts. It is necessary to connect at several points, followed by insulation of the connection points. An exception is working with insulated sleeves for crimping, which do not require additional insulation.

When choosing this method of connecting wires, you need to remember that the contact will not be disconnected in the future. Taking this into account, work will need to be carried out carefully and prudently.

Technical specifications

The main types and brands of thin-walled insulated lugs and terminals widely represented on our market are the following:

NKI ring tips - all their data and technical parameters are given at the beginning of the article above.

NVI insulated fork lugs:

Insulated flat pin lugs NSHPI:

Insulated round pin lugs NShKI:

Connectors—flat insulated “female” terminals RPI-M:

Connectors - flat insulated male terminals RPI-I:

You can view the current prices for tools for crimping such tips here.

The main points of the process of crimping wires and twists

To do this, you will need to strip the wire from the outer insulation, and then use a mounting knife to remove the inner protective sheath. To make it convenient to twist the wires, I personally collect the bare wires into a bundle and bend the ends.

Then, first twisting the wires by hand, I achieve greater contact through the work of the pliers with which I tighten the twist.

Having bitten off the excess wires with the same tool, I get a good connection 3-5 cm long.

Next, the only thing left to do is put copper sleeves of suitable sizes on the twists and crimp them. Moreover, crimps come in different diameters (6 mm, 8 mm, 10 mm and more). Usually, I use 6 mm products to connect strands of light groups, where the cross-section of the wires is not so large (1.5 sq. mm). For socket groups, sleeves with a diameter of 8 mm or more are taken, since here the wires have a cross-section from 2.5 to 4 sq. mm.

After that, I insulate the connections, put them in the junction box and close the lid so that everything is “feng shui”.

CS-CS.Net: Laboratory of the Electroshaman

Tips NSHVI, TML and tools for crimping them

...one reader once wrote to me: why don’t you make a post about NShVI tips and how to handle them. At first I thought that he had become insolent, because NShVI tips are the simplest nonsense, which is not even worth writing about. And then I remembered that even with these simple tips I had developed my own technologies and techniques that I can share. So consider this post another master class.

However, please forgive me for the quality of the photos: the idea for the post came to me this evening, and I took some of the photos in the light of a table lamp, so their white balance and focusing are off. But since I don’t teach specifics and don’t repeat stupid things, but general principles and deep ideas, I can convey information to you with the help of these photos.

Please go to cat. The entire post is divided into several parts to make it easier to read. I also discovered the band Uriah Heep, to which the post at 02:32 in the morning somehow went well. Hm. Sometimes I wonder if I should add a note indicating which music or film was used to write which post. So, the post was written to the looped “Uriah Heep - Come Back to Me (Acoustically Driven 2001)”, performed acoustically.

General. Why is this necessary?

The time when shields were assembled with “hard” wire is gradually becoming a thing of the past. Together with those who are still screaming with foam at the mouth that somewhere in the PUE it is written that boards should be mounted only with single-core (for example, electricians from housing offices and management companies periodically try to prove this to me). This is crap and nonsense, because some shields simply cannot be assembled with a single core due to its rigidity and other problems.

Any installer who starts collecting panels in large quantities and loves his work, his hands, his tools, gradually reaches flexible (stranded) wire and after that never returns to monocore. And in my posts I teach you to love yourself and your work. Well, your instrument and the world around you. In the end, sooner or later you come to the understanding that you are not working for money, but to improve the world and help other people. In this case, money somehow appears by itself.

So. It is more convenient to work with a soft wire, because it is easier to bend, it can be laid beautifully in bundles, and shorter connections can be made on larger sections: it will be easy to lead the wire where it is needed, because its flexibility is much higher than that of a monocore.

But there is the most important problem. Not all things are designed for stranded (soft) core. For example, according to the rules, fixed wiring must be done with cables. And the cables are made monocore for a bunch of different reasons, and all sorts of sockets and switches are designed for monocore. For example, spring contacts of switches, WAGO terminals, spring zero bars and other things. There are also a number of things in which the wire is clamped with the end of a screw. These are Chinese terminals, and some connectors and clamps of all kinds of equipment.

If you clamp a stranded core directly into such contacts, the screw will cut the wires of the core, and little of the useful cross-section will remain. This is bad. Some of the Kulibins are trying to tin the vein the old fashioned way. This is even worse because the solder flows under pressure and melts at a low temperature. Did you know, for example, that during some short circuits, copper busbars and all their fasteners are designed to heat up to +300 degrees? What will happen to the soldered or tinned wire in such cases? The solder will melt, the contact pressure will weaken, the contact will weaken even more and begin to heat up even more. Until it burns off.

Here I probably need to say why I think that all soldering and twisting should be prohibited in power engineering. The fact is that some wire connections are low-tech. The quality of execution depends on the specific person who makes them. Well, for example, one will make a twist 3 cm long and solder, and the other will make a twist 5 cm long. Who is right? How to evaluate this? Testing in the laboratory. But what next? A person will get tired, think, miss a couple of turns of his twist... and the technology is broken.

Other connections (crimping, spring terminals), if you use them not thoughtlessly, but considering which is better, are technologically advanced: contact is made either due to the technology of the terminal itself, or due to a certain tool, which is standard for everyone and does the same thing in different hands.

So, in order to turn a soft wire into a “hard” one, special tips are made. We use tips of the NShVI and NShVI(2) types in shield assemblies. This is a thin metal tube with an insulating skirt. Don't confuse them with cartridge cases! The purpose of the NSHVI tip is only to hold the wire wires together. And the job of the sleeve is to create hellish clamping force and electrical contact. Therefore, the sleeve is much thicker, and those Kulibins who use NShVI as an analogue of sleeves are very wrong with the word “completely”.

In no case should a monocore (rigid, solid) wire be crimped with NShVI lugs. This, by the way, is what happens when assembling the shield. Inside the shield we assemble everything with PuGV wire and NShVI lugs, and “outside” the external lines are connected with monocore.

But what if we need to tighten the wire under a bolt or screw? And for this they came up with TML tips. You can press a wire (solid or flexible, multi-wire) into this tip, like into a sleeve, and screw the tip itself where necessary. This solution is used to supply power to buses, to connect PE or powerful power lines and cables.

And since the NSHVI is a thin-walled tube, in principle, in some cases we can stuff several wires of a smaller cross-section, or one large and one small wire, into this tip. This is something that does not work with monocore when assembling shields. For example, we need to power a frail LED light bulb from a 16 square input (post about such light bulbs from ABB). What to do? In the case of a monocore, we would have to make some kind of “loop” and seamlessly insert the monocore into this light bulb. The light bulb would have burst.

And in the case of NShVI, we will slip a thin 1.5 square wire under the 16 square NShVI and connect it to the light bulb. At the same time I give a remark. In this case, the LED light bulb does not need to be protected. There's not much to breathe there. And if it were a voltmeter or other device, then it would be good to plug a fuse into this 1.5 square piece of wire (I use terminals with .SF fuses). In large shields I began to do this.

Tool. Hand size. Why haven't I been able to get hooked on Knipex?

Here they also asked me to tell you about my instrument. OK, I’ll tell you why I can’t get rid of the KVT and why I chose just such a tool that was not intended by the manufacturer for the tasks that I assigned to it.

What types of tools are there for crimping tips? There are special pliers with fixed dies (for KVT these are STK-type pliers). The matrices of these pliers sometimes go wrong if the wire has a low cross-section. Well, you also have to keep a bunch of pliers: for single, for double tips. And another pliers for large sections.

Pliers with a set of dies. This is what I didn’t like right away, because I often need to change the crimping section. Take the same example about the input of 16 squares and 1.5 for a light bulb. I press my NShVI by 16 squares, and then I need to compress my NShVI by 1.5 squares. What, rearrange the matrix? This is a labor-intensive process, you can’t do much. Therefore, I immediately brushed aside such ticks.

To assemble all my shields I now need the following tool:

- KVT WS-04A (on the KVT website). This is my most basic and very favorite tool. I recommend it to those who are starting to get into panelboards or repairs. This tool, due to the undocumented feature of crimping NSHVI, covers most of the tasks of assembling panels. The tool can bite and strip cables up to approximately 10..16 squares. It also has grooves into which NShVI tips fit up to 1x10 (with difficulty up to 1x16) or 2x6 (with difficulty up to 2x10) squares. I’ll tell you more about this feature when I get to the NSHVI itself. Important! There is the same tool WS-04 B (on the KVT website) with dies for crimping NShVI. But I don’t like it: the matrices there are made without taking into account counterfeit wires and wires of undersized cross-sections and they press NShVI only up to 6 squares. And with matrix grooves from WS-04 A you can press more sections. Using WS-04 A I press the tips into 6 squares. I also chose WS-04A because it’s not good to clutter up the workplace with a bunch of tools. It’s good when part of the tool is universal (of course, if this versatility does not interfere with the work and quality of the tool).

- KVT PKVk-10 (on the KVT website). This tool is positioned as a universal crimp for NShVI with sections from 0.5 to 10 squares. But in reality this is not entirely true. To press the NSHVI even 6 squares, you need to have a strong hand and press with all your strength. And if you adjust the pressing force downward, it will not press small NShVIs well. But this thing is cool and very compact when you need to crawl into a difficult place on the shield and press something there. I use it for crimping very small sections - up to 2.5..4 squares.

- KVT STK-03 (on the KVT website). These are tough pliers for crimping NShVI for 10, 16, 25 squares. With them I press the NSHVI into 10, 16 squares. And in the position for 16 squares you can press NShVI (2) into 10 squares. I will also tell you about this technique. Since I assemble the shields in parts - first the thick input, then the small lines - it turns out that first I work with these pliers, and then I put them aside and do not clutter up the table.

- KVT PK-16 (on the KVT website). These press pliers are suitable for crimping TML sleeves and tips up to 6..10 squares, although they are stated to be up to 16 squares. If your hands are sensitive and you love them, then you won’t force yourself trying to squeeze your hands as hard as you can. The press jaws are not very good, but they are cheap. Now there is a reinforced version of the PK-16u, which is more durable. In general, if you need to crimp TMLs once every couple of months or press the cartridges once during repairs, then the PK-16u is your choice (take the reinforced version right away).

- KVT PGRs-70 (on the KVT website). This is my new acquisition - a hydraulic press for TML and cartridges as a replacement for the PK-16. The press has replaceable dies from 4 to 70 squares, which is enough for my eyes for my new tasks (it’s easy to press TMLs for 50 square). It’s a great pleasure to press the TMLs of my common sections (6, 10, 16 squares) - your hands don’t get tired, no effort is required.

So why not Knipex or Weidmuller? Damn, because HANDS. My hands are designed in such a way that the longer my fingers are extended, the less force I can create with them. I like my hands and I don't want to be some kind of super macho. I love my sensitive fingers, so I wanted a tool that had handles that diverged at a slight angle.

I took a lot of photos for the article. Look how the WS-04 lies in my hands. The main working fingers (index, middle, ring) fit perfectly on the handle of the instrument and I can control its pressing or squeeze it with force.

Convenience of the tool handles for the hand (WS-04A)

Like this:

Convenience of the tool handles for the hand (WS-04A)

Tools like Knippex (I wanted to buy their crimp from Valentinich, but I felt it and got confused because of the handles) have handles that diverge like on STK pliers. You see, my fingers are barely enough anymore. What saves me in STK is that the handles first squeeze the jaws idle and when the jaws of the matrix reach the very tip, the squeezed handles allow me to grab the pliers more conveniently and apply force.

Inconvenient tool handles: open too wide

Also note that I'm holding them backwards. As far as I understand, the red pen should move, and the black one should lie in the corner between the thumb and forefinger. But at the same time, the matrix with grooves moves in my hands, and I have to hold the tip and wire - they move along with the matrix. And if I hold the pliers as in the photo, then the wire and tip do not move.

Well, PKVk-10 also has widely diverging handles. Don’t think that my fingers are short and my palm is not like a child’s. I just don't like forcing my fingers to do things they're not meant to do. Let the instrument suffer, not my hands.

Inconvenient tool handles: open too wide

In another position of the tool the same garbage:

Inconvenient tool handles: open too wide

Actually, that’s why pretentious brands didn’t work for me, although I tried them. But they did not pass the test for force and opening of the handles.

Tips NShVI, NShVI (2) and methods of working with them.

Well, now let’s move on to the NShVI tips themselves (here is their description on the KVT website). I have already written about why these tips are created. Two of their features should be mentioned:

- Skirt color. This color encodes the cross section of the tip. We usually adopt the KVT standard, where the tip of 1.5 squares corresponds to black; 2.5 squares - blue; 4 squares - gray; 6 squares - yellow; 10 squares - red. There is also either a branded or Chinese standard, in which six or ten can be brown, green or whatever. Typically, such tips are of poor quality and the skirts themselves crack. So don’t try to look for “10 square lugs for phase and zero.” The color should code the wire cross-section - that's all.

- Package. Most often, the tips come in packs of 100 pieces, which are packed in packages of five, that is, 500 pieces each. Not everyone sells individual tips. For example, in Moscow this is Elektromontazh or the store where Igor Valentinich used to work - ElektroMaster.

- Double tips. There is no need to try to invent something to connect two wires in one place. For this purpose there are tips NSHVI(2) . These lugs are immediately designed to connect two wires of the specified cross-section. That is, NSHVI(2) for 6 squares will accept two wires of 6 squares each.

Here are different samples of tips and the same crimping tool that I talked about above when I talked about hands and handles. The bold blue tip is 50 squares =). By the way, double NShVIs are not produced for large sections. The maximum double NSHVI seems to be 16 squares.

Tips NShVI, NShVI(2) and tools for crimping them

Let's take a look at my favorite stripper KVT WS-04A in action. I will try it on maximum sections - 10 sq. mm.

Cleaner KVT WS-04A

First, she bites the wire. Anyone who can fit into the teeth. I sometimes managed to bite NYM or VVG 3x1.5 or even 3x2.5 squares the second time. In the case of assembling shields, this means that it can cut off large cross-section wires. I bite off the six with nippers with carbide jaws, but I bite off the ten and 16 with a scraper.

Stripper KVT WS-04A: Wire cutting

Well, she also strips the wire. Standardly, it has a stripping length adjuster, which didn’t work for me and just gets in the way. So I unscrew it the hell out, and determine the stripping length by the right rivet. For the six, the wire should not reach the rivet a little, and for the ten, it should go a little over it:

Stripper KVT WS-04A: Wire stripper

Usually it is enough to squeeze a dozen tips so that the eye and hands remember the position of the wire - and then stripping proceeds on an intuitive level, without consuming the brain.

So we have stripped our wire. It is noteworthy that this cleaner cleans everything it comes across. It can even remove the insulation from a flat VVG or ShVVP in order to connect temporary structures at sites. One movement - they pulled off the top insulation, the second - they stripped two or three conductors at once. Just keep in mind that the thicker the wire or cable, the greater the load on the jaws, which are actually intended for one wire. Therefore, if you constantly clean VVG with such a cleaner, it will quickly die.

Stripper KVT WS-04A: Wire stripper

Well, what I really like is that the remainder of the insulation is held by the stripping sponge if you continue to squeeze the handles. I usually take it to a trash box (a box from OT63F3 switches is great). As a result, I don’t have anything lying around in my workspace and it’s clean.

Stripper KVT WS-04A: Remaining insulation is retained

And of course, I found a screw zero bar to screw the bare ten into. Do you see how she was crushed there? Do you see that some of the wires have simply moved to the sides and are not even pressed?

PuGV wire clamp into screw busbar

But what happens to the wire strands after such pressure and a screw:

Clamping the PuGV wire into a screw busbar - trace of deformation

We are not happy with this. By the way, this is also bad because if you move the wire, then all these wires will break one by one, the pressing force will weaken, and as a result we will get poor contact.

Look at the matrices (grooves, teeth) of the WS0-04A . It is precisely thanks to the lower teeth that the undocumented freebie and crimping of the NShVI is obtained. If you want to order a Chinese analogue of such a scraper, then order it with exactly these teeth!

Teeth for crimping tips in the KVT WS-04A stripper

Our NShVI tip can be placed in this tooth like this:

Using the KVT WS-04A stripper for crimping NShVI

And then press it with a stripper. There is a pressed place on the tip:

Using the KVT WS-04A stripper for crimping NShVI

The groove itself compresses the tip in this way - quite tightly. The tip crimped in this way is difficult to remove from the wire, I tried it.

Using the KVT WS-04A stripper for crimping NShVI

Well, if we repeat such crimps, moving the tip, then in the end we will get a picture like the one in the photo below. In fact, if you immediately twist your tip into the shield, you don’t need to pervert it so beautifully. It is enough to make two or three crimping points, and then the tip will be flattened with a contact screw.

NShVI tip, crimped with stripper KVT WS-04A

Now let's screw our tip into the shredder and tighten it properly. Here, perhaps, we should mention another ficus for those who don’t just look at photos in a row, but also read the text around them. In general, if you clamp a wire with an NShVI tip somewhere, then you can safely reduce the maximum cross-section of the terminal by one step. Let's say, if on some cross-module it is indicated that it accepts a monocore of 16 squares, then most likely the NSHVI for 16 squares will not fit there, but will only fit into 10 squares.

Twisting the PuGV wire in the NShVI lug into a screw busbar

After using the tip, the following is obtained. The pressure of the screw is now distributed over all the cores, because the tip prevents them from moving apart. And due to the thickness of the tip wall, the screw does not damage individual wires. In this case, such a screwed wire can be bent as much as you want - the individual wires are “tied into a bundle” and will not break.

Deformation of the NShVI tip by a screw tire

Let's play around with PKVk-10. As I said, I use it for small sections. It is a pleasure to press them with it. Sticked the tip in, squeezed - and got it!

Crimping of small tips using KVT PKVk-10

This crimper has a different design: the jaws have four edges and converge on all sides. The result is not a trapezoidal, but a rectangular crimp profile. Sometimes this helps to win precious microns of tip width that does not want to fit into some particularly small automation terminal.

Crimping of small tips using KVT PKVk-10

Sometimes the crimper becomes malfunctioning (from frequent use it becomes a little loose) and it jams part of the tip. It's not scary if you're not a perfectionist.

NShVI tip 1.5 sq.mm after crimping KVT PKVk-10

Well, here is a double tip NSHVI (2) for 6 squares. When I first bought them, I was terribly confused with their sections and tried to look for NShVI (2) for 12 squares. In fact, everything has been calculated for you and me. These lugs have a wider wire skirt and are specially designed for two wires. Sometimes I see shields where people use a 10 tip for 2x6 squares. This is bad. I did this myself, but as soon as I started collecting more than one shield every three months, I bought NSHVI(2). Don't waste your money, do it right!

NShVI(2) tip for two PuGV wires

Such NShVIs can also be safely used with the same WS-04A . This is why I say that if you want to do your own electrical repairs and assemble a small panel, then start with WS-04A.

Crimping of the tip NShVI(2) 6 using KVT WS-04A

The result is a digestible contraption. It should be taken into account that NShVI(2) is 6 squares slightly longer than a regular NShVI and in order for it to fit correctly into the machine or RCD, it will need to be bitten off a little (by ~2 mm).

Crimping of the tip NShVI(2) 6 using KVT WS-04A

Well, I press the big tips with STK-03 :

Pressing the tip to 25 sq. mm. using KVT STK-03

It turns out like this. The matrix is cool and presses the tip very well!

Pressing the tip to 25 sq. mm. using KVT STK-03

Clamping of wires of different sections into one NShVI lug

Now let's talk about the undocumented features of installing shields with soft wire using NShVI tips. The first task is to remove the small wire from the large cross-section wire. It is implemented due to the fact that not all wires have thick insulation, and the tip skirt is made with a reserve in diameter.

Therefore, we can simply slip a small-section wire next to the larger one. Here I have a wire for 6 squares and 1.5 squares.

Trick: you can press wires of different sections into the NSHVI tip

I strip the small wire longer than the main one and move it forward so that it goes into the tip first:

Trick: you can press wires of different sections into the NSHVI tip

In this way. I need the wire insulation to fit into the skirt of the lug.

Trick: you can press wires of different sections into the NSHVI tip

After this, all I have to do is push the main wire all the way in and crimp the tip.

Trick: you can press wires of different sections into the NSHVI tip

The same thing can be done with double tips. I’ll take ten and the same one and a half rubles as an example.

Pressing in the tip NSHVI(2) 10 and small wire

We start again with one and a half rubles. We bring it inward to the beginning of the metal tip, and then push in the main wires.

Pressing in the tip NSHVI(2) 10 and small wire

I press NShVI (2) tips for 10 squares on the matrix “16” of STK-03 pliers. To prevent the pliers from snapping, I hold the ratchet lever.

Pressing the NShVI(2) 10 tip and small wire using KVT STK-03

It turns out that this is the crimping, also durable and high quality.

Pressing the NShVI(2) 10 tip and small wire using KVT STK-03

I also developed this same technique to the point where you can simply take several small-section wires (for example, 4 pieces of 1.5 squares each) and push them all together into a suitable NShVI (it is better to use a double tip NShVI (2)). This is necessary if we divide the lines in the panel into terminals and we need, for example, to take a zero from one machine or RCD to several different terminals at once (where a jumper is not suitable).

Crimping several wires of small cross-section into an NShVI tip of a larger cross-section

Then we can make something like this. In NSHVI(2), three wires of 2.5 or four wires of 1.5 fit into 4 squares.

Crimping several wires of small cross-section into an NShVI tip of a larger cross-section

Manufacturing of long NShVI (for meters)

I’ll make a separate point about long tips. They are most often needed to connect meters, because a regular NShVI tip is enough for exactly half of the terminal. If you constantly work with meters (or those that require such long NShVI), then you can clearly order them. But for example, I connect one meter every six months.

So I just press the two tips one after the other. There are two ways to do this. One is to press two NShVIs against each other and bite off the skirt of the second one. But there it is difficult for the veins to get into the tip tube - after all, it does not have a skirt on the opposite side.

Therefore, I do the opposite - I bite off the skirt at the tip (my side cutters with carbide jaws are just visible here). To do this, it is enough to bite it sharply almost to the very edge. Then it cracks and is easily removed.

Manufacturing of an extended tip NSHVI (for meters)

Well, then all we have to do is add another tip tube and press it all in.

Manufacturing of an extended tip NSHVI (for meters)

As a result, with careful execution, we get this design:

Manufacturing of an extended tip NSHVI (for meters)

That's all with NSHVI. Let's move on to more evil things. And then I'll go get some sleep

TML tips and tools for crimping them. Shells.

Well, now let's dive into the world of thicker copper. TML-type terminals accept both a monocore and a stranded core, because they are actually made from GML sleeves, which are used for crimp connections. One of the edges of the sleeve is simply flattened and a hole is stamped in it. Therefore, everything that I will describe below will be applicable to cartridge cases.

These lugs are useful when you need to screw PE onto the panel body, make a transition from a steel grounding strip to copper near the facade of the house, how to transfer the connection of the old floor panel body to the riser zero... and much more. Here's what you need to know about TML tips:

- They differ not only in cross-section, but also in the diameter of the hole for the screw/bolt. For example, you can find TMLs for 10 squares for an 8 mm or 10 mm bolt.

- The shape of their plane, which is screwed on, does not fit in all places. For example, not all tips fit into machines with a molded case (TMax and others). My TMax XT1 barely fit TMLs of 25 square meters. Therefore, for such cases, you need to either buy special tips (at KVT they are called TML DIN, I think), which have a narrow contact pad specially designed for such machines, or order special extended terminals for the machine (this is useful if no one knows who will connect the cables after the machines and it will not have special tips).

Well, it’s clear that these tips have a thick wall and you can’t press them in with any WS-04 or pliers. And this is where press pliers are needed. If you need to press TMLs once or twice or press about 100 cartridges once during a repair for repairs in your apartment, then you can take the KVT PK-16 or PK-16u (reinforced version, I haven’t bought it and won’t - because it’s hydraulic bought a press).

ATTENTION! I periodically see attempts here to wriggle out. For some reason, some people try to press the tips of NShVI with such press pliers. This is not at all correct! Such pliers develop a lot of pressure and press pointwise, and because of this they can break the thin tube of the NSHVI tip! Don't do this! Buy the same WS-04A!

TML tips and press tongs KVT PK-16

Over time, the PC-16 develops the following glitch: if you often press sections into 10 or 16 squares (which, however, they are designed for), then their jaws break out like this:

Press jaws KVT PK-16 - jaw divergence

My PC-16s served me faithfully for about four years, because I pressed or mostly TMLs into 6 squares (a 10-square PuGV fit into them with force). But as soon as I started pressing dozens of them, the jaws began to bend.

I will show you how to pressurize a TML with such pliers. We clean our ten to the length of the crimp:

Tip TML-10 and its crimping using KVT PK-16

Well, we continue to press. The effort that must be applied to the PK-16 is hellish. My hands don't like it. As I already said, choose the right tool, feel yourself, your strength and hands. It’s one thing if you press something once a month. And if every... at least a week, then take care of your hands! Love yourself!

This is how the lips warp:

Tip TML-10 and its crimping using KVT PK-16

For crimping TMLki, two points are enough. I did one in the front and one in the back. Do you see how the tip was cut off during crimping due to the skew of the jaws?

Tip TML-10 and its crimping using KVT PK-16

It looks the same from the back. This is not fatal and will work, so PK-16 (I say it again) have the right to life. By the way, if you selected everything correctly, then the conventional matrix number will be printed on the tip. This means that the pressure for crimping was sufficient.

Tip TML-10 and its crimping using KVT PK-16

Well, what should you do when you need to press something into sections larger than 10 or 16 squares? For example, I needed to press TMLs for 25 and 50 squares:

TML tips of large sections (16, 25, 50)

I'm sorry, what? Buy a hydraulic press! When I was afraid to buy it, I thought it would cost about 20-40 thousand. But it turned out that it costs 6-8 rubles, depending on the model! This means it is available quickly if you start needing to press a lot. Let's say, you can even buy it for some object with an advance payment. And this is good!

Hydraulic press KVT PGRs-70 for crimping TML and GML

I bought a PGRs-70 press. He presses everything he can (TML, GML), from 4 to 70 squares. The kit includes the entire set of matrices for these sections. Such a press is already a serious contraption that makes the work much easier.

Hydraulic press KVT PGRs-70 for crimping TML and GML

The press develops pressure up to 5 tons. So he will crush his fingers in a moment. Also in press models with the letter “c” (PGR s ) an automatic pressure release is provided when the crimping is completed. I note that this pressure release rarely works for me. I noticed that this has to do with the speed of pressure applied to the press handle. If you press sharply and strongly, then the automatic pressure release works. But if it’s gentle and smooth, like me, then it doesn’t work.

Hydraulic press KVT PGRs-70 for crimping TML and GML

These are the matrices that come with the press:

Dies for crimping tips

The matrices snap into the holes at the bottom and top of the press:

Installation of dies in the press

This press has a small bug. Sometimes the matrices can be slightly skewed. But unlike PK-16, here this will not affect the quality of crimping, because the matrices are wide and they should (as it seems to me, according to the designers’ intention) automatically align.

Distortion of matrices in the press

To pressurize something with it, you need to close the tap. The tap is a small twist on the press cylinder. It closes by hand very easily. If it is closed, then the press pumps up pressure and does not release it. And if you open the tap, the pressure is released, and the press cylinder smoothly moves down.

I press the tips like this. First, I adjust the dies closer to the crimping site, so as not to do three things at once (hold the press, the tip and pump the lever):

Crimping of a TML tip using KVT PGRs-70

After this, I move the jaws with light pressure to grab the tip with them:

Crimping of a TML tip using KVT PGRs-70

Well, then I press it all the way.

Crimping of a TML tip using KVT PGRs-70

After that, I step back and repeat the crimping process just once for beauty.

Crimping of a TML tip using KVT PGRs-70

Let's have some fun?

TML tips of large sections and dies for crimping

This is what it looks like (25 and 50 squares)::

Pressed TML tips of large sections

I thought that it would be difficult to press on large sections. No matter how it is! As I pressed lightly on the handles, I pressed. The press doesn’t care what you have clamped there: 6 squares or 50. I liked it so much that now I press everything only with this press and on the PC-16 I didn’t give a damn. Well, then you just need to put heat-shrink on the tips and you’ll get something like this (machines without covers):

An example of connecting a TMax XT1 machine using TML lugs

Actually, I bought this press to crimp these wires.

Working knife.

Well, as a bonus, I want to tell you about my favorite knife, which I once found in Leroy (now they are not sold there) and at Rozhdestvenka on Mitki. This knife fits perfectly in the hand, doesn’t slip anywhere, and I use it everywhere - to trim, trim, cut.

Working knife for all tasks with replaceable blades and locking mechanism

This knife has a magazine inside with replaceable blades (you can charge 3-4 pieces). And these blades can be quickly changed automatically.

Working knife for all tasks with replaceable blades and locking mechanism

To change the blade, you need to move it all the way forward. Then the piece of iron that secures the blade will rise and release the blade. And then we move the handle all the way back, and it picks up a new blade from the magazine.

Pushing out the knife blade to replace it

Well, there is also a screw to secure this blade.

Fixing the knife blade

I won’t part with this knife either, because it covers all my tasks. When the blade is twisted, it can cut plastic without any problems! I finished this post at 04:31. Go to sleep!

Common mistakes when crimping

Cutting shells

At first glance, they are long. People who do not have the necessary knowledge and experience believe that using the entire cartridge case is wasteful, and cut it into pieces. This leads to a reduction in the length of the section where the conductors are bonded. The result is that the mechanical strength of the contact suffers, since working with pliers becomes inconvenient, and the number of pressure points decreases.

Wrong choice of sleeve diameter

If it is larger than required, then it is unlikely that it will be possible to produce high-quality crimping. The only way out is to bend the tip of the wire and then insert it into the sleeve. But such crimping is only suitable for “copper”, but the strength of the connection becomes lower. Aluminum wire breaks easily, so it is not an option.

With a smaller sleeve diameter, people without experience try to “plant” the ends of the wires into it by sharpening them a little. This is absolutely forbidden to do! Reducing the cross-section in a particular area leads to overheating and destruction of the metal. By the way, this often causes inflammation. It remains to add that the contact strength also decreases.

Crimping with pliers

Press jaws are specially designed for this specific job. Crimping with pliers is fraught with the fact that the conductor is deformed, and quite significant. After all, with this connection method it is impossible to control the clamping force. The consequences of reducing the cross-section of the core are indicated above.

Some craftsmen do crimping exactly this way, while assuring that everything is “acceptable.” But this does not mean that this technique is correct. The author came across such a situation and asked the unfortunate master a question: if he needs to do crimping at home, will he also work with pliers? As expected, there was no clear answer.

Useful tips

- It is not always possible to select a sleeve so that after placing the ends of the conductors in it, there are no voids left. The more free space, the higher the risk of poor contact after crimping it. How to proceed? The easiest way out of the situation is to cut pieces of wire (bare) with a length slightly shorter than that of the sleeve, and “hammer” them into it. Such artificial compaction will significantly improve the quality of crimping.

- If the connection of wires is made to extend the line, then their joint should be located in the center of the sleeve.

- When insulating the joint, the tape (tube) must extend beyond the sleeve cuts by at least 10 mm.

- In the case when at least one of the wires is multi-core, or different numbers of them are spliced on both sides, not metal sleeves are used for crimping, but insulated lugs (NSHVI).

It turns out that there is nothing complicated about crimping with sleeves. The main thing is to choose the right size. If the reader takes into account the recommendations given, then it is quite possible to cope with such work on your own. Good luck!

Recommendations for crimp testing

If difficulties arise in selecting a sleeve that is ideally suited for the wires in size, it is better to opt for a tube slightly larger than required. In this case, the void can be filled by cutting bare wire with a slightly shorter length than the sleeve. Compaction in this way will improve the quality of the crimp.

Extending the wire using crimping should imply that the connection joint is located exactly in the center of the tube.

When isolating the joint, the connecting tape must extend beyond the edges of the sleeve by at least 10 mm. If multi-core wires are connected to each other or it is necessary to splice different numbers of them on both sides, then the correct solution would be insulated type connecting sleeves.

In conclusion, we note that crimping as a process is not difficult if you act consistently, use a special tool and suitable sleeves. One way or another, you need to remember that we are talking about a permanent connection, so you will need a wiring diagram. Having a plan at hand will help you avoid mistakes during the work.

Connection Features

The technology involves two options for crimping. This is a method of local indentation and continuous compression. Copper or aluminum wires are used for work. The sleeve must also be made of these materials. There are also elements made of copper-aluminum alloy.

Since aluminum cables are prone to the appearance of oxidative films on them, the sleeve must first be cleaned and treated with special lubricants. Copper wires are also pre-treated. The use of lubricants in the process reduces the risk of possible damage to the cores. The friction force is also noticeably reduced. Pressure testing is carried out using manual or hydraulic tools. In the latter case - with a figure press. It is usually used in large industries.

How it works? The two ends of the cable are crimped until they take a round shape. Next, the core is inserted into the sleeve until it stops. It is possible to connect not exactly end-to-end. But in this case, the cross-section of all cores does not exceed the bushing. In the case of local compression, contact directly depends on the depth of the pits. The latter can be measured with a caliper. If continuous compression is used, then check the cross-sectional area. Then, when the crimping of the wires is completed successfully, it is necessary to treat the outer layer with electrical tape or elbow cloth. Next, the wire and cable are carefully laid in the junction box.

Types of connecting tubes

Crimping of wires can be carried out using connecting sleeves in several designs. The choice of connecting tube will depend on the electrochemical properties of the metal from which it is made and its interaction with the material of the wire.

There are several options for materials for the manufacture of sleeves:

- copper;

- tinned;

- combined universal;

- isolated.

Copper tubes (CM) are used for copper wires, the crimping of which cannot damage the protective layer due to its absence. The tubes cannot be used in aggressive environments.

Tinned sleeves (GML) are suitable for copper type cables used in aggressive conditions. The white protective layer covering the surface of the product fully copes with the main functions. The tubes are not suitable for working with aluminum wires due to possible contact of the protective layer, which is partially destroyed during compression, with aluminum.

Combined wire sleeves have a distinctive feature - their shape. The aluminum part is larger than the copper part. This is due to the resistance of aluminum, which exceeds the resistance of copper. During the crimping process using such tubes, wires are inserted on each side, taking into account the type of metal.

The last option for sleeves is insulated (GSI). They replace additional insulation with PVC tapes due to the presence of heat-shrinkable tubing. Their structure is similar to the structure of GML tubes, with the exception of a PVC layer that does not transmit electricity. The protective layer is quite plastic and reliable, indestructible even during the crimping process, taking the shape of a metal.

What does the tip marking mean: full explanation

Each type and type of product has its own alphanumeric marking, without knowing which it is impossible for a home craftsman to explain in the store what he needs. Let's look at popular markings:

- TML is a tin-plated tip, to work with which you need a special tool - a crimper. Looks like NSP. The only difference is that NShP is copper;

- TA – the same tip, but made of aluminum;

- SIP is a self-supporting tip that has its own insulation along the tube and an annular mounting plate;

- NSHVI - common in household use, sleeve pin;

- NKB - used in industry as geophysical cable;

- RFI-M is already a flag tip;

- IEK – copper fork;

- TMD – double blind connectors;

- NKI - isolated ring.

Aluminum products are regulated by GOST-9581-80, copper - GOST-7368-80.

Products for crimping are made of copper, aluminum or bimetal

What is the essence of the method?

Crimping is a method of connecting wires using special sleeves. Outwardly, they look like ordinary tubes and serve as a connecting mechanism.

The wire strands that are to be connected are inserted into the tube from two opposite ends, crimped with press pliers, and as a result, a strong and reliable electrical unit is obtained. The tube is compressed in two or three places, depending on its length and the cross-section of the switched conductors. The connected cores and the sleeve are jointly subjected to deformation. At this moment, the tube compresses and squeezes the conductive surfaces of the conductors. Due to this, the wires interlock with each other, which provides reliable electrical contact.

The junction is then isolated.

Most often, this method is used in situations where it is not possible to use another type of connection. For example, welding requires the presence of electricity so that the welding machine can be connected. When working in a small junction box, it is inconvenient to position the bolt connection, nut clamp or terminal block. And reaching up to the distribution box from the ceiling with a soldering iron is also not very convenient. It is in such cases that crimping wires using sleeves helps out.

The crimping method is most in demand:

- if it is necessary to connect wires in power lines with a high current load;

- for switching multi-core conductors;

- if it is necessary to connect large cross-section wires.

This is interesting: How to choose a cable channel for electrical wiring: let's look carefully

What is crimping with sleeves?

The essence of crimping is that electrical wires or cables are connected using conductive sleeves, which are tubes made of metal. The process of crimping cables, as a result of which a strong and reliable electrical connection is created, is as follows:

- The cores of the electrical wires, previously stripped of insulation, are inserted into the inner part of the crimp tube at both ends and must be connected.

- Using special press pliers or ordinary pliers, crimp the sleeve around the conductor placed in it. For higher reliability, the tube is crimped in two or three places.

- The place where the crimping is performed is isolated using TUT or electrical tape made of PVC for this purpose. If connection sleeves covered with a layer of insulation are used for crimping, there is no need for additional insulation of the formed connection.

Stages of crimping an electrical wire with a sleeve

Crimping wires with sleeves is especially relevant in the following situations:

- when connecting elements of electrical networks operated under high load;

- when connecting wires with a large cross-section;

- in cases where it is not possible to connect the wires in any other way (in particular, this method is used to connect wires in a junction box in which it is quite difficult to mount a terminal block;

- In addition, crimping sleeves are used to connect wires located at high altitudes or in conditions of limited visibility).

Crimping of wires with sleeves ensures excellent electrical contact and high mechanical strength of the connection

Let us list the most significant advantages of connecting wires by crimping.

- The tool for crimping wires, which is mainly used as press pliers, does not need to be connected to an electrical network, which distinguishes it favorably from electrical devices with which wires are connected by soldering. Thus, crimping (or sleeve, as this process is also often called) is practically the only possible way to form a high-quality connection of wires in places where there is no possibility of connecting the tool used to the electrical network.

- To connect wires using the crimping method, special knowledge and skills are not required. This cannot be said, for example, about soldering, which is unlikely to be done efficiently without the appropriate skills and experience.

- Using a special tool for crimping sleeves, you can create high-quality wire connections even in hard-to-reach places, such as distribution boxes and socket boxes. Moreover, the use of the crimping method for connecting wires in socket boxes makes it possible to reduce the length of the connected contacts to a minimum, which makes it possible to increase the density of the electrical installation performed.

An important advantage of using crimping is that using this method you can successfully connect wires whose cores are made of different metals. The same soldering cannot achieve this.

Twist connection

The easiest way to connect wires is twisting. Previously, this was the most common method, especially when wiring in a residential building. Now, according to the PUE, connecting wires in this way is prohibited. The twist must be soldered, welded or crimped. However, these methods of connecting wires begin with twisting.

In order to perform high-quality twisting, the connected wires must be cleared of insulation to the required length. It ranges from 5 mm when connecting wires for headphones to 50 mm if it is necessary to connect wires with a cross-section of 2.5 mm². Thicker wires are usually not twisted together due to their high rigidity.

The wires are stripped with a sharp knife, insulation stripping pliers (ISR) or, after heating with a soldering iron or lighter, the insulation is easily removed with pliers or side cutters. For better contact, bare areas are cleaned with sandpaper. If the twist is supposed to be soldered, then it is better to tin the wires. Wires are tinned only with rosin and similar fluxes. This cannot be done with acid - it corrodes the wire and it begins to break at the soldering site. Even washing the soldering area in a soda solution doesn’t help. Acid vapors penetrate under the insulation and destroy the metal.

The stripped ends are folded parallel into one bundle. The ends are aligned together, the isolated part is held firmly with your hand, and the entire bundle is twisted with pliers. After this, the twist is soldered or welded.

If there is a need to connect the wires to increase the total length, then they are folded opposite each other. The cleaned areas are placed crosswise on top of each other, twisted together by hand and tightened tightly with two pliers.

You can only twist wire made of the same metal (copper with copper, and aluminum with aluminum) and of the same cross-section. Twisting wires of different sections will turn out uneven and will not provide good contact and mechanical strength. Even if it is soldered or crimped, these types of wire connections will not ensure good contact.

Standard crimping errors

There are several typical mistakes that novice electricians or those who carry out the core crimping process themselves make. For example:

- The used sleeve has a cross-section smaller than the wire. There is never any need to reduce the cross-section of the cores and adjust it to the diameter of the sleeve. This leads to an increase in resistance and a decrease in throughput. Where there was a combination, the vein will heat up and collapse.

- Large size sleeve. If the socket is used with a large diameter, it will not bring a strong and reliable connection. Even if you bend the wire several times, this will not lead to good performance, since the mechanical strength will drop by almost half.

- Cutting the sleeve into several parts. When crimping a cable with a short length of exposed ends, it is inconvenient to work with pliers, and the contact area is reduced.

- Crimping should be carried out exclusively using press jaws. Special tools were invented for this joining method. Therefore, you should not use pliers or a hammer, as this can damage both the sleeve and the cable. To prevent this from happening, it is necessary to use a tool such as press pliers, as they greatly simplify the work of crimping cable connections.

That's all I wanted to tell you about how wires are crimped with sleeves. We hope the information provided was useful and interesting for you!

You probably don't know:

- Methods for connecting LED strip

- Which electrical tape is best for electrical wiring?

- How to find a junction box in a wall

Additional recommendations

For proper crimping, you must use the following tips:

- Make the junction of the conductors in the center of the connecting tube.

- Select the correct sleeve section. There will be fewer voids inside the clutch, and contact will become more reliable.

- Apply the insulation so that it extends 1 cm beyond the connecting tube on both sides.

- Use ferrules if cables with different numbers of cores are spliced.

Crimping is a procedure that allows you to obtain maximum adhesion of conductors when installing electrical networks. However, to carry it out correctly, the appropriate tools and materials are required.

Wire crimping: common mistakes

Many novice electricians or people who do not have information in the field of electrical installation often make a number of mistakes that affect the subsequent operation of the entire electrical circuit.

Pressure testing can be carried out using sleeves or tips

Installation errors:

- The sleeve cross-section is smaller than the cable cross-section;

- Sleeve of larger cross-section;

- Saving;

- Crimping without using pliers.

When purchasing crimps (sleeves), many do not take into account such an important factor as the cable cross-section. Therefore, after purchasing a crimp sleeve or sleeves, it turns out that its cross-section is smaller than the cross-section of the wire.

The main mistake that is made in this case is reducing the cross-sectional area of the cable, which is completely unacceptable. This is due to the fact that at the junction of the wires, resistance increases, which leads to heating of the wires during operation. And if a device with higher power is connected to this network, the wire may simply burn out and lead to a short circuit.

The use of sleeves with a large cross-section will not allow achieving high-quality and reliable contact

It is important to understand that with this connection, the mechanical strength also decreases

In order to save on connecting elements, many divide one sleeve into several parts, thereby increasing the resistance accordingly.

The rules stipulate that crimping of sleeves must be done only with a special tool in the form of press pliers. Therefore, a hammer or pliers are completely unsuitable for this job.

This is due to the fact that using a hammer can damage the sleeve, and compressing the sleeve with pliers is not enough for good contact.

Required Tools

Crimping is carried out with a special tool that allows you to create the necessary force. The following tools are popular:

- Press pliers for crimping PK2 and PK2M lugs are used for terminating cores with a cross-section of up to 10 sq. mm;

- PK1 and PK1M brand tools are a more powerful version of hand pliers;

- hydraulic pliers allow you to crimp wires up to 10 sq. mm;

- In industrial production, a hand press is used. It is suitable for wires up to 240 sq. mm;

- hydraulic press with electric drive is used for cables up to 300 sq. mm.

Types of instruments

Press pliers with hinges increase the pressure of the tool, which makes the manual crimping process easier. Devices with a ratcheting mechanism are especially convenient. They prevent the instrument from unclenching until the procedure is completed.

You can watch how to crimp a wire without tools in this video:

Types of press jaws

The manual crimper is used for crimping non-insulated cable lugs, contact connectors, terminals and contact sleeves of various sizes. If a manual crimper has special blades (usually they are located where the handles are attached), then this tool can also be used for cutting cables and wires.

Electric pliers are a multifunctional tool for professional use. They can do almost any work with wires. Electric pliers are mainly used for cutting and stripping wires, but they can also be used to crimp uninsulated and insulated cable ends.

A crimper is a tool for crimping wire lugs, twisted pair cables, and connectors. It has two long handles (one or both can be movable) and a massive working part in the form of metal jaws, which have holes for cables.

When the handles are brought together, the jaws close and the cable connector is crimped using forceful pressing. Some models have a blade on the working part, which simplifies the work - no additional tools are required to cut the cable.

How to choose press jaws

The choice of crimping tool is determined by the cross-section of the wire. The larger it is, the more powerful the device should be. Human effort is not enough to create a tight and uniform pressure, even when using household tips.

Crimping of cable lugs is performed using one of the following tools:

- Press pliers of brands PK2 or PK2M - for manual use, suitable for wires with a cross-section of up to 10 sq. mm.

- Hydraulic pliers – designed for terminating cables up to 10 sq. mm.

- Press pliers for crimping terminals, brands PK1 or PK1M - similar to the first tool, but reinforced with long handles, due to this they are capable of crimping a wire up to 50 sq. mm.

More powerful devices, such as manual and hydraulic presses, are used in production. With their help, you can crimp wires with a cross-section of up to 30 sq. mm.

Hand press pliers for home use

Classification by material of manufacture

One of the main parameters, depending on which wire sleeves are divided into different types, is the material of their manufacture. The need to use dissimilar sleeves is determined by differences in the electrochemical properties of the connected wires made of different metals. So, if an inappropriate sleeve is chosen to connect wires made of a certain metal, the place of the formed contact will oxidize, which over time will lead to a decrease in its reliability in terms of electrical conductivity.

The main types of sleeves for crimping electrical wires, depending on the material from which such tubes are made, are:

- copper sleeves;

- tinned connecting sleeves;

- combined;

- isolated.

Copper

A copper sleeve, which is marked GM, is needed for crimping wires also made of copper. Taking into account the fact that the copper sleeve does not have a protective coating, it can only be used to connect wires operated in a non-aggressive environment. If you neglect this requirement, the copper sleeve will quickly oxidize and cease to perform its functions.

Copper cable sleeves must be made from copper tubes of grades M1 or M2

Tinned

To connect electrical wires operated in an aggressive environment, tinned copper sleeves for crimping are used, which are marked GML. In order to protect the main material of their manufacture - copper - from electrochemical corrosion, GML sleeves are coated with a special compound.

This is explained by the fact that part of the protective coating of such a tube is destroyed when it is compressed, which will lead to contact between aluminum and copper and, accordingly, to the development of electrochemical corrosion.

Connecting sleeves type GML, made of electrical copper with a tin-bismuth protective coating

Combined

Quite often, when installing electrical networks, it becomes necessary to connect wires whose cores are made of different metals. To solve such problems, combined type sleeves have been specially developed and are successfully used. The design feature of such crimp tubes, which are marked GAM, is that one half of them is an aluminum connecting sleeve, and the second is made of copper. At the junction of two such tubes, which are connected to each other by welding, there is a special limiter. It is necessary in order to prevent contact of two dissimilar wires inside the sleeve itself.

Adapter cable sleeve aluminum-copper 16/10 sq. mm

Another design feature of combined crimp tubes is that the part of them, which is the aluminum connecting sleeve, has a larger diameter than the tube intended for copper cables. This design feature is explained by the fact that aluminum, when compared with copper, has greater electrical resistance, therefore the wire made from it, which will be connected to the same electrical network with a copper conductor, must have a larger diameter.

The crimping itself using combined sleeve clamps is performed according to the same algorithm as the procedure with sleeves of any other type. However, it is necessary to carefully ensure that dissimilar wires are inserted into a tube of the appropriate metal.

Isolated

Among the crimping tubes used for crimping electrical wires, the category of insulated connecting sleeves is distinguished. The use of the latter eliminates the need to perform additional insulation of the contact area formed with their help. In terms of their design, insulated sleeves are the same tinned copper tubes, the outer surface of which is covered with an insulating layer of fairly durable and at the same time plastic PVC. Due to the mechanical properties of such a protective layer, sleeves of this type can be successfully crimped without compromising their original characteristics.

Fully insulated connection sleeves

Insulated sleeves for hermetically sealed connection of SIP wire cores

Marking and decoding

The industry produces a large number of all kinds of tips, which differ in design and materials.

Color coding option

There is a special marking system that allows you to distinguish the material and use it for its intended purpose. Here is a breakdown of some of the symbols:

- A – the sleeve is made of aluminum;

- L – brass is used;

- M – the base of the product is copper;

- T – the element is made of tubular metal;

- U – the connector is made in the shape of an angle.

There is also a designation in the form of the letter O, which indicates the presence of an inspection window through which you can make sure that the cables are correctly located in the sleeve inside.

If the marking is TML (O), then it means tinned tubular copper with an inspection window. NSHVI - means a pin sleeve tip, and NKI - a ring one. In this case, the numbers indicate the cross-sectional area or diameters of the rod. To make it easier to find suitable connectors, for example, NShVI or KVT, you can use a special catalog or tables.

After the letter designations in the markings there are usually numbers that contain information about:

- nominal section;

- diameter of the contact rod;

- internal diameter of the shank.

For example, the product is marked TML (O). This means that this wire termination is made of copper tubing and is tinned. Its distinctive feature is the presence of a small hole - an inspection window, with which you can verify whether the wire is inserted correctly for crimping.

Such contacts are used mainly in production, so not all electricians are aware of their existence.

How to connect electrical wires by soldering

Connecting electrical wires by soldering is very reliable. You can solder untwisted wires, but such soldering will be fragile due to the fact that the solder is a very soft metal. In addition, it is very difficult to lay two conductors parallel to each other, especially when suspended. And if you solder on some kind of base, the rosin will stick the soldering area to it.

A layer of rosin is applied to the pre-tinned and twisted conductors with a soldering iron. If another flux is used, it is applied in the appropriate manner. The power of the soldering iron is selected based on the cross-section of the wire - from 15 W when soldering headphones to 100 W when soldering twisted wires with a cross-section of 2.5 mm². After applying the flux, tin is applied to the twist with a soldering iron and heated until the solder completely melts and flows into the twist.

After the soldering has cooled, it is insulated with electrical tape or a piece of heat-shrinkable tubing is put on it and heated with a hairdryer, lighter or soldering iron.

When using a lighter or soldering iron, be careful not to overheat the heat shrink.

This method reliably connects wires, but is only suitable for thin wires, no more than 0.5 mm², or flexible ones up to 2.5 mm².

Terminal block connection

A development of the bolted connection is the terminal connection. Terminal blocks come in two types - with a rectangular pressure washer and with a round one. When using a terminal block with a pressure washer, the insulation is removed to a length equal to half the width of the terminal block. The bolt is released, the wire is slipped under the washer and the bolt is clamped again. On one side, you can connect only two wires, preferably of the same cross-section and only flexible or only single-core.

Connecting to a terminal block with a round washer is no different from using a bolted connection.

The connection of the wires is reliable, but cumbersome. When connecting wires with a cross-section of more than 16 mm², the connection is unreliable or the use of lugs is necessary.

How to connect wires by crimping

Another way to connect wires is crimping. This is a method in which a copper or aluminum sleeve is placed on the wires or cables to be connected, and then crimped with a special crimper. For thin sleeves, a manual crimper is used, and for thick ones, a hydraulic one is used. This method can even connect copper and aluminum wires, which is unacceptable with a bolted connection.

To connect using this method, the cable is stripped to a length greater than the length of the sleeve, so that after putting on the sleeve, the wire sticks out 10–15 mm. If thin conductors are connected by crimping, then twisting can be done first. If the cable has a large cross-section, then, on the contrary, in the stripped areas it is necessary to align the wire, fold all the cables together and give them a round shape. Depending on local conditions, the cables can be folded with the ends in one direction or in the opposite direction. This does not affect the reliability of the connection.

A sleeve is tightly placed on the prepared cables or, when laid in opposite directions, the wires are inserted into the sleeve from both sides. If there is still free space in the sleeve, it is filled with pieces of copper or aluminum wire. And if the cables do not fit in the sleeve, then a few wires (5–7%) can be cut off with side cutters. If you do not have a sleeve of the required size, you can take a cable lug by sawing off a flat part from it.