Tubular electric heaters are the most popular type of heating elements in both industry and household appliances. Each electric heating element, even if it is designed for 220V, can be connected to both single-phase and three-phase networks. Let's take a closer look at what types of connections to a three-phase network for heaters exist and what requirements for the characteristics of heating elements are imposed on them.

To connect electric heating elements to a 3-phase network, the following types of circuits are used:

- Connection type STAR

- Connection type TRIANGLE

If we do not have special heaters, such as a block of heating elements or dry ceramic heating elements, but ordinary tubular heating elements, then to obtain a uniform load it is necessary to have three times the number of electric heaters in each phase. That is, the minimum number of heaters will be 3. Moreover, in the technical parameters of the heating elements, the supply voltage can be either 380 or 200 Volts.

For electric heating elements with a power supply voltage of 220 V, you must use the connection type to a 3-phase STAR network. And for those that are produced with a voltage characteristic of 380 Volts, it is possible to use both connection schemes: both the STAR option and the TRIANGLE option.

How to install and connect a heat gun? — EcommerceMarket.ru

Monitors, Keyboards and mice, Printers and MFPs, Scanners, Web cameras, TV tuners, Computer headsets, Steering wheels and joysticks, Computer acoustics, Graphic tablets, Microphones Processors, Motherboards, Memory modules, Hard drives, Cases, Power supplies, Video cards, Optical drives, Sound cards, Coolers and cooling systems, Containers for hard drives, Controllers Air grills, Blenders, Pancake makers, Coffee makers, Coffee grinders, Kitchen scales, Food processors, Mixers, Multicookers, Meat grinders, Steamers, Juicers, Toasters, Deep fryers, Bread makers , Electric kettles ecommercemarket.ru

Boiler heating element connection diagrams

Option 1. Connection diagram to a single-phase network

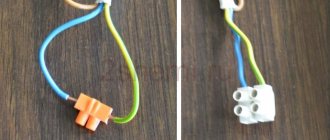

Typically, three single heating elements in such a design are placed so that the contacts from different heating elements are located opposite each other.

To connect a heating element to 220 Volts, you need to connect three contacts from different single spirals with a jumper and connect them to the working zero.

The three remaining contacts also need to be connected and connected to the working phase. This will ensure that all heating elements are turned on simultaneously for heating when power is applied.

However, the connection is not made directly this way, and for every second contact the heating element is connected to a phase after its own machine or, what is done more often, it is connected from its own control line (automation).

Option 2. Three-phase connection

If we look at the heating elements for boilers sold, we will see that almost all of them are labeled as 220/380 Volt heating elements.

If you have this version of the heating element, and you have the opportunity to connect to a three-phase power supply of 220 Volts or 380 Volts, then you need to use connection diagrams called “star” and “delta”.

According to the “star” circuit of 220 Volts, three phases, you need to connect the three contacts of single heating elements with a perm and connect them to the working zero. Apply to the second free contacts via a phase wire. Each single heating element will operate from 220 Volts, independently of each other.

According to the “triangle” circuit of 380 Volts, you need to connect contacts 1-6, 2-3, 4-5 with jumpers, for single heating elements 1-2.3-4.5-6 and supply phase wires to them. Each single heating element will operate at 380 Volts, independently of each other.

Connection option to a three-phase STAR power supply network

The STAR type is used in dry heating elements from the Polimernagrev company in connection option No. 3 with four bolts as the current output type. Also, the “star” connection type can be used when connecting a block of heating elements. In these cases, the heating coils are connected according to the following electrical diagram:

Let's now look at how we can connect heaters according to this scheme, if we have not special, but standard electric air or water metal heating elements.

Only one terminal from each heating element should be connected to the supply voltage. That is why, to connect to a three-phase network, we must have a multiple of three electric heaters. The remaining contact terminals that are not connected to voltage must be connected to one so-called zero point. Thus, we get a three-wire connected load.

Let's take a closer look at the three-wire connection diagram at 380 V for turning on 3 water heating elements. In the first figure, you can consider the circuit for switching on the heating elements described above, and in the second, a special device is added to the diagram for supplying voltage to the heating elements with protective switches. As can be clearly seen in the diagram, every second heater current lead is supplied to phases A, B and C, and the rest are connected together.

By connecting heating elements in this way, we obtain a power supply voltage value on each electric heating element between the connection to the network and the neutral point equal to 220 V.

In the above diagram you can see that the heater terminals on the right are connected to phases A, B, C. The terminals on the left are connected at a common neutral point. The operating voltage between the terminals on the right and the neutral point is 220 Volts.

There is also an option for connecting to a three-phase STAR network, which uses a four-wire circuit. With this method, three-phase power is used with a voltage of 230V, and the zero point is supplied to the neutral of the power supply.

Here, as in the previous case, some terminals are connected to the zero point, while others are connected to a three-phase network. If the connection to the zero point is transferred to the zero bus of the power supply, we will receive a voltage of 220-230V on each heater between the power supply and zero.

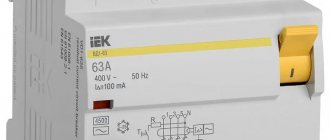

When it becomes necessary to completely turn off the power to the heaters, you need to use switches of the 3+n or 3p+n type, capable of operating in automatic mode. Automatic machines of this type can be used to completely transfer all power electrical contacts to a fully automatic operating mode.

Let's look at how the STAR connection type should be used in practice, using the example of installing heating elements in an electric boiler.

How to convert an electric stove socket from 380 volts to 220? Stove Lysva EP-31

If it is a household electric oven, it cannot operate on 380 V; all household ovens operate on 220 V. Maybe you mean that it has a large round plug with 3 large pins? This is a 220V plug for high power electrical appliances. There is no point in replacing it with a regular one - it will simply melt. You need to replace the socket with a similar one. It’s simple - the side sockets are phase/zero, the middle one is grounding. For reliability, you can disassemble the plug of the panel - the ground wire is always green and white. And it is advisable to have a separate wire from the panel to the stove, otherwise the plugs will be knocked out.

When asking a question, you need to at least explain in detail what you want to do. where is the so-called socket or what do you call the terminal block in the stove, people begin to guess and guess and are unable to answer the question that interests you

This outlet is already 220 volts. the three contacts there are: phase zero ground. if the outlet had 3 phases and 380 volts, then there would be 4 contacts!!!!

touch.otvet.mail.ru

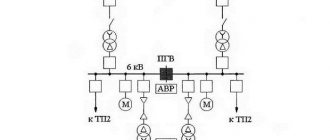

Input of three phases into the building and outgoing lines

Electricity from the pole is connected to the building through the air or underground.

All conductors are connected to the electrical panel, then the electric current enters the meter and passes to the distribution unit. Here the working zero and the grounding wire are separated, they are connected to the grounding bus, which is connected to the repeated grounding branch. Formation of outgoing lines :

- additional circuits come from the input switchboard (VRS);

- an introductory switch is installed in it, all phases are connected to it;

- circuit breakers are installed for each group circuit in the home, each of them is powered from different phases;

- groups are formed according to the power of units and devices so that each phase has approximately equal value;

- three phase conductors and a neutral conductor from the grounding bus are connected to the meter contacts;

- the meter output is connected to a common circuit breaker for the entire house.

Valera

The voice of the construction guru

Ask a Question

For connection, use the triangle or star method. The first method is to connect the phases sequentially: the end of the first to the beginning of the second, the end of the second to the beginning of the third, and so on. Star - when the ends of the phases are joined at a common point and the ends of the phases of consumer windings - also in one place.

Electric heat gun in action

Of the many designs of heating devices of this type, the electrical circuit of a heat gun is the simplest and safest. During operation, an air flow comes from the fan, blowing on the heating elements. When heated, the air acquires a predetermined temperature using a thermostat.

The body of the heat gun can be rotated relative to the supporting structures that support it. In the horizontal plane, the required angle can be set in both directions from the main axis.

The device is turned on after connecting it to the network. At the same time, the warning light lights up. Direct start is carried out by a switch by placing it in a certain position. The required power is set using a separate switching device. The electrical circuit contains a special thermal switch. It completely disconnects the heat gun from the network when the temperature of its body rises above 100 degrees.

The operation of an electric heat gun is recommended in places where the climate is cold or temperate. Relative humidity should not exceed 80%, and moisture entering the device is completely excluded. The general conditions in the room must ensure reliable and safe operation of the device.

Review of popular units

For heating 10 sq. meters of any room requires 1 kilowatt of thermal energy - this is what all calculations are based on when users go to the store to buy heating appliances. If you have a garage or cottage with ceilings no higher than 3 m, then a gun with a power of 3 kW or more is suitable for you. Considering that in some regions severe frosts rage in winter, you need to buy a more powerful product in order to quickly heat the selected room.

BALLU BHP-6.000C

A domestic heat gun with a power of 6 kW creates a heat flow that is enough not only to dry a garage space. Capacity - 820 cubic meters / hour, the stainless steel heating element is shaped in such a way that significantly increases the heat transfer to the passing air.

Safety grilles are installed at the ends, the built-in thermostat strictly controls the ambient temperature and switches the product to ventilation mode when the set temperature is reached.

Areas of use:

- if your upstairs neighbors caused a flood, the product will quickly dry out the walls;

- during repairs, it effectively dries plaster and pasted wallpaper;

- during prolonged rains, this unit will become an indispensable assistant in drying clothes and creating a cozy microclimate in the apartment.

The cost of the device starts from 5990 rubles, the design of the product provides all types of protection, including against short circuits. The weight of the product is 7.7 kg - it fits perfectly in the trunk of a car, so it is in demand among summer residents.

Hintek T-06380

Manufacturer: Russia, body made of steel. The unit can be used in production workshops of small businesses, shopping malls, offices of large companies, and in the construction of buildings; for temporary or permanent heating of warehouses. The heating element is made of stainless steel and does not burn oxygen when heated.

Basic technical data:

- productivity - 720 cubic m/h;

- two operating modes - average 2.0 kW and maximum 6.0 kW;

- power supply - 380 V;

- weight - 13 kg.

It can heat the air from 0 to +40°C quite quickly. Cost from 6,250 rubles.

Zilon ZTV-15

Another representative of domestic products. This compact portable heat gun with a power of 15 kW is used for heating various construction sites, service stations, trade pavilions and warehouses where other types of fan heaters cannot be used.

It is installed on the floor, the operating mode is intermittent and short-term, it must be constantly monitored. There is built-in overheating protection, cost from 10,290 rubles.

Basic technical data:

- power - 15 kW;

- air flow - 1700 cubic meters per hour;

- number of modes - three 5/10/15 kW;

- power supply - 380 V.

How does a heat gun work?

An electric fan draws cool air through the back of the gun and forces it through the entire system to the outlet. The air inside the gun heats up. The guns use electricity to operate the fan and heat. The heating principle itself differs for different types of devices:

- Electric - air passes through a spiral or tubular heating element and is heated.

- Gas - instead of a heating element, a burner is used for heating. The gas enters the device, where it is ignited by a piezo element. The air passes through the flame and heats up. If the flame goes out, the automatic system automatically turns off the gas supply.

- Diesel - an internal combustion engine is used for heating. There are two ways to heat air using a diesel engine: Direct heating - a fan drives cold air directly into the combustion chamber. The air exits through the nozzle along with the exhaust gases.

- Indirect heating - the combustion chamber is placed so as to heat the inside of the gun body. The air is heated from the walls without entering the combustion chamber. Exhaust gases are discharged separately.

Infrared – Flamentines are used for local heating. These are ribbed tubular heating elements made of aluminum. When heated with electricity, gas or kerosene, flamenines emit infrared radiation. Mirror reflectors are placed behind the tubular heating elements. This way the radiation is not scattered and does not heat up the device.

Selection of materials and equipment

Input components and the meter are placed on the distribution panel, the dimensions of which are determined by the number of connection points. Metal boxes with protection from moisture are placed outside, steel and plastic cabinets are used inside.

Set of components for connection:

- corrugated tubes, self-extinguishing or non-flammable cable ducts;

- copper cable VVGng;

- three-phase meter;

- connecting switches: combs, buses, terminals;

- protective and safety fittings;

- automatic circuit breakers complete with RCDs or combined automatic circuit breakers;

- a relay that protects against voltage surges in the circuit.

A DIN rail is prepared for high-quality fastening of automatic machines and protective devices; mounting spaces for these devices are provided on the bar.

To carry out internal wiring , you need wires, boxes for changing the direction of wiring, socket boxes and for switches. You will need alabaster or plaster to fix the cables in the wall grooves, clamps, electrical tape, and adapters.

general description

The diagram for connecting the fan heater to the Volt network looks like this: If the power of the product is over 6 kW, you cannot do without three-phase electrical wiring. Connect the plug to the voltage, switch the device to operating mode, set the desired heat supply.

For example, the Ballu electric heat gun is distinguished by the presence of heating elements of an improved design, which significantly increases their working life. The fan is one of the important parts of the design.

Afterwards, the fuel pump is attached, and a metal pipe is connected to the tank, with the help of which the fuel is supplied first to the fuel filter, and then to the injector.

Small size and weight make devices of this type transportable and mobile. Any device in this category is prone to consuming large amounts of electricity.

You can also choose a regular metal tank, which must be covered with a thermal insulation layer. The power of the heating element should be stamped on its body or written down in the accompanying documentation, but if it is an old device, you can measure its resistance with a multimeter and determine the power using the above formula. In addition to the three main elements of the housing, the motor and the heating element, for operation you will need a three-core cable, bolts, safety automatic circuit breakers and residual current devices (RCDs) that disconnect the network in a dangerous situation.

Device design The circuit of an electric heat gun assumes the presence of very specific components, but there are also optional components. With proper assembly of the electrical circuit, the risk of spontaneous combustion for such guns is minimal.

It is important to remember that it is almost impossible to heat a plank shed, a large hangar or an iron garage. DIY pneumatic machine

Read more: How to restore electrical

Design features of starters

In the photo of the magnetic starter in the disassembled position, the largest parts are clearly visible: housing, magnetic circuit, coil, contacts, return spring. The body is collapsible, divided into two parts connected with screws.

- Made of non-flammable, refractory dielectric material. One part of it is a removable molded cover.

- It is divided into three cavities according to the number of closed contacts.

To reduce the negative impact of self-induction currents that occur when contacts open, the design of the magnetic starter includes ribbed electric arc absorbers. They are located in each section of the lid.

An important part of the starter is the magnetic circuit. It consists of movable and fixed parts. Made from a set of electrical steel plates. The plate structure prevents the occurrence of Foucault currents, reduces heating, but does not interfere with the flow of magnetic flux. The plates are shaped like the letter “W”.

The part of the magnetic circuit located at the bottom is stationary, rigidly fixed at the base, the upper part moves; there are movable contacts on it. They come in two types: normally closed, open; When a pulse arrives, open contacts close, and closed contacts break the circuit. The coil is installed in the grooves of the lower part.

Installation and repair of a heat gun

My garage needs heating. There is no stove, but I have a 380, which I want to hang a gun on. I bought the gun in non-working condition. Under restoration. 3 pieces of tensile wires on the gun are connected according to the “star” type. Connection diagram 2+1 6/9 kW. Each heater is 3 kW. Without using zero. The control is powered from one of the phases and zero. There is a starter. The scheme is like this. The shadow phases are supplied directly to the starter. The control phase comes to the fan button. When it is turned on, the extra-tilator is turned on and the phase goes on to the button for turning on the shadows 2pcs. When pressed, the starter clicks and releases current to 2 tenons and the switch button for the third tenna. When the button is turned on, current flows through it to the ten.

Where to connect the grounding

In addition to neutral and phase, modern electrical wiring uses another conductor - protective grounding. The housings of electrical appliances and lamps are attached to it.

If the insulation between these parts and live elements is broken, a short circuit occurs or a leakage current appears. As a result of this phenomenon, the circuit breaker or differential protection trips, respectively.

In a modern residential power supply system, three grounding schemes are used:

- TN-C. The old grounding system, in which the grounding of power lines is carried out only in the substation, on the neutral of the secondary winding of the transformer, after which a combined PEN conductor is supplied to the consumer, which simultaneously performs the functions of grounding and neutral. In this case, instead of protective grounding, there is a protective grounding and connecting electrical appliance housings to it is prohibited in PUE 1.7.132. To protect people from electric shock in such a system, it is necessary to use an RCD or a circuit breaker.

- TN-CS. This is a more modern system in which in the input panel the combined PEN wire is divided into neutral N and ground PE. The separation point is connected to the building's grounding loop. According to PUE clause 1.7.135, after separation, the connection of these conductors is prohibited. The grounding wire in the apartment electrical wiring in this system must be connected specifically to the PE conductor.

- TN-S. The most modern scheme in which power supply is carried out using five wires - three phase L1, L2 and L3, neutral N and grounding PE. In this case, the grounding is connected only to the grounding conductor.

As a last resort, it is allowed to connect the protective grounding to a separate circuit manufactured in accordance with the PUE standards, paragraphs 1.7.100-118. In this case, a CT grounding system will be obtained.

| Important! It is prohibited to use water, sewer or heating pipes as a grounding conductor. |

Communications liner

It is necessary to take into account that the heating main must provide the required cross-section (the diameter must meet the technical requirements). And yet, the necessary flow of coolant through the fan heater must be ensured. If the diameter of the pipes and the temperature of the coolant are sufficient, but the speed of movement (flow) is very weak, this will negatively affect the thermal power of the device!

Also, think about how to supply power and control circuits. Calculate the required distances to purchase the required footage of electrical wire.

And one moment. Make sure that the wall (or ceiling) on which the fan heater will be mounted is of sufficient strength to withstand the load.

- We design an inverter from 12 V to 220 V with our own hands, a circuit of an automobile voltage converter

Features of the electrical circuit

Among the many modifications, the electrical circuit of a heat gun is widely popular. All electrical parts are placed inside the housing. Heating elements with ribs are also located here to improve heat transfer.

In the general diagram, all controls are located at the rear of the housing. With their help, the temperature is regulated and switched from one mode to another. Special devices emit light and sound signals when the device is connected to the network.

When choosing an electric heat gun, it is necessary to determine as accurately as possible the volume of space and the overall dimensions of the room that is supposed to be heated. The reliable and safe operation of the device will depend on this.

Connection option to a three-phase power supply network type TRIANGLE

Let us consider in the diagram the second option for connecting heating elements to a three-phase network called TRIANGLE.

With this option, the heaters are connected to each other in series. As a result, we should have three shoulders for phases A, B and C. For example:

- For phase A - we connect the first terminal of the heating element No. 1 and the first terminal of the heating element No. 2

- For phase B - connect the second terminal of the heating element No. 2 and the second terminal of the heating element No. 3

- For phase C - connect the second terminal of the heating element No. 1 and the first terminal of the heating element No. 3

Now that we have become familiar with the two types of connecting heating elements, we can consider the dependence of the power and temperature of the heaters on the type of connection circuit.