Infrared heated floors laid under linoleum or other floor coverings are a common way to heat rooms for various purposes for those who follow the trend in the heating system.

This synthetic film material has long been used as flooring. Most often they cover the floors in kitchens and hallways. The main advantages are low cost and ease of work. Laying it on the floor does not require much experience. An additional advantage is that such a floor is easy to clean and does not allow water to pass through.

Previously, laminate or tiles were used as a finishing coating for heated floors. But the development of technology has made it possible to produce linoleum that copes with the task perfectly. It is important to know that not every linoleum is suitable for these purposes, and you will learn which one you need to choose from this article - there are special types of linoleum suitable specifically for heated floors.

It is also necessary to take into account which particular underfloor heating system interacts with linoleum. This has its own characteristics, if carefully observed, both the warm floor and linoleum will last a long time and without complaints.

Why IR film is the best heated floor for linoleum

Warm floors are divided into 2 groups: water and electric, one of the varieties of which is infrared film. The material received the name “film” because of its appearance. This is a two-layer polymer film in which carbon heating elements with a unique nano-structure are mounted. They emit infrared radiation, heating the surrounding surfaces.

The heating elements look like black strips 15 mm wide, connected by copper and silver contact bars. The structure is additionally protected from damage by a layer of polymer. The system has a number of advantages:

- The film operates in a temperature range favorable for linoleum, which is why IR underfloor heating is considered an excellent choice for installation under this type of coating. The optimal power for linoleum is about 150 - 230 W per square. Infrared film provides these parameters. When installing other options, there is a risk of overheating. Even if its consequences are not immediately obvious, over time they will manifest themselves as deformation, softening, and swelling.

- The film can be laid in rooms with a non-standard layout, on balconies, loggias. Its small thickness makes it possible to use it in buildings with low ceilings.

- The installation process is simple, since “wet” work on pouring the screed is not necessary. The system ensures uniform heating of the room, is perfectly amenable to automatic adjustment and can be integrated into a “smart home” type system.

- IR heated floors have a long service life. Most manufacturers guarantee effective performance for 15 to 20 years.

A significant positive point is the easy dismantling of the system. If necessary, it is enough to remove the floor covering and lay the film on a new base or in another room. Electricity consumption when using film systems is 30% less than when using an electric heating cable over a similar area.

The most efficient heating system

Home owners often think about which heating system to choose. A competent approach in this matter ensures the normal functioning of the project. Today there are two groups.

Option #1 - water heating scheme

The coolant circulates through a reliable pipe design. This form of flooring is characterized by durability and efficient heat transfer.

The cost of a water system is lower than an electric one, but there are also disadvantages. For example, the path along the contours of a heated floor reduces the temperature of the coolant, so there is a limitation on the length of the lines.

Connecting water floors to centralized heating is possible only after obtaining special permission; in practice, this is unrealistic. To do this, it is necessary to change the set of design documents for a residential building

But water floors are quite suitable for heating individual housing, especially for the first floor. They are connected to the boiler, which creates a truly economical scheme.

The main feature of such a system is that its installation is carried out “wet”, in a high-quality concrete screed. To do this, qualified installers maintain a given height and rules for the formation of a cement-sand layer on a wooden floor.

It is possible to place the screed on the subfloor, which will increase the load several times. In addition, here you will need to create high-quality waterproofing that will prevent the ingress of any amount of moisture. Thus, the floor height increases from 8 to 12 cm.

Option #2 - electric heating circuit

Infrared film products are a particularly productive and profitable option. The heating elements are flexible carbon-based heaters that have a laminated shell. In practice, a solid plate is obtained, symmetrically divided into heating sections.

Carbon-based film heaters are used for “dry” installation. This option is considered the most effective for forming a heated floor with a wooden base.

The advantage of the film type of floor is that it transfers heat into the room evenly. The structure lasts a long time and does not require systematic and expensive maintenance.

Disadvantages of IR heated floors

It’s difficult to connect the system with your own hands without basic skills.

The system has relatively few disadvantages:

- After laying the film, you cannot rearrange the room. Bulky furniture and household appliances should not be installed at the locations of the heating surfaces - this can lead to overheating of the film and its failure.

- It is difficult to install and connect the system with your own hands without basic skills. It is not always possible for a non-professional to connect the contact to the film. It has to be cut off and connected to another contact.

- Laying a heated floor under linoleum on a concrete floor with defects leads to its deformation. Therefore, sometimes a new screed is still necessary.

- The need to install thermostats in every room.

- If infrared heating is used as an auxiliary heating system, the air humidity level in the room may be too low.

Criteria for choosing linoleum for film flooring

The issue of choosing linoleum for laying on a warm floor must be approached with all responsibility. Materials that do not meet the requirements react poorly to heat: they deform and release harmful substances.

The following types cannot be used in tandem with IR film flooring:

alkyd or glypthal

nitrocellulose(colloxylin)

rubber (relin)

To achieve optimal room heating results and not cause harm to health, choose vinyl (PVC) or natural (marmoleum) linoleum. These materials have important characteristics:

PVC linoleum.

Not dangerous, suitable for residential premises. When purchasing, read the labeling of the material: there should be a mark on the packaging that the coating is intended for installation on underfloor heating systems. Regular linoleum can be equipped with an additional layer of heat-insulating material, which is completely unnecessary over a heated floor. This option is not worth purchasing.

Marmoleum (natural linoleum).

The best option for installing heated floors. The material contains only natural ingredients. When heated, this linoleum releases harmful substances, does not change color over time, and effectively resists fire. Marmoleum has the only drawback - its high price. But its wear resistance and safety completely justify the costs.

Marmoleum is sensitive to strong heat, so the issue of choosing a temperature regime for such a coating must be approached very responsibly. However, this is also true for PVC materials.

Flooring installation

At this point, the installation of the underfloor heating system itself can be considered complete, and the installation of the floor covering begins. It is recommended to use fiberboard as a base for linoleum. Linoleum is laid and secured on top in accordance with technology.

After this, it is recommended to set the thermostat to approximately 28 degrees and turn on the power to check the system again.

In combination with a heated floor system, it is recommended to use high-quality linoleum that is not too thick to ensure sufficiently high heating efficiency. Before laying, the material should be laid out on a flat surface and left for a day or even longer to level it.

After the film is laid and covered with a fiberboard base, linoleum is laid on it, but it is not secured first. The heated floor is turned on so that the floor covering warms up and becomes as even as possible.

This will have a positive effect on the quality of the floor covering and on the uniformity of heating.

Linoleum in combination with a warm infrared floor system is recommended to be fixed with a special mastic, and not with double-sided tape

It is not recommended to use double-sided tape to secure linoleum with a heated floor system. Adhesive mastic allows for the most reliable and uniform adhesion of the coating to the base, which means more uniform heating.

For installation on a heated floor system, it is recommended to choose linoleum with the highest thermal conductivity. Since the heating process can lead to deformation and changes in the surface of the coating, preference should be given to a material that is resistant to thermal effects.

Most often, multilayer polyvinyl chloride linoleum, which has the above characteristics, is chosen for underfloor heating systems. The color palette of this flooring is very wide; there is almost always a suitable option.

But it should be remembered that excessive heating of any linoleum during its operation is unacceptable.

Tools and materials

Set of infrared film heated floors

To install a warm infrared floor under linoleum you need to prepare:

- heating set: infrared sheet, insulator, contact clamps;

- temperature sensor and thermostat, hollow corrugated tube;

- wiring;

- double sided tape;

- polyethylene film;

- plywood sheets;

- heat-reflecting substrate;

- nails;

- knife, scissors;

- pliers, pliers;

- screwdriver;

- tools for wall chipping.

To fix the material, you can use a construction stapler or furniture nails. if you plan a large number of small pieces of film (up to 1 m), purchase additional terminals.

Marking the room and preparing the base

The film must be placed along the entire length of the room

Before installation begins, sketch out the floor plan of the room and mark the places where stationary pieces of furniture or large household appliances that fit tightly to the floor will be installed. It is not advisable to install infrared film in these areas. When planning, consider the following points:

- The film must be placed along the entire length of the room. This will avoid a large number of connection points for installation wires.

- If electrical wiring runs inside the floor, it should be at a distance of approximately 50 mm from the IR film and insulated from the floor or wiring with heat-insulating material.

- There must be a distance of at least 200 mm between heat sources (pipes, ovens, fireplace) and the film.

- The base for infrared heated floors must be clean and level. Often it is enough to make minor surface repairs. But if there are significant irregularities, pouring a fresh concrete screed is necessary.

- A layer of thermal insulation material is placed on the prepared base. If it is a rolled material, the strips are laid end-to-end and the joints are secured with tape. The insulation should lie very evenly.

Open the films

The film is cut along the lines along the heating strips every 250 mm

After drawing up a plan for laying the film, they begin to prepare it. The procedure is as follows:

- The film is cut along lines along the heating strips every 250 mm. Cutting along any other path is prohibited! Otherwise, the warm floor will not work.

- Contact clamps are installed on the finished heating elements. In places where current-carrying copper strips and a two-layer film pass, the tip of the wire is installed on the contact strip inside the thermal film. Then a grommet is inserted into the hole and riveted with a special stapler or hammer.

- The cutting lines of the contact strip are insulated on both sides with a waterproofing strip. Protected copper wires with a cross section of 1.5 square meters. mm is brought to the tip and clamped with pliers. After this, the junction of the copper busbar and the electrical wire with the tip is insulated on both sides with a waterproofing strip.

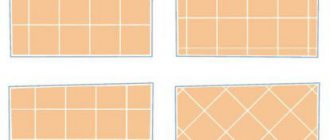

IR film can be laid lengthwise or across the room. Optimal placement of stripes longitudinally. In this case, the number of connection points will be minimal.

Laying and connecting the film

Parts of the heating film are connected in parallel to each other

After cutting the film, install thermal insulation with a reflective layer and secure it with tape. Heating elements are laid down on the thermal insulation with copper strips. They should be positioned so as to avoid the contact of adjacent strips touching! Rules and installation procedure:

- The heating elements are secured with tape, a stapler or furniture nails. This will minimize the likelihood of the strips moving during installation of the coating. The heating elements should be attached through the transparent rim located on the sides of the element.

- The heating element must be located 5 mm from any supply section of the element, which includes copper electrical bars. The wires are positioned so that the main ones are under the baseboard. In places where the contact strips are insulated and thickening of the system is observed, cutouts are made in the thermal insulation to level the surface for the final coating.

- Parts of the heating film are connected in parallel to each other. The highest total power of the heating elements that are connected to the thermostat should not exceed 3500 W. When connecting the heating system, you should definitely take into account the presence of other electrical appliances that will be connected to this network.

- If the total power of the heating system is more than 3500 W, it is advisable to make the connection using separate electrical wiring, protected by a separate circuit breaker. Heating devices should be connected using a magnetic starter.

- After installation, you need to inspect the system, check the reliability of the insulation and fastening of the wires. Then you need to measure the resistance of the heating strips. If there are sources of possible system short circuit, they should be eliminated and the performance test repeated.

- A temperature sensor is attached with tape under the cutting line, where there is no heated section of the film. It is placed under the film and connected to the thermostat with wires. Heating elements and a sensor are attached to the thermostat.

- The thermostat itself is hung on the wall in an easily accessible place. Its connection must be made in accordance with the diagram. Those inexperienced with electricity should consult a professional. Thermal sensors Then you need to turn on the thermostat and leave it for a few minutes.

- To hide the cable leading from the thermostat, you can make a groove in the wall. If the repair has already been completed, the cable is placed on top of the wall and covered with a decorative plastic box. Below, a plinth is used to disguise the cable. The edges of the cable providing power are connected using connectors and pressed with pliers.

- The final test is to check the degree of heating of the film. Place your hand against the heating element: the warm floor under the linoleum should generate heat at a pleasant temperature.

- Finally, the infrared film is covered with a vapor barrier material, and the joints are secured with tape.

Sheets of fiberboard or plywood are laid on the vapor barrier. They are fastened with screws through a transparent rim located along the cut lines of the IR film and the sides of the element. The element should not be attached closer than 5 mm from the supply areas of the elements. The finished heated floor is covered with linoleum.

Preparing a wooden base

Builders claim that a warm water floor can also be laid on an old structure. However, this will require careful preliminary surface preparation. First of all, it is necessary to eliminate cracks and gaps of different sizes. Otherwise, the system will not provide the expected operational efficiency.

Brief instructions:

- We sand the old coating.

- We mask cracks and gaps.

- We lay sheets of plywood.

- Having adjusted the fragments, we fix them with self-tapping screws.

The newly formed base must be treated with an antiseptic solution and allowed to dry.

The presence of water floor systems implies the existence of minor differences in height, and for film and rod analogues the base must be level

Experienced craftsmen use functional scraping or a flat covering (plywood, chipboard sheet, etc.) to create a thin but durable base. With the second option, you should carefully ensure that the edges of the canvas fit tightly together.

Possible mistakes

The film floor should be heated evenly. If there is no heat or some areas are colder or hotter than others, it means the installation was done incorrectly. Possible errors should be found and eliminated. Problems usually arise with the following violations:

- Laying film strips overlapping. This position of the heating material is unacceptable.

- Cutting the film too close to the copper bar. This may cause insulation failure. Complete or partial lack of insulation is one of the most common causes of underfloor heating failure.

- Using mastics to fix linoleum. All these compounds are sources of harmful compounds. In addition, during uneven heating they will form swelling on the surface. Removing such defects is difficult and often impossible.

Questions

What happens if you install a more powerful IR heated floor than recommended (for example, 240 W sq./m)?

This will cause negative consequences. Due to more intense heating, linoleum can become vulnerable to tearing and soft, and begin to move away from the base and expand. The most dangerous thing is that in the places where the thermal film is laid, the release of harmful substances will begin in fairly large volumes.

Is it possible to connect two heated floors to one thermostat?

Can. But you need to take into account their total power: it should not exceed the power for which the regulator is designed (3-3.2 kW). It is also worth understanding that only one floor temperature sensor comes from the regulator. If the rooms differ greatly in heat loss from each other, then the same temperature will not be achieved. Therefore, this connection is recommended to be used exclusively for large areas in one room, or adjacent ones, without a door partition.

Is it possible to connect two heated floors, cable and film, to one thermostat?

It is forbidden. They have different performance characteristics that require individual adjustment.

I set the recommended temperature, but the floor is not warm enough, only +28 degrees. Maybe the film is not working properly?

The floor is working correctly. It is the temperature of + 28 degrees that guarantees the energy efficiency of the IR floor. If you select a higher temperature, the energy efficiency will become negligible. If you think that the floor is not warm enough, check its heating with your hand and you will make sure that it warms up as it should. The linoleum surface should not be hot. If you want to get hot air in your house, you should think about additional heating for the walls and ceiling. But in any case, it is the warm floor that will help you achieve the recommended indicators.